Designing a new racing control line aeromodel, we opted not on some extravagant options, but the proven classic design, well established and fully proven to date. The base design was made by the sports equipment K. Chistov, the champion of Russia. It’s a model we liked, although some decisions of its individual parts and assemblies we have been critical, based on specific conditions and capabilities of our LC too rich equipment of the group.

So completely taking the idea of a monolithic power metal piece, we abandoned this time-consuming details in favor of Assembly wood. The last option for us much easier and with high quality work and Assembly is not inferior to aluminum in strength and thus much easier. The main requirement in the processing of wooden parts,— the accuracy of their mutual adjustment and high quality sealing. Power the details of the model, performed from the selected aircraft plywood, and elements (frames and motor mount) are cut from pre-prepared blanks, glued four layers of mm plywood. Don’t be surprised that when the total thickness of the workpieces, equal to five millimeters, they are collected only from four layers of “graph paper”. It is not the excess epoxy binder (all the excess is squeezed after you place the “sandwich” under a press), but the fact that the original thin plywood has a standard thickness of 1.2 mm (the other we’ve not met).

It seems to us, in an interesting way were able to reliably associate the power of wooden models with metal mounting bracket and a cord strap analog is not met. Therefore, having a number of test models on the go, we can confidently recommend podobnou solution for other types of cars and snowmobiles. However, it is important to use high quality epoxy resin before Assembly and thoroughly prepare the surfaces of metal parts (including fastening screws).

Also we refused the heavy metal stabilizer in favor of dramatically lightweight wood. Of course, the latter is not so “hardy”, however, as we know, any technique aimed at removing weight from the tail section of aeromodel aircraft type, is beneficial to the sustainability of its stroke. At the same time replacing the metal on the wood of Linden we

get rid of excess massive screw of the attachment of the stabilizer — now he is on the tail boom firmly. Detachable, performed again at the regular screws with nuts, tail skates in this embodiment, transformed into the lightest details of aluminum foil with a thickness of 0.5 mm, sealed in the end parts of the “tail” of the model.

