What is to be the model for the development of radiopilot? This question every year, stands in front of a considerable number of modelers, who finally received the opportunity to engage in an interesting sport.

A variety of educational technology created to date suggests that the answer to a seemingly simple question is not so simple. Too many conflicting requirements shall be presented simultaneously to such devices. Durability and excellent flight performance, good controllability and stability, low speed flight and high verosimilmente — this is not a complete list of tasks facing the designer “school”. And it seems to collect in one design only successful solution is impossible, so sometimes they are incompatible. You have to follow the path of compromise. And in the end, it’s the optimization process and its result determine the success design “school” in General.

One of such decisions, in our view, meet the basic requirements for microplane for beginners, we offer today the beginners-radio operators. Represented on their court model is not only a good combination of high flight performance, but a fairly simple design, though with increased strength.

Special attention in the design process, “school” was given the maximum availability of the materials used. We can assume that this problem has been solved: not that balsa wood, even mm plywood is almost not required, except that small clipping polutorametrovy. Specified in the captions of the drawings lime can be replaced by others of the same type of wood (aspen, poplar). However, the best option is to use boards from the usual packaging of food products. Unfortunately, to accurately classify the wood we could not, therefore, give only “signs” by which to distinguish right boards from others. First of all, draws attention to the pure white color of the boards, even partially covered with mud. When processing becomes visible slight yellow or pink “warm” colors; surface under planer is very smooth and without pile; structure of the material resembles a light lime. Compared to the last few difficult handled cutting tool, fine sawn and even better skurida. But the most interesting mechanical properties; strength comparable to the average density of the lime, however, the resistance against cracking is much higher, the wood seems to be much more viscous. And all this at a specific gravity of about 0.35 to 0.38 g/cm3 ! In General, we can say that this material allows you to create designs that are close to balsa in weight, but more durable.

