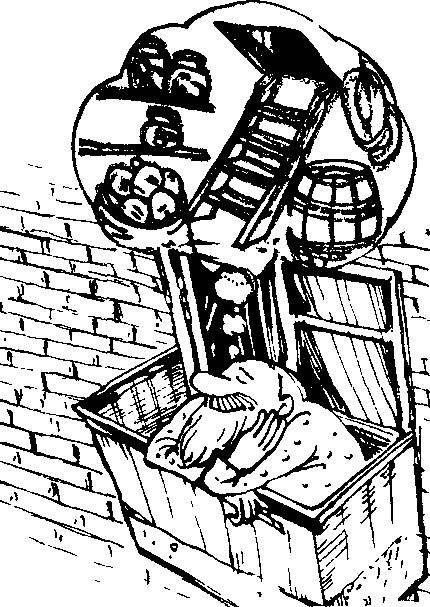

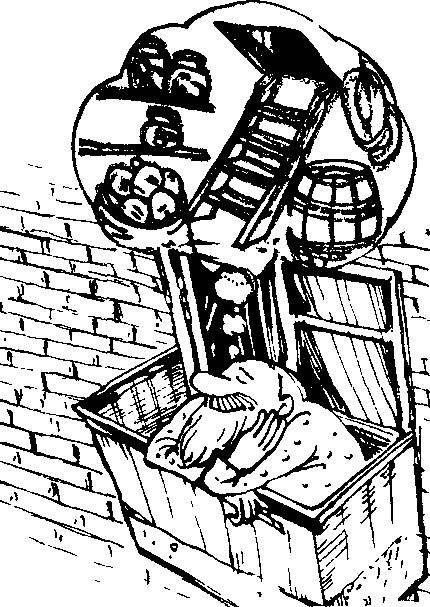

In the journal “modelist-Konstruktor” has repeatedly published materials on the makeshift “fridges” where to store your products use natural cold which in the middle zone of our country, not to mention its North, more than enough. In all of these devices when too much frost, the optimum temperature is maintained by heating the food. The sensors used for this are very different, but for some reason, nobody comes to use the effect of phase transformation. In short, a physical phenomenon accompanying the freezing and melting of water.

In the journal “modelist-Konstruktor” has repeatedly published materials on the makeshift “fridges” where to store your products use natural cold which in the middle zone of our country, not to mention its North, more than enough. In all of these devices when too much frost, the optimum temperature is maintained by heating the food. The sensors used for this are very different, but for some reason, nobody comes to use the effect of phase transformation. In short, a physical phenomenon accompanying the freezing and melting of water.THE REFRIGERATOR IS 0°C!

In the journal “modelist-Konstruktor” has repeatedly published materials on the makeshift “fridges” where to store your products use natural cold which in the middle zone of our country, not to mention its North, more than enough. In all of these devices when too much frost, the optimum temperature is maintained by heating the food. The sensors used for this are very different, but for some reason, nobody comes to use the effect of phase transformation. In short, a physical phenomenon accompanying the freezing and melting of water.

In the journal “modelist-Konstruktor” has repeatedly published materials on the makeshift “fridges” where to store your products use natural cold which in the middle zone of our country, not to mention its North, more than enough. In all of these devices when too much frost, the optimum temperature is maintained by heating the food. The sensors used for this are very different, but for some reason, nobody comes to use the effect of phase transformation. In short, a physical phenomenon accompanying the freezing and melting of water.

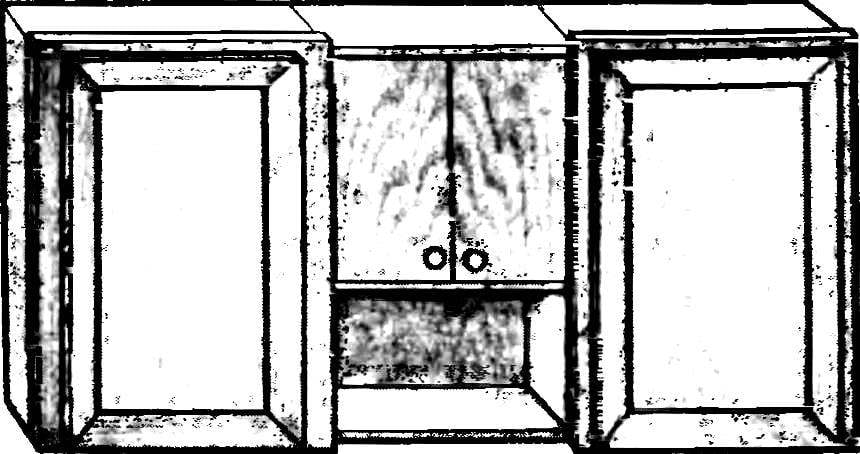

For harvesting for the future fruit for several years, use convenient dryer of our own making. Frame design and vertical placement allows you to place it on the Sunny wall of the garden shed without taking up additional space on the site.

For harvesting for the future fruit for several years, use convenient dryer of our own making. Frame design and vertical placement allows you to place it on the Sunny wall of the garden shed without taking up additional space on the site.

