Creating some kind of mechanism or tool, the person usually by its name defines its main functional purpose. So, saw, saws, drill — sowing, the hole punch punch holes, and, say, a wrench used for screwing or unscrewing the nuts.

Creating some kind of mechanism or tool, the person usually by its name defines its main functional purpose. So, saw, saws, drill — sowing, the hole punch punch holes, and, say, a wrench used for screwing or unscrewing the nuts.POLISHING LATHE…

Creating some kind of mechanism or tool, the person usually by its name defines its main functional purpose. So, saw, saws, drill — sowing, the hole punch punch holes, and, say, a wrench used for screwing or unscrewing the nuts.

Creating some kind of mechanism or tool, the person usually by its name defines its main functional purpose. So, saw, saws, drill — sowing, the hole punch punch holes, and, say, a wrench used for screwing or unscrewing the nuts.

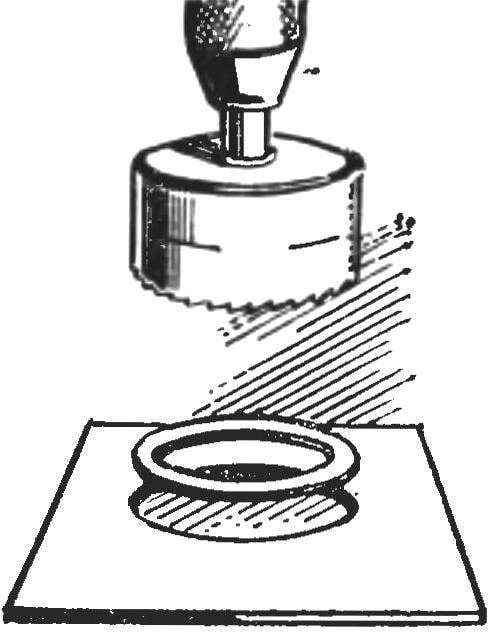

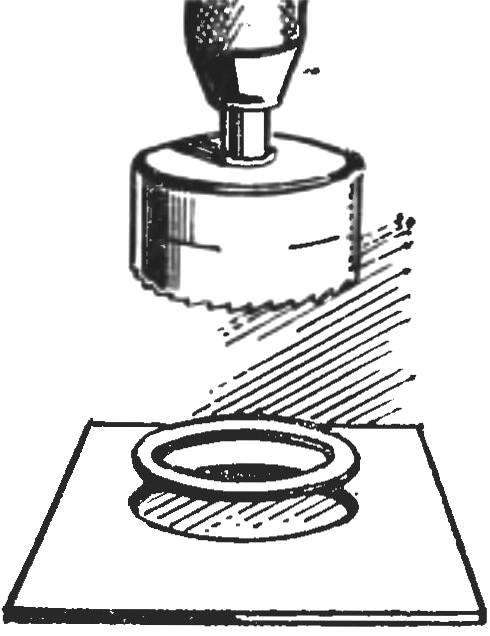

These two even look something like a high-performance tool developed by young innovators Dmitrov excavator plant. Brings them closer, and purpose: making large-diameter holes. The difference between constructive because they are intended for use with different materials.

These two even look something like a high-performance tool developed by young innovators Dmitrov excavator plant. Brings them closer, and purpose: making large-diameter holes. The difference between constructive because they are intended for use with different materials.

In the conditions of the automated production of metal-cutting tools are especially high requirements of reliability and durability, especially when cutting hard materials and alloys.

In the conditions of the automated production of metal-cutting tools are especially high requirements of reliability and durability, especially when cutting hard materials and alloys.

