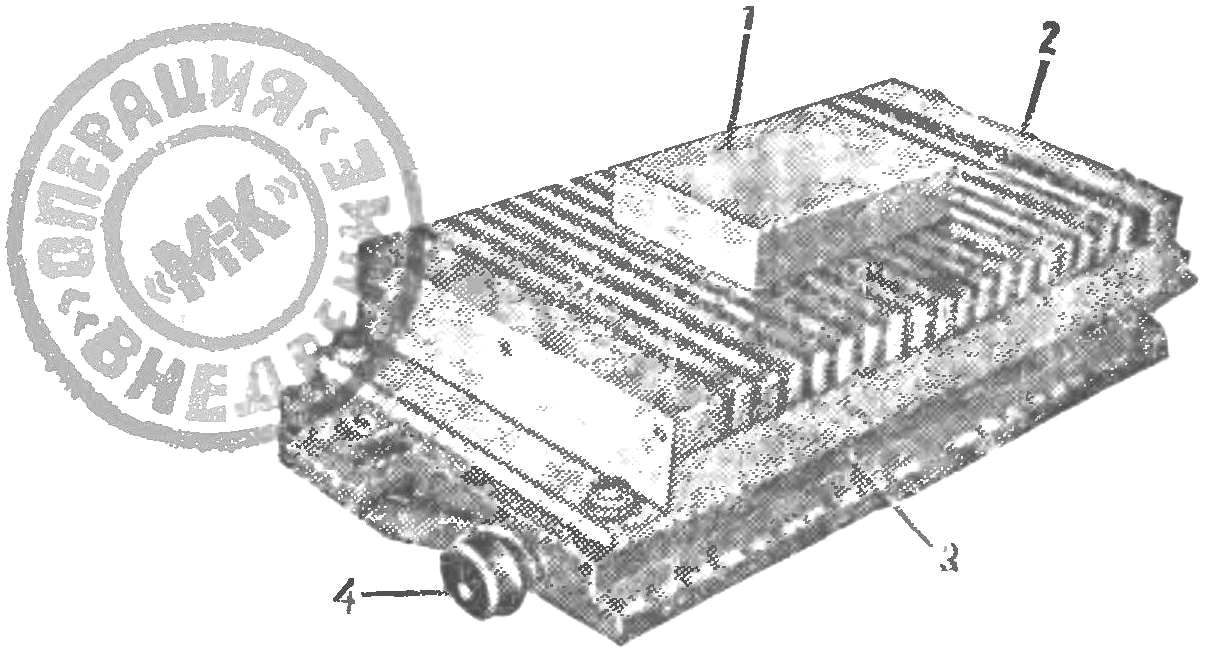

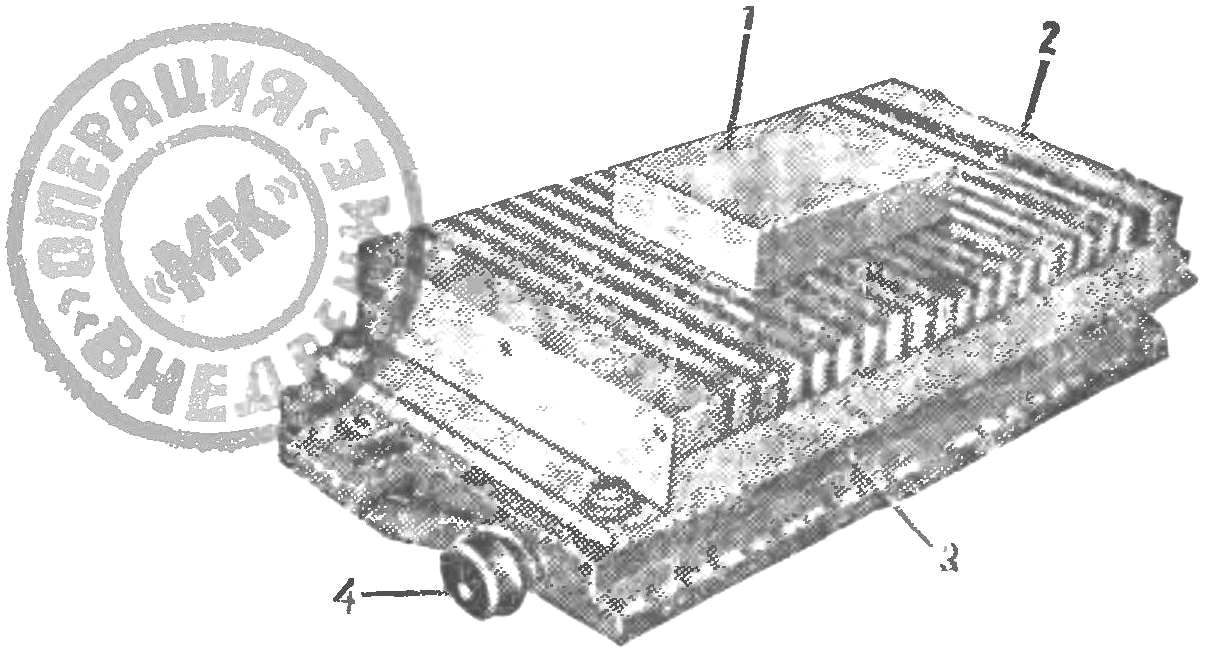

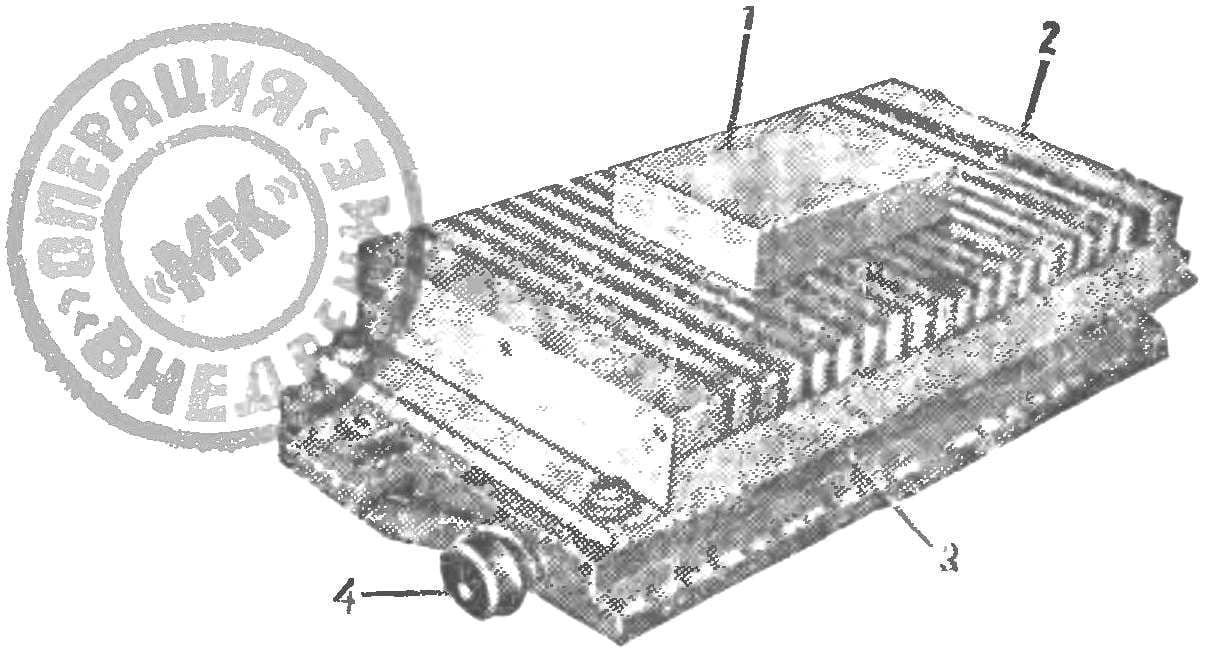

It’s like a magic trick: the metal part is placed on small size book, like a table and instantly welded to it — has no force can not budge it. How it works magnetic plate is designed for reliable and quick fastening of the workpiece during grinding, milling, and in conducting measuring and marking operations. Unlike other existing methods part clamping in a Vice or by using universal prefabricated devices — this device allows mounting auxiliary tool holders parts of even complex configurations.

It’s like a magic trick: the metal part is placed on small size book, like a table and instantly welded to it — has no force can not budge it. How it works magnetic plate is designed for reliable and quick fastening of the workpiece during grinding, milling, and in conducting measuring and marking operations. Unlike other existing methods part clamping in a Vice or by using universal prefabricated devices — this device allows mounting auxiliary tool holders parts of even complex configurations.THE GRIP OF DARKNESS

It’s like a magic trick: the metal part is placed on small size book, like a table and instantly welded to it — has no force can not budge it. How it works magnetic plate is designed for reliable and quick fastening of the workpiece during grinding, milling, and in conducting measuring and marking operations. Unlike other existing methods part clamping in a Vice or by using universal prefabricated devices — this device allows mounting auxiliary tool holders parts of even complex configurations.

It’s like a magic trick: the metal part is placed on small size book, like a table and instantly welded to it — has no force can not budge it. How it works magnetic plate is designed for reliable and quick fastening of the workpiece during grinding, milling, and in conducting measuring and marking operations. Unlike other existing methods part clamping in a Vice or by using universal prefabricated devices — this device allows mounting auxiliary tool holders parts of even complex configurations.

