The subject of today’s article – geophysical rocket R-2A. In previous publications we described in detail the technology of making copies of R-1 and R-2. The same technology used to create the model of R-2A. Will not be superfluous once more to tell for those who have not read those numbers.

The subject of today’s article – geophysical rocket R-2A. In previous publications we described in detail the technology of making copies of R-1 and R-2. The same technology used to create the model of R-2A. Will not be superfluous once more to tell for those who have not read those numbers.

I want to draw the reader’s attention to the fact that a copy of the R-2A for the competition will undoubtedly be more difficult than the previously described R-1 and R-2. But it justifies itself. First, the presence of side boosters (containers) due to the complexity of manufacture of the Central block leads to an increase in points for “the stand”. Secondly, if you do the ejection side of the mortars in the model (but more on that below), increased the rating for the flight demonstration.

After the adoption in 1952 of a ballistic long-range missiles (R-2) necessitated the study of the atmosphere at altitudes above 200 km. Apparently, at the time and was tasked with creating and launching of artificial Earth satellites. It was then, in 1954, on the basis of the R-2 and began to develop a geophysical rocket R-2A. The basis for its creation took technical solutions used for test firing in the first modifications of R-1 and R-1E. So, for the R-2A designed a new head part with a mass of about 1400 kg – sealed compartment for studies of animals that were saved together with the head part.

Deceleration of the head portion produced by the opening of the brake flaps. At its further decrease sequentially was introduced three exhaust chute, and at 1600 -2500 meters revealed two main parachute.

The payload is housed in the head part and the two side containers, fire back pneumatic mortars at an altitude of about 65 km. the Head part was separated at the altitude of 195 km, includes a sealed cabin for the dog, camera and scientific equipment.

Sequence diagram of the missile R-2A is as follows: start – 0, ejection side containers (67 km) – 103 C, the separation of the head portion (at an altitude of 195 km) – 188 with the opening of parachutes at WARHEAD and shoot containers (altitude 5 km), the time from start – 400 p

From 1957 to 1960 there have been 13 launches of geophysical rockets R-2A, 11 of them successful.

Tracing the idea of their creation, will not escape from our attention and some pattern in the technology of their construction on the example of case diameter rockets. He first -1652 mm. It is apparently allowed then to use the technological mandrel, dies for manufacturing large series of missiles. To ensure a rational approach to the creation of the then new technology.

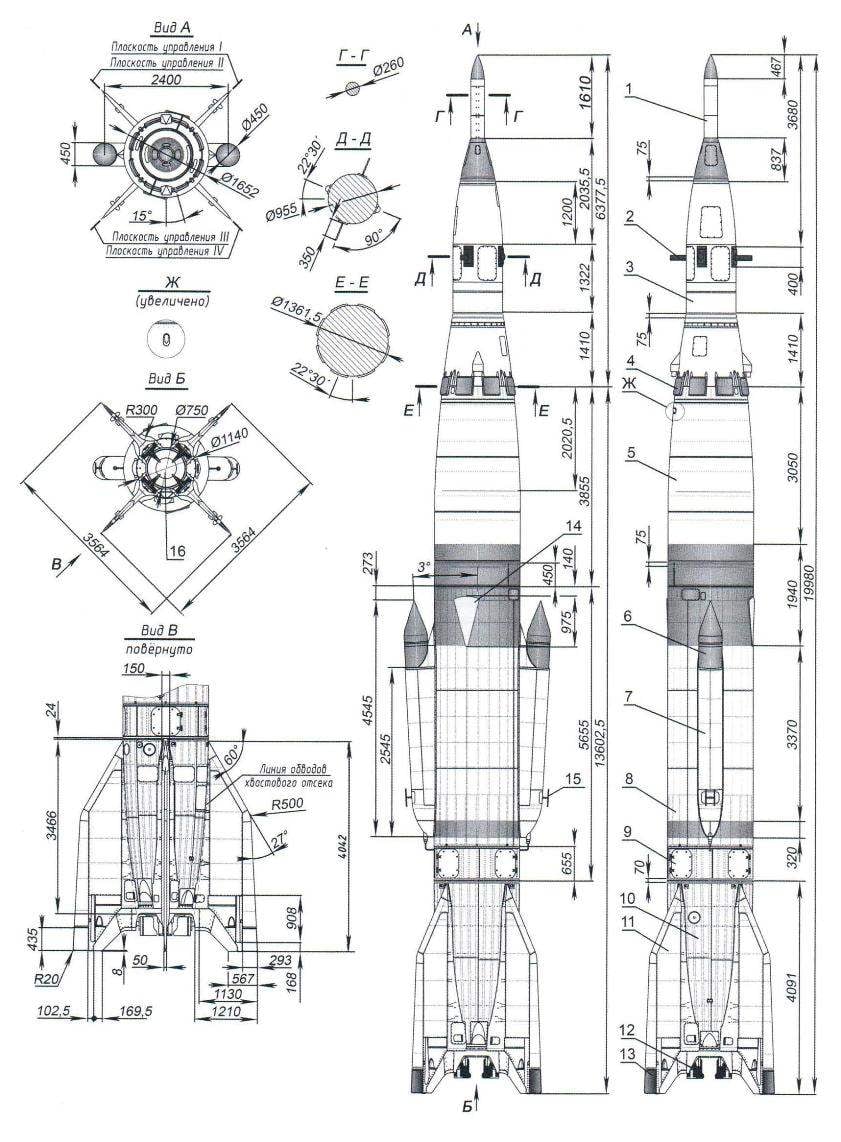

Model-a copy of the R-2A made in scale 1:25. It should be noted that the selected scale allows you to use a previously manufactured mandrel for a large series of models first domestic missiles.

In our circle model was built in two versions. For beginners the copyists – no shooting, and prepared, with a branch in flight layouts side mortars.

The first step in creating any copy -selection documentation – drawings and photographs. I must say that today its a lot – you just have to look.

Practical work can begin with the manufacture of elements of the case. The Central body (cylindrical) are glued together on a mandrel with a diameter of 65 mm and two layers of construction paper with a thickness of 0.2-0.25 mm.

After drying the resulting workpiece treated (sanded joint) emery paper and coated with a single layer of nitro lacquer. Then paste it on the one layer of paper, after making the workpiece markings riveted joints with knurled – cog from the clock with a diameter of 30 mm. After drying, the surface is cleaned with fine emery paper and cover with two layers of nitrocellulose lacquer. I want to note that all of these technological operations are performed on the mandrel. Giving to dry the workpiece, it is clamped in the Chuck of the lathe and on small speed (150 – 170 rpm) butt to the desired size is 284 mm.

The elements of the arched form is the nose and tail is glued on the respective mandrels by means of papier-mache. The mandrel with the pre-heated and grease separation with mastic. The label of the “petals” are the clay “the Carpenter”, and before that they must be wet for a better fit to each other, the shape of the mandrel. On one layer you will need eight or nine “petals” – width 20 – 22 mm. And just have to stick to seven or eight layers.