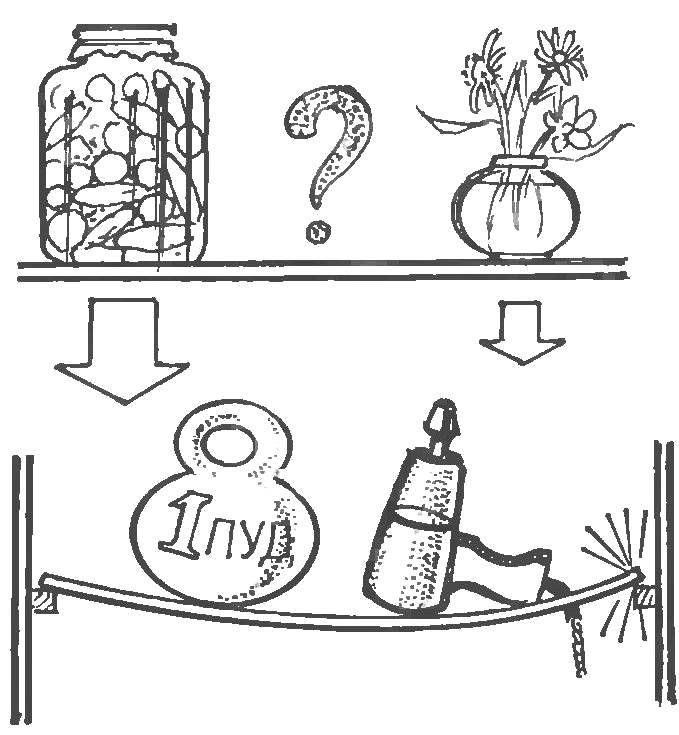

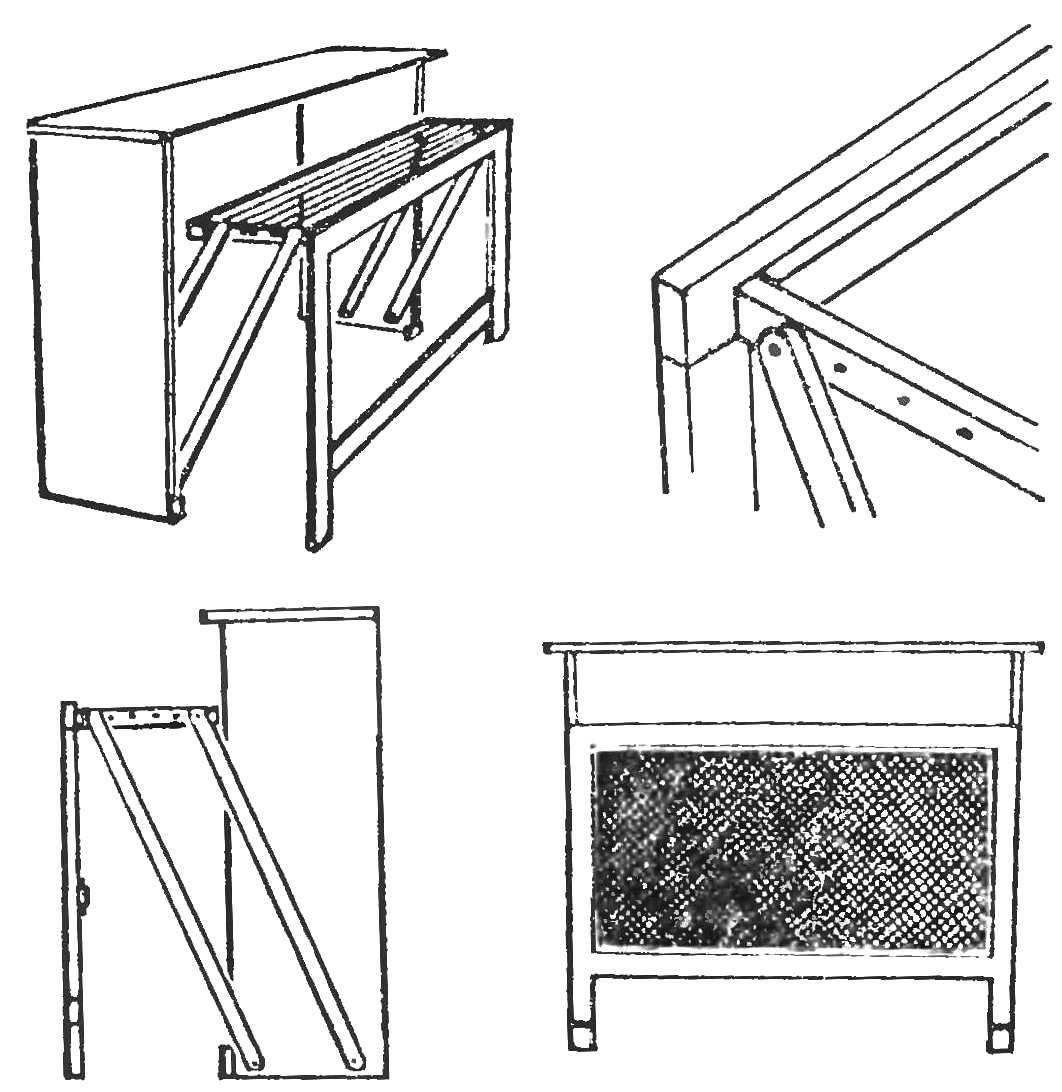

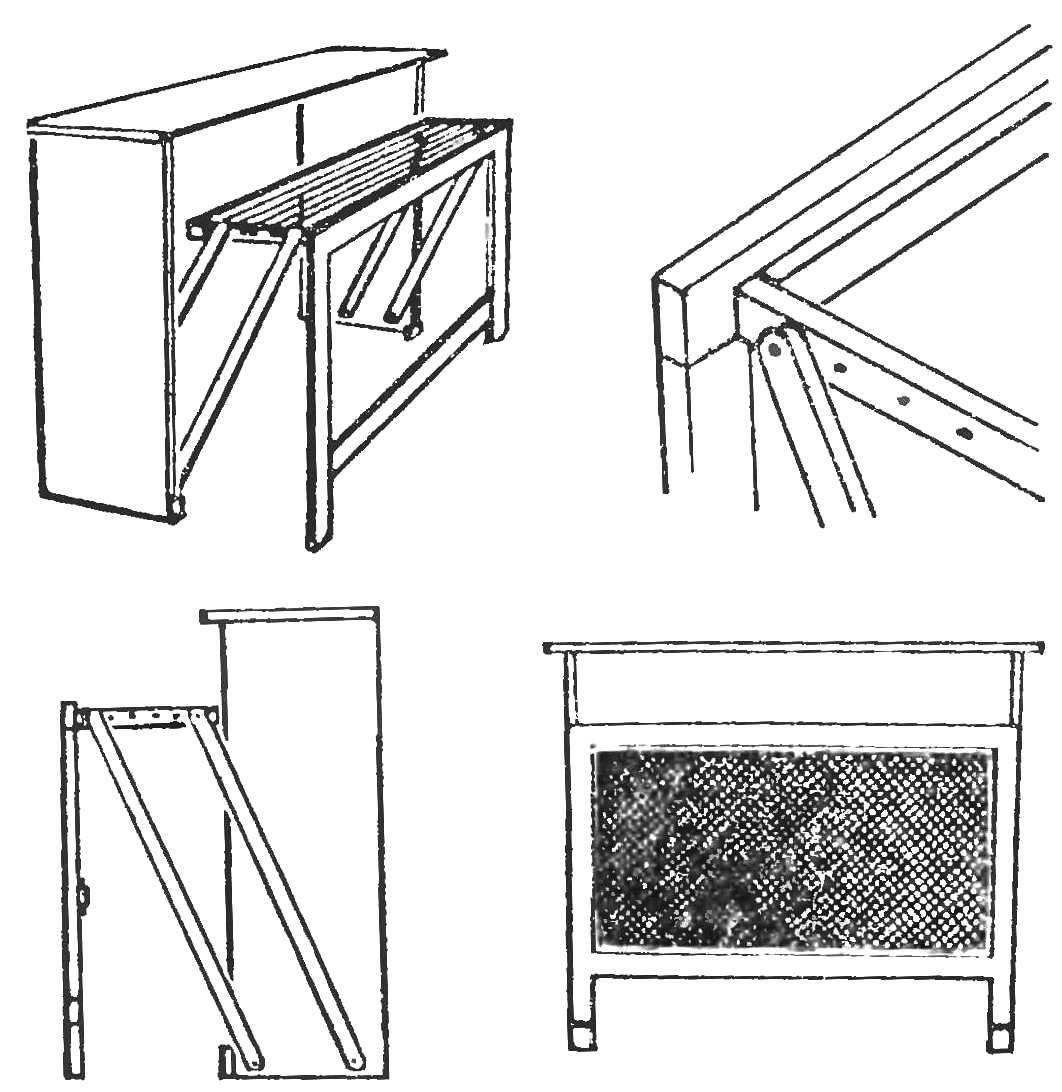

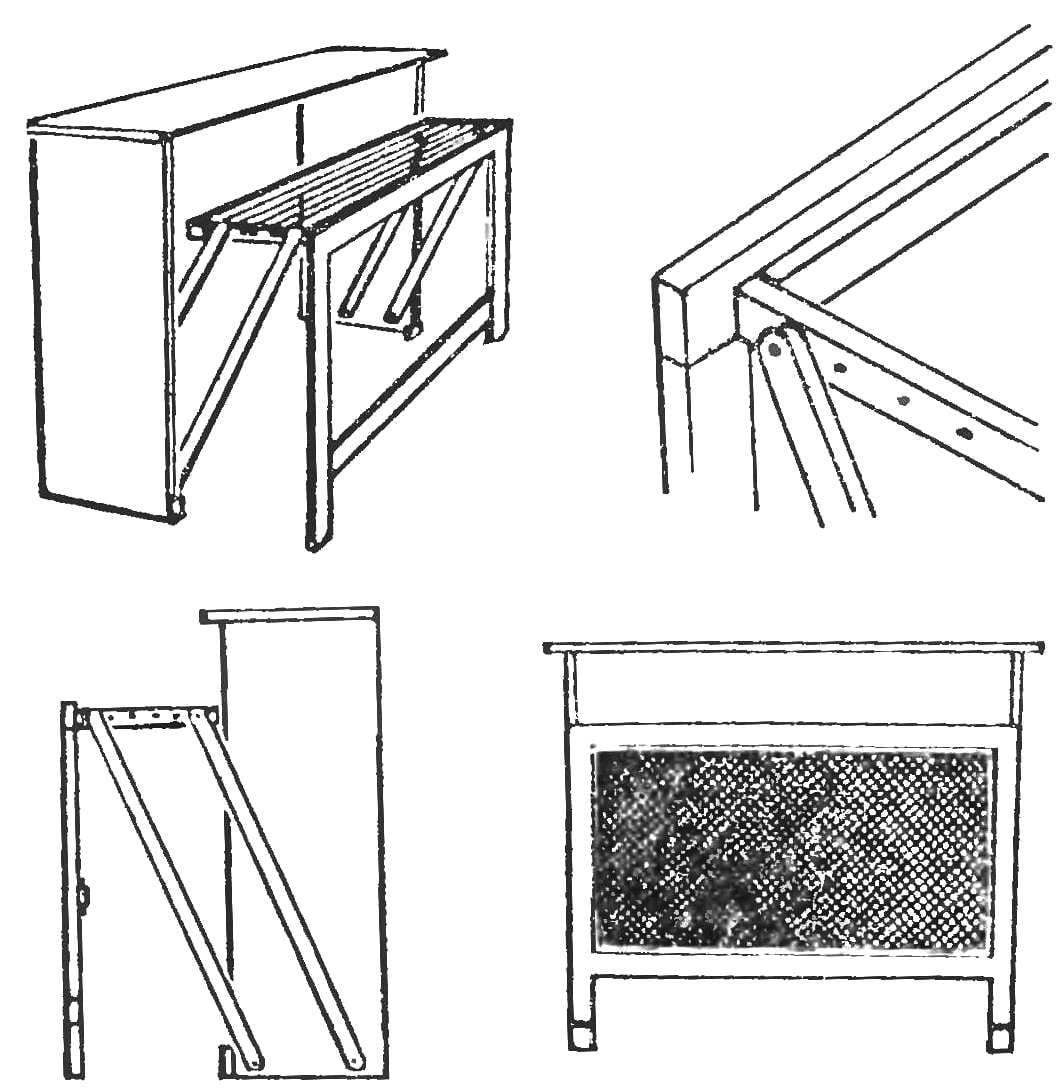

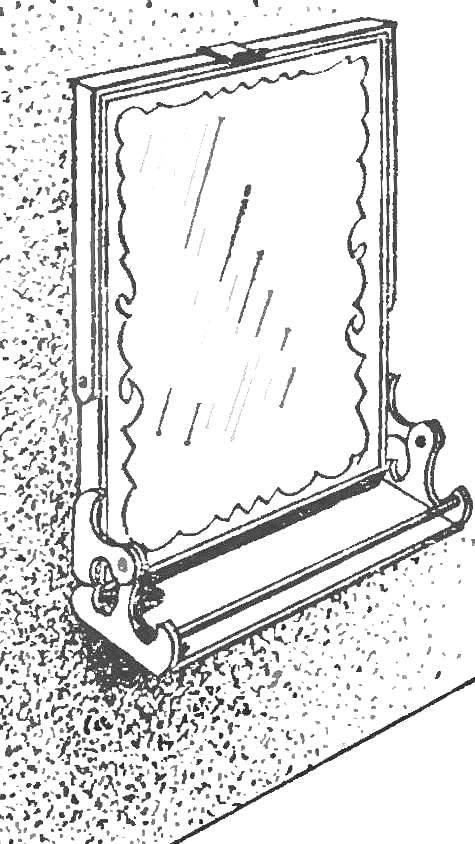

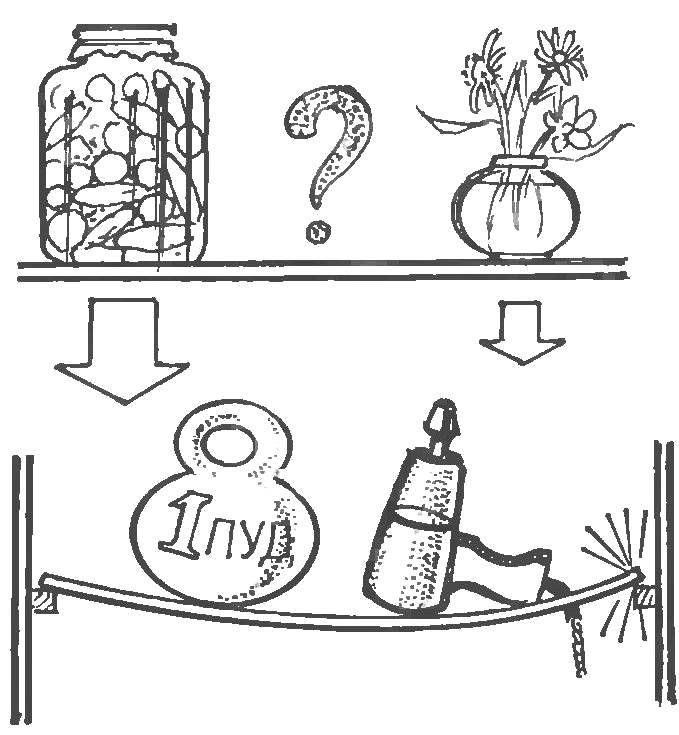

It would seem, from all furniture designs are the most simple — it’s a shelf. As a rule, it is a narrow bar of suitable material such as wood, metal or glass, based on any basis or appropriately fixed on the wall. However, the regiment executed without the required margin of safety and incorrectly mounted or suspended, face unpleasant surprises at the most unexpected point of operation: that somehow bent, then broke, all broke or fell. What is the secret of such a simple design? Consider some of them.

It would seem, from all furniture designs are the most simple — it’s a shelf. As a rule, it is a narrow bar of suitable material such as wood, metal or glass, based on any basis or appropriately fixed on the wall. However, the regiment executed without the required margin of safety and incorrectly mounted or suspended, face unpleasant surprises at the most unexpected point of operation: that somehow bent, then broke, all broke or fell. What is the secret of such a simple design? Consider some of them.