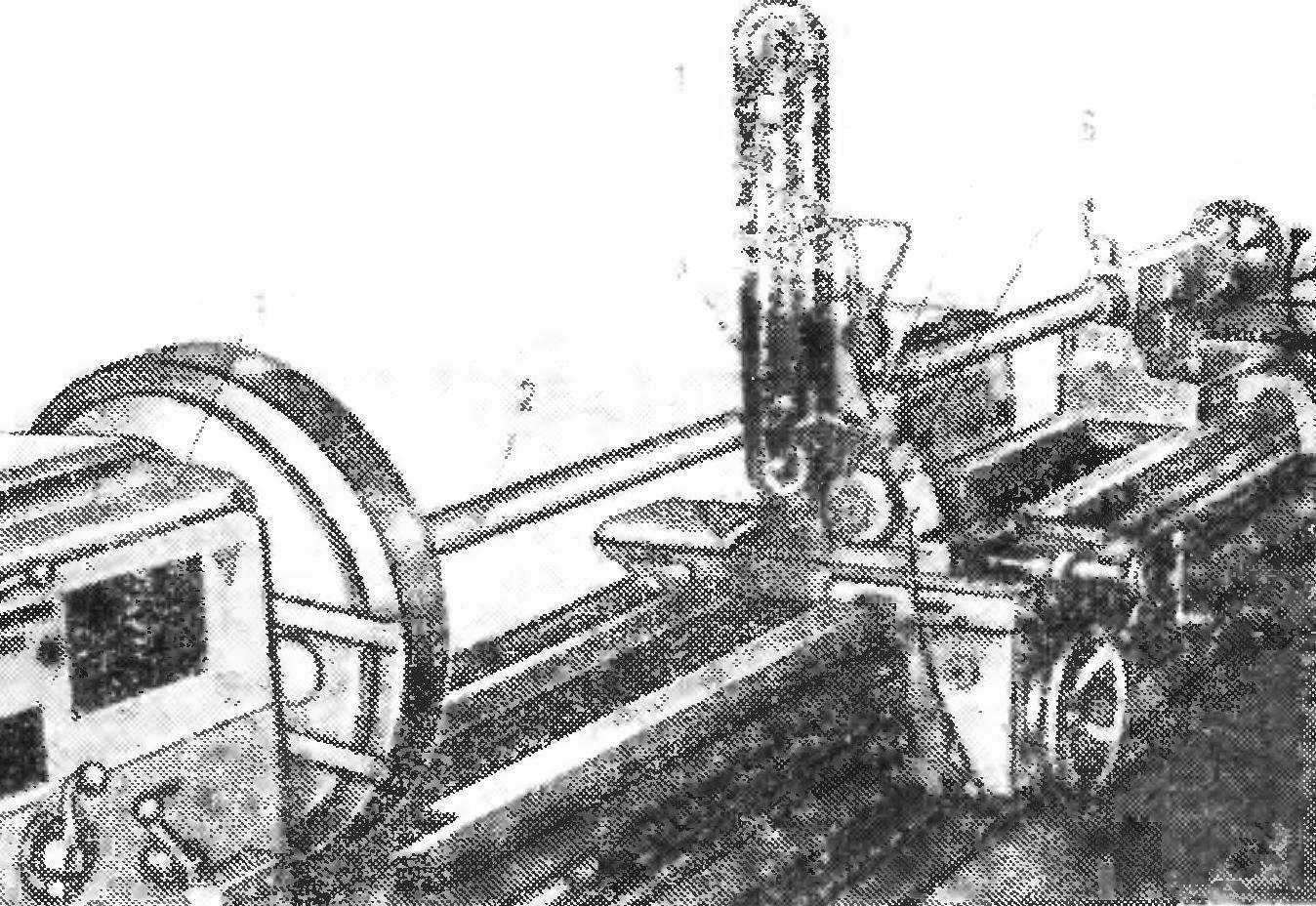

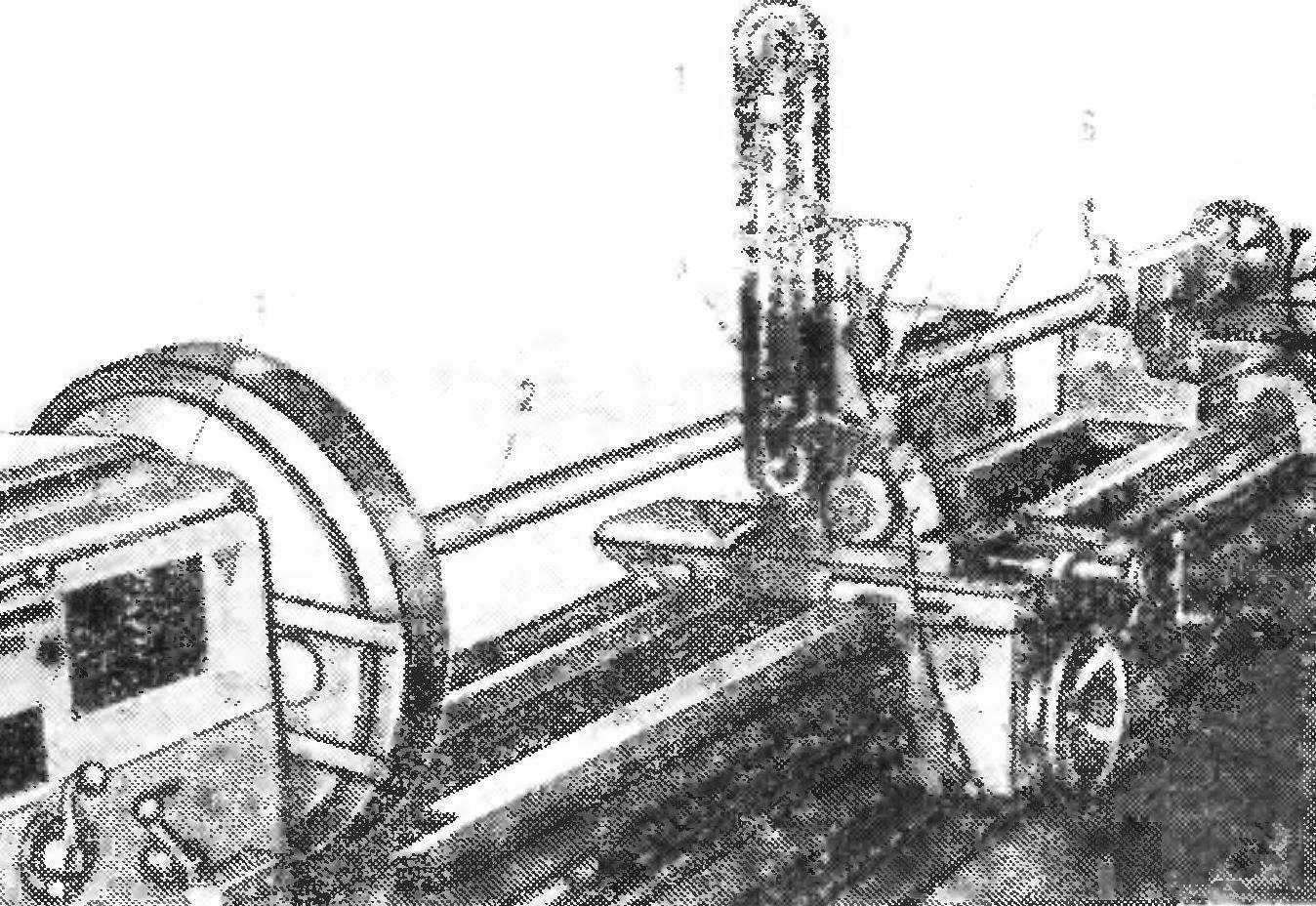

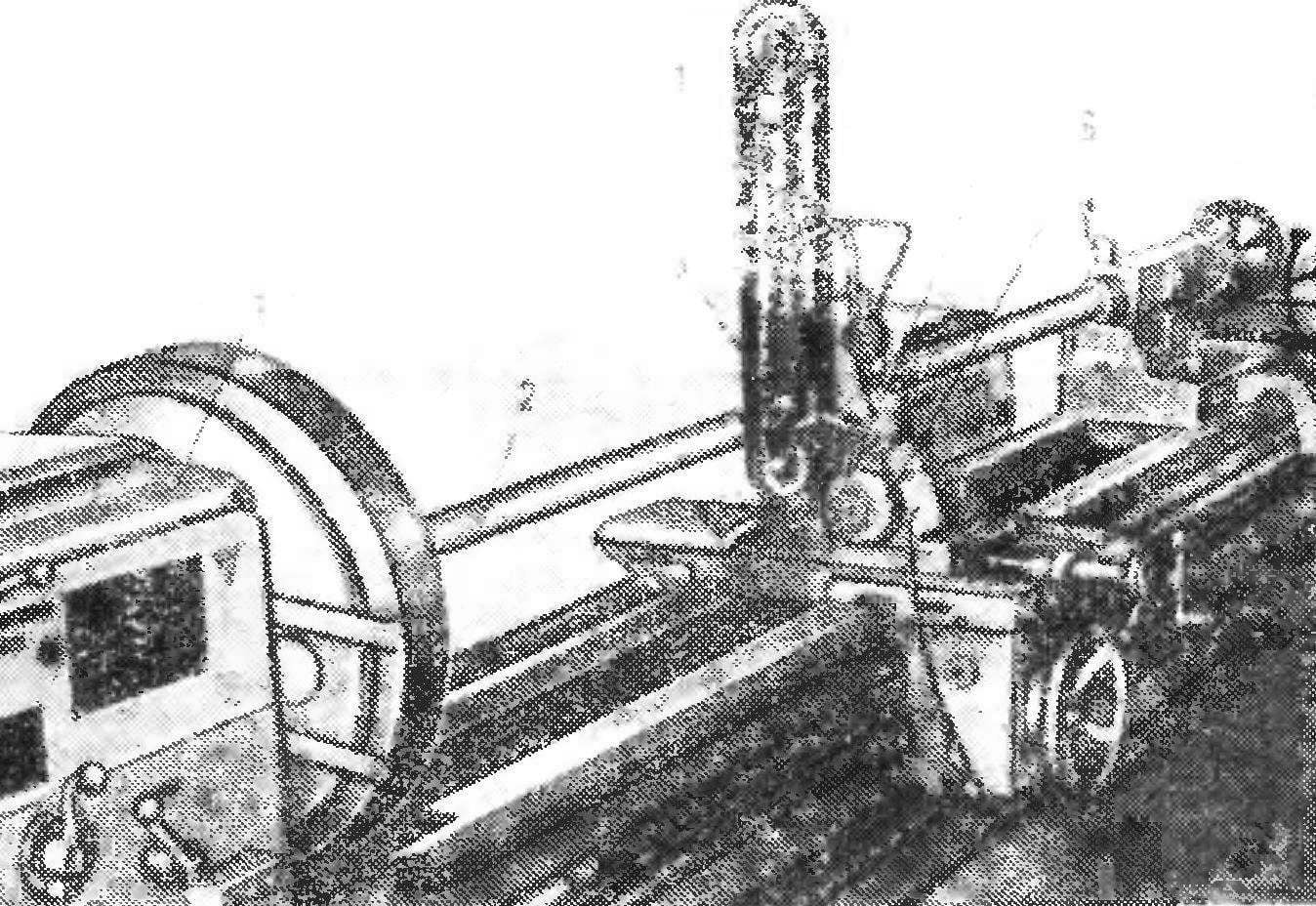

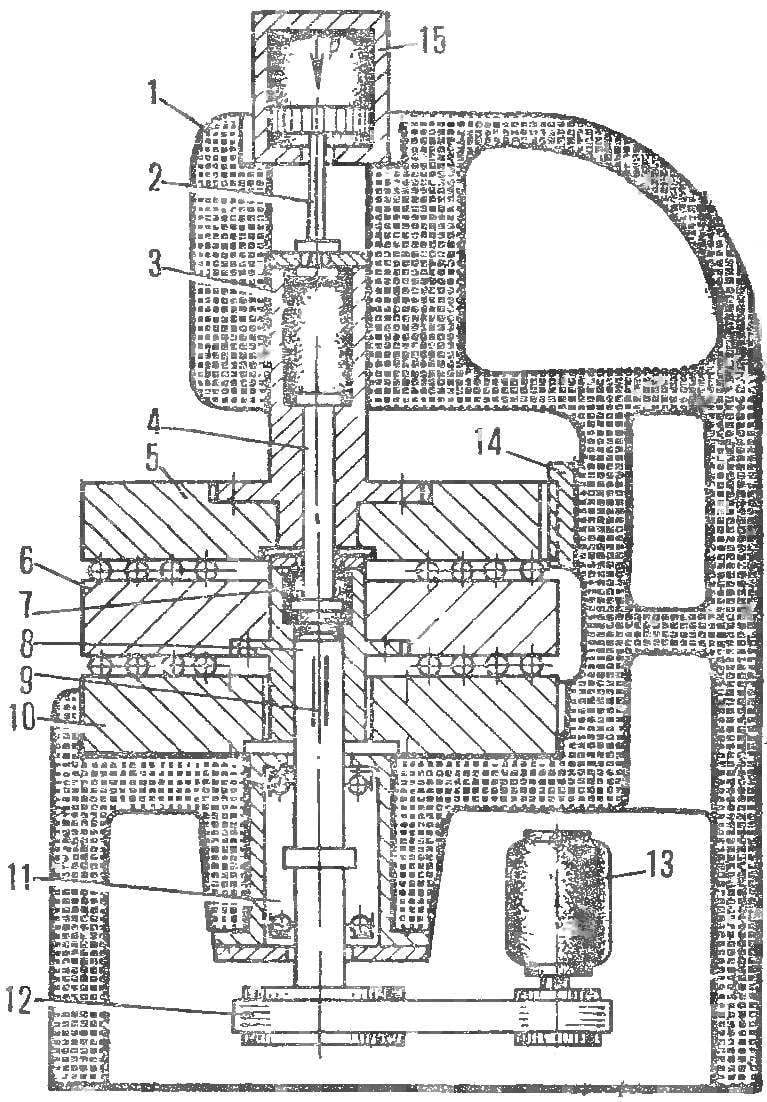

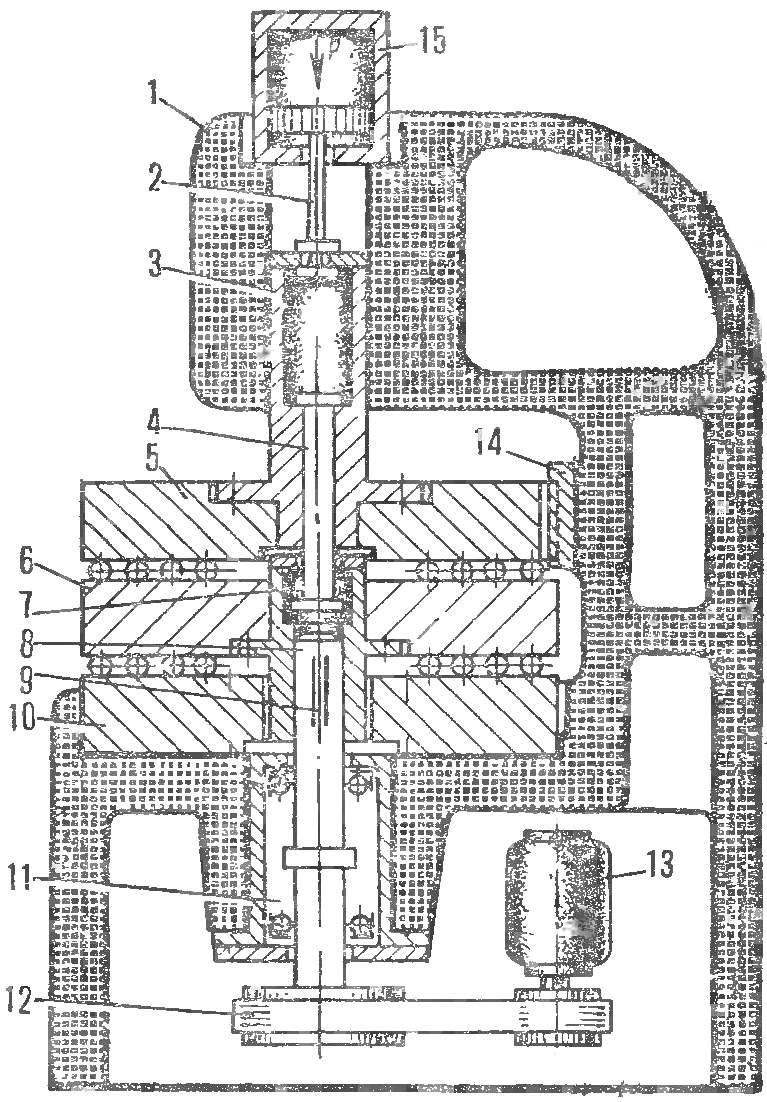

On lathes one of the most common operations — machining centers. And here a lot of time is usually lost on such auxiliary stage, both the clamp and release the part in the Chuck. Especially noticeable these losses in large-scale and mass production. Participants NTTM-78 with the Moscow machine-tool plant named after Sergo Ordzhonikidze has developed a cartridge that at the beginning of the rotation he grips the workpiece. In what way?

On lathes one of the most common operations — machining centers. And here a lot of time is usually lost on such auxiliary stage, both the clamp and release the part in the Chuck. Especially noticeable these losses in large-scale and mass production. Participants NTTM-78 with the Moscow machine-tool plant named after Sergo Ordzhonikidze has developed a cartridge that at the beginning of the rotation he grips the workpiece. In what way?

