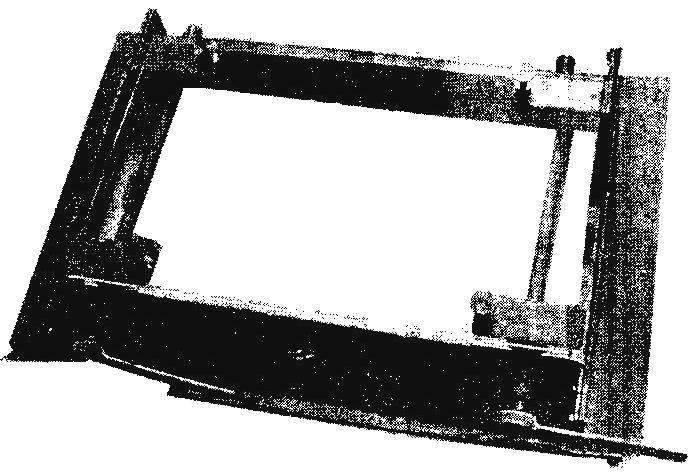

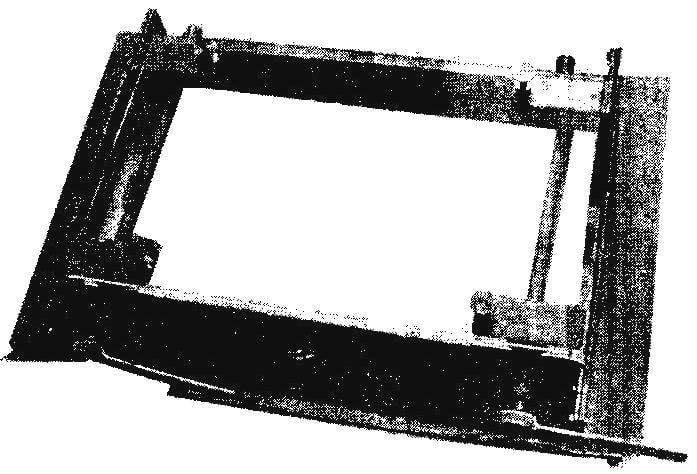

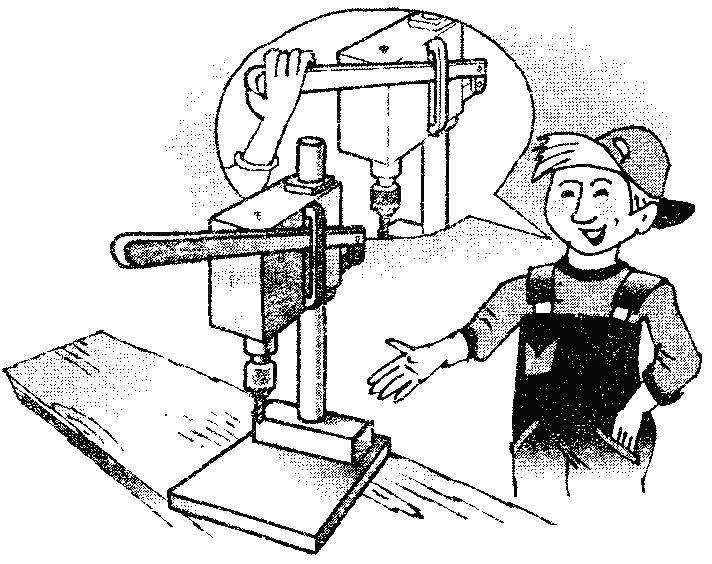

In the “Modeller-designer” has repeatedly published materials on woodworking machines-“circular saw” circular saw and planer, so necessary for the house masters. On this publication have done for a similar machine and I. But when I did, I realized that not everything in it is fine with me. In particular, the mechanism of lifting-lowering of the table. And the device is called the mechanism was only possible with the big stretch. The table was mounted on four studs-the uprights and vertical movement required to turn is to roll as many as eight nuts. And to set the plane of the table parallel to the axis of the plane (and saws) had “by eye”. In the end decided to make another table with more “advanced” mechanism (table) of lifting-lowering.

In the “Modeller-designer” has repeatedly published materials on woodworking machines-“circular saw” circular saw and planer, so necessary for the house masters. On this publication have done for a similar machine and I. But when I did, I realized that not everything in it is fine with me. In particular, the mechanism of lifting-lowering of the table. And the device is called the mechanism was only possible with the big stretch. The table was mounted on four studs-the uprights and vertical movement required to turn is to roll as many as eight nuts. And to set the plane of the table parallel to the axis of the plane (and saws) had “by eye”. In the end decided to make another table with more “advanced” mechanism (table) of lifting-lowering.EASY GOING

In the “Modeller-designer” has repeatedly published materials on woodworking machines-“circular saw” circular saw and planer, so necessary for the house masters. On this publication have done for a similar machine and I. But when I did, I realized that not everything in it is fine with me. In particular, the mechanism of lifting-lowering of the table. And the device is called the mechanism was only possible with the big stretch. The table was mounted on four studs-the uprights and vertical movement required to turn is to roll as many as eight nuts. And to set the plane of the table parallel to the axis of the plane (and saws) had “by eye”. In the end decided to make another table with more “advanced” mechanism (table) of lifting-lowering.

