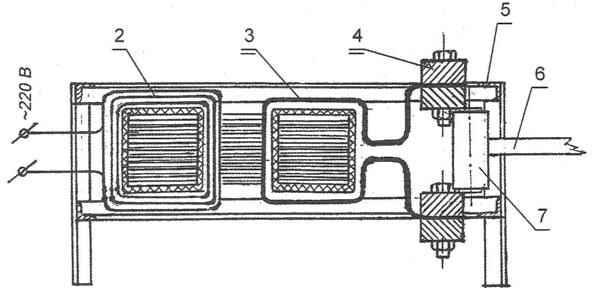

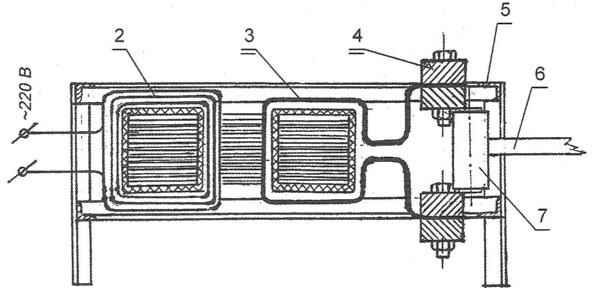

The furnace is designed for metals with suitable melting temperature in a volume of 10 cm3. It is an electrical transformer, the secondary winding ends of which are closed with a conductive vessel in which melting occurs. Oven can be used for artistic casting, in jewelry, for casting billets, alloys.

The furnace is designed for metals with suitable melting temperature in a volume of 10 cm3. It is an electrical transformer, the secondary winding ends of which are closed with a conductive vessel in which melting occurs. Oven can be used for artistic casting, in jewelry, for casting billets, alloys.

Our workshop

WORKBENCH-THE TRIPTYCH

To design present a universal (I believe) bench is a necessary desktop DIY I came across several years of studying technical creativity. It was designed based on their needs. But I think about the same requirements to such equipment his Studio have most other home handymen. Workbench foldable and small in size. However, due to the original pressure of the knot on it to handle you can pin a fairly large parts and products, installing them in a vertical plane, and at multiple fixed angles.

To design present a universal (I believe) bench is a necessary desktop DIY I came across several years of studying technical creativity. It was designed based on their needs. But I think about the same requirements to such equipment his Studio have most other home handymen. Workbench foldable and small in size. However, due to the original pressure of the knot on it to handle you can pin a fairly large parts and products, installing them in a vertical plane, and at multiple fixed angles.

CUT SLOTS AND GROOVES

In the conditions of a home workshop without special tools and fixtures can be performed, perhaps, only the so-called “collective” keyway: when impaled on the shaft gear or pulley is drilled by the drill joint hole centered on the circle stitching. Then in this hole is inserted a cylindrical key. But such a connection of the parts securely — no wonder because it is not in any Guest.

In the conditions of a home workshop without special tools and fixtures can be performed, perhaps, only the so-called “collective” keyway: when impaled on the shaft gear or pulley is drilled by the drill joint hole centered on the circle stitching. Then in this hole is inserted a cylindrical key. But such a connection of the parts securely — no wonder because it is not in any Guest.

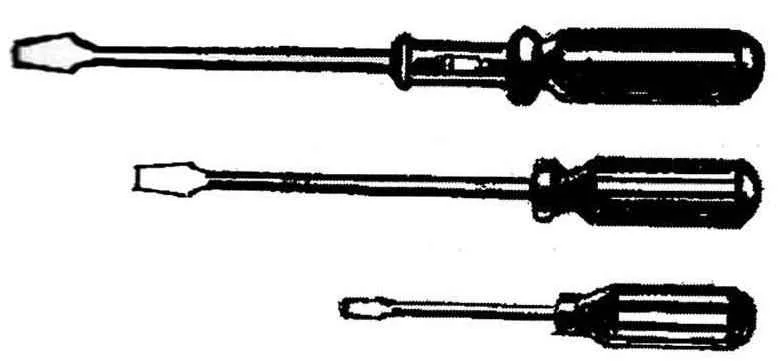

ARSENAL HOME WORKER

Today’s “unobtrusive service”, which have to apply for the small problems of household systems, effectively “bite”. Even the call an electrician, technician or plumber to diagnose, not to mention the simple elimination of minor faults, is quite expensive.