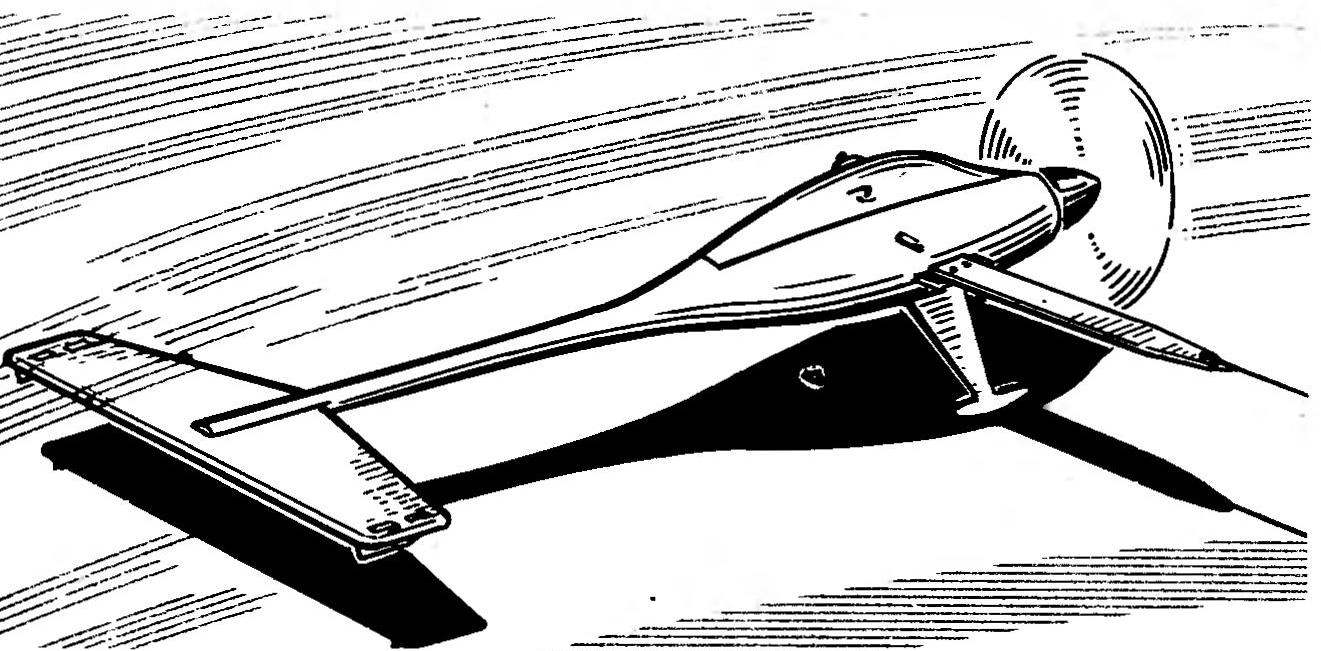

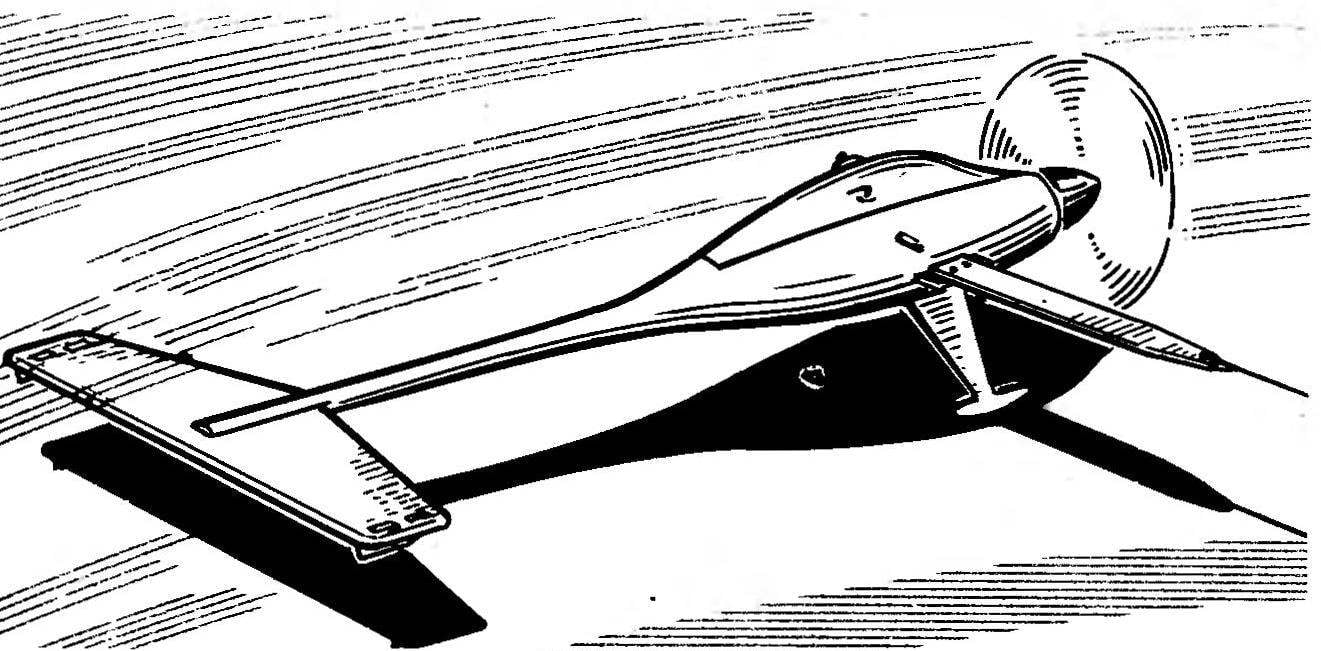

The result is relief of all the tail node of the racing EV cord strap sharply moved forward, which is clearly seen in these images. Rough calculations showed that the moment of inertia of the model has decreased almost twice, as required.

Fig. 1. Layout scheme córdoba racing model snowmobiles with motor working volume of 2.5 cm3.