In the “Modeller-designer” has repeatedly published materials on woodworking machines-“circular saw” circular saw and planer, so necessary for the house masters. On this publication have done for a similar machine and I. But when I did, I realized that not everything in it is fine with me. In particular, the mechanism of lifting-lowering of the table. And the device is called the mechanism was only possible with the big stretch. The table was mounted on four studs-the uprights and vertical movement required to turn is to roll as many as eight nuts. And to set the plane of the table parallel to the axis of the plane (and saws) had “by eye”. In the end decided to make another table with more “advanced” mechanism (table) of lifting-lowering.

Improvised creativity are addicted to for a very long time. And in many respects it was promoted by my favorite magazine “modelist-Konstruktor”. Released since 1972. The recommendations and tips magazine has done a lot useful on the farm structures. The biggest of them —the tractor Arkhipova (“M-K” № 1, 1984), Gromov and all-terrain vehicle (“M-K” No. 1 for 1985).

Improvised creativity are addicted to for a very long time. And in many respects it was promoted by my favorite magazine “modelist-Konstruktor”. Released since 1972. The recommendations and tips magazine has done a lot useful on the farm structures. The biggest of them —the tractor Arkhipova (“M-K” № 1, 1984), Gromov and all-terrain vehicle (“M-K” No. 1 for 1985).