Today’s “unobtrusive service”, which have to apply for the small problems of household systems, effectively “bite”. Even the call an electrician, technician or plumber to diagnose, not to mention the simple elimination of minor faults, is quite expensive.

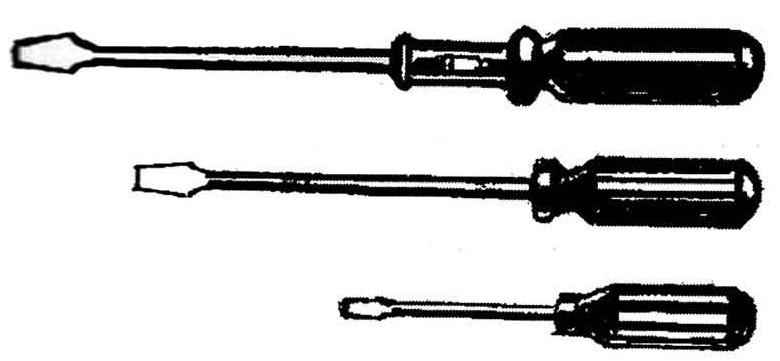

Therefore, minor damage or imperfections is much better to perform on their own. But to do this at home worker should be at least the most basic set of working tools. But if the head of the family or children, there is also passion, desire something to make with your own hands, you will need an Arsenal of tools.

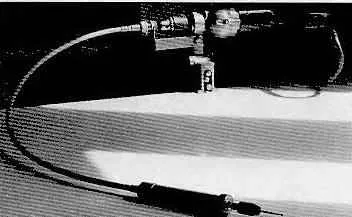

VENEER DO

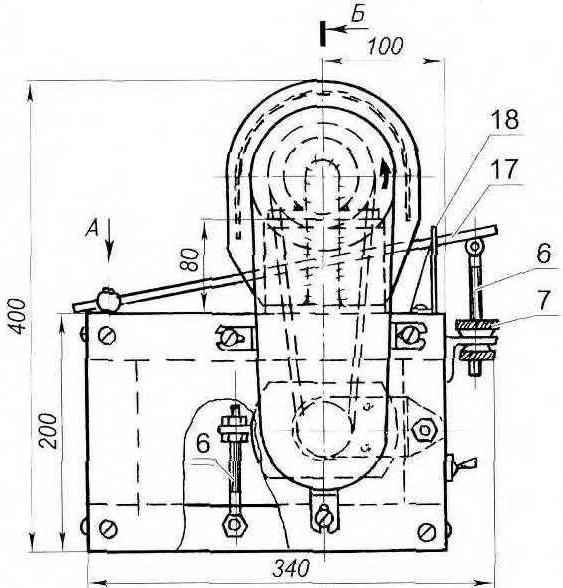

During the construction of the models is often necessary to apply a veneer of varying thickness. Typically the desired thickness is obtained by grinding with fungus with glued on end cloth, is inserted in the Chuck of the drilling machine. This method is most affordable, but it has several drawbacks: poor performance, inability to process veneer with thickness less than 0.5 mm, because of the rotation of the fungus veneer escapes from the hands and broken, and finally, the main drawback is the large air pollution wood dust. To handle more than three or four plates is not possible even a respirator.

During the construction of the models is often necessary to apply a veneer of varying thickness. Typically the desired thickness is obtained by grinding with fungus with glued on end cloth, is inserted in the Chuck of the drilling machine. This method is most affordable, but it has several drawbacks: poor performance, inability to process veneer with thickness less than 0.5 mm, because of the rotation of the fungus veneer escapes from the hands and broken, and finally, the main drawback is the large air pollution wood dust. To handle more than three or four plates is not possible even a respirator.

