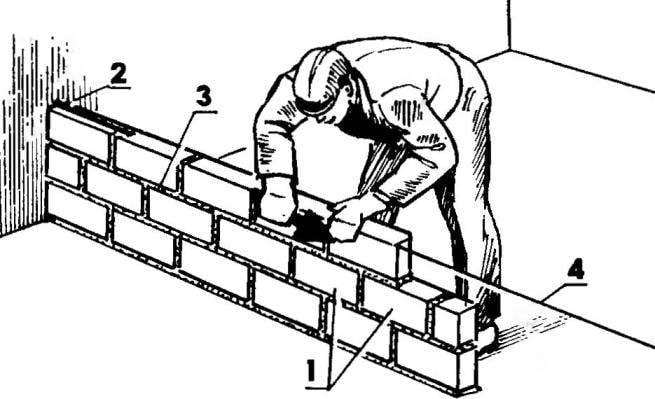

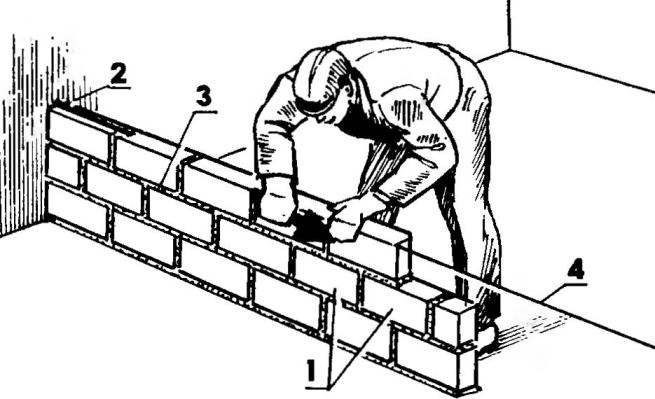

Partitions of brick in construction are widely distributed. Without them it is difficult to do even in houses built of wood. In many cases, for example, in the construction of sanitary units, boiler rooms and other similar areas, brick walls are simply irreplaceable. They are fireproof and moisture proof, environmentally friendly, not susceptible to rot, frost, do not lose strength at high temperatures and thus do not emit harmful substances.

Partitions of brick in construction are widely distributed. Without them it is difficult to do even in houses built of wood. In many cases, for example, in the construction of sanitary units, boiler rooms and other similar areas, brick walls are simply irreplaceable. They are fireproof and moisture proof, environmentally friendly, not susceptible to rot, frost, do not lose strength at high temperatures and thus do not emit harmful substances.

DIY

“WALKING” PADDLES

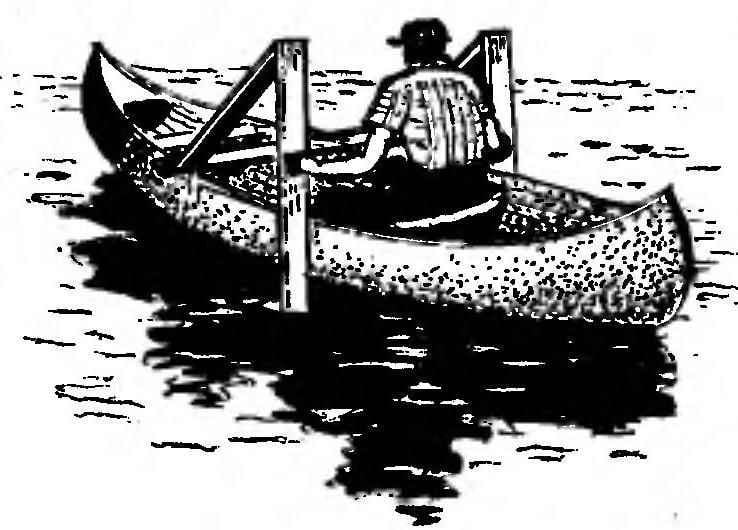

Traditional hinged paddles allow you to do a powerful stroke, dramatically sending the boat forward. But it is not visible, but where is the Boat: the oarsman sits with his back to the nose, and to adjust course, we have to look back, especially if he’s alone and no one to tell, what of the oars need to work harder to course-correct. With the exception of kayaks: paddle, looking ahead, due to the feature landing paddler and person-to-side movement.