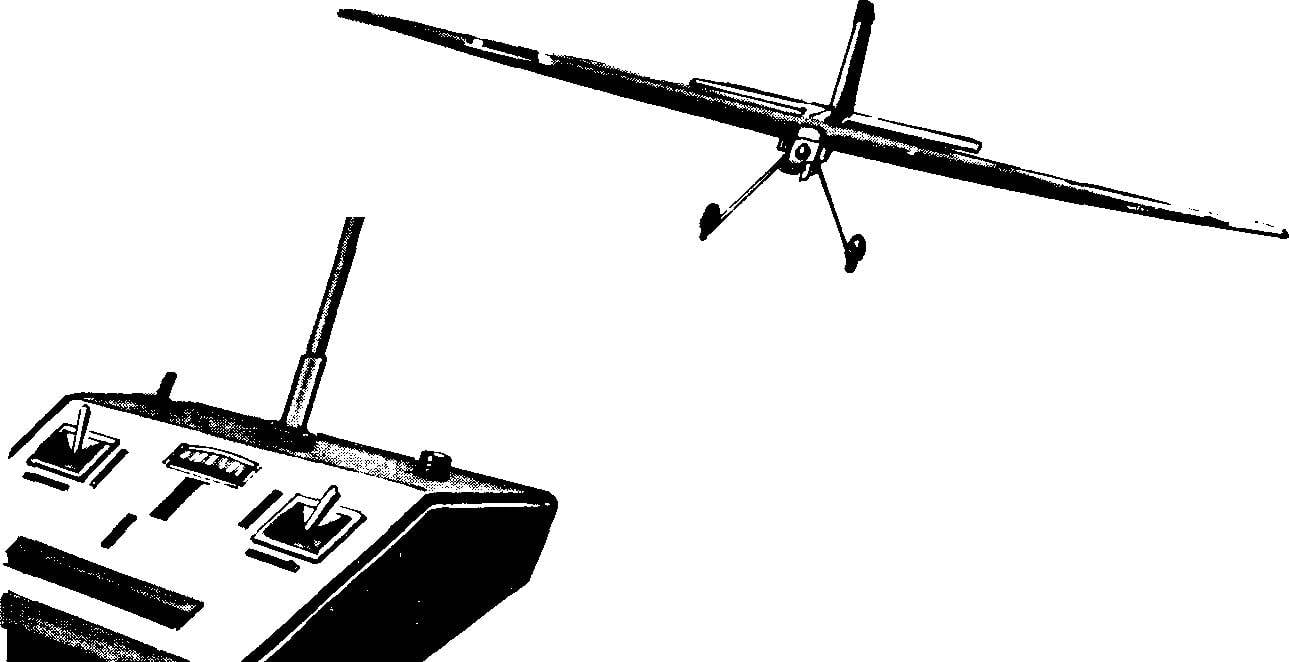

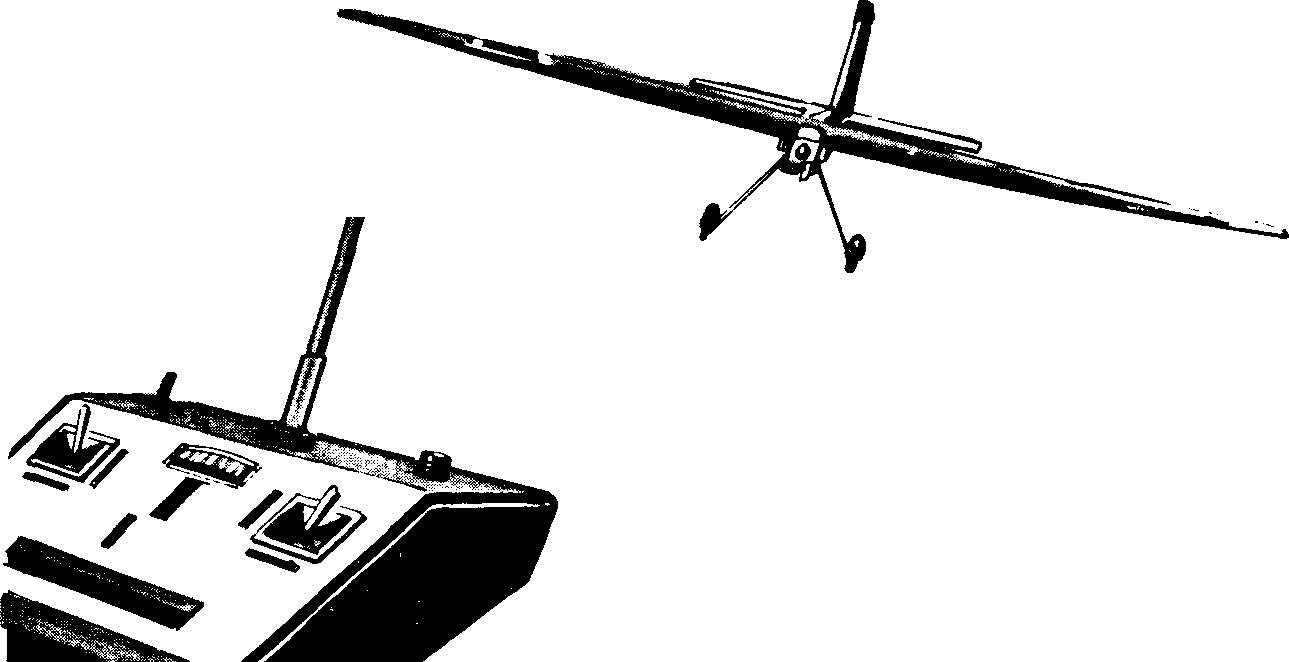

RC model:

1 — fuel tank 2 — detachable chassis, 3 — body, 4 — Kiel, a 5 — rudder, 6 — nozzle-container for the power supply of radio equipment, 7 — regulator 8 — the Elevator 9 — wing 10 — Microdrive MK-17 (forced).

So, one of the main materials becomes container Board. It is sawn to the desired plate on the simplest machine of the type “Skillful hands”. Still need high quality mild pine (preferably spruce). Where to get it: in sets-the packages? You can find, but is extremely rare. The only concrete hint: lattice wooden “mats” for baths, especially in larger sizes. And so… do Not leave without attention to any one of a Board or bruska, and in a month you will be the owner of the blanks, which is never purely model sets.

And the last material in the list, core is plywood. Yes, of course, safer to use aviation with a thickness of about 3 mm. But is quite suitable and conventional construction with a thickness of 4 mm! The weight-loss will be not so big, but the strength of the plywood, and superior (due to less pre-impregnation of layers of wood binder) adhesive joints will more than compensate for these losses.