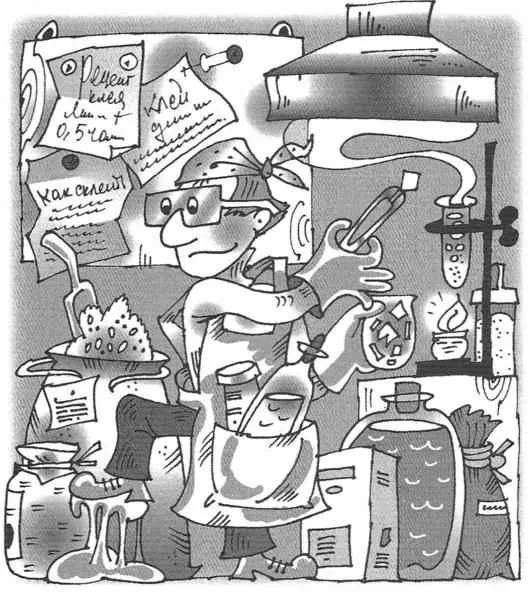

GLUE COOKING

Advantages of adhesive bonding are well known. So to advertise no need. Amateur masters have long been actively using the method of bonding parts in their designs.

Advantages of adhesive bonding are well known. So to advertise no need. Amateur masters have long been actively using the method of bonding parts in their designs.

Currently, the range of materials has expanded considerably, and each requires its own glue. Need, unfortunately, is not always on sale. But in hardware stores and in the pharmacies you can buy individual components from which it is easy to make adhesives for many materials.

Today’s edition of the “Club house masters” introduces readers to recipes for adhesives that can be manufactured at home.

WITH ONE CALL

In your journal in one of the rooms of yesteryear has published an article — “the plug”. I must say that the proposed options combined metal dowels rather complicated to manufacture, but their use is justified for hollow panels and panels of partitions, which in modern buildings are not too frequent. Novosel is usually found with the need to drill or punch holes in concrete, brick and rarely in gipsolitovye panels, and requires significant skills, experience and special tools. Besides produce during operation the noise causes discomfort to the neighbors.

In your journal in one of the rooms of yesteryear has published an article — “the plug”. I must say that the proposed options combined metal dowels rather complicated to manufacture, but their use is justified for hollow panels and panels of partitions, which in modern buildings are not too frequent. Novosel is usually found with the need to drill or punch holes in concrete, brick and rarely in gipsolitovye panels, and requires significant skills, experience and special tools. Besides produce during operation the noise causes discomfort to the neighbors.

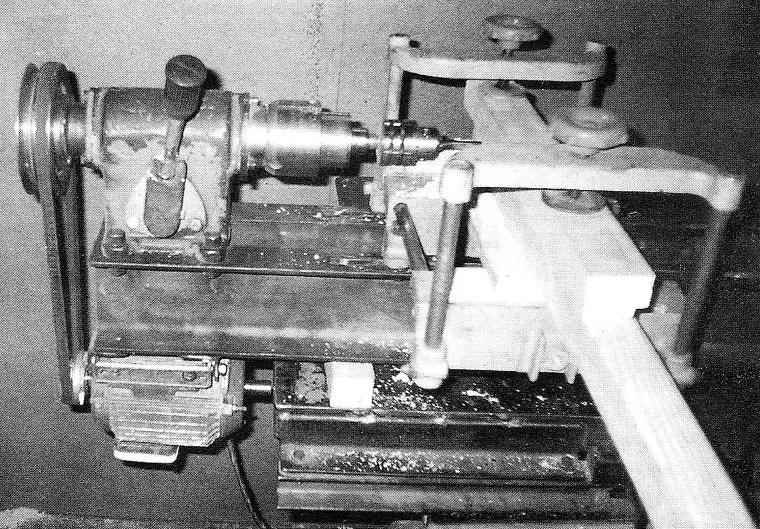

AND SHARPENING, AND DRILLING, AND MILL

To create a lathe-boring woodworking machine me prompted memories of school days when in the classroom I received the first skills of work on a lathe — lesson interesting and exciting. Since then, as they say, much water has flowed, but the desire to do of wood pieces of furniture with a beautiful chiseled details is preserved, but the necessary lathe I had. And I decided to do it, adapting to the bed of the other machine, consisting of a “circular saw” and electrofunk (see “M-K” № 1 ‘2011), thus obtaining woodworking mini-complex.