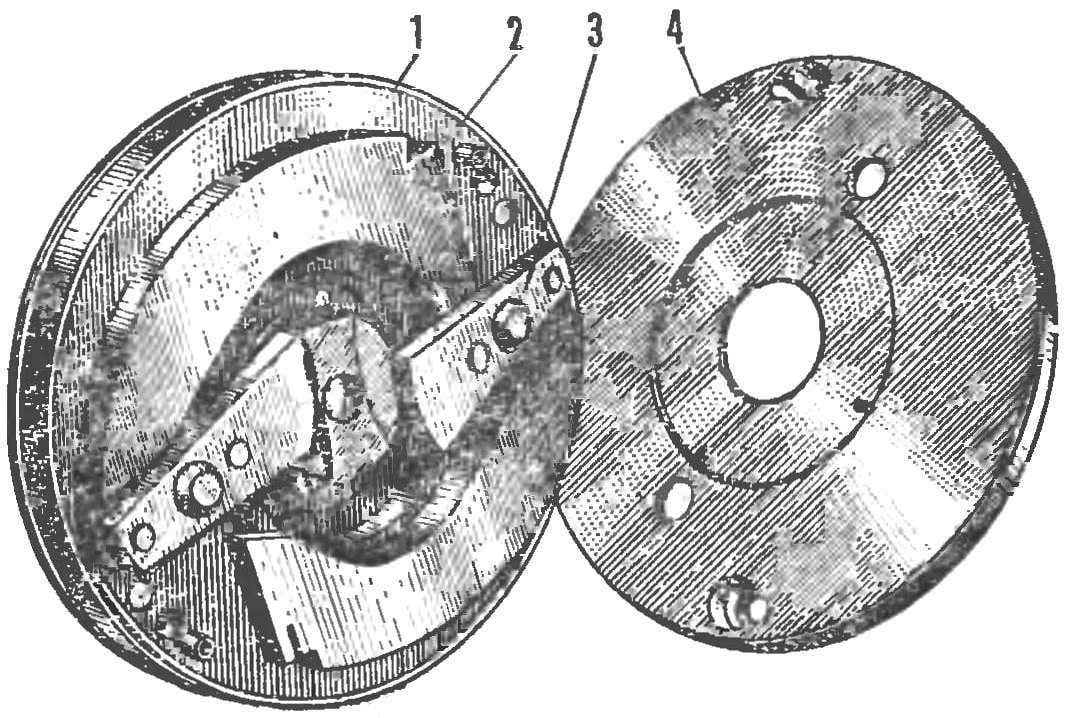

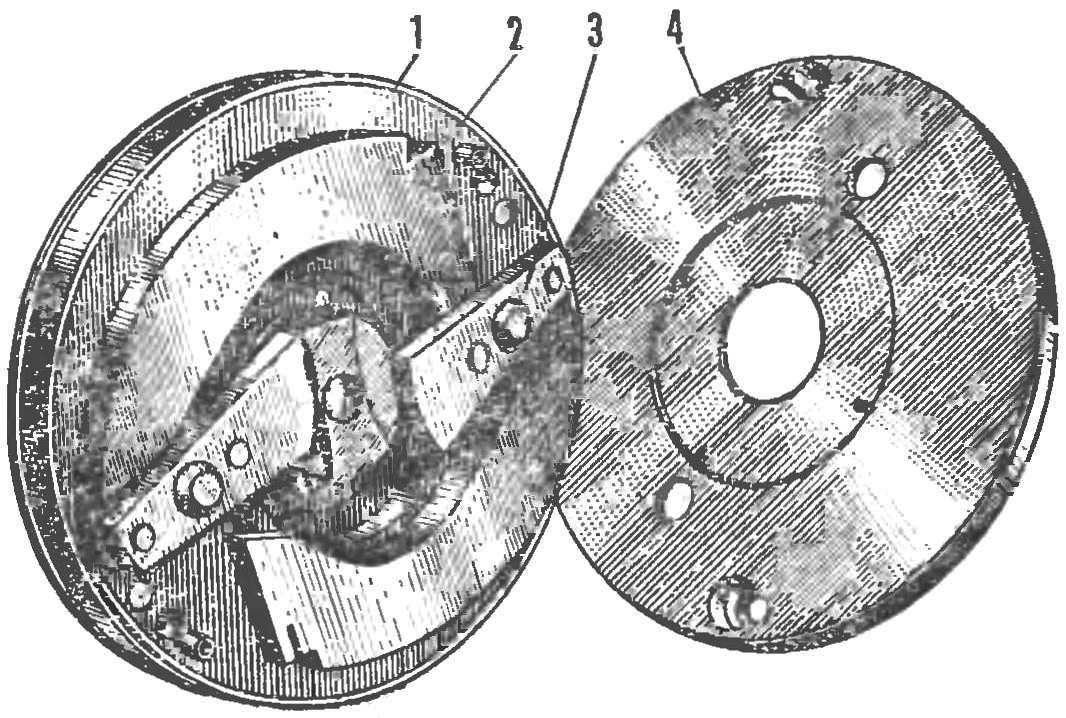

Old hunters, when there was a fraction that came out of the difficulty is quite simple: crumbled in the pan scraps of lead, covered them with heavy disk and rotated it: rolling between two surfaces of the lead pieces took on a spherical shape. The same principle is incorporated in the machine used in the ball bearing industry for the finishing of the balls. They also run between the two discs, getting the perfect spherical surface.

Old hunters, when there was a fraction that came out of the difficulty is quite simple: crumbled in the pan scraps of lead, covered them with heavy disk and rotated it: rolling between two surfaces of the lead pieces took on a spherical shape. The same principle is incorporated in the machine used in the ball bearing industry for the finishing of the balls. They also run between the two discs, getting the perfect spherical surface.