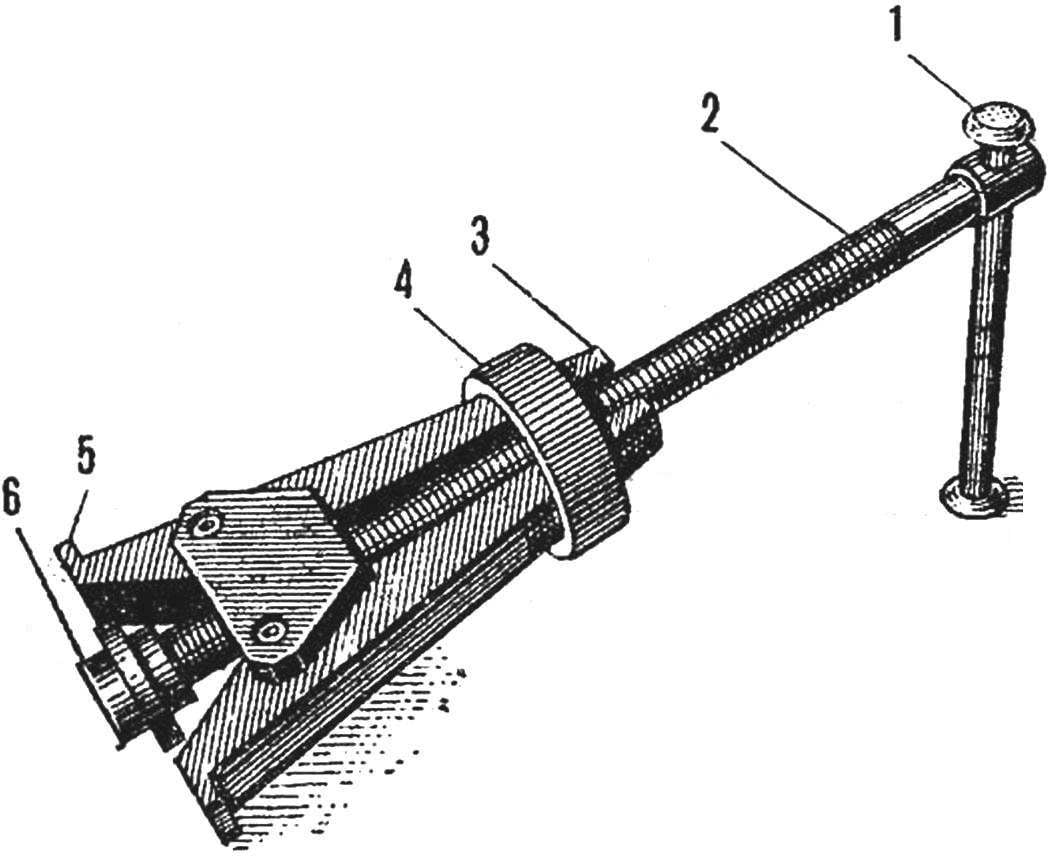

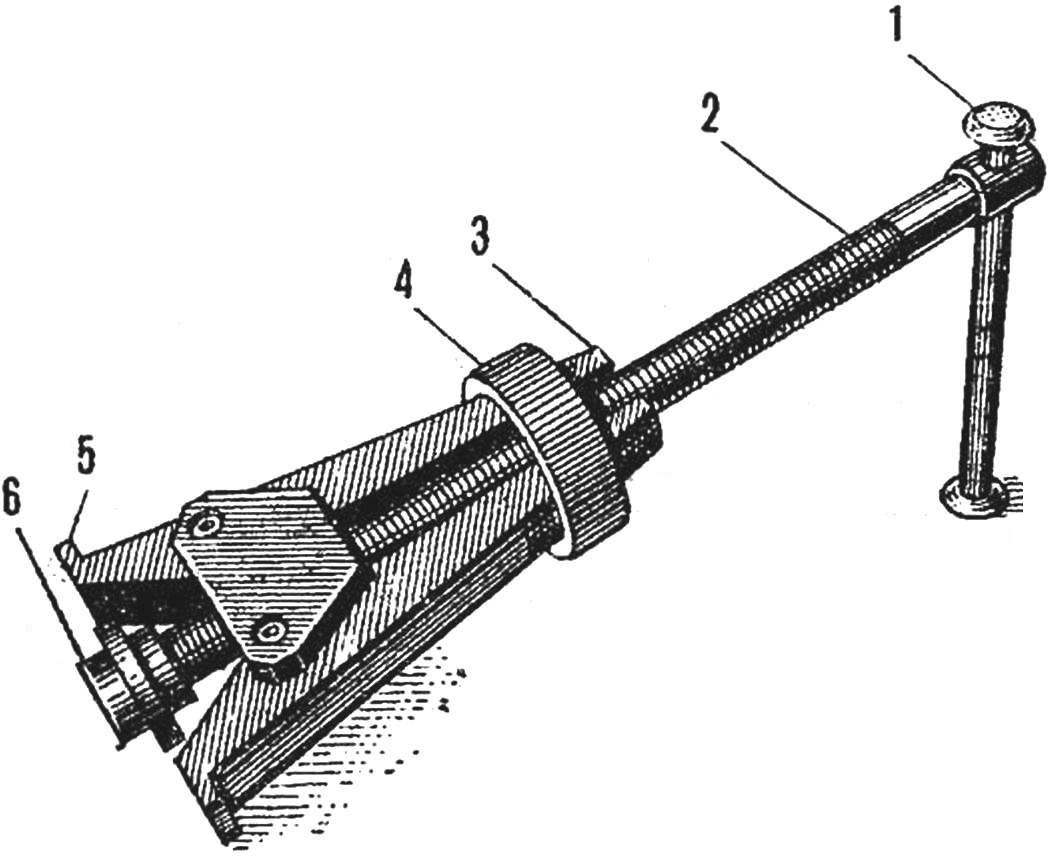

How diverse is pressed in units of parts so numerous and adaptations for wheel — pullers. However, the majority of them operates on the principle of ejection. Well, if the part is pressed into a blind hole? How to extract, for example, the sleeve or the bearing? The original puller for these cases, constructed by the innovator A.V. Yakimenko with the Odessa plant “Stroget-replica”. The principle of it is somewhat reminiscent of some designs of household tailspin.

How diverse is pressed in units of parts so numerous and adaptations for wheel — pullers. However, the majority of them operates on the principle of ejection. Well, if the part is pressed into a blind hole? How to extract, for example, the sleeve or the bearing? The original puller for these cases, constructed by the innovator A.V. Yakimenko with the Odessa plant “Stroget-replica”. The principle of it is somewhat reminiscent of some designs of household tailspin.