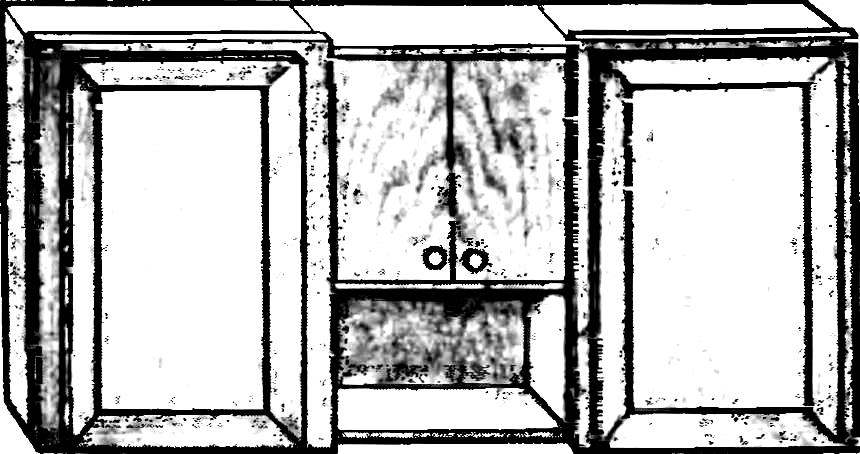

Children’s is usually the smallest room in the apartment. The rational use of its area arises particularly to parents, when the family has another child. In particular, when the first class went my youngest son, thinking where to place the second working place.

Children’s is usually the smallest room in the apartment. The rational use of its area arises particularly to parents, when the family has another child. In particular, when the first class went my youngest son, thinking where to place the second working place.

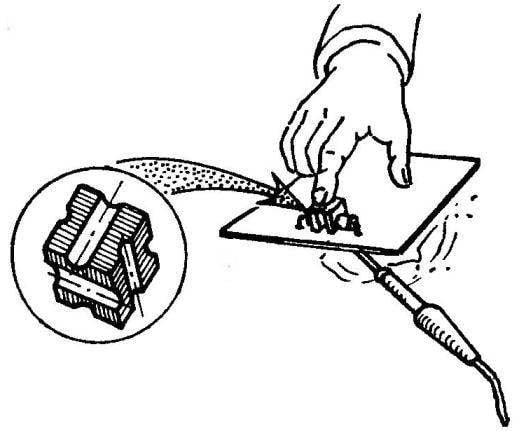

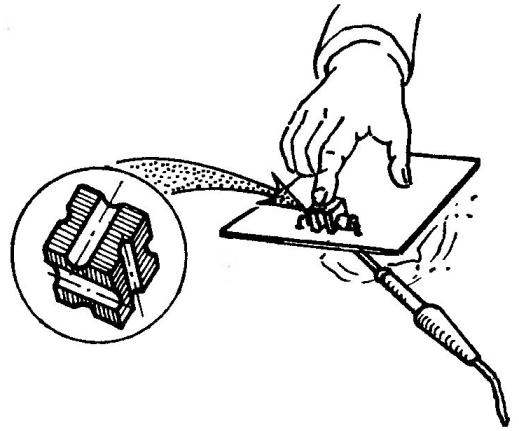

An extremely important piece of technology in the manufacture of engines is the coating of the friction elements of the antifriction alloys or metals. This thin layer, except for the anti-friction properties, should have high wear resistance, and appearance to be appropriate.

An extremely important piece of technology in the manufacture of engines is the coating of the friction elements of the antifriction alloys or metals. This thin layer, except for the anti-friction properties, should have high wear resistance, and appearance to be appropriate.

It is known that if two are going to swap, say, apples, then in the end they will still be an Apple. Well, if these two will exchange ideas, then each will have two ideas…

It is known that if two are going to swap, say, apples, then in the end they will still be an Apple. Well, if these two will exchange ideas, then each will have two ideas…

In electronic equipment with high density have more difficulties to get to various units and parts when setting up or replacing them during the renovation. Therefore, in the serial devices are widely used in various moving joints of construction elements. However, in Amateur conditions is not always possible to produce such compounds.

In electronic equipment with high density have more difficulties to get to various units and parts when setting up or replacing them during the renovation. Therefore, in the serial devices are widely used in various moving joints of construction elements. However, in Amateur conditions is not always possible to produce such compounds.

In the “M-K” No. 8 for the year 1991 was published an article devoted to the technology of processing of shells for cylinder-piston pairs of current model engines. Judging by the numerous reader responses, this topic is highly relevant and widely recognized. Therefore, in addition to already published material, we offer a number of tips that will allow Amateur and professionals made the crossing of the micro-motors to reach the heights of excellence in their field.

In the “M-K” No. 8 for the year 1991 was published an article devoted to the technology of processing of shells for cylinder-piston pairs of current model engines. Judging by the numerous reader responses, this topic is highly relevant and widely recognized. Therefore, in addition to already published material, we offer a number of tips that will allow Amateur and professionals made the crossing of the micro-motors to reach the heights of excellence in their field.

“Development, published in the journal “modelist-Konstruktor”, make ourselves photoelectron shooting. Works flawlessly. It is a pity that the sounds in the scheme is not provided. Help!”. The fraction of machine-gun fire, screeching min, heavy bass bombs… Simulates a similar sound picture of the fight is pretty simple device, made only three transistors.

“Development, published in the journal “modelist-Konstruktor”, make ourselves photoelectron shooting. Works flawlessly. It is a pity that the sounds in the scheme is not provided. Help!”. The fraction of machine-gun fire, screeching min, heavy bass bombs… Simulates a similar sound picture of the fight is pretty simple device, made only three transistors.