Our workshop

THE MILLED DRILL

FROM PIGGY CRAFTSMEN

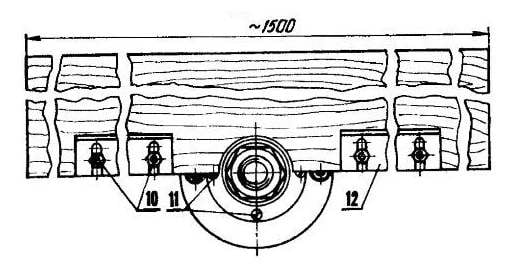

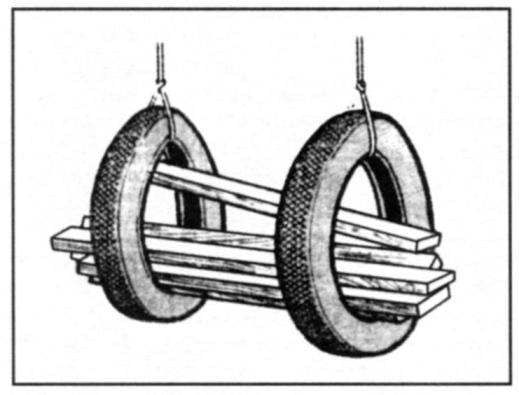

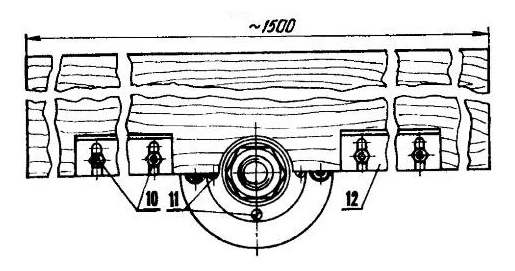

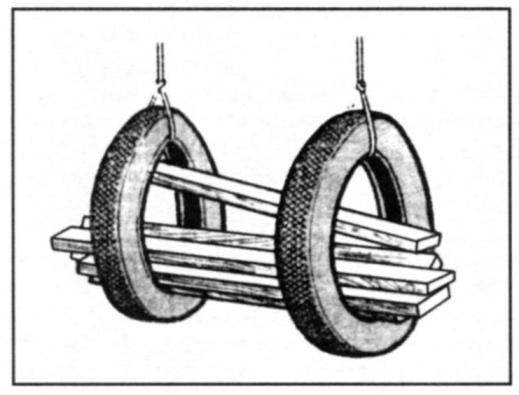

The lumber before use is recommended long to dry. In the traditional laying on the ground, it is difficult to protect them from moisture, and in the premises because of their size, they interfere.

The lumber before use is recommended long to dry. In the traditional laying on the ground, it is difficult to protect them from moisture, and in the premises because of their size, they interfere.

HOW TO REPAIR AIR CONDITIONER?