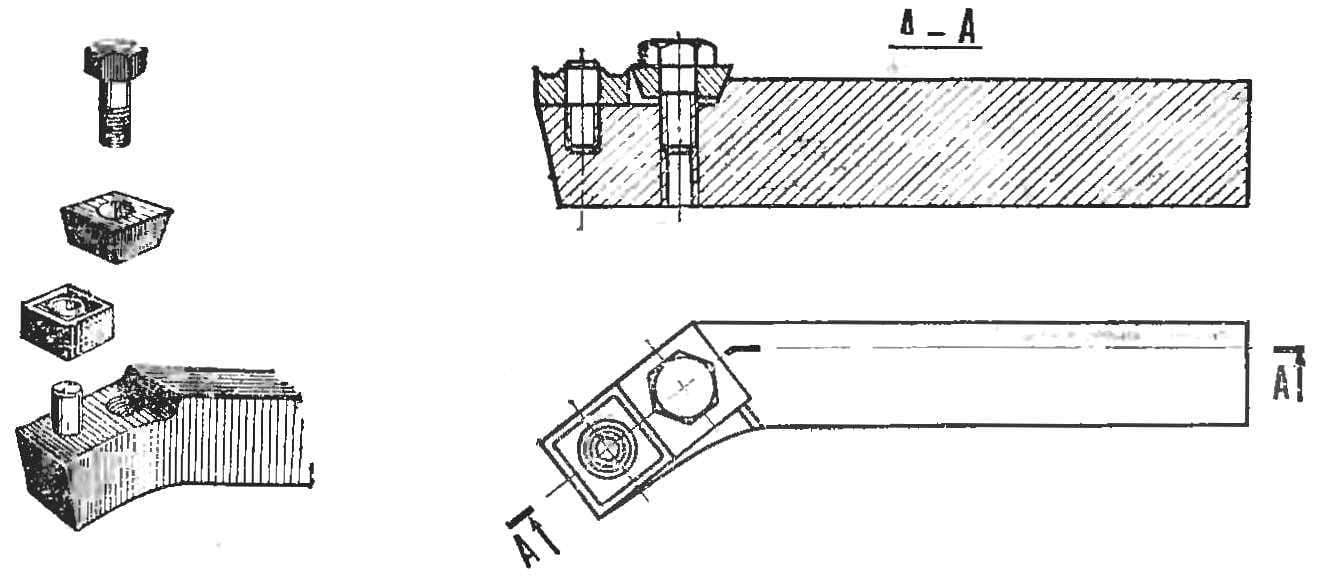

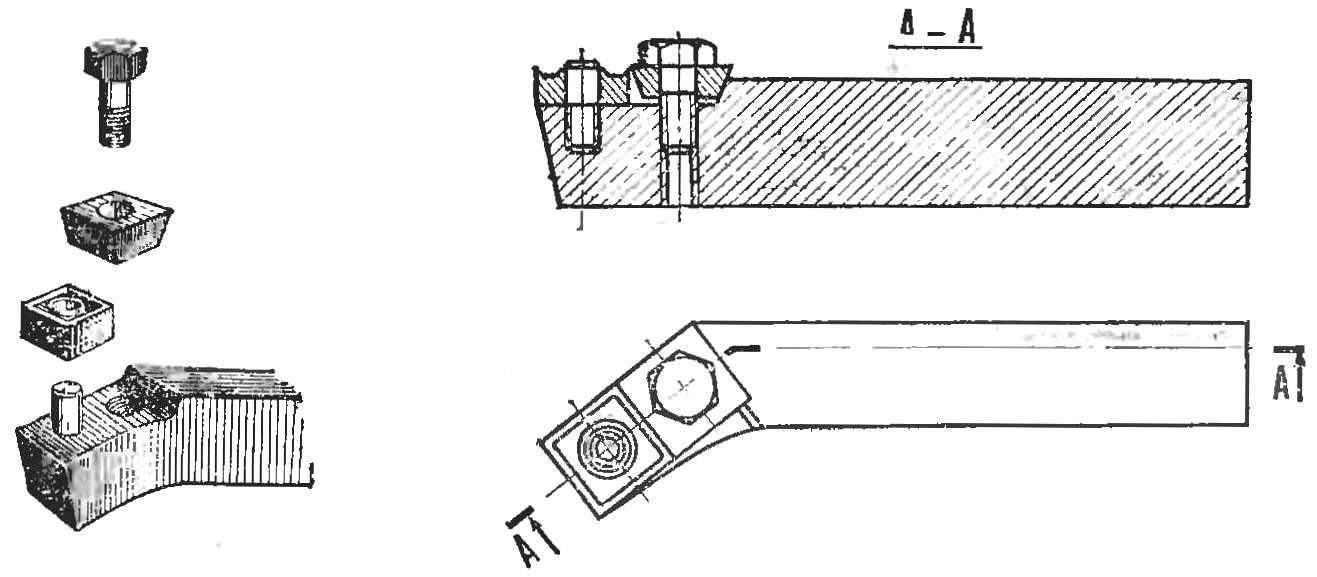

Rationalization proposal Lyubertsy student of secondary school № 42 of Yuri Furmanov. How to ensure all novice turners cutters? Almost every school workshop this problem exists. The HSS tools quickly become dull and break in inexperienced hands boys, standard tool holders with brazed them on the plates from hard alloys are not suitable for school machines high. The same applies to the most affordable cutters with exchangeable sintered plate (durable, able to withstand the most critical conditions).

Rationalization proposal Lyubertsy student of secondary school № 42 of Yuri Furmanov. How to ensure all novice turners cutters? Almost every school workshop this problem exists. The HSS tools quickly become dull and break in inexperienced hands boys, standard tool holders with brazed them on the plates from hard alloys are not suitable for school machines high. The same applies to the most affordable cutters with exchangeable sintered plate (durable, able to withstand the most critical conditions).