To create a lathe-boring woodworking machine me prompted memories of school days when in the classroom I received the first skills of work on a lathe — lesson interesting and exciting. Since then, as they say, much water has flowed, but the desire to do of wood pieces of furniture with a beautiful chiseled details is preserved, but the necessary lathe I had. And I decided to do it, adapting to the bed of the other machine, consisting of a “circular saw” and electrofunk (see “M-K” № 1 ‘2011), thus obtaining woodworking mini-complex.

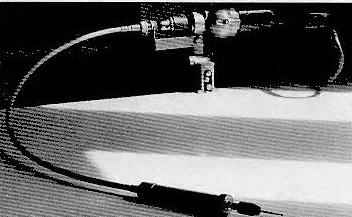

THE DRILL OF DRILLS

I’m probably not mistaken saying that the majority of home handymen’s dream is to have a universal bormashenko. How many opportunities it opens! Engraving, abrasive machining of parts of complex configuration, the manufacture of dies and molds, drilling and countersinking holes located in hard to drill places, jewelry work — this is not a complete list of operations to perform which allows this mechanism. It is not surprising that bormashenko, due to its large SROs, it is not easy to get.

I’m probably not mistaken saying that the majority of home handymen’s dream is to have a universal bormashenko. How many opportunities it opens! Engraving, abrasive machining of parts of complex configuration, the manufacture of dies and molds, drilling and countersinking holes located in hard to drill places, jewelry work — this is not a complete list of operations to perform which allows this mechanism. It is not surprising that bormashenko, due to its large SROs, it is not easy to get.

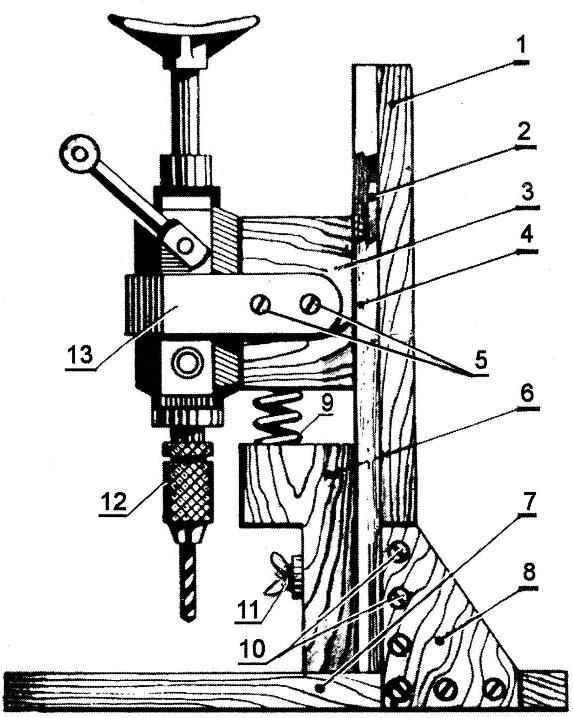

THE MACHINE OF DRILLS

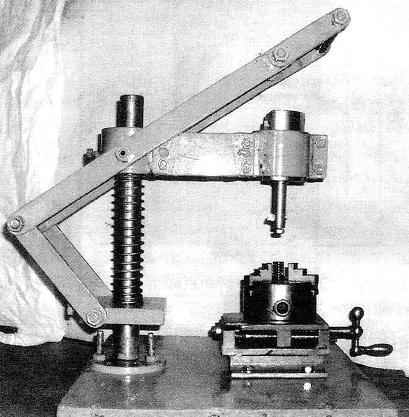

Everyone who had to drill holes using a hand drill or a hand brace, knows how difficult it is to keep the drill bit in the desired position (usually perpendicular to the surface of the workpiece). In many cases, to avoid such difficulties helps homemade machine hand drill.

Everyone who had to drill holes using a hand drill or a hand brace, knows how difficult it is to keep the drill bit in the desired position (usually perpendicular to the surface of the workpiece). In many cases, to avoid such difficulties helps homemade machine hand drill.

Its design can be like this. Thick wide stand mounted vertical stand with two guide rails. In the grooves of the rails easy to move the strap connected to the Shoe (“slide”), to which by means of a metal strip is attached to the body of the drill.