Read more

The sleigh is, of course, perfect! But what to do with baby clothes when the child returned from the street after riding on all these sleds? Dry, you say, and you’re right. But the question is, how?

The sleigh is, of course, perfect! But what to do with baby clothes when the child returned from the street after riding on all these sleds? Dry, you say, and you’re right. But the question is, how? The sleigh is, of course, perfect! But what to do with baby clothes when the child returned from the street after riding on all these sleds? Dry, you say, and you’re right. But the question is, how?

The sleigh is, of course, perfect! But what to do with baby clothes when the child returned from the street after riding on all these sleds? Dry, you say, and you’re right. But the question is, how?

Started summer vacations, exciting travel, tourist trips. Among a variety of troubles, not the least is care leave for home plants or inhabitants of the aquarium. Some need daily watering, others — feeding. And you never know happens in the house other animals that require daily care.

Started summer vacations, exciting travel, tourist trips. Among a variety of troubles, not the least is care leave for home plants or inhabitants of the aquarium. Some need daily watering, others — feeding. And you never know happens in the house other animals that require daily care.

The management of these sleds is somewhat reminiscent of airplane: it also consists of the pedals and handles. The direction of the descent is aged using the pedals, and the handle is used for braking.

The management of these sleds is somewhat reminiscent of airplane: it also consists of the pedals and handles. The direction of the descent is aged using the pedals, and the handle is used for braking.