Fig. 2. The power of the shell model :

1 — prednicarbat (reto the lake from mm plywood 5 mm thick),2 — motor mount (plywood of mm plywood, 5 mm thick), 3-body (tight lip), 4 — power frame (mm of plywood of plywood, thickness 5 mm), 5 — loop fuel tank, 6 — bracket for attachment of cord strap (aluminum), 7—”fungus” under the screw MZ engine mounts (steel), 8 — supporting screw bracket, length 10— 12 mm, 9 — the main screw bracket, length 20-22 mm (gluing during Assembly, as det. 8, epoxy resin), 10 – cord strap.

Fig. 3. “FUNGUS”

R and S. 4. Bracket for attachment of cord strap (Tweedy made of anodized aluminum) is milled.

Fig.5. Cord strap (solid aluminum).

Fig. 6. Fuel tank with built-in nozzle. Filling system, drainage and nozzle is arbitrary.

Fig. 7. Stand with ridge (D16T).

Another innovation in our version of the aeromobil — installation toplivnogo analog is not met. Therefore, having a number of test models on the go, we can confidently recommend podobnou solution for other types of cars and snowmobiles. However, it is important to use high quality epoxy resin before Assembly and thoroughly prepare the surfaces of metal parts (including fastening screws).

Also we refused the heavy metal stabilizer in favor of dramatically lightweight wood. Of course, the latter is not so “hardy”, however, as we know, any technique aimed at removing weight from the tail section of aeromodel aircraft type, is beneficial to the sustainability of its stroke. At the same time replacing the metal on the wood of a Linden we got rid of extra massive screw of the attachment of the stabilizer — now he is on the tail boom firmly. Detachable, performed again at the regular screws with nuts, tail skates in this embodiment, transformed into the lightest details of aluminum foil with a thickness of 0.5 mm, sealed in the end parts of the “tail” of the model.

The result is relief of all the tail node of the racing EV cord strap sharply moved forward, which is clearly seen in these images. Rough calculations showed that the moment of inertia of the model has decreased almost twice, as required.

Another innovation in our version of the aeromobil — a installation of the fuel tank with a built-in nozzle. It is unclear why this is a grateful solution is not widespread in automodelisme! It seems that deficiencies had not, and there are only “pros”. This increased engine power, and improve the stability of the regime over the all-in, and a small influence of the temperature of both the motor and the ambient air debugging your plant.

Possibly controversial, will be used by us variant of the installation of the skate above the lower foot engine of the IDS. However, experience shows that, in principle, such solutions have no disadvantages and no it just depends on layout and design considerations. This scheme of mounting rack is quite suitable in summer conditions, when virtually no alterations proposed technique is used on kartodromo as a full-fledged flying car. With regard to the possibility of installing a pair of front wheels in the rack in advance is done the hole and 3 mm.

In conclusion — about the engine and the cooling system. In winter conditions this is not so important, although in the sled it is helpful to keep in mind: throttling the flow of cooling air passing through the hood, should be solely due to selection section the front entrance window at much open the rear output. Only in this case excluded the possibility of formation in the engine compartment kind of air cushion, dramatically worsens the degree of cooling of the engine cylinder head. On the model installed slightly modified motor NMD, which, however, were selected after bench testing out of the party in three pieces. Additionally it had a little tilt back cylinder axis (due to the lapping of the upper end of the casing, which sits on a ribbed shirt of the cylinder) with the simultaneous permutation of the screw M2,5 in the top of the head. The back wall with the spool upheld, she just filed off flush the whole carburetor part. Spinner — large size that gives you the opportunity to Refine the aerodynamic shape of the front part of the model and to close the outside of the inboard area of the blade.

V. MACHINES, the head of the circle

Recommend to read “CROCODILE” FOR HEAT SINK Restraint solder radiodetal tweezers also serves as a heat sink. With the same purpose and possibly the use of clamp type "crocodile", if it is put on the output of the semiconductor ... “DISAPPEARING” STAIRS A lot of trouble delivers the design of internal stairs, for example, the attic. For convenient large marches, as a rule, not enough space and they are very steep, which is dangerous,... Scroll back to top