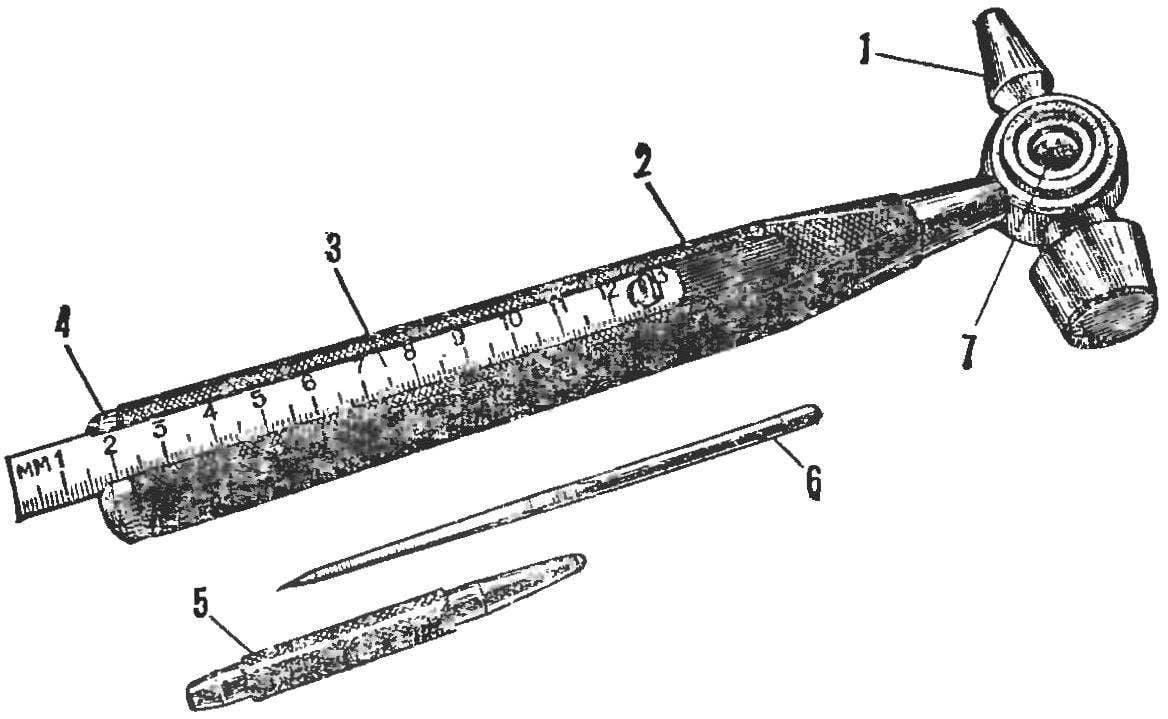

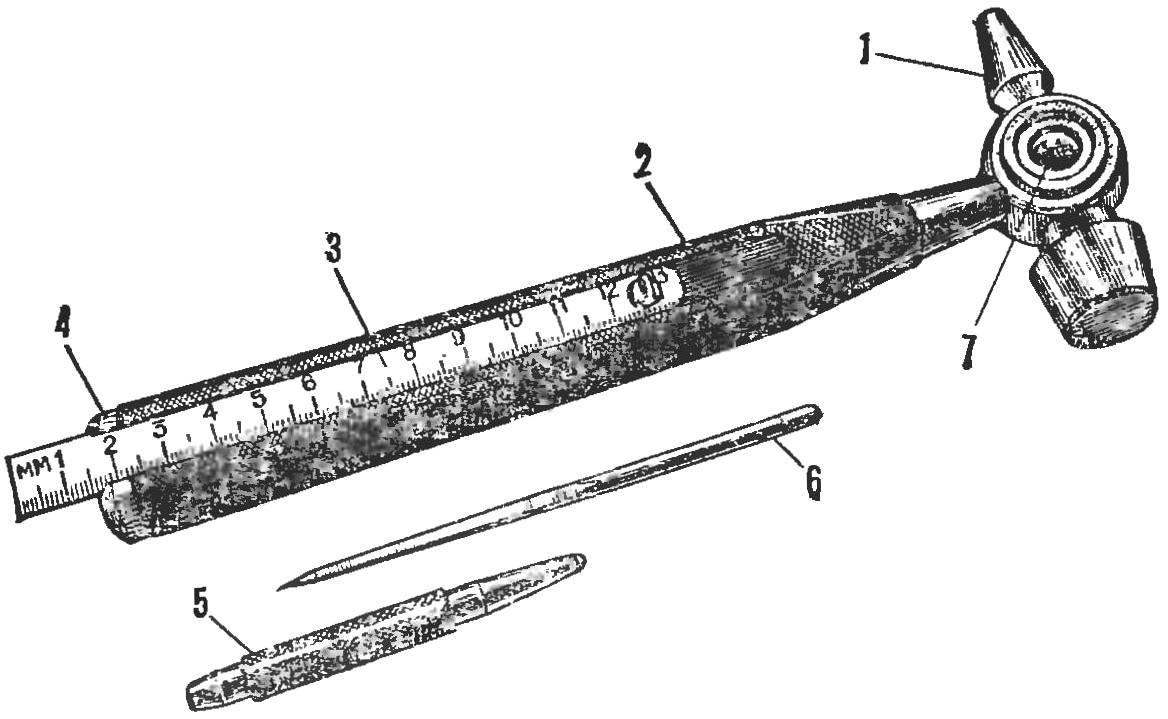

Of all the plumbing tools in the “conservative” design remained still, probably only a hammer. However, the innovators of the production Association Zhdanovtyazhmash found the opportunity to improve it. They created multi-purpose bench hammer. It can rightly be called a harvester — informed so many unusual functions, it can now make thanks to the extra built-in details.

Of all the plumbing tools in the “conservative” design remained still, probably only a hammer. However, the innovators of the production Association Zhdanovtyazhmash found the opportunity to improve it. They created multi-purpose bench hammer. It can rightly be called a harvester — informed so many unusual functions, it can now make thanks to the extra built-in details.

