Hams often have to drill into circuit boards of a large number of holes of small diameter. To do this a serial drills is not very convenient — too big size. And slim drill not so easy to squeeze in a larger cartridge.

Hams often have to drill into circuit boards of a large number of holes of small diameter. To do this a serial drills is not very convenient — too big size. And slim drill not so easy to squeeze in a larger cartridge.

Our workshop

ELECTRONOVA

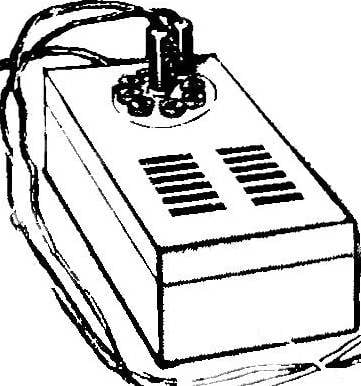

Not long ago I discovered, in his home workshop old Microdrive MK-12-In, preserved, apparently, since childhood. What to do with it? Throw a pity, and here decided though somehow to use.

Not long ago I discovered, in his home workshop old Microdrive MK-12-In, preserved, apparently, since childhood. What to do with it? Throw a pity, and here decided though somehow to use.CLAMP-“HARVESTER”

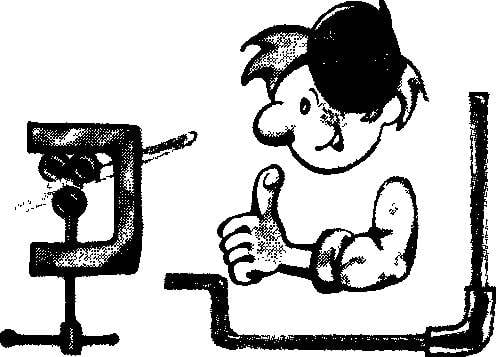

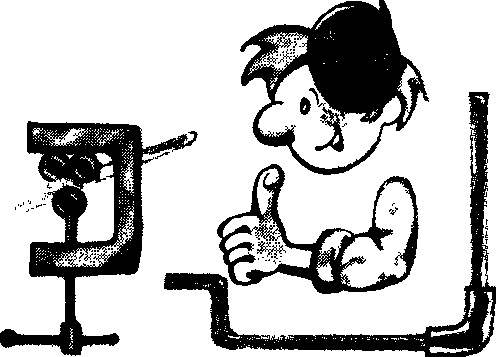

When repairing thin lines (such as a car or refrigerator), it would be good to have on hand a small pipe cutter, and for connection of pipes with swivel nuts — device for rolling. Not hurt in a home workshop and a small vise. All of these devices can be made in the form of a set of interchangeable tool based on a simple clamp of suitable size (or specially manufactured). The design will need slight modification for mounting of tools for different purposes. In the first place must be milled afterwards the groove under all replacement fixtures (cage support rollers, rolling, vise) and drill a hole for the stopper.

When repairing thin lines (such as a car or refrigerator), it would be good to have on hand a small pipe cutter, and for connection of pipes with swivel nuts — device for rolling. Not hurt in a home workshop and a small vise. All of these devices can be made in the form of a set of interchangeable tool based on a simple clamp of suitable size (or specially manufactured). The design will need slight modification for mounting of tools for different purposes. In the first place must be milled afterwards the groove under all replacement fixtures (cage support rollers, rolling, vise) and drill a hole for the stopper.

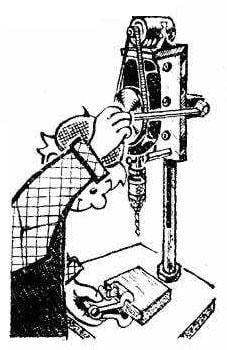

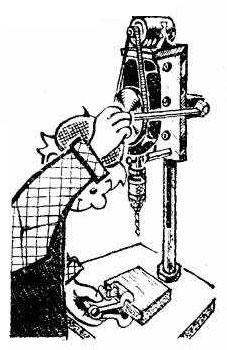

HOMEMADE DRILL

Osnova difficulty in creating a homemade drilling machines — making mechanism of vertical movement of the working body. What if you make a machine entirely without the mechanism to serve Chuck with a drill bit, and the item itself? In this case the structure is greatly simplified. No claim to originality for his decision, but it is this idea that allowed me to design and manufacture the machine, the device which is shown in the figure.