As for the power scheme to “school”, we can simplify wore a double meaning. Of course, they were given reduce the labor intensity. But most importantly — reducing the number of parts is allowed to move to such sections of the individual elements, which until now was characterized by pereobrazhennya, eretailing and therefore completely non-volatile. We have the same in the heaviest variant of the model when it assembled the chassis and used equipment “Novapro”, the load-bearing surface does not exceed 28 g/DM3 ! And the pure glider with the instrument Signal (GDR) and powered equipment transferred to the detachable part of the fuselage to preserve the balancer when removing the engine load is in the range of 22-23 g/DM2 ! Again to clarify: all this with a very high strength of the model overall and perfect protection of the control equipment.

Fuselage:

1 — front panel (plywood 1.5 mm), 2 — power side panel (plywood 3…4 mm) 3 — wall (foam PVC thickness: 2…2.5 mm), 4 — upper longitudinal member (Linden section 4X32 mm), 5 — stand (Linden section 2H8 mm), 6 — lower spar (lime cross section 5X10 mm), 7 — dorsal fin (Linden thickness of 2 mm), 8 — plywood gusset plate to output thrust, 9 — tail boss (Linden), 10 — stand stabilizer (plywood 3 mm), 11 — “crutch” (plywood 1.5 mm), 12 — socket fastening screw of the wing, 13 — fairing transition of the sidewalls in the longitudinal (lip thickness of 5 mm), 14 — blocks of the fixing Board, 15 — Padmasana fee (D16T thickness of 2…3 mm at the ends to glue cut along the rubber tube), 16 — reinforcing pad (plywood 3 mm), 17 — Foundation block fixing Board 18 — guide bar Foundation, 19, 25, 29 — frames (plywood 5…6 mm) 20 triangular slats enhance the joints (Linden cross section 8X8 mm), 21 — compartment cover, a 22 — block engine mounts (hornbeam section 8X15 mm), 23, 24 — filling the bow (Linden), 26 — lower sheathing (plywood 1.5 mm), 27 — a guide (straw), 28 — pull (wire D16T Ø 2 mm) 30 — pin socket of the wing, 31 in the contour of the window under the cables.

Wing:

1 — the rear edge of the pine (3X12 mm), 2 — the ending (plywood 3…4 mm), 3 — vertical rack gain of the junction (Linden 10X10 mm), 4 — front edge (pine section of 15X15 mm, the end section reduced to 10X10 mm), 5 — rib (lip thickness of 1.8…2 mm), 6 — Klondike solitaire (Linden), 7 — tail trim (plywood 1.5 mm on both sides), 8 — lug (black 10 mm thick), 9 — the Central rib (lip thickness of 1.8…2 mm), 10 — the bridge 11 — additional spar (pine section 8X18 mm), 12 — bow cleat (plywood 1.5 mm on both sides), 13 — trim junction edge, 14 — bow scarf (plywood 5…6 mm) 15 — the Central rib (lip thickness 15 mm) 16 — tail gusset (plywood 3…4 mm).

Templates to build the profile of the wing.

The sequence (indicated by letters) the construction of intermediate ribs in the blanks:

A — drawing of the lower palubicki, B — marking of the length of the rib and the thickness of the trailing edge, In — drawing of the upper palubicki using the template of the root rib (the combined notch the front edge), used as templates, G — markup trimming the front part (the size of t measure on the edge) and the slot under the rear edge.

In addition to record-low load on the new model, and achieved good handling characteristics-stability. Initially, when learning she is forgiving and the most flagrant intervention in a sustainable and rapidly renewable mode. And after the acquisition of basic skills of piloting the same training machine will prove that in skilled hands able to work “on five” — due to the aerodynamic layout with a strong shoulder a large tail, with moderate angles of degradation, angle transverse V-wing and Vicosa the axis of the engine. Benefit is not too great rise of the SEA wing relative to the axis of the fuselage, which makes the model more to signalnum than verneplan.

Horizontal tail:

1 — the rear edge of the stabilizer (blank — pine cross-section of 5X5 mm), 2 — the Central rib (lip thickness of 4 mm), 3 — the front edge (lip section 4X20 mm), 4 — rib (lip section 2X4 mm), 5 — ending (lime 4 mm thick), 6 — trailing edge rudder (pine section of 2X4 mm) 7 — insert-rib (birch thickness 4 mm), 8 — spacer plate-insert (foam PVC 1.5 mm thickness), 9 — edge (pine section of 3X4 mm) 10 — ending (Linden cross section of 3X4 mm) 11 — spacer (pine section 1,5X1,5 mm, to glue in the slots of the spacer plates).