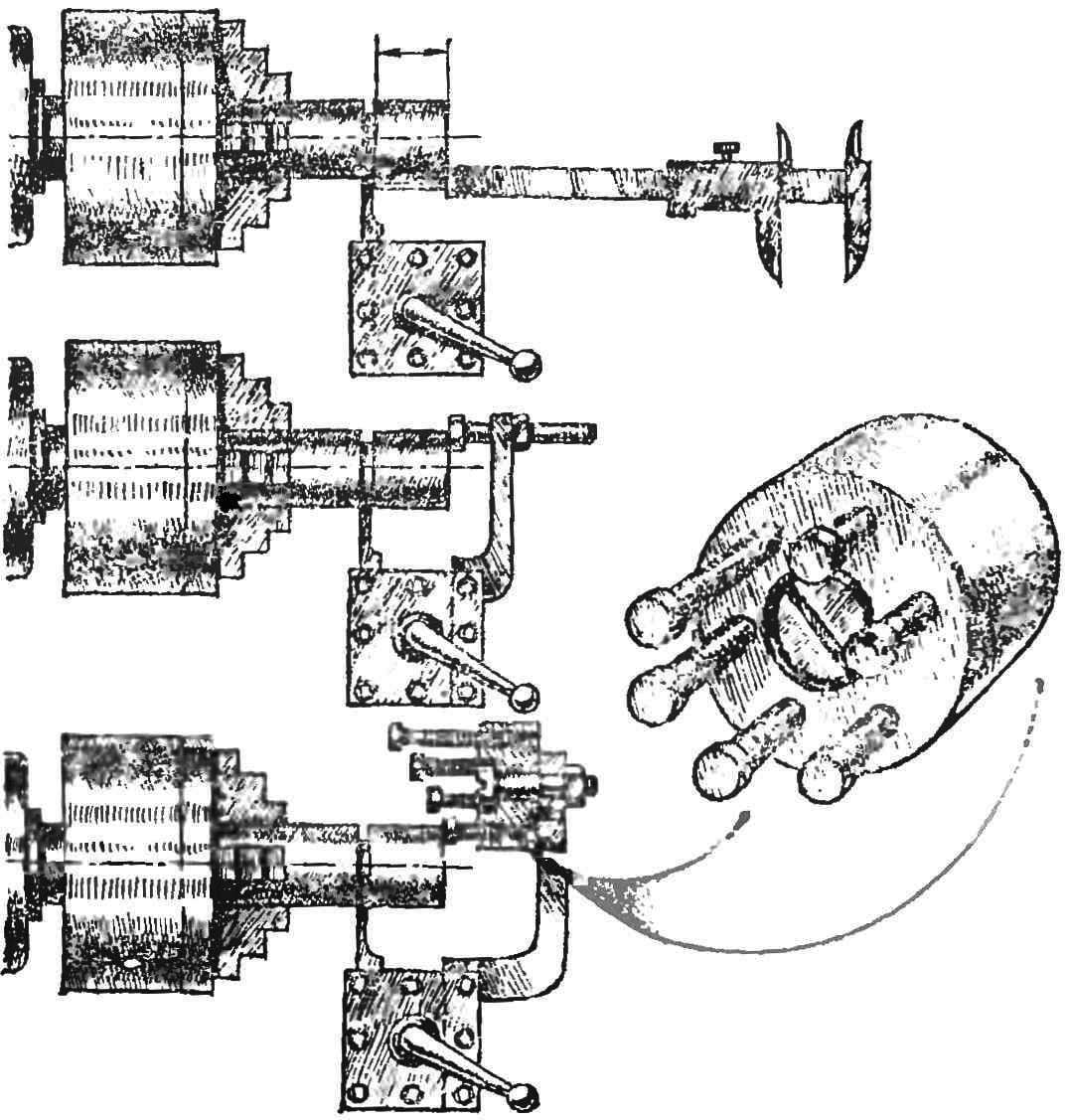

Small lathe for wood can actually be very simple. The overall layout and main components are known is a base with rails, front and rear headstock; the first is integral with the frame, the second movable in the guide; on the front of the headstock spindle is mounted with the actuator on the rear — support center. In fact, the feature of the machine, its simplicity and the possibility of manufacturing craftsman are determined by the design of main components.

Small lathe for wood can actually be very simple. The overall layout and main components are known is a base with rails, front and rear headstock; the first is integral with the frame, the second movable in the guide; on the front of the headstock spindle is mounted with the actuator on the rear — support center. In fact, the feature of the machine, its simplicity and the possibility of manufacturing craftsman are determined by the design of main components.