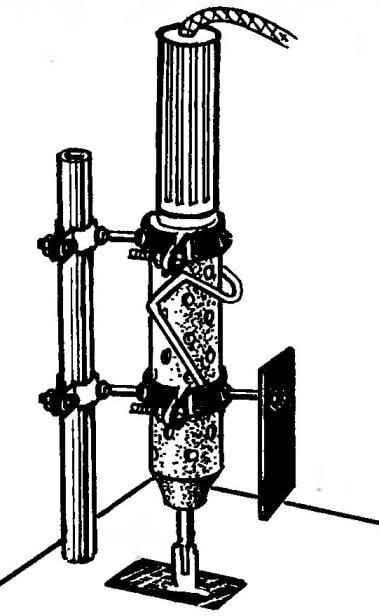

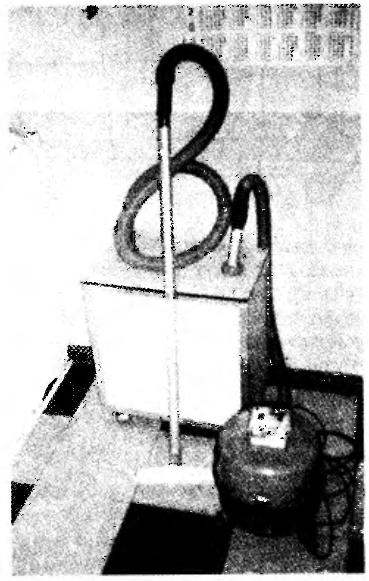

CAPACIOUS CLEANER

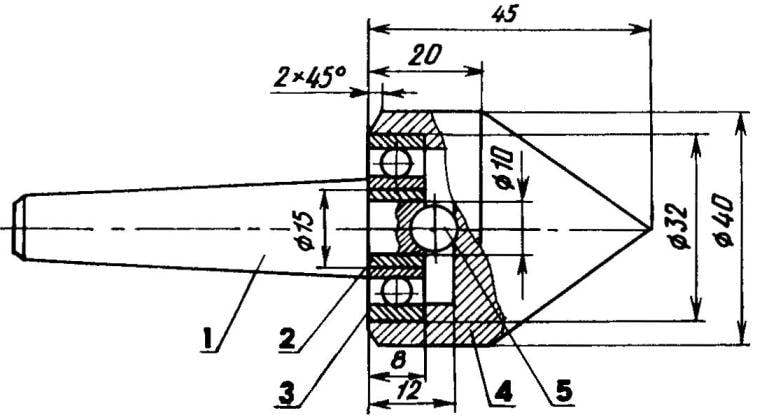

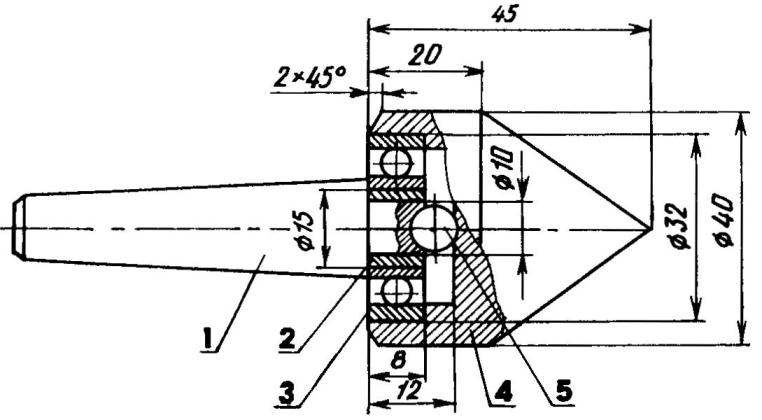

DURABLE CENTER

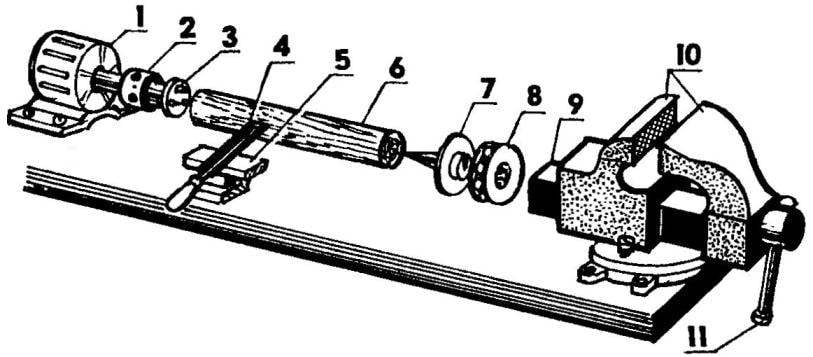

TURNING FROM THE CLUTCHES OF…

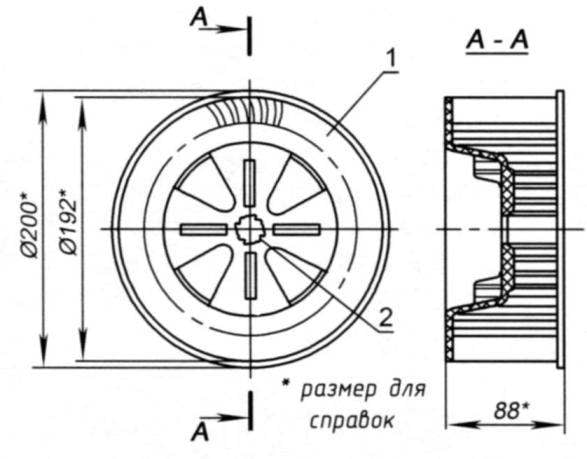

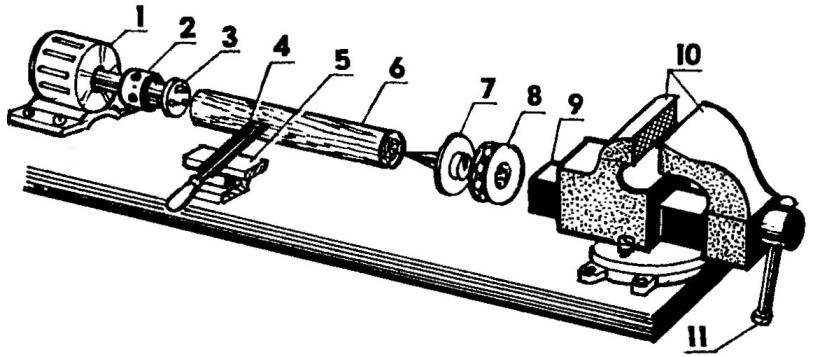

The journal “modelist-Konstruktor” I love since childhood. In Kazakhstan we have now it is not for sale, but I regularly read it in the library. Responding to the call of the editors to be not only a reader but also an author, I want to share my little experience performing turning operations on a tree without a special lathe. To do this, at the right time are available to me elektrotochilo and grip, adding to them two auxiliary elements: the Trident and the back area with a small thrust bearing (they then shall say more about). Bench grinder with a Trident causes a wooden block into rotation and vise play the role of the tailstock.

The journal “modelist-Konstruktor” I love since childhood. In Kazakhstan we have now it is not for sale, but I regularly read it in the library. Responding to the call of the editors to be not only a reader but also an author, I want to share my little experience performing turning operations on a tree without a special lathe. To do this, at the right time are available to me elektrotochilo and grip, adding to them two auxiliary elements: the Trident and the back area with a small thrust bearing (they then shall say more about). Bench grinder with a Trident causes a wooden block into rotation and vise play the role of the tailstock.