Osnova difficulty in creating a homemade drilling machines — making mechanism of vertical movement of the working body. What if you make a machine entirely without the mechanism to serve Chuck with a drill bit, and the item itself? In this case the structure is greatly simplified. No claim to originality for his decision, but it is this idea that allowed me to design and manufacture the machine, the device which is shown in the figure.DESIGN THE PRINTED CIRCUIT BOARD

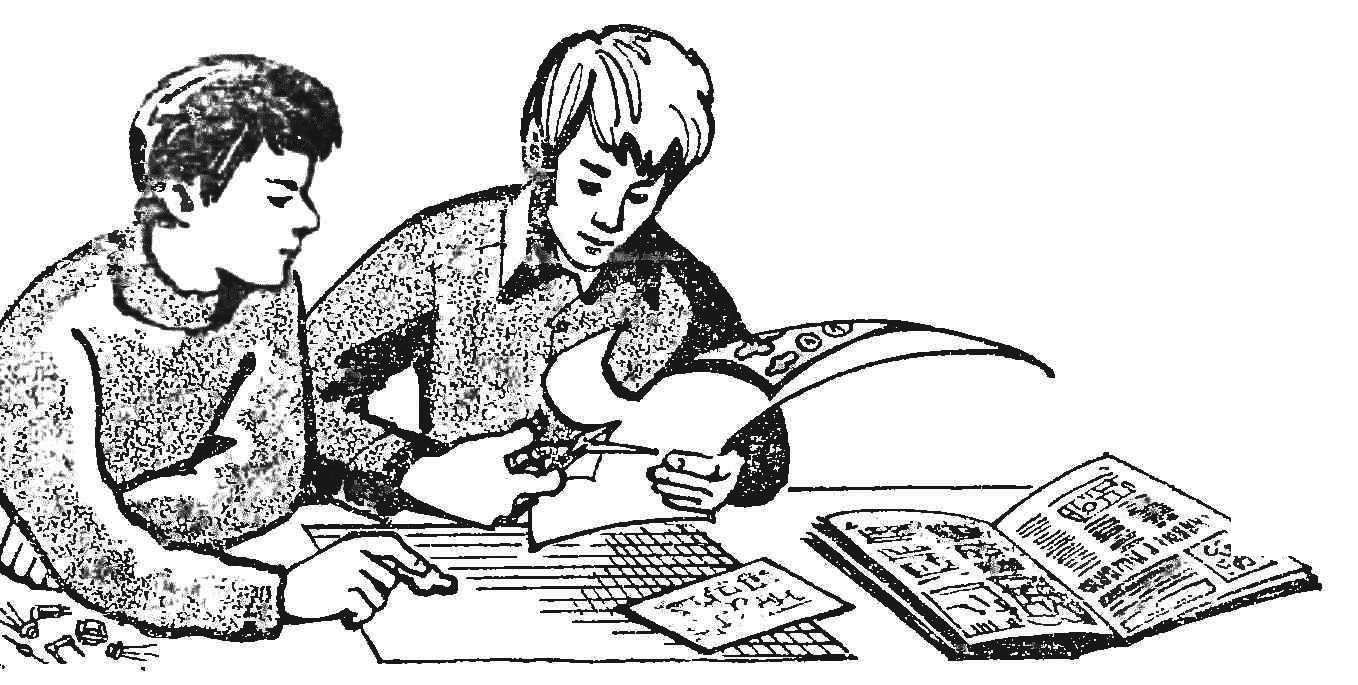

Novice hams are often hesitant to begin the Assembly of electronic devices just because in the description is missing the picture of the PCB, and to develop its own not everyone can. Indeed, without sufficient experience to make it easy: it is necessary to know how to choose the best dimensions to correctly place items in a timely manner to detect and correct errors. Therefore, we recommend you to master the design of printed circuit boards with the simplest.

Novice hams are often hesitant to begin the Assembly of electronic devices just because in the description is missing the picture of the PCB, and to develop its own not everyone can. Indeed, without sufficient experience to make it easy: it is necessary to know how to choose the best dimensions to correctly place items in a timely manner to detect and correct errors. Therefore, we recommend you to master the design of printed circuit boards with the simplest.CUTS HOT THREAD