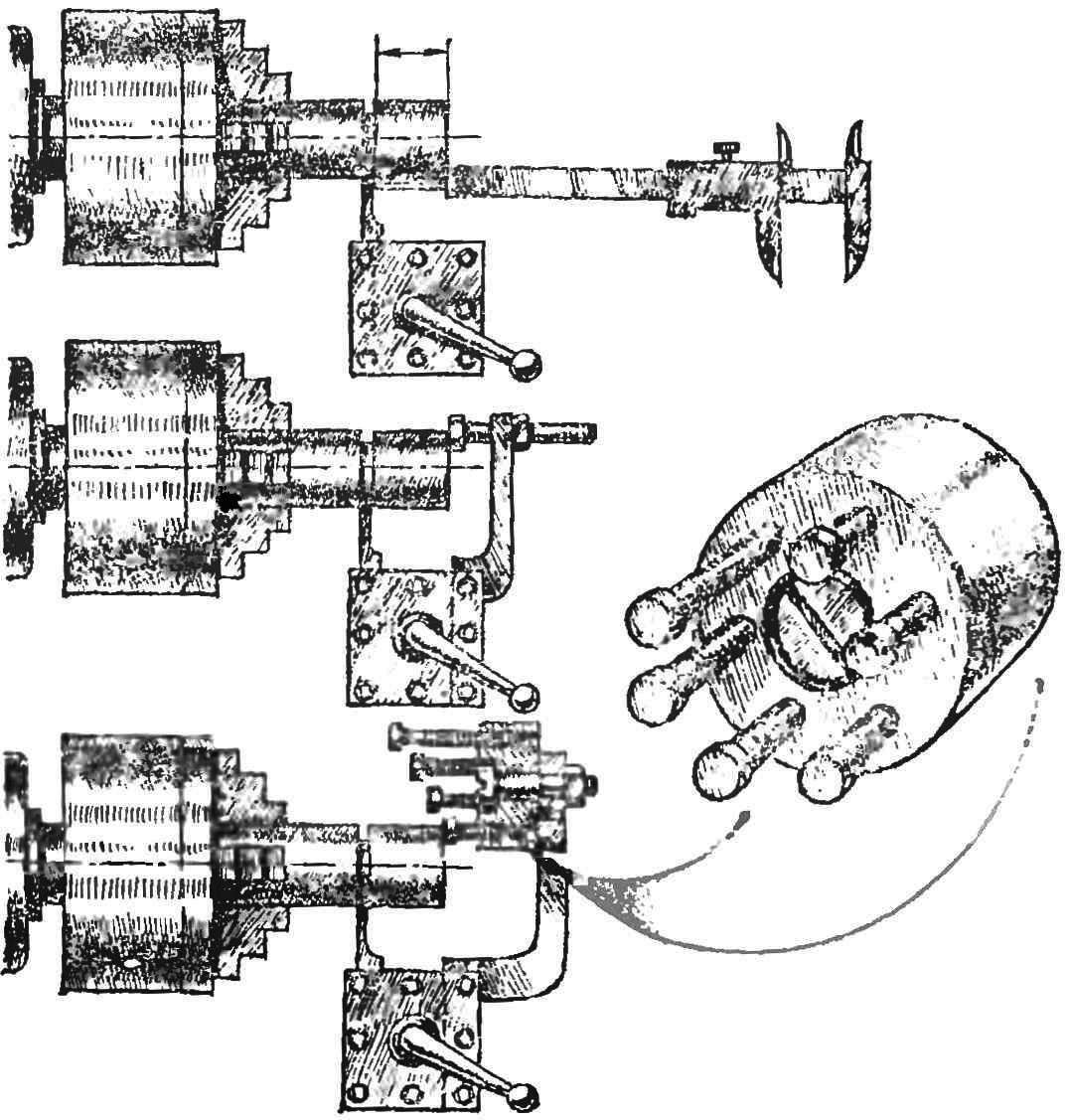

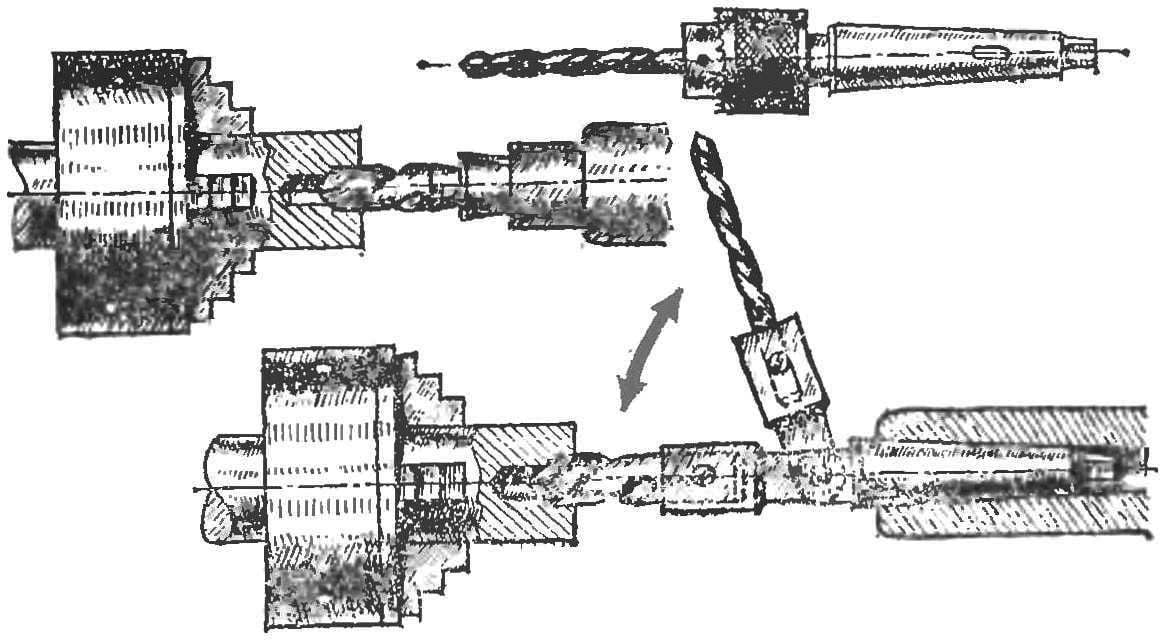

Try to cut multiple identical workpieces on a lathe. How many times have to use a caliper! But if you make for his Studio, universal focus, the workpiece will turn out one in one — and without the frequent use of any measuring tool. Arranged focus just. In the tool post of the lathe near the cutter secured using a steel strap with a screw hole, in which is wrapped a screw. He will serve as a measuring stop is enough to set it to the desired size and fix it with the locknut. Now, to cut the workpiece of a given size, the rod from the holder just forward of the machine until it stops at the bolt head.

Try to cut multiple identical workpieces on a lathe. How many times have to use a caliper! But if you make for his Studio, universal focus, the workpiece will turn out one in one — and without the frequent use of any measuring tool. Arranged focus just. In the tool post of the lathe near the cutter secured using a steel strap with a screw hole, in which is wrapped a screw. He will serve as a measuring stop is enough to set it to the desired size and fix it with the locknut. Now, to cut the workpiece of a given size, the rod from the holder just forward of the machine until it stops at the bolt head.