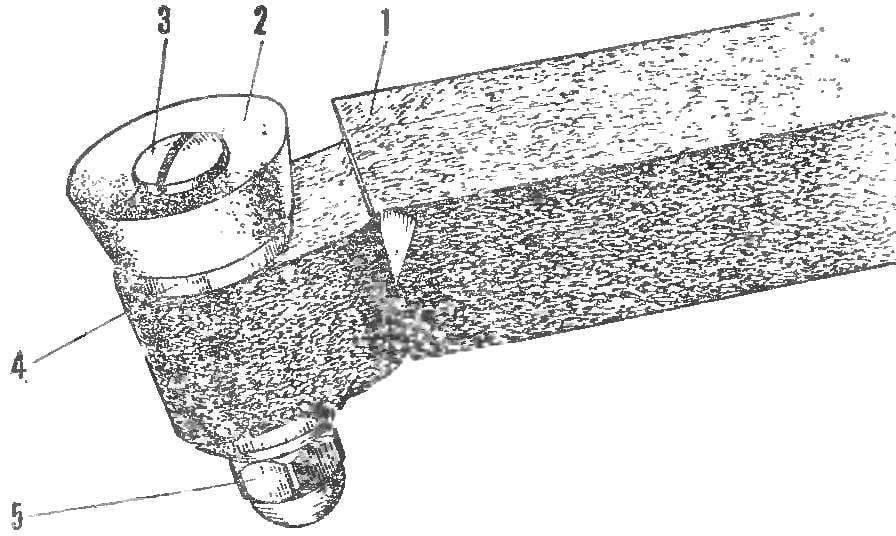

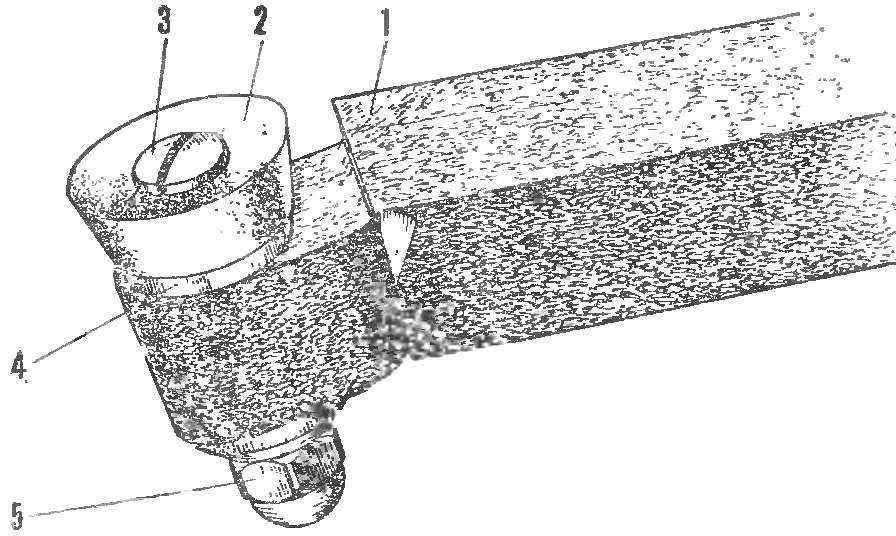

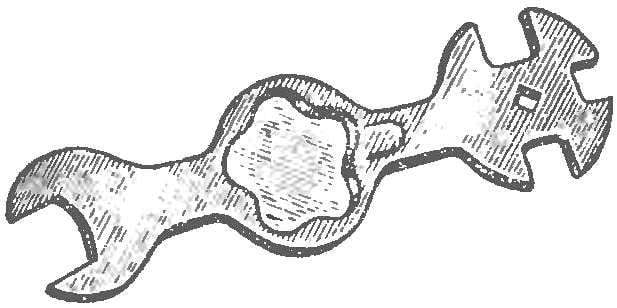

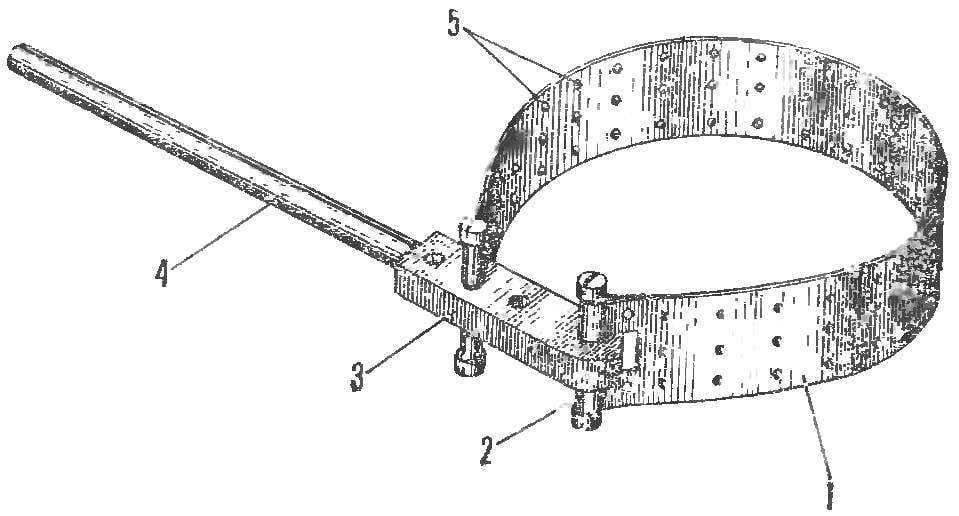

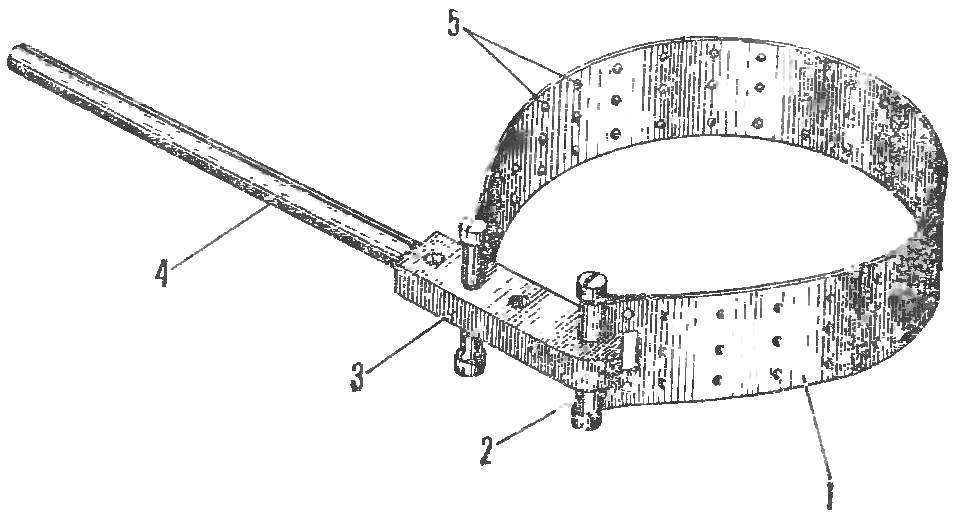

Young metallurgists, participants of the exhibition NTTM-78, developed a key for their production needs: screwing graphite electrodes Ø 300 mm electric steel furnaces. However, they believe that the principle laid down in its design, applicable and to create a tool with the other, but a close target (for example, for unscrewing the studs).

Young metallurgists, participants of the exhibition NTTM-78, developed a key for their production needs: screwing graphite electrodes Ø 300 mm electric steel furnaces. However, they