Traditional hinged paddles allow you to do a powerful stroke, dramatically sending the boat forward. But it is not visible, but where is the Boat: the oarsman sits with his back to the nose, and to adjust course, we have to look back, especially if he’s alone and no one to tell, what of the oars need to work harder to course-correct. With the exception of kayaks: paddle, looking ahead, due to the feature landing paddler and person-to-side movement.

AND THE SUN AND THE WIND

At their summer cottage in inclement weather you can hide in the room. However, on a Sunny day sometimes want to hide from the scorching rays. And if the area no big trees, which would give a saving shadow, then it is not necessary to build a solid capital gazebo, as is often done. It is possible to equip the area with simple covers, like shown in the figures. This is not difficult to find these available designs that will not only be saved from heat, but also decorate the area.

At their summer cottage in inclement weather you can hide in the room. However, on a Sunny day sometimes want to hide from the scorching rays. And if the area no big trees, which would give a saving shadow, then it is not necessary to build a solid capital gazebo, as is often done. It is possible to equip the area with simple covers, like shown in the figures. This is not difficult to find these available designs that will not only be saved from heat, but also decorate the area.

HIMSELF MOE

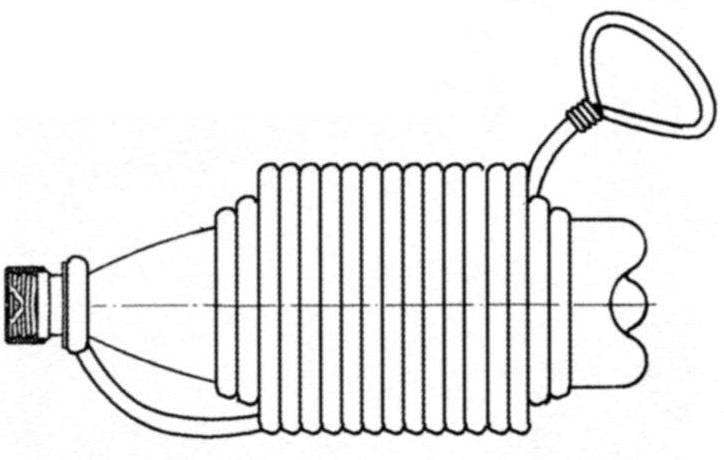

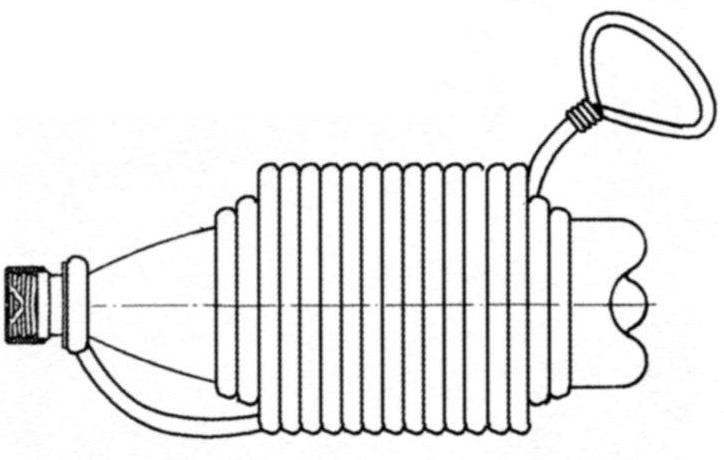

Emergencies are always unexpected – they are extraordinary. Most often, they happen when a person puts himself in a precarious position in its oversight find themselves in a critical situation: in the mountains, on the river, ice fishing. Of course, just impossible to anticipate, but be aware that the case may occur beyond our will and endeavour, if possible, to be ready for it.

Emergencies are always unexpected – they are extraordinary. Most often, they happen when a person puts himself in a precarious position in its oversight find themselves in a critical situation: in the mountains, on the river, ice fishing. Of course, just impossible to anticipate, but be aware that the case may occur beyond our will and endeavour, if possible, to be ready for it.