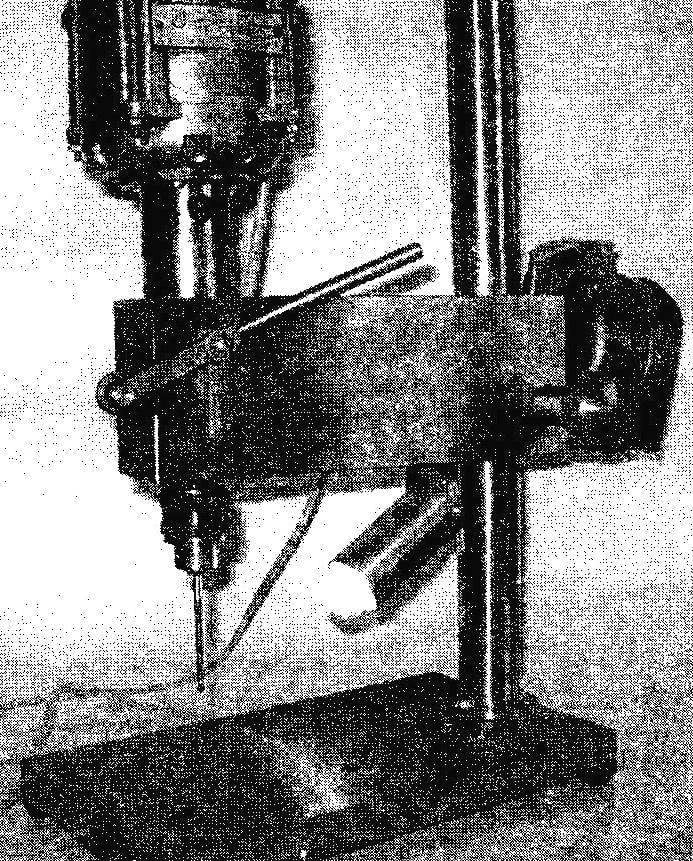

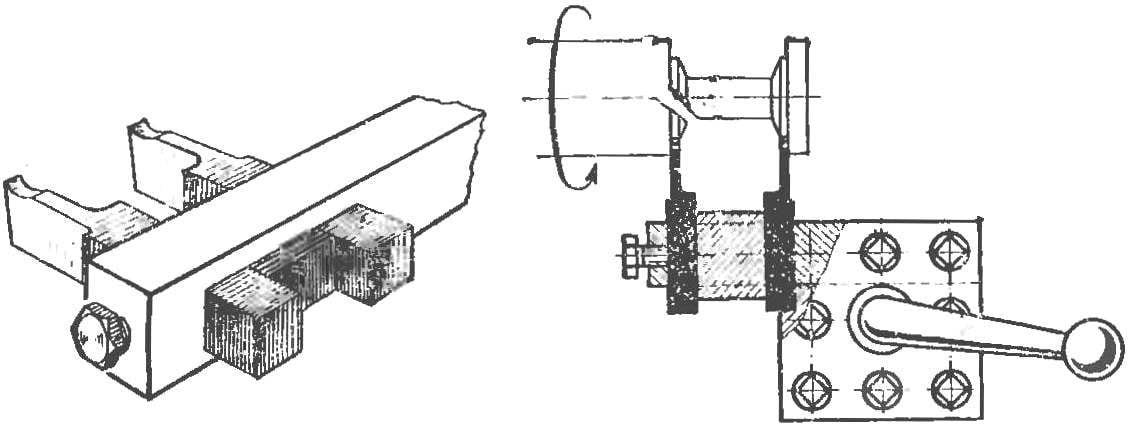

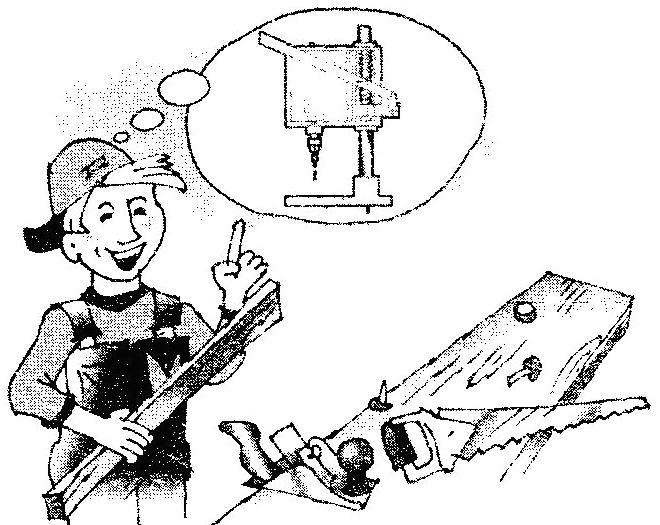

It is generally accepted that a drill is the main tool DIY, hobbyists tinkering something with their hands for home, for family, as well as the main means of mechanization of labor-intensive processes in the creation of makeshift equipment. It is not surprising, because thanks to various auxiliary or additional devices drill can replace even some machinery. For example, a drilling machine, which can produce very simple equipment, published in the Hungarian magazine “Earmaster”.

It is generally accepted that a drill is the main tool DIY, hobbyists tinkering something with their hands for home, for family, as well as the main means of mechanization of labor-intensive processes in the creation of makeshift equipment. It is not surprising, because thanks to various auxiliary or additional devices drill can replace even some machinery. For example, a drilling machine, which can produce very simple equipment, published in the Hungarian magazine “Earmaster”.