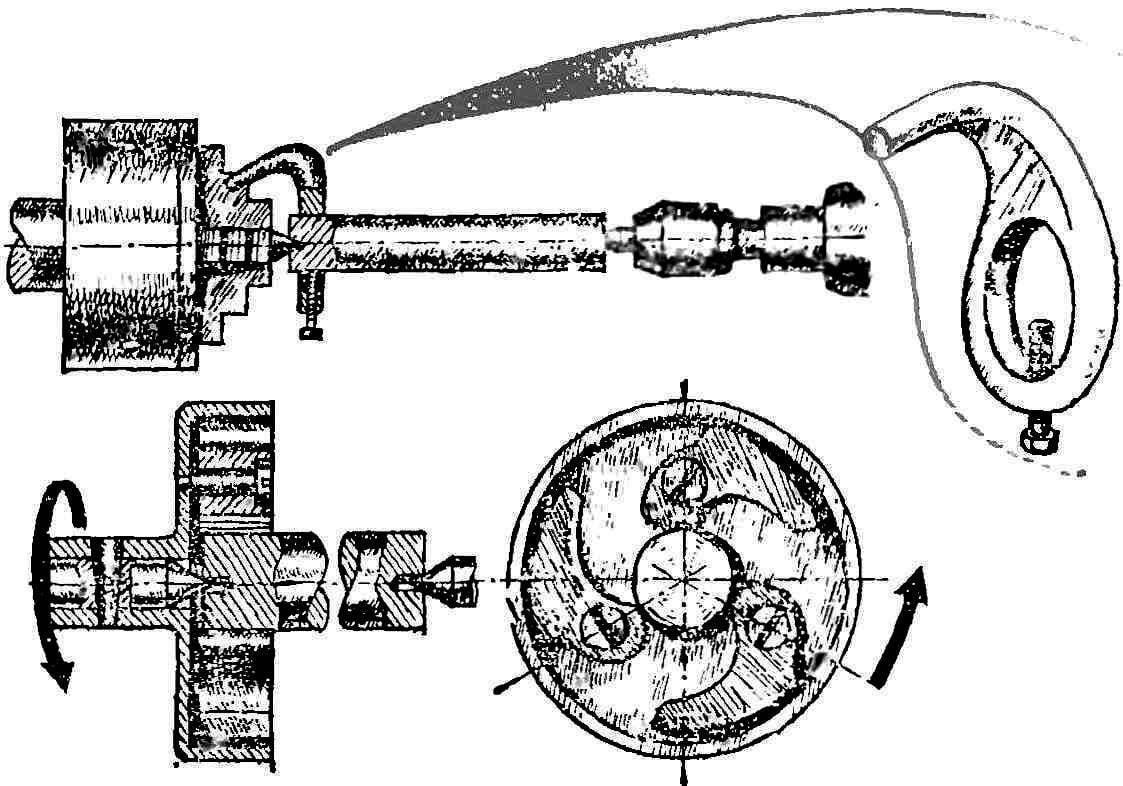

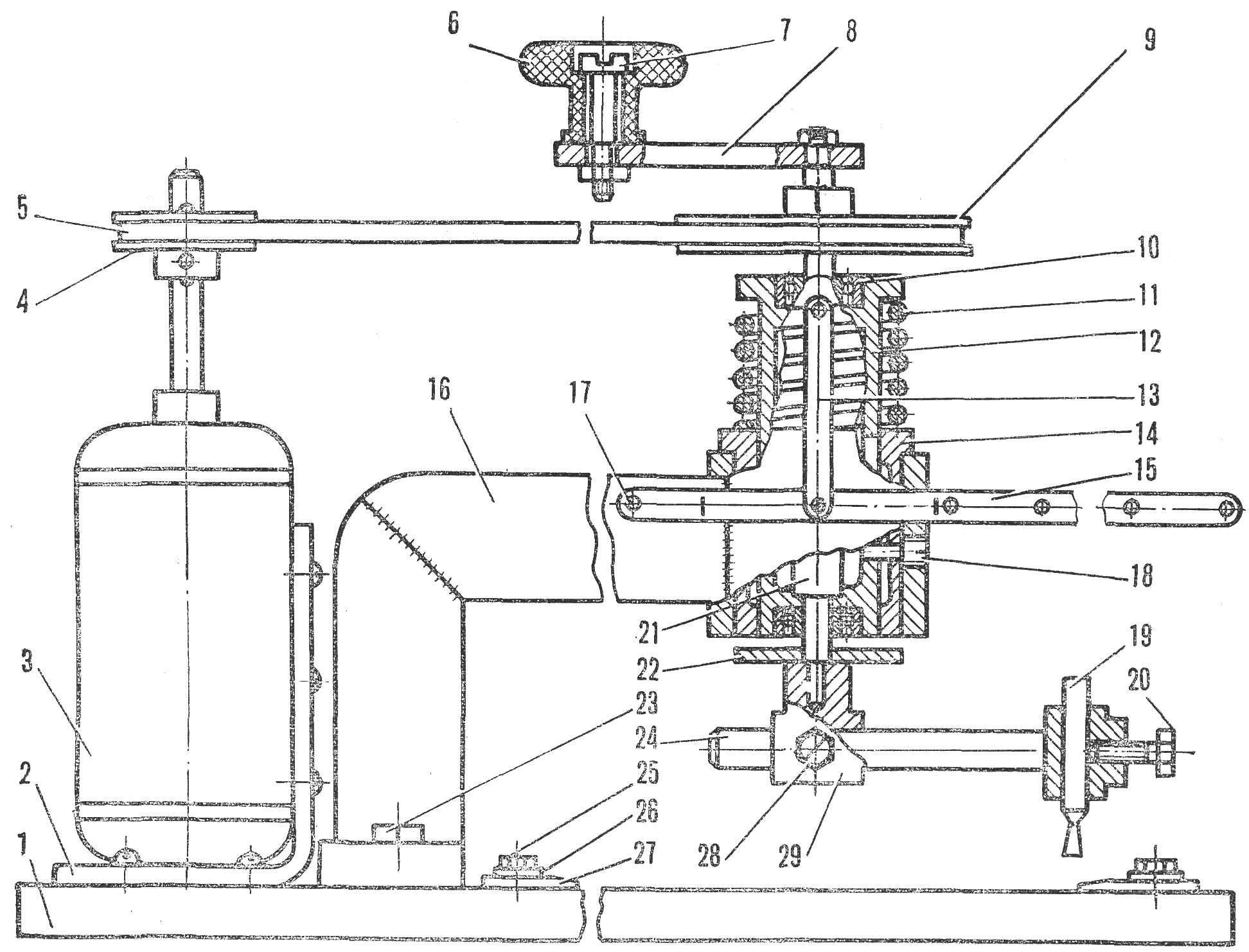

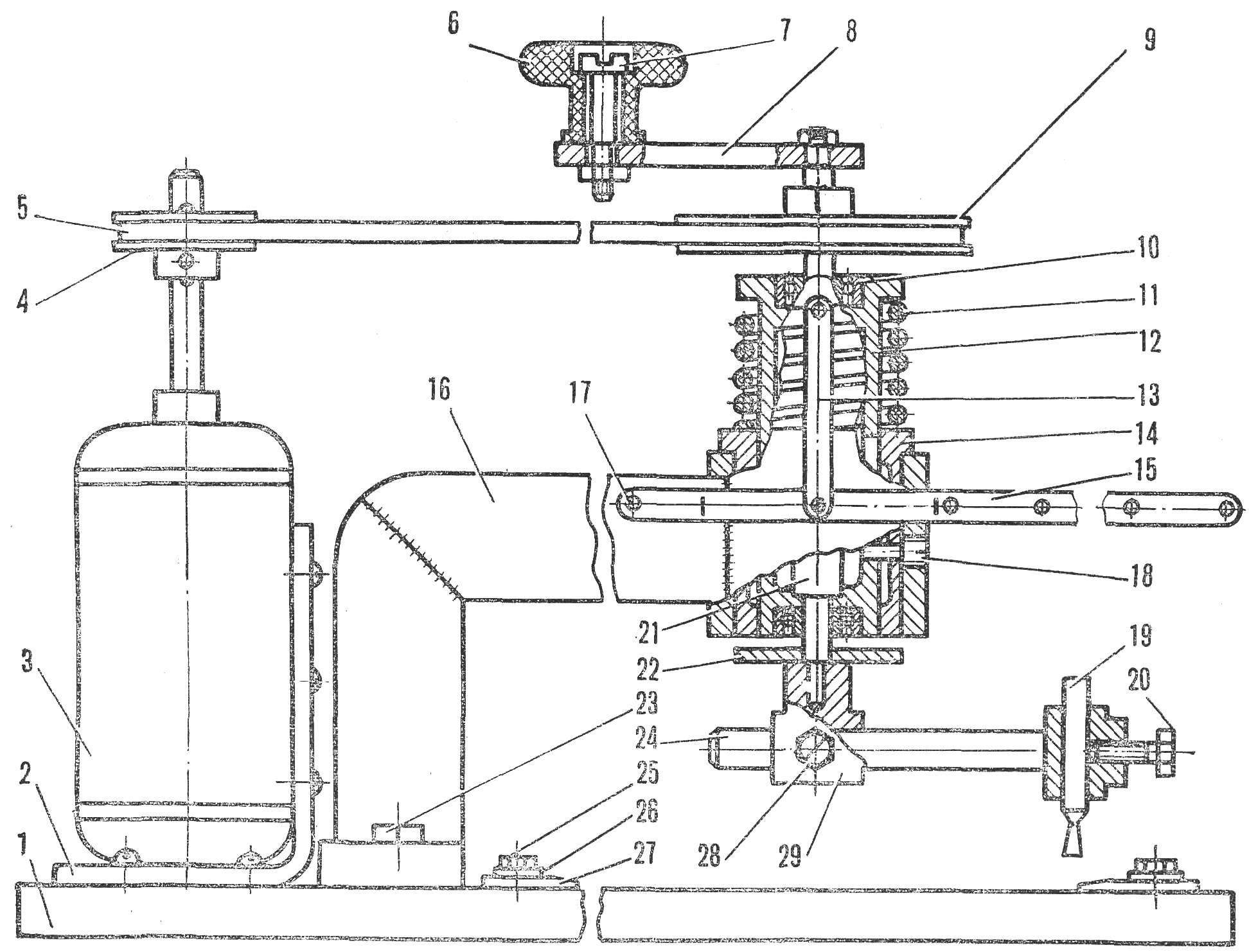

Vocational school graduates, finishing school, to protect diploma. They are often self-development: engineering and manufacturing of complex parts, assemblies, or fixtures. Cartridge-machine — theme of the graduation project of the former student of vocational school № 40, now training master M. Arkhangelsk.

Vocational school graduates, finishing school, to protect diploma. They are often self-development: engineering and manufacturing of complex parts, assemblies, or fixtures. Cartridge-machine — theme of the graduation project of the former student of vocational school № 40, now training master M. Arkhangelsk.

Usually a heavy box, container or pallet with a load attaching to a lifting mechanism using four ropes-slings; lumber, pipe of large diameter it is possible to raise two. If you overwhelm sling loop-the loop, the normal load will rise and it one. Well, if you want to move, say, heavy sheet metal?

Usually a heavy box, container or pallet with a load attaching to a lifting mechanism using four ropes-slings; lumber, pipe of large diameter it is possible to raise two. If you overwhelm sling loop-the loop, the normal load will rise and it one. Well, if you want to move, say, heavy sheet metal?