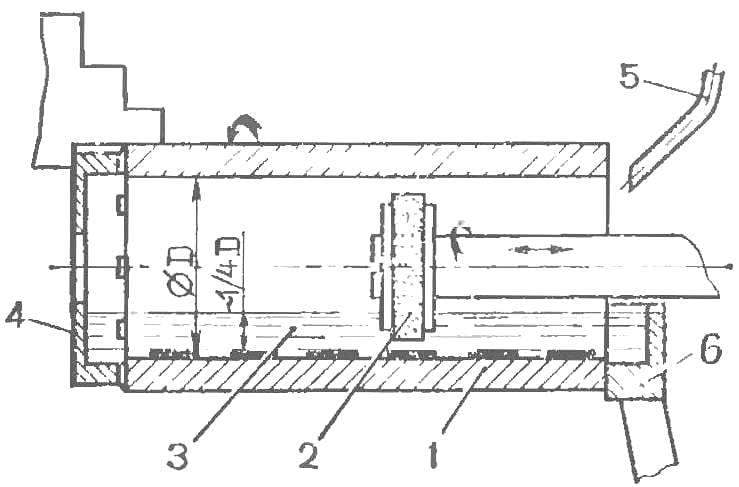

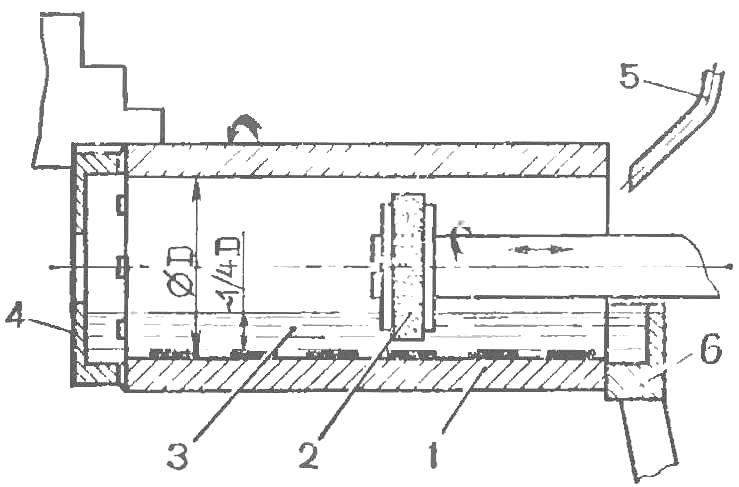

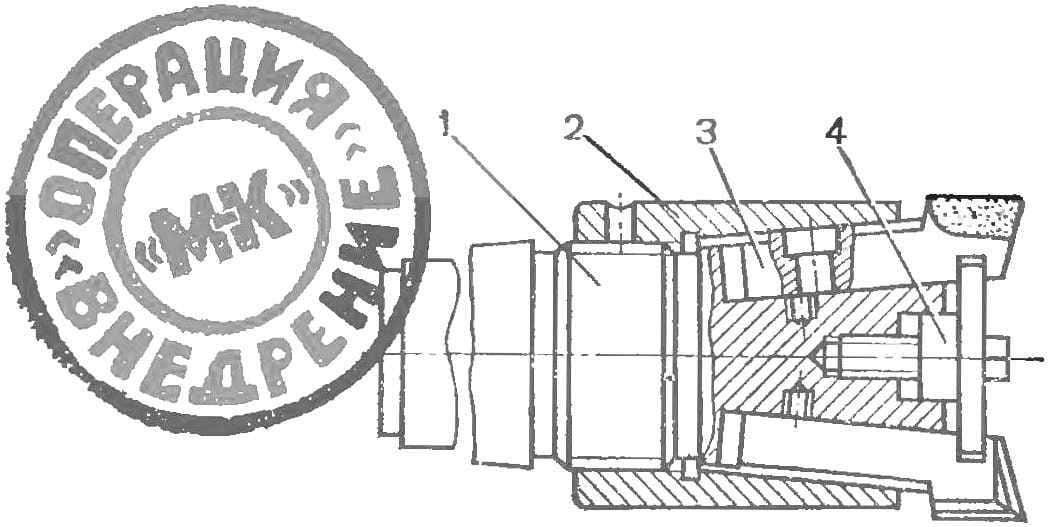

An ingenious solution processing grinding wheel internal surface of tubes or hollow parts offered innovators N. Epifanov, A. Chuprikov, Y. Shabalin.

An ingenious solution processing grinding wheel internal surface of tubes or hollow parts offered innovators N. Epifanov, A. Chuprikov, Y. Shabalin.

Yes, how would it work, no matter how perithecial — it does not decrease! To maintain a times a predetermined diameter with high accuracy allows her to design feature.

Yes, how would it work, no matter how perithecial — it does not decrease! To maintain a times a predetermined diameter with high accuracy allows her to design feature.