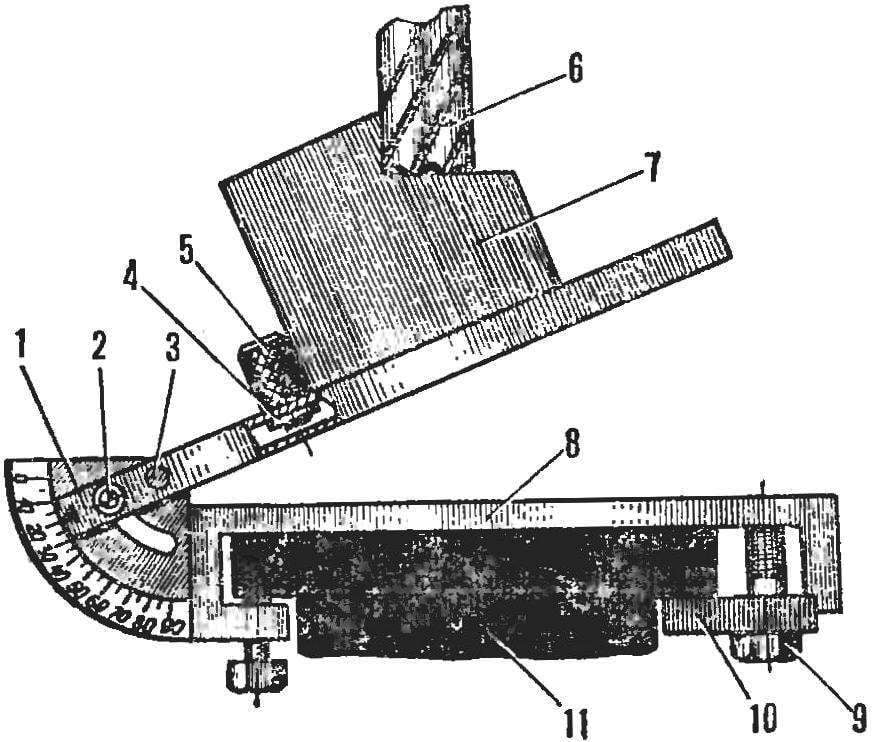

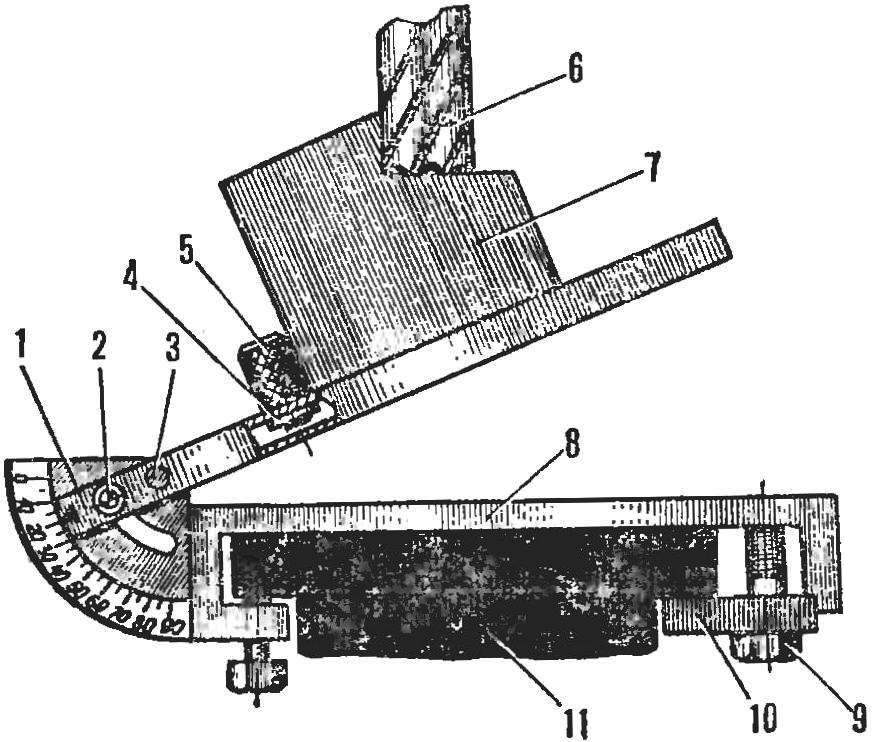

When machining on milling machines it is frequently necessary to install the item at a certain angle. An original device for this purpose was shown in NTTM-78 military innovators. This unique milling angle for the inclined fastening of machine parts. It consists of a base, a graduated sector and the movable hinge strap.

When machining on milling machines it is frequently necessary to install the item at a certain angle. An original device for this purpose was shown in NTTM-78 military innovators. This unique milling angle for the inclined fastening of machine parts. It consists of a base, a graduated sector and the movable hinge strap.