Vertical tail:

1 — root rib (lip thickness 4…5 mm), 2 — leading edge of keel (Linden section 4X20 mm), 3 — rib (lip section 2X4 mm), 4 — ending (lime 4 mm thick), 5 — posterior edge of keel (blank — pine cross-section of 5X5 mm), 6 — edge handlebar (pine section of 3X4 mm), 7 — ending helm (lime a cross section of 3X4 mm), 8 — trailing edge rudder (pine 2X4 cross-section mm), 9 — root rib rudder (birch thickness 4 mm), 10 — distance plate-insert (foam PVC with thickness of 1.5 mm), 11 — spacer (pine section 2,5X1,5 mm). Axial lines represent the locations of the sealing wire racks mounting of the keel into the fuselage.

Wire rack (OVS Ø 2.5 mm).

The dimension “a” stand before bonding, thoroughly degrease and ticks to make the thread indentations. Back front same front, but runs from OVS Ø 2 mm and shorter front.

Model node the hog steering:

1 — nut M2,5, 2 — birch steering insert with hole Ø 2.5 mm, 3 — hour wild boar (OVS wire Ø 2.5 mm), 4 — biscuit (PTFE 4X4X8 mm), 5 — tube”nut” (plastic sleeve), 6 — pull (wire or D16T aluminum knitting needles Ø 2 mm, at the end of the cut thread M2).

Fuel tank (sheet 0.3 mm, soldering on a wooden mandrel, the inside before Assembly to solder the two screws M2,5, version — stamping of celluloid of a thickness of 1 mm).

Standard hinge (clip stationery; seal the liner to roll through the large needle file on a wooden substrate and thoroughly degreased).

Thanks to the aerodynamic cleanliness of the proposed glider can be very fast even at low load on the supporting surface. As for the profiling of the wing… it is difficult to judge, at least on the geometrical parameters. The fact that is shown in the templates profile, similar to the classic PLANO-convex type “Clark”, there is only rarely close to the set of ribs of the wing, then the upholstery under tension takes the form of contributing to the overall profile is much smaller relative thickness. About the merits of the proposed scheme is debatable, but undeniable are… good flight characteristics! Do not forget that the wing has to be after the final tuning of the tension of the plating is completely flat (no twists), and is equally supple in both directions when manual samples of rigidity on the twist. When tightened on the rail (the permissible value of tension to 7 kg) can cause significant deflections of the consoles, but the pattern with the front edge of the spar provides a “flat” character of the curves, no twists. Negative twist the end parts is not necessary, as in our case, enough to sweep the edges to keep them from stalling on the wing at the exit on critical angles of attack.

Unusual power circuit model of causes and some features of the manufacturing process. But I think you can refer to them in detail is not necessary. Find methods for carrying out specific operations difficult, but the experience gained then will be very useful in further work on other RC types. Hope a number of constructive tips introduced in the proposed model, will be useful in the design of other devices. One of them is a sharp decrease in the mass of feathers. This is a factor “pulling” a chain of beneficial effects: the minimum load on the beam of the fuselage during crash landing; the abrupt shortening of the forward fuselage with the appropriate relief and the increase in stiffness of the loaded parts RC. And the other side is the acquisition of design skills is elementary simple, light and durable, efficiently performing its role…

The weights of individual model elements, g

Stabilizer (without covering): 16

Handlebar height (without covering): 6,5

The keel with a pin (without covering): 10

The rudder (without stitched): 4

The removable parts of the tail Assembly, pylon, covered with Mylar film and partially painted: 43

Wing Assembly (basic version), fitted with Mylar film and partially painted: 174

The fuselage Assembly, with the skinny tail boom Kraft paper, varnish and painting: 215

The engine with a propeller: 148

Fuel tank: 26

Total: 642,5

Chassis Assembly units: 117

V. dolgozhilov has engineer

Recommend to read BUGGY – SPORT CROSS-OVER VEHICLE Student design Bureau Carian Polytechnic Institute named after A. M. Gorky is known not only in redkach edges, but also far outside the Republic. The original snowmobile, transport on an... SIBERIAN FLY SWATTER Each warm season from spring to autumn throughout recorded history of human existence it bugged various harmful insects, and the stronger the closer to nature it is. And the most common... Scroll back to top

What is to be the model for the development of radiopilot? This question every year, stands in front of a considerable number of modelers, who finally received the opportunity to engage in an interesting sport.

What is to be the model for the development of radiopilot? This question every year, stands in front of a considerable number of modelers, who finally received the opportunity to engage in an interesting sport.