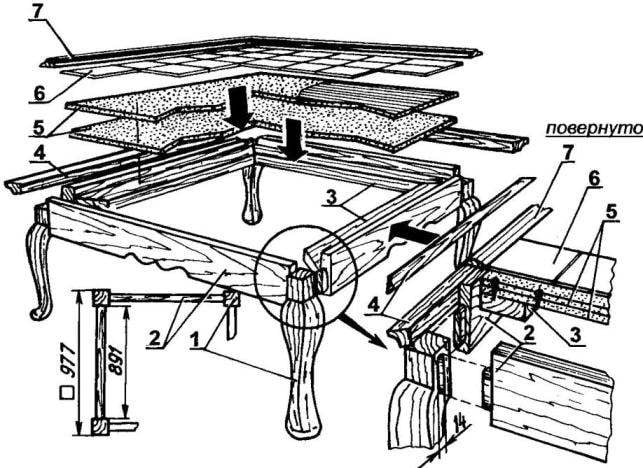

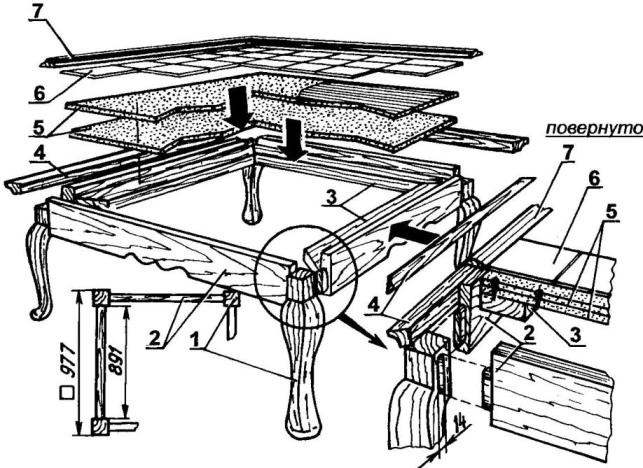

THE CURVED LEGS — A SIGN OF STYLE

Antique furnishings you’ll find out soon in a special form and, in the first place, legs. In the old days, Cabinet makers loved to make them curved, not now. At first glance it seems that to make such difficult and not to everyone under force. But do the same people, and without modern mechanization, by hand, simple tools. So, you can try to repeat the techniques of the old masters.

Antique furnishings you’ll find out soon in a special form and, in the first place, legs. In the old days, Cabinet makers loved to make them curved, not now. At first glance it seems that to make such difficult and not to everyone under force. But do the same people, and without modern mechanization, by hand, simple tools. So, you can try to repeat the techniques of the old masters.