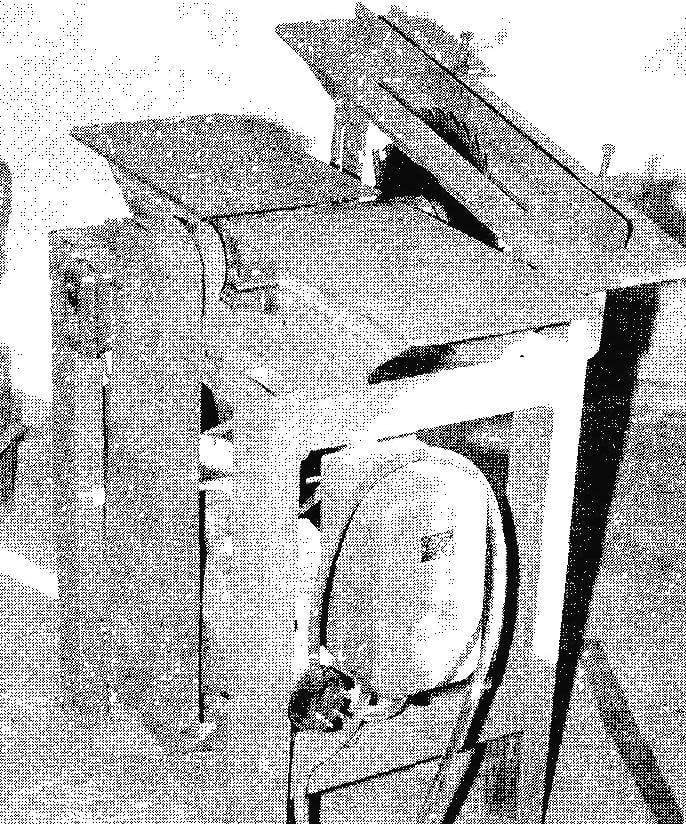

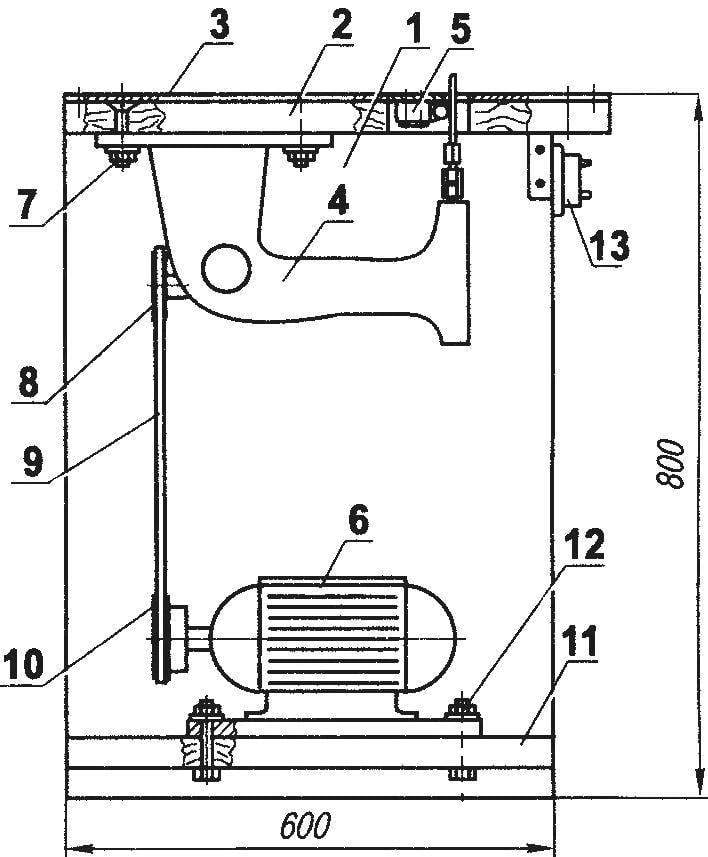

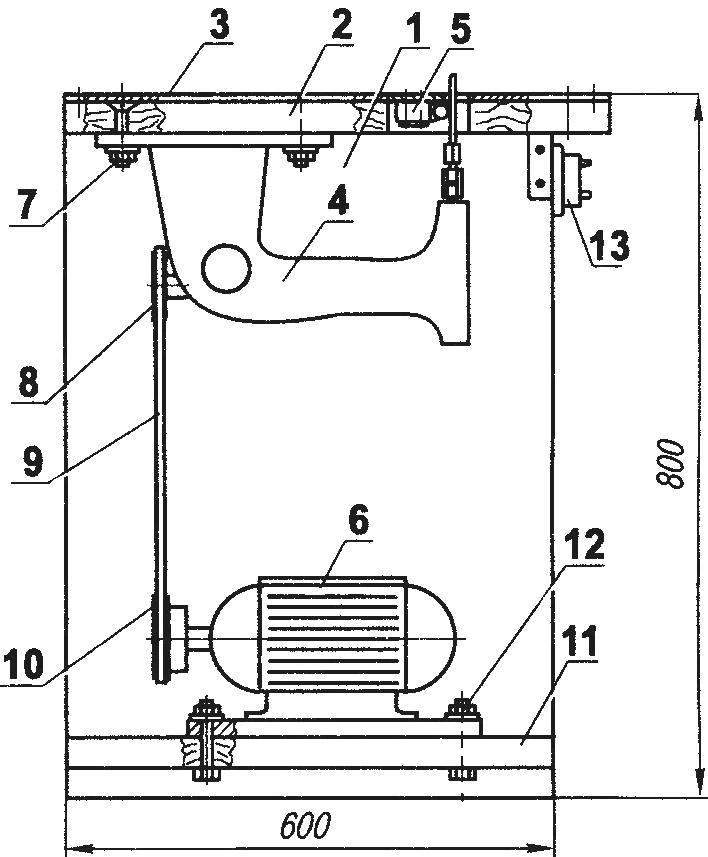

When my family moved to is not a new manor house with land, I faced the problem of its thorough repair and erection of outbuildings. It was clear that with only hand tools this kind of work will not do. And therefore decided before you start construction, along with concrete mixer, to make at least a simple woodworking sawing-planing machine, called artisans “circular saw”.

When my family moved to is not a new manor house with land, I faced the problem of its thorough repair and erection of outbuildings. It was clear that with only hand tools this kind of work will not do. And therefore decided before you start construction, along with concrete mixer, to make at least a simple woodworking sawing-planing machine, called artisans “circular saw”.

The need for large apertures of various diameters occurs very often. Some cut them with a jigsaw, others use a drill and then sanded the edges with a file, others are turning to so-called centraliza — fit to a normal drilling machine.

The need for large apertures of various diameters occurs very often. Some cut them with a jigsaw, others use a drill and then sanded the edges with a file, others are turning to so-called centraliza — fit to a normal drilling machine.