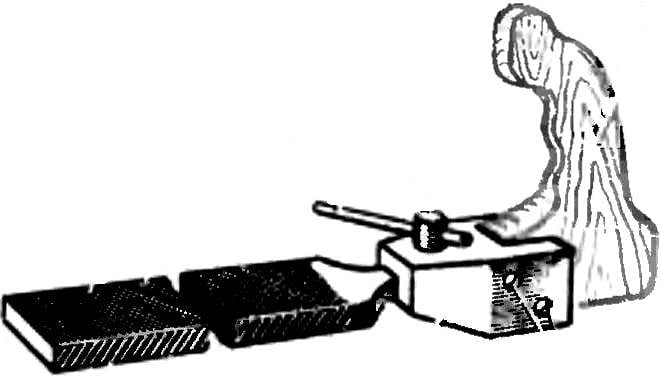

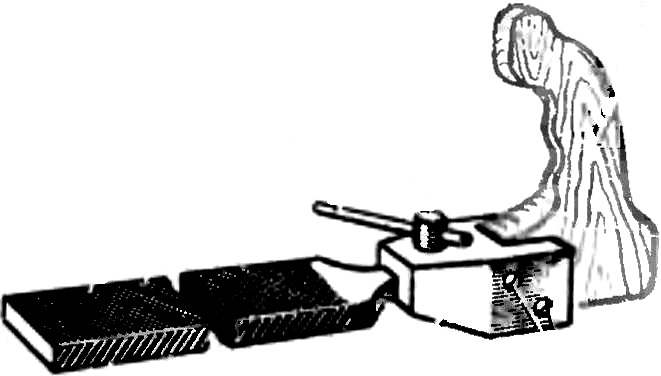

This simple device can be useful to the house master in the manufacture of various frames, boxes, lampshades and other articles made from organic glass sheet, thermoplastic plastic or foam.

This simple device can be useful to the house master in the manufacture of various frames, boxes, lampshades and other articles made from organic glass sheet, thermoplastic plastic or foam.HANDLE FOR A FILE

Handle to a file? What could be easier! Bought, planted a file, and you’re done! Well, if the file is too large size and its shank when the head is just going to break a normal pen? It turns out that the handle for the larger, so-called dracopoli file not so simple.

Handle to a file? What could be easier! Bought, planted a file, and you’re done! Well, if the file is too large size and its shank when the head is just going to break a normal pen? It turns out that the handle for the larger, so-called dracopoli file not so simple.THE GYM IN THE APARTMENT

Even in a small room it is possible to allocate a place under a sports area, as required for the normal development of the child. “Club Home of the Masters” already familiar with similar structures; today, we offer another option, made entirely of wooden parts.

Even in a small room it is possible to allocate a place under a sports area, as required for the normal development of the child. “Club Home of the Masters” already familiar with similar structures; today, we offer another option, made entirely of wooden parts.

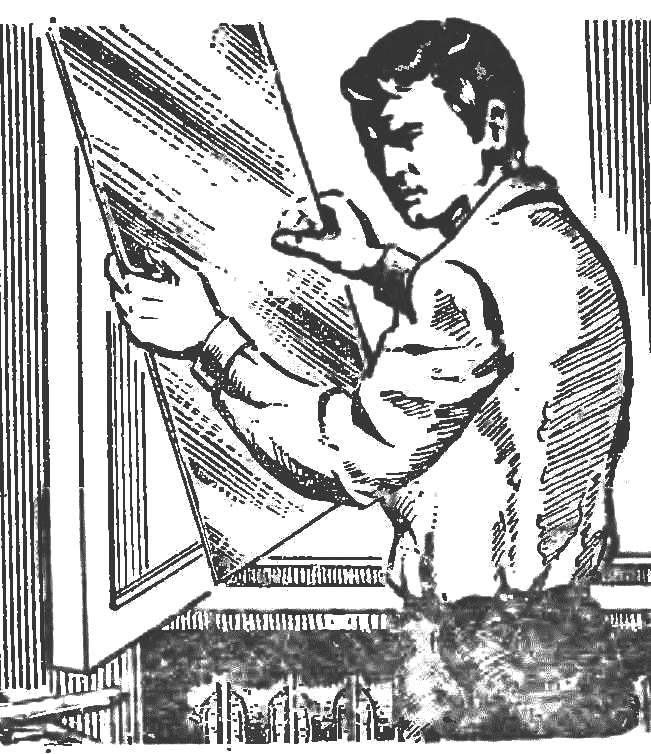

GLASS CARE

Remember: it was not cold in your house last winter? Do not rush to blame the heating system, even if it furnace: victoriat room can and Windows. Check to see if the putty on the frames and I wanna see if she cracks through the thin slit between the glass and the wood heat is rapidly going out of the house and cold air is not less noticeable comes inside. The measurements indicate, through window and door openings can dissipate up to 2/3 of the generated heat-generating appliances heat. That’s why remaining before the real cold days are useful to restore the integrity of window glazing. As describe in detail. Our tips will be useful for individual developers, and those who want to make a greenhouse or glasshouse.

Remember: it was not cold in your house last winter? Do not rush to blame the heating system, even if it furnace: victoriat room can and Windows. Check to see if the putty on the frames and I wanna see if she cracks through the thin slit between the glass and the wood heat is rapidly going out of the house and cold air is not less noticeable comes inside. The measurements indicate, through window and door openings can dissipate up to 2/3 of the generated heat-generating appliances heat. That’s why remaining before the real cold days are useful to restore the integrity of window glazing. As describe in detail. Our tips will be useful for individual developers, and those who want to make a greenhouse or glasshouse.TSENTROISKATEL