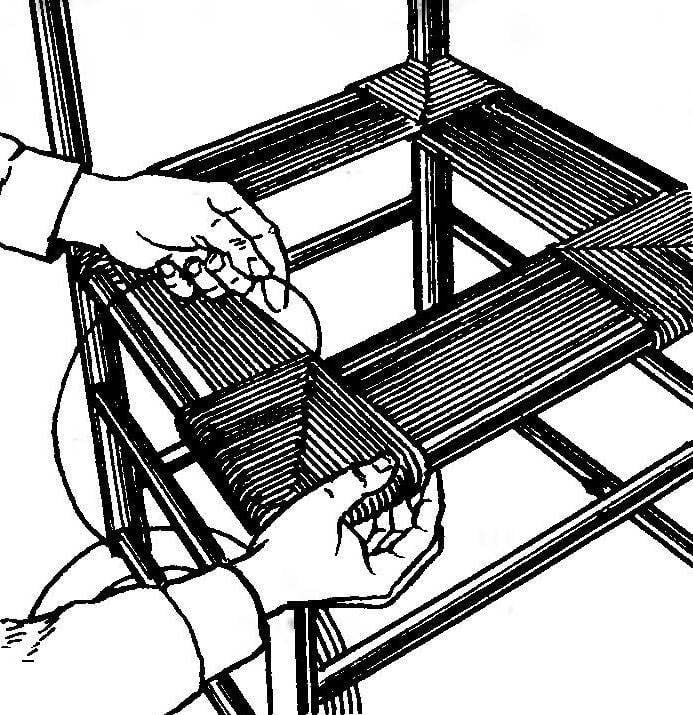

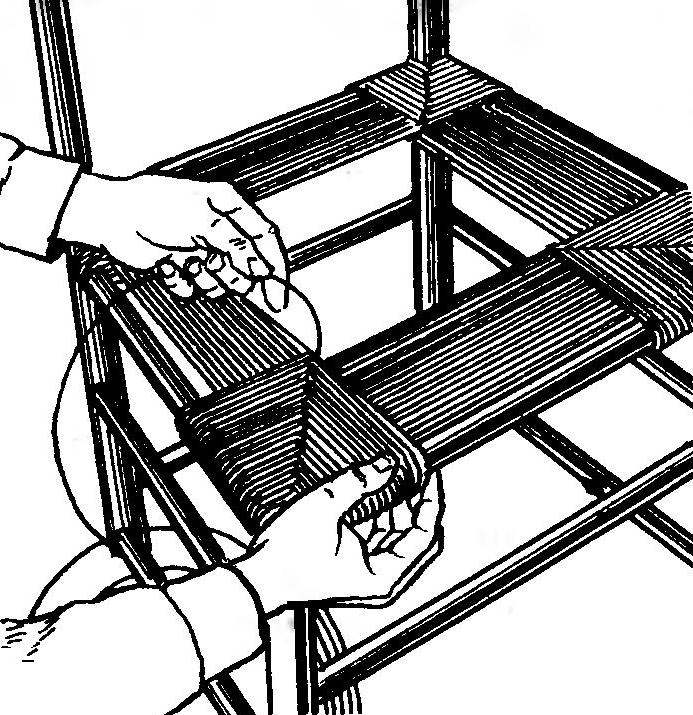

… WEAVE CHAIR

The proposed technology of manufacturing of seats is suitable in the case of repair of old furniture, and when you create a new one. It is equally applicable for both stool and chair, and armchairs. Methods of work proposed by the Hungarian magazine “Earmaster”, as simple as they were effective on the final result. The result is beautiful and quite durable seat. The basic operation is really similar to basket weaving, only in this case is not used willow rod, and a cord, rope, synthetic tube, or even insulated electrical wires.

The proposed technology of manufacturing of seats is suitable in the case of repair of old furniture, and when you create a new one. It is equally applicable for both stool and chair, and armchairs. Methods of work proposed by the Hungarian magazine “Earmaster”, as simple as they were effective on the final result. The result is beautiful and quite durable seat. The basic operation is really similar to basket weaving, only in this case is not used willow rod, and a cord, rope, synthetic tube, or even insulated electrical wires.

BENCH KNEES

No matter how small nor was a country station, the cultivation of it requires a lot of work and everyday stress. It must be something to plant, paraklit, Spud. And all this has to do bent over or squatting, why start the back pain or aching legs. Work home grower or grower much easier universal bench, proposed by the Hungarian magazine “Earmaster”. Its versatility lies in the fact that when working in the beds prove to be useful almost all of its component parts – just enough to change their situation. This is considered in the development of simple design of the seat. Judge for yourself.

No matter how small nor was a country station, the cultivation of it requires a lot of work and everyday stress. It must be something to plant, paraklit, Spud. And all this has to do bent over or squatting, why start the back pain or aching legs. Work home grower or grower much easier universal bench, proposed by the Hungarian magazine “Earmaster”. Its versatility lies in the fact that when working in the beds prove to be useful almost all of its component parts – just enough to change their situation. This is considered in the development of simple design of the seat. Judge for yourself.

THERMORESIN FROM THE SOLDERING IRON

Many of the materials the born chemicals using elevated temperatures, for example, various plastics and synthetics, more manageable when shaping or processing temperature than the tools traditionally used to working with metal or wood. That’s why for cutting, for example, foam plastic, foam rubber or polyethylene are constructed of various homemade devices and devices in which the main working instrument is a hot plate or wire.

Many of the materials the born chemicals using elevated temperatures, for example, various plastics and synthetics, more manageable when shaping or processing temperature than the tools traditionally used to working with metal or wood. That’s why for cutting, for example, foam plastic, foam rubber or polyethylene are constructed of various homemade devices and devices in which the main working instrument is a hot plate or wire.

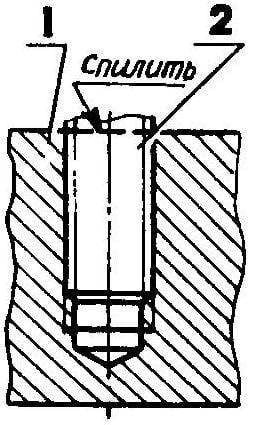

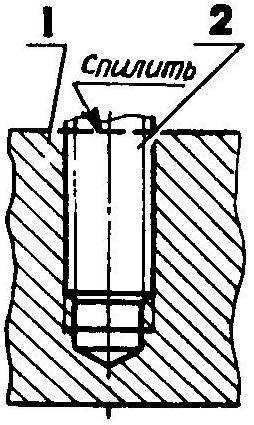

WHEN BROKE OFF THE SCREW…

Hard turns (as, indeed, trudnosmyvaemye) fastener (screw or stud) face many troubles, both small and large. The latter can be safely attributed the breakage in the body parts of the stud or screw, as the extraction residue of the fastener from a threaded hole or socket parts is very thin, requires great accuracy. The reasons of breakages of fasteners can be several: excess torque; the use of low-grade threaded products; “welding” of the parts and threads of the fastener due to corrosion or high-temperature heating, and others.