believe that the principle laid down in its design, applicable and to create a tool with the other, but a close target (for example, for unscrewing the studs).

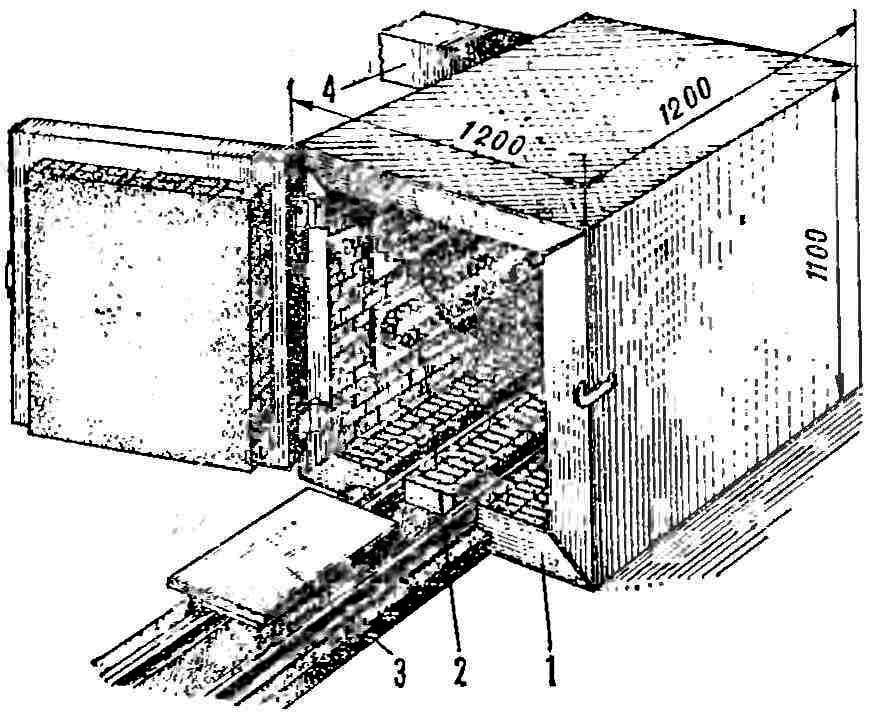

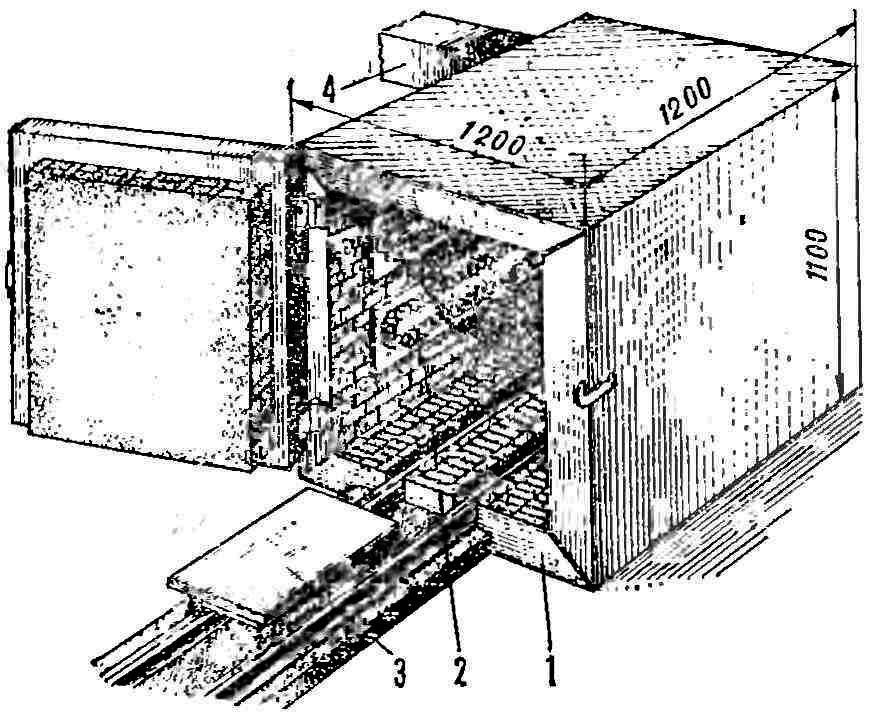

Yes, this oven lay on the wood, and… motors that require repair. “Burn” them in her invited young innovators Omsk CHPP-4, participants NTTM-78. It is easy to imagine how much work and time consuming in the repair of electric motors, the extract from the grooves of the rotor and stator are tightly Packed windings with insulating filling. In furnace insulation under high temperature burns, its volume is reduced by more than a third, and the wire is easily removed.