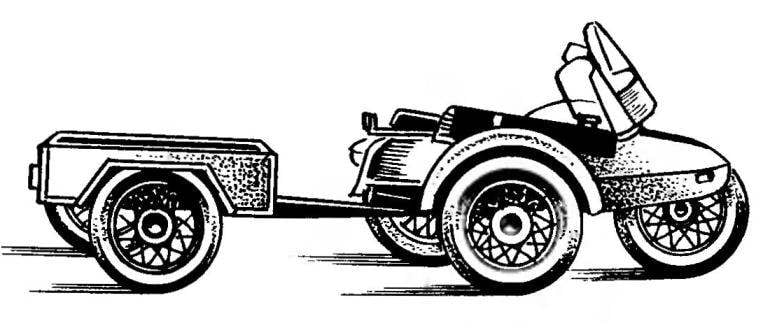

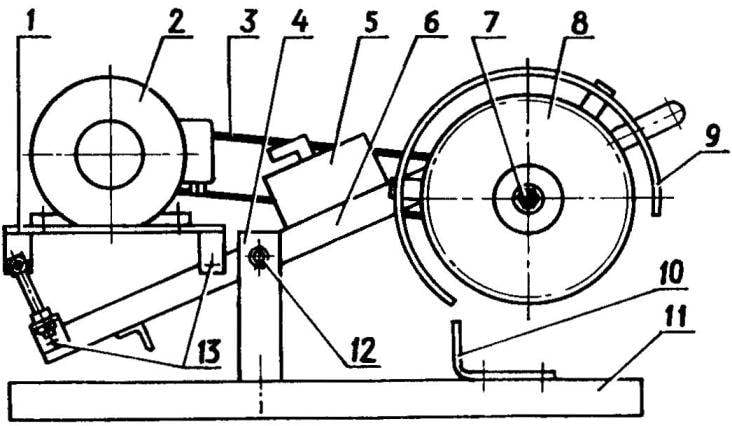

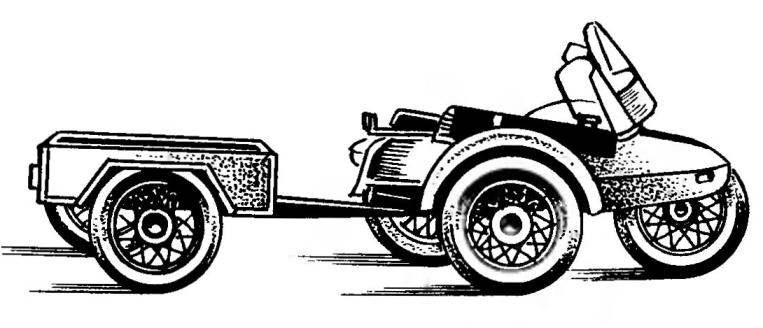

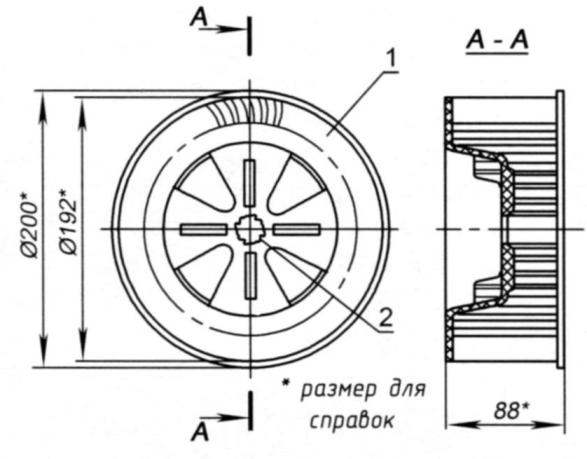

COMPACT AND MOBILE

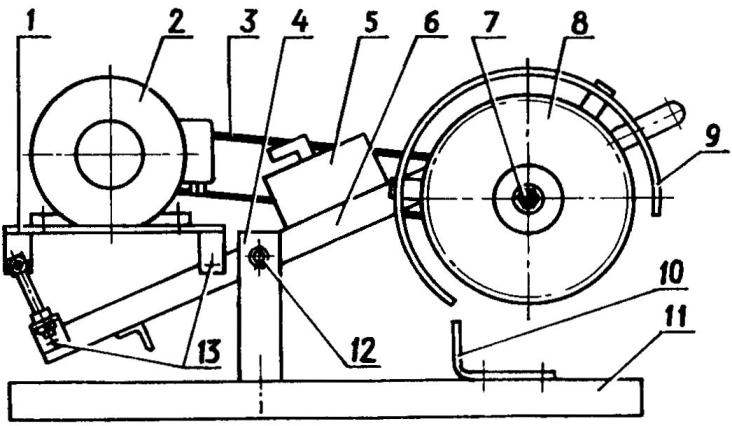

Balance small circular saw. After pruning trees in the garden goes into the waste a significant amount of branches of various thickness. Usually they go on the stove. Small branches are easily chopped with an axe, and the larger cut. Hand sawing — it is quite time consuming. To ease the gardening chores, I made a portable circular power saw. Quite light and compact. In addition, it balance, but more on that below.

Balance small circular saw. After pruning trees in the garden goes into the waste a significant amount of branches of various thickness. Usually they go on the stove. Small branches are easily chopped with an axe, and the larger cut. Hand sawing — it is quite time consuming. To ease the gardening chores, I made a portable circular power saw. Quite light and compact. In addition, it balance, but more on that below.

THERMORESIN FROM THE SOLDERING IRON

Many of the materials the born chemicals using elevated temperatures, for example, various plastics and synthetics, more manageable when shaping or processing temperature than the tools traditionally used to working with metal or wood. That’s why for cutting, for example, foam plastic, foam rubber or polyethylene are constructed of various homemade devices and devices in which the main working instrument is a hot plate or wire.

