All the elements of the rod supporting part of the frame is made of steel wire Ø1,6 mm (short knitting needles), tube-bearing axis of the driving axle is made of copper or bronze tube. Spring steel with a thickness of 1 mm will go to the frame side plates.

How to assemble the chassis next. Textolite part is embedded in the core design is fixed and the front and rear of the brazed parts. Side plates with the front hinges are mounted on the frame Tang that between them and the core design remained a gap of 1 mm. the plates are mounted rear hinge and the through-rod-spring. The angle of rotation is suspended so side postme limited stops from the flat vertical offset them hold the other elastic elements, torsion rods, krupeshina loose ends on the Central part.

TECU axis of the frame napivaetsya the headstock guide slideway with brushes of the current collector. The distance between the axis of rotation of the slideway and the axis of the drive wheels is equal to 121 mm. In the last turn set hinges mounting axle of the front axle and front stops limiting the tilt of the axles.

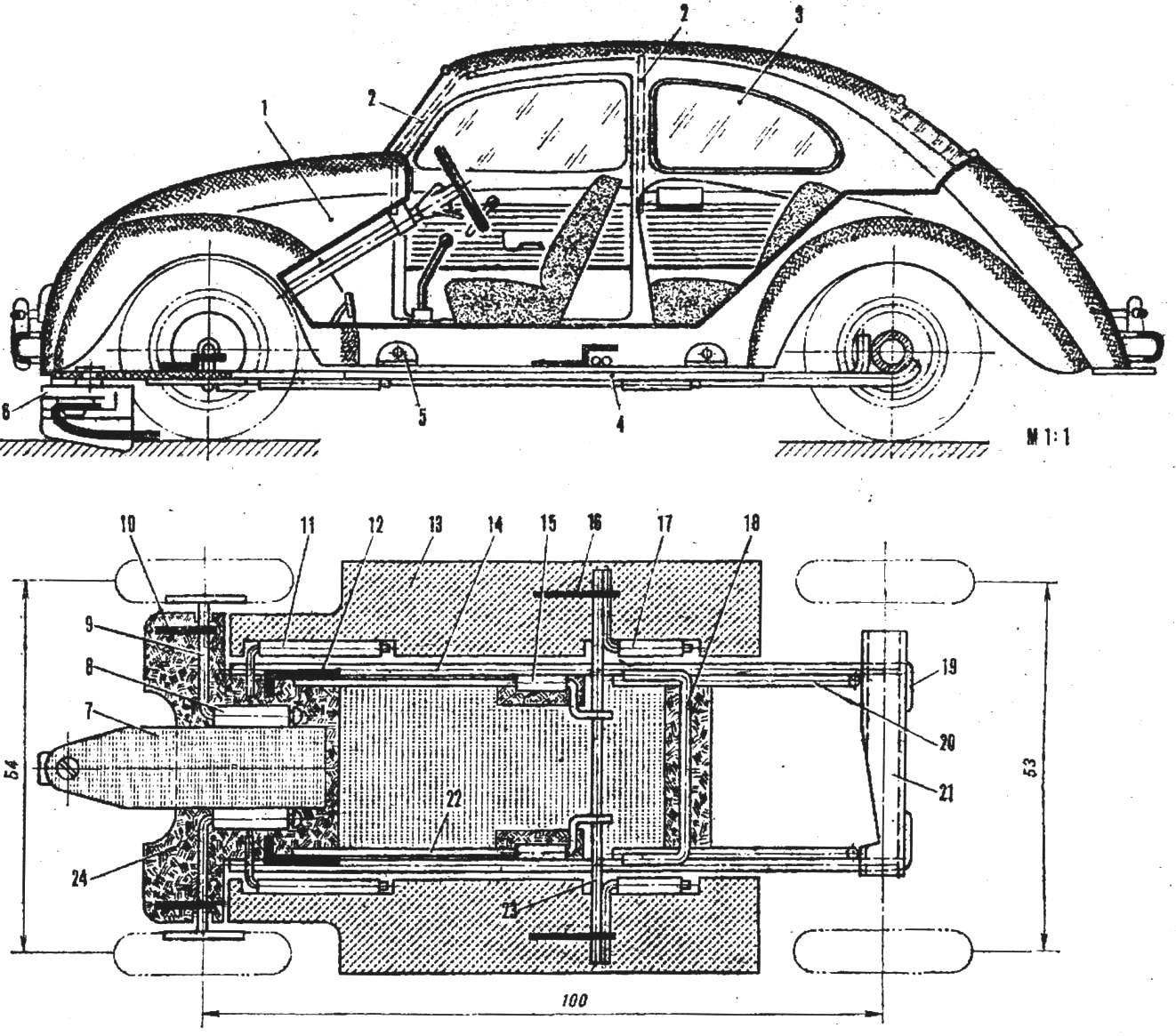

Fig. 2. Trace the car — a copy of “Volkswagen”:

1 — fiberglass body, 2 — wire gain stands, 3 — imitation of glazing interior, 4 — chassis Assembly, 5 — unit mounting chassis, 6 — guide the snake to slip rings, 7 — bracket slides 8 — joint front axle, 9 — axle shaft front, 10 — front axle focus (OVS wire Ø 0,8 mm), 11 — front hinge hinge side plates (OVS wire Ø 0.8 mm copper tube Ø 1. 6X0. 4 mm), 12 — forward area (OVS wire Ø 0,8 mm), 13 — side plate (spring steel with a thickness of 0.7—1 mm), 14 — external rod frame (OVS wire Ø 1.6 mm), 15 — a guide torsion bar (copper tube Ø 1,6 X 0,4 mm), 16 — backgauge hitch side plates (OVS wire Ø 0,8 mm), 17 — rear hinge portion (OVS wire Ø 0.8 mm copper tube Ø 1,6 X 0,4 mm), 18 — cross (OVS wire Ø 1.6 mm) 19 — shoulder of the mounting tubular housing, the 20 inner core frame (OVS wire Ø 1.6 mm) and 21 of the tubular bearing housing drive axle (copper pipe Ø 6X1 mm) 22 — rod torsion bar (OVS wire Ø 0.8 MJ), 23 — rod-spring (OVS wire Ø 0,8—1 mm), 24 — base, chassis (foil glass fiber).