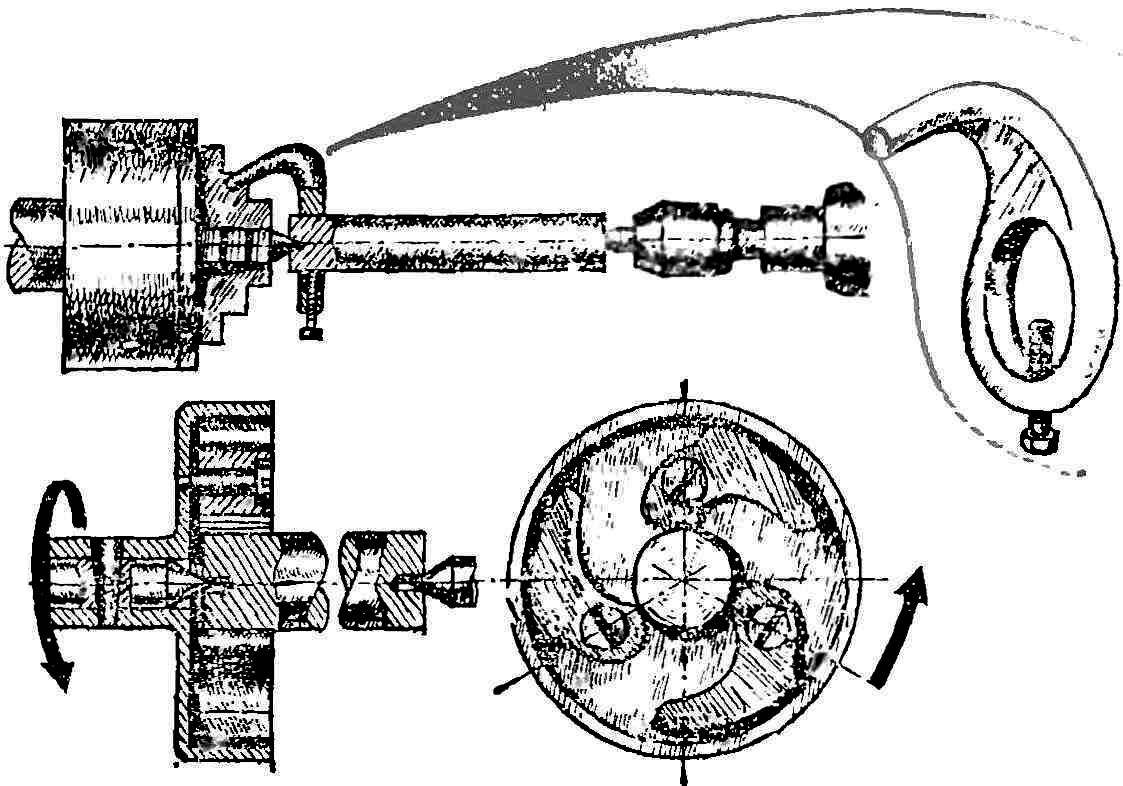

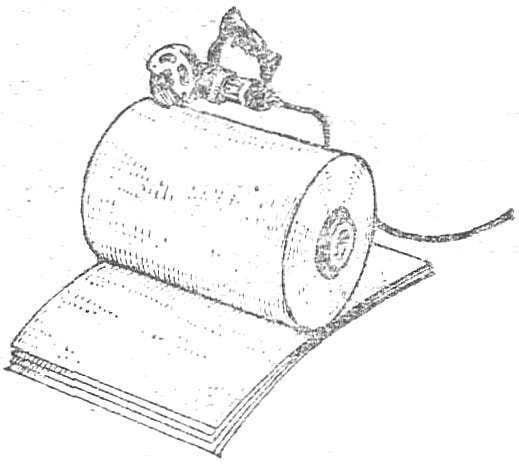

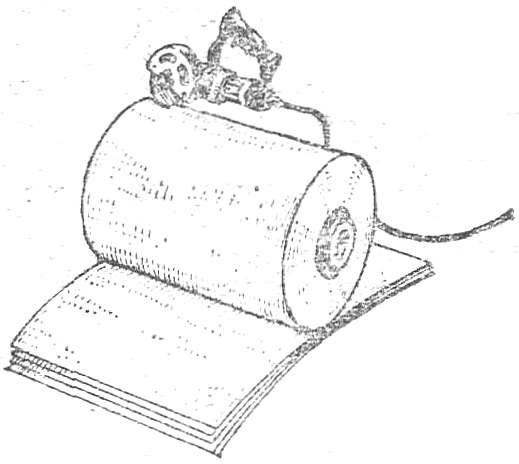

The coil is the most convenient form of packaging thin sheet materials and for the transportation and storage in warehouses. Foil, a synthetic film or paper in a tightly collapsed become a monolith, convenient in handling and are not particularly suffering from the hard grips of different mechanisms.

The coil is the most convenient form of packaging thin sheet materials and for the transportation and storage in warehouses. Foil, a synthetic film or paper in a tightly collapsed become a monolith, convenient in handling and are not particularly suffering from the hard grips of different mechanisms.

The idea is to make the jigsaw came to me many years ago, but brought it to life much later — when I got someone thrown the faulty sewing machine production Podolsk factory. From the “inside” machines only took the main shaft and the node of the “needle bar”, and other parts dismantled. Cut and the front part of the platform, leaving only a foot under the bar of a G-shaped case. On the sandpaper I ground off all the tides on the lower surface. The bearing at the corners of the drilled hole and through them, inverted the machine was attached to the top of the pedestal bottom. By the way, the Cabinet is also used from the old foot-operated sewing machine. However, to find such a Cabinet should be harder than the machine itself. But it may or may not be made of chipboard with 20 mm thick Top cover closed steel sheet thickness of 1.5 mm (and dural).

The idea is to make the jigsaw came to me many years ago, but brought it to life much later — when I got someone thrown the faulty sewing machine production Podolsk factory. From the “inside” machines only took the main shaft and the node of the “needle bar”, and other parts dismantled. Cut and the front part of the platform, leaving only a foot under the bar of a G-shaped case. On the sandpaper I ground off all the tides on the lower surface. The bearing at the corners of the drilled hole and through them, inverted the machine was attached to the top of the pedestal bottom. By the way, the Cabinet is also used from the old foot-operated sewing machine. However, to find such a Cabinet should be harder than the machine itself. But it may or may not be made of chipboard with 20 mm thick Top cover closed steel sheet thickness of 1.5 mm (and dural).