Hard turns (as, indeed, trudnosmyvaemye) fastener (screw or stud) face many troubles, both small and large. The latter can be safely attributed the breakage in the body parts of the stud or screw, as the extraction residue of the fastener from a threaded hole or socket parts is very thin, requires great accuracy. The reasons of breakages of fasteners can be several: excess torque; the use of low-grade threaded products; “welding” of the parts and threads of the fastener due to corrosion or high-temperature heating, and others.

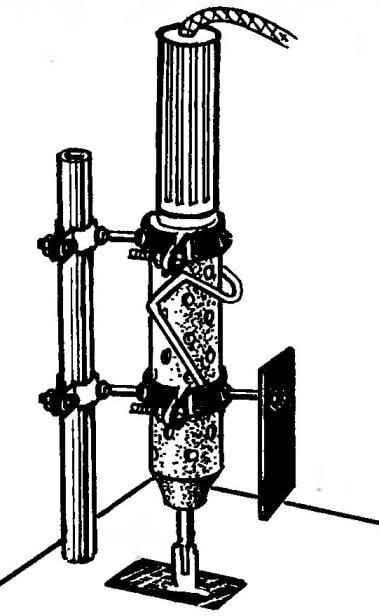

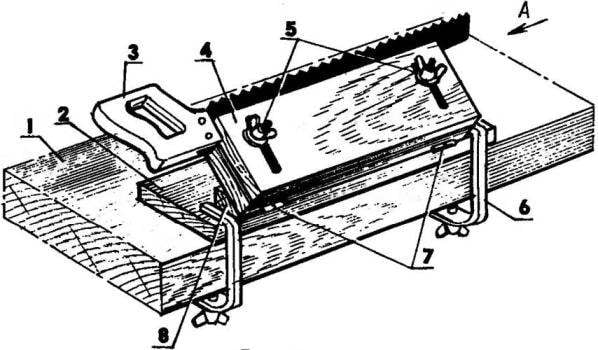

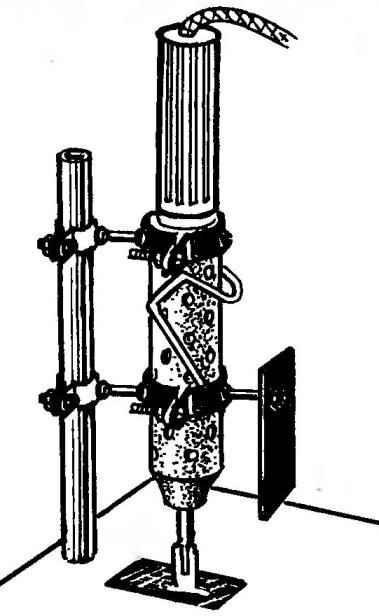

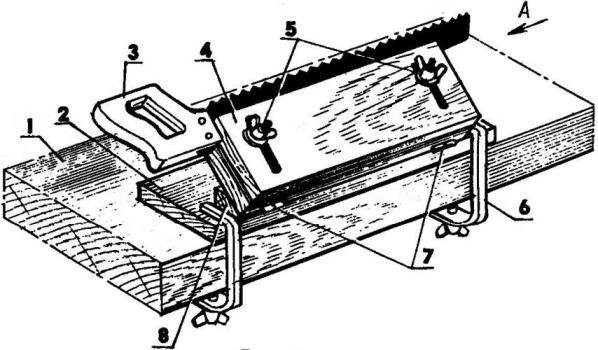

DRANK, SAW!

For the workman man a good tool — it is, as they say, is half the battle. For cutting tools (e.g., saws) it is important that it was sharp. With a significant amount of grinding you have to do periodically, and if the material is solid and hard, it is time for this, in General, support the operation, spent even more than the work itself. But, making edits “on the knee”, and get tired quickly and the quality suffers.

For the workman man a good tool — it is, as they say, is half the battle. For cutting tools (e.g., saws) it is important that it was sharp. With a significant amount of grinding you have to do periodically, and if the material is solid and hard, it is time for this, in General, support the operation, spent even more than the work itself. But, making edits “on the knee”, and get tired quickly and the quality suffers.