It remains to perform a normal installation of the engine, a drive axle With drive wheels of the current collector and the body. On the model established Japanese microelectromotors “Mabuchi” ФТ160, designed for a voltage supply from 6 to 12 V. the Maximum frequency of rotation of the shaft 38 800 rpm, the idling current of about 0.7 A.

Sea trials EN-route fully met expectations. Now we can confidently recommend to all modelers like the chassis design, the second of the “heart” of little micro-car. In the first place was and remains the engine, whose power defines the dynamic and speed characteristics, use completely wow reserves will help a good diagram of the chassis, providing stable motion of the faster performance in all modes.

V. ZAVITAEV

Recommend to read

BIPLANE “GRASSHOPPER”

BIPLANE “GRASSHOPPER”

Building my own plane has been my dream since childhood. However, I was able to implement it not so long ago, although I paved the way to the sky in military aviation, and then on a... THE TRUNK ON UAZ

THE TRUNK ON UAZ

My friend Valeria was a nuisance - the new krysheval the trunk, purchased in the showroom together with the car UAZ Hunter, crumbled after the first fishing trip! Not going home, Valery...

Most often the chassis of modern highway car made of metal. In the case are tinplate, thin sheet duralumin and brass, steel wire. Requirements and the chassis is presented are many, and each new version is to some extent intended to satisfy them. Designs, at the same time perfect in all respects, have not yet been.

Most often the chassis of modern highway car made of metal. In the case are tinplate, thin sheet duralumin and brass, steel wire. Requirements and the chassis is presented are many, and each new version is to some extent intended to satisfy them. Designs, at the same time perfect in all respects, have not yet been.