Many of the materials the born chemicals using elevated temperatures, for example, various plastics and synthetics, more manageable when shaping or processing temperature than the tools traditionally used to working with metal or wood. That’s why for cutting, for example, foam plastic, foam rubber or polyethylene are constructed of various homemade devices and devices in which the main working instrument is a hot plate or wire.

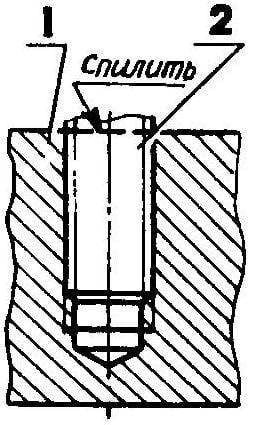

WHEN BROKE OFF THE SCREW…

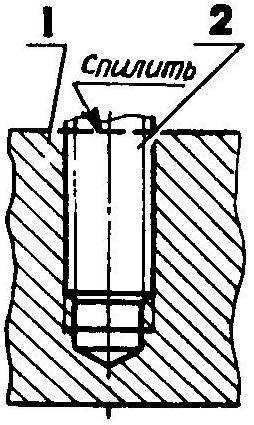

Hard turns (as, indeed, trudnosmyvaemye) fastener (screw or stud) face many troubles, both small and large. The latter can be safely attributed the breakage in the body parts of the stud or screw, as the extraction residue of the fastener from a threaded hole or socket parts is very thin, requires great accuracy. The reasons of breakages of fasteners can be several: excess torque; the use of low-grade threaded products; “welding” of the parts and threads of the fastener due to corrosion or high-temperature heating, and others.

Hard turns (as, indeed, trudnosmyvaemye) fastener (screw or stud) face many troubles, both small and large. The latter can be safely attributed the breakage in the body parts of the stud or screw, as the extraction residue of the fastener from a threaded hole or socket parts is very thin, requires great accuracy. The reasons of breakages of fasteners can be several: excess torque; the use of low-grade threaded products; “welding” of the parts and threads of the fastener due to corrosion or high-temperature heating, and others.