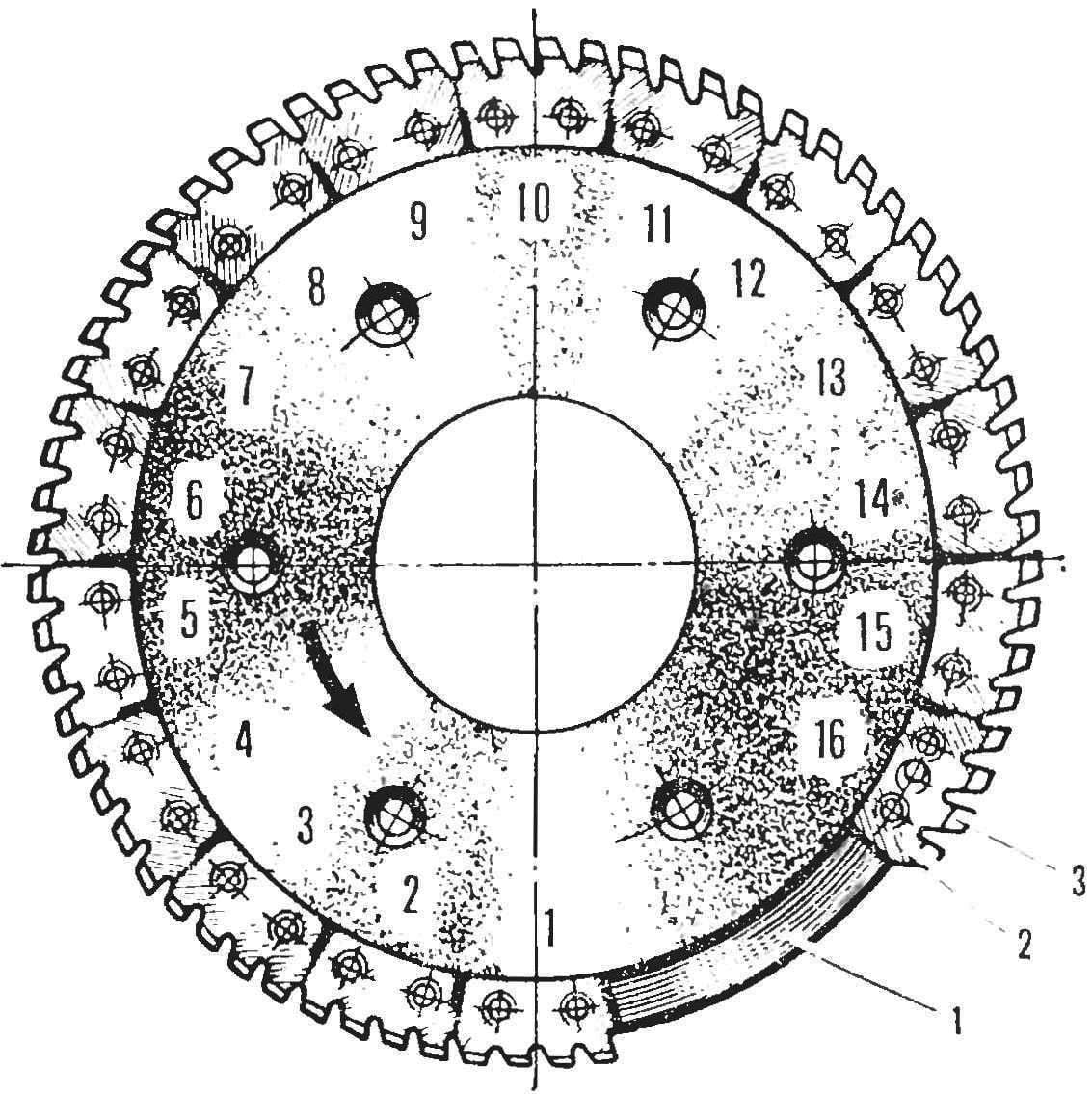

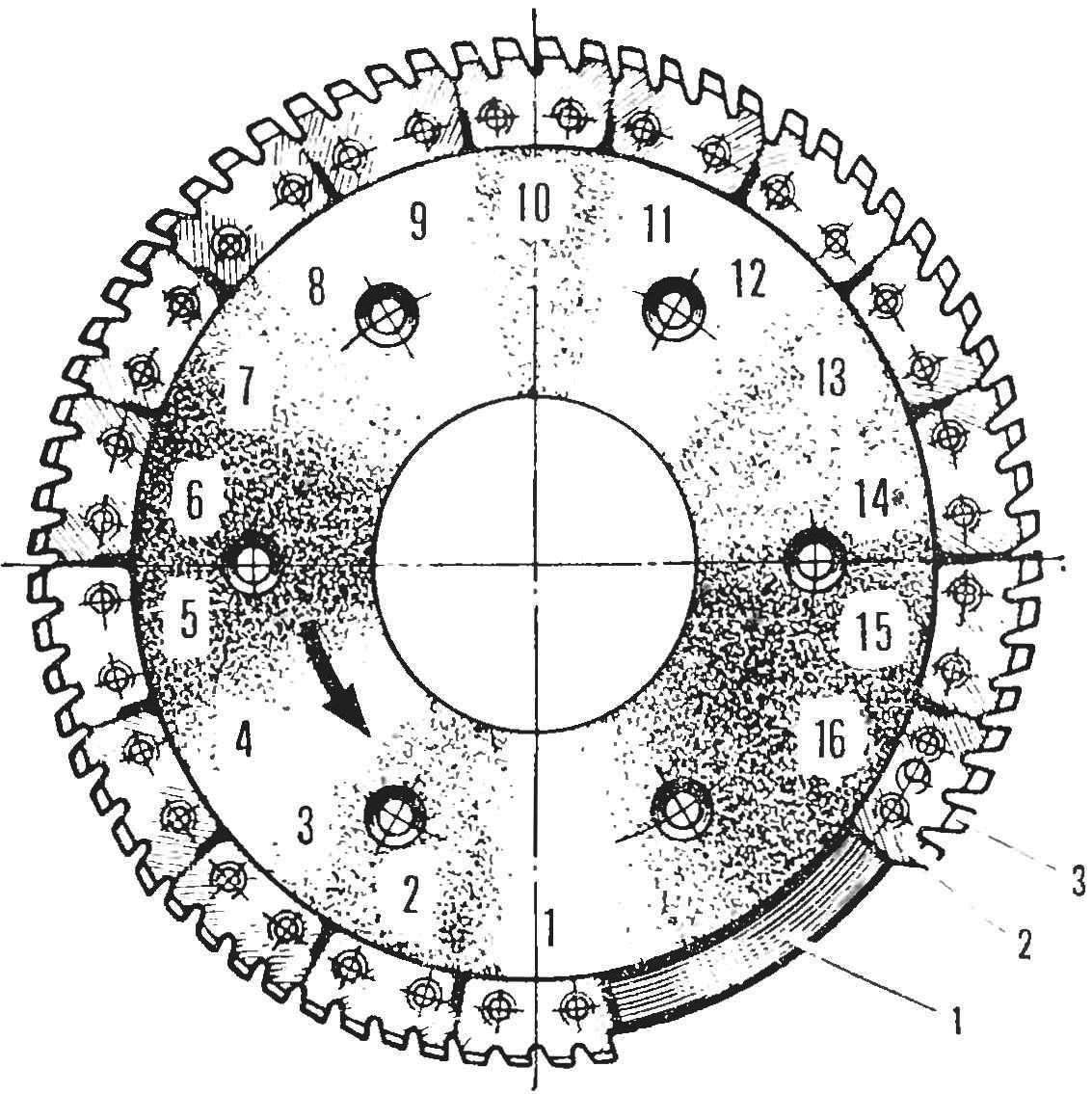

The method of circular broaching increasingly used for cutting the teeth of bevel gears, such as differential drive axle of the vehicle. The essence of the method of machining the workpiece cutting tool of a large diameter with radially arranged cutters. This technology is one of the most productive methods of manufacturing straight bevel.

The method of circular broaching increasingly used for cutting the teeth of bevel gears, such as differential drive axle of the vehicle. The essence of the method of machining the workpiece cutting tool of a large diameter with radially arranged cutters. This technology is one of the most productive methods of manufacturing straight bevel.