Yes, this oven lay on the wood, and… motors that require repair. “Burn” them in her invited young innovators Omsk CHPP-4, participants NTTM-78. It is easy to imagine how much work and time consuming in the repair of electric motors, the extract from the grooves of the rotor and stator are tightly Packed windings with insulating filling. In furnace insulation under high temperature burns, its volume is reduced by more than a third, and the wire is easily removed.

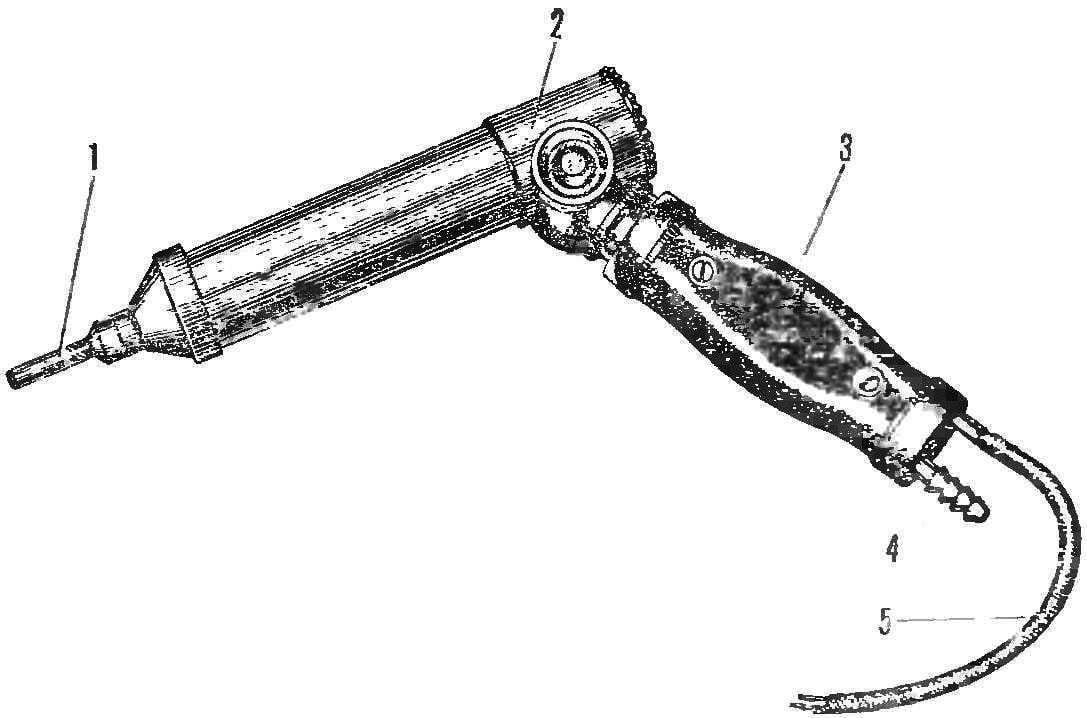

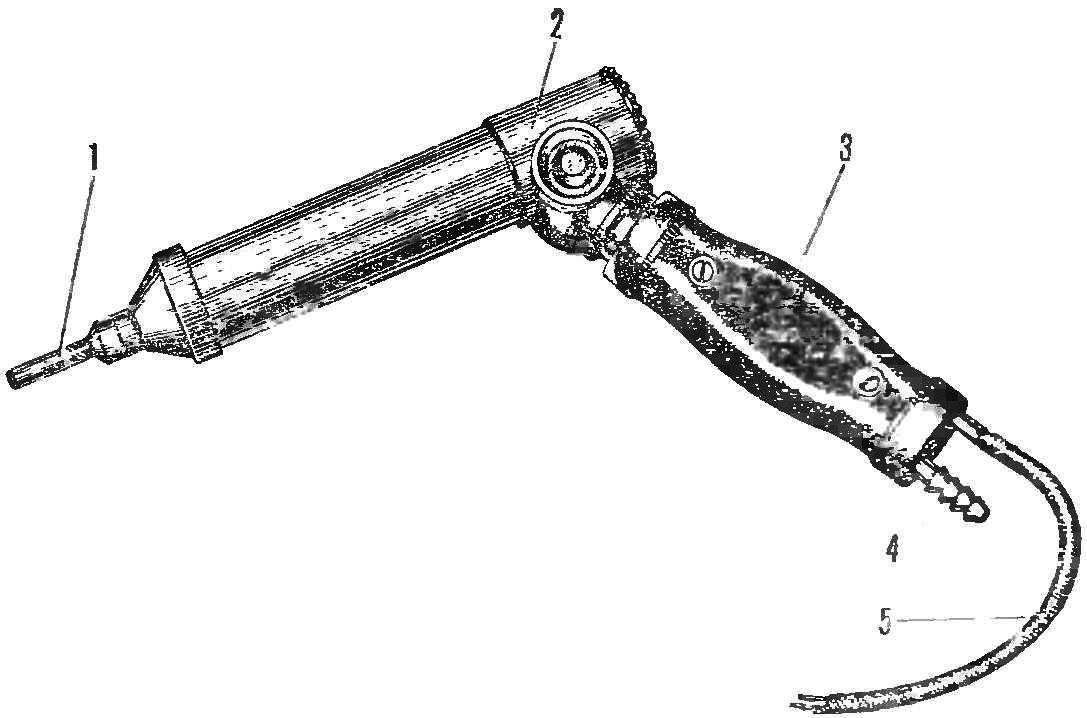

By analogy with existing devices for welding and brazing working “with the light”, this device is also called a burner. However, it acts on the mating parts do not flame, and hot air jet. “Pneumogram” created by participants NTTM Institute Vniiavtogenmash Kirovakan in machine and plant autogenous engineering, designed for welding of plastics and based on the use of such advantageous properties as the thermo plasticity. If the welding of metals requires a high temperature, many plastics soften at a temperature of.