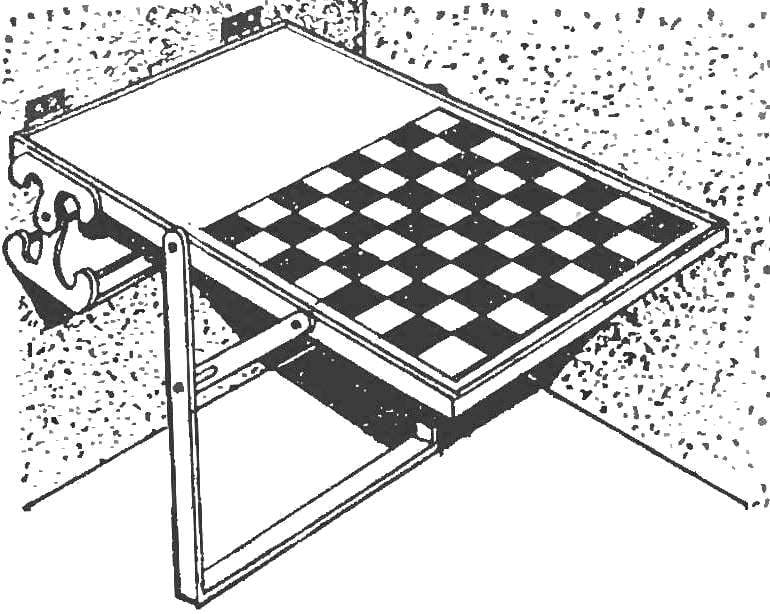

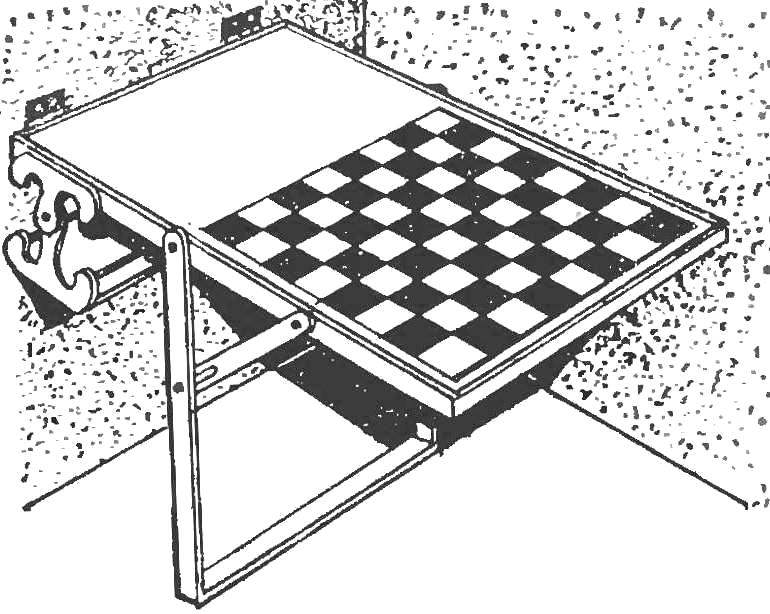

Modern small apartment is not always possible to place it with all the furniture that you feel necessary. Here, say, chess table — the place is quite a lot, is used relatively rarely. If you make it in our drawing, the “one shot kill two hares”: to create a “chess area” and a dressing table.

Modern small apartment is not always possible to place it with all the furniture that you feel necessary. Here, say, chess table — the place is quite a lot, is used relatively rarely. If you make it in our drawing, the “one shot kill two hares”: to create a “chess area” and a dressing table.

For those who have a family has small children, especially those under the age of fifteen years do not need to explain how they are curious in the knowledge of their surrounding environment. And this sometimes leads to their getting abrasions, cuts, which should impose povyazochki with medication or tampons with ointment. But the wound hurt, itch, bandage prevent — and the little man tries to tear them or remove. Well, how to explain to him that you cannot do it! So sometimes you have to take quite radical measures, up to the hospital, where the child’s hands tied to the bed.

For those who have a family has small children, especially those under the age of fifteen years do not need to explain how they are curious in the knowledge of their surrounding environment. And this sometimes leads to their getting abrasions, cuts, which should impose povyazochki with medication or tampons with ointment. But the wound hurt, itch, bandage prevent — and the little man tries to tear them or remove. Well, how to explain to him that you cannot do it! So sometimes you have to take quite radical measures, up to the hospital, where the child’s hands tied to the bed.

We usually dig? Pushing leg, bury the shovel, then bend down, take the lower part of the handle, raise the shovel from the ground and turned a seam, having unbent, then re-bury and bend the cycle of movements is repeated quickly start aching hands and back.

We usually dig? Pushing leg, bury the shovel, then bend down, take the lower part of the handle, raise the shovel from the ground and turned a seam, having unbent, then re-bury and bend the cycle of movements is repeated quickly start aching hands and back.

A good host never gave up his horse under the open sky: proskakal, carefully covered him, flushed, with a blanket, fed-fed and wound up in the stables to rest. The same respect is preserved to the car: as a rule, even at their summer cottage built for him “stable”. Only the bike remains without its premises — in the best case awarded film “blankets” for shelter from the weather.

A good host never gave up his horse under the open sky: proskakal, carefully covered him, flushed, with a blanket, fed-fed and wound up in the stables to rest. The same respect is preserved to the car: as a rule, even at their summer cottage built for him “stable”. Only the bike remains without its premises — in the best case awarded film “blankets” for shelter from the weather.

It would seem, from all furniture designs are the most simple — it’s a shelf. As a rule, it is a narrow bar of suitable material such as wood, metal or glass, based on any basis or appropriately fixed on the wall. However, the regiment executed without the required margin of safety and incorrectly mounted or suspended, face unpleasant surprises at the most unexpected point of operation: that somehow bent, then broke, all broke or fell. What is the secret of such a simple design? Consider some of them.

It would seem, from all furniture designs are the most simple — it’s a shelf. As a rule, it is a narrow bar of suitable material such as wood, metal or glass, based on any basis or appropriately fixed on the wall. However, the regiment executed without the required margin of safety and incorrectly mounted or suspended, face unpleasant surprises at the most unexpected point of operation: that somehow bent, then broke, all broke or fell. What is the secret of such a simple design? Consider some of them.