By analogy with existing devices for welding and brazing working “with the light”, this device is also called a burner. However, it acts on the mating parts do not flame, and hot air jet. “Pneumogram” created by participants NTTM Institute Vniiavtogenmash Kirovakan in machine and plant autogenous engineering, designed for welding of plastics and based on the use of such advantageous properties as the thermo plasticity. If the welding of metals requires a high temperature, many plastics soften at a temperature of.

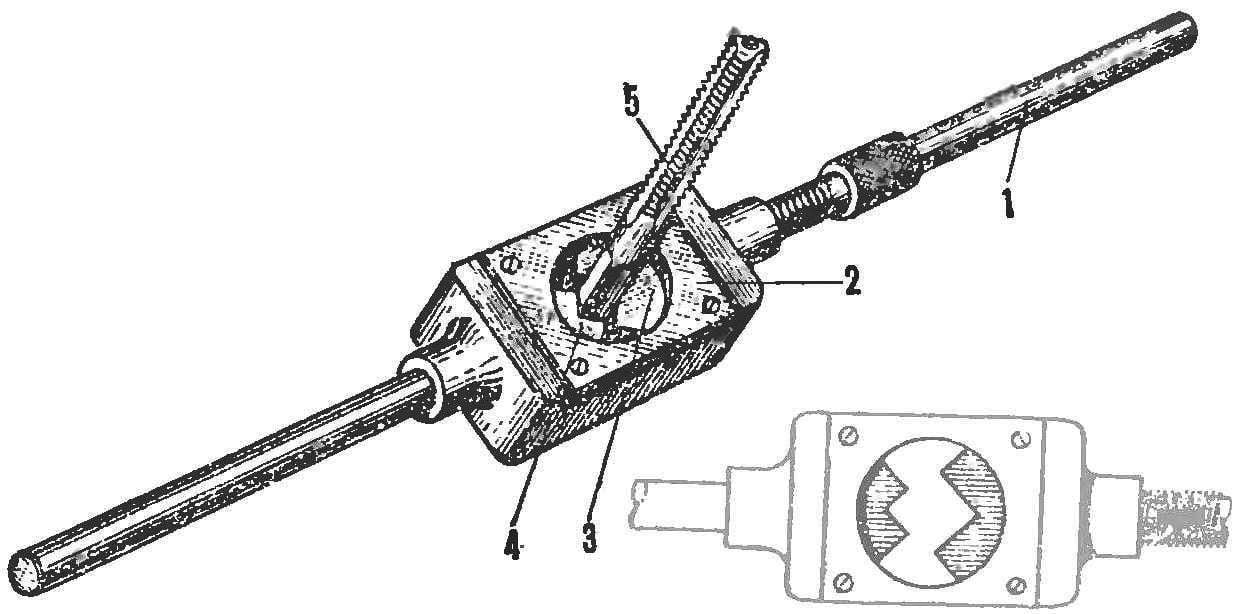

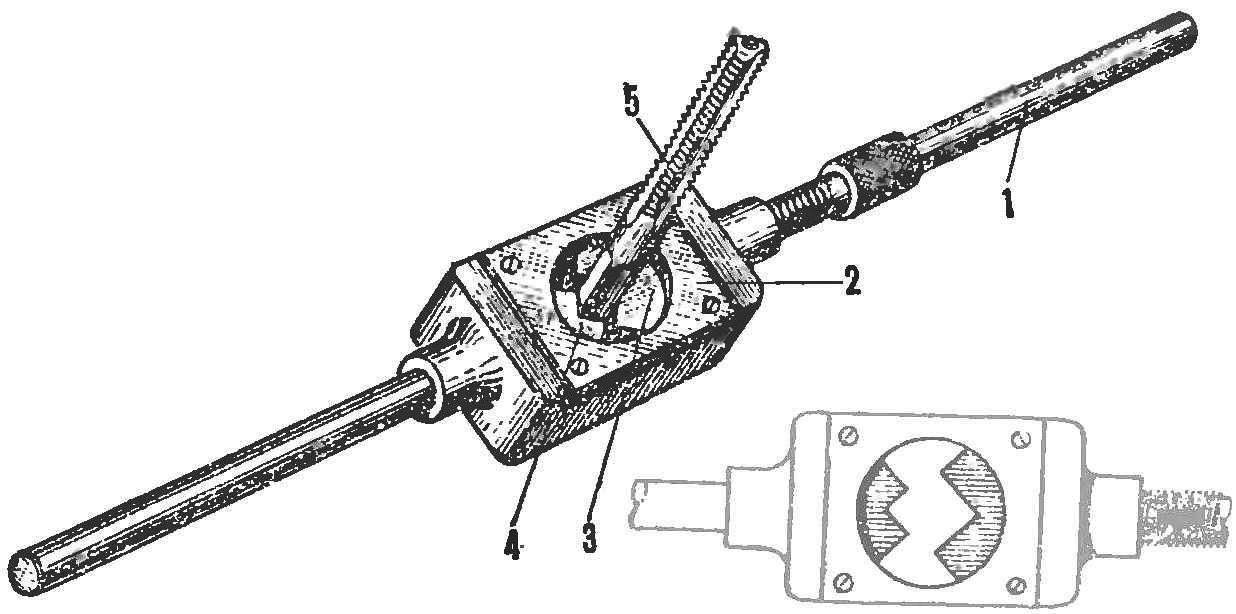

Often in the repair of threaded holes used hand tools — tap for mounting which uses a special tool holder — handle, and each diameter requires its own hardware. Young innovators Kyiv repair and mechanical plant has developed and introduced the universal knob. It is suitable for taps of various diameters — with squares from 5 to 15 mm. Feature of the device in that the clamping plate has a movable biscuit, freely connected with a threaded handle. Rotating it, you can increase or decrease the clamping hole by the movable rusk, holding the tap.

Often in the repair of threaded holes used hand tools — tap for mounting which uses a special tool holder — handle, and each diameter requires its own hardware. Young innovators Kyiv repair and mechanical plant has developed and introduced the universal knob. It is suitable for taps of various diameters — with squares from 5 to 15 mm. Feature of the device in that the clamping plate has a movable biscuit, freely connected with a threaded handle. Rotating it, you can increase or decrease the clamping hole by the movable rusk, holding the tap.