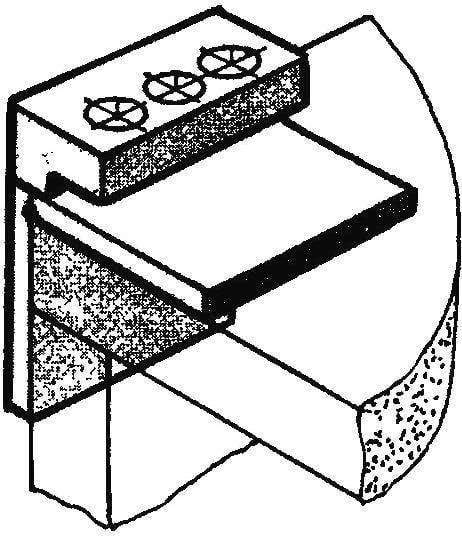

Billet parts designed for machining, not be displaced, to rotate, to vibrate or deform under the action of the cutter. In the process of manual handling (this applies primarily to the production of their own designs) can be used multiple ways of fastening plates, cylinders or tubes In the pictures are some of the options appropriate devices.

Billet parts designed for machining, not be displaced, to rotate, to vibrate or deform under the action of the cutter. In the process of manual handling (this applies primarily to the production of their own designs) can be used multiple ways of fastening plates, cylinders or tubes In the pictures are some of the options appropriate devices.HOLD STILL, DETAIL!

Billet parts designed for machining, not be displaced, to rotate, to vibrate or deform under the action of the cutter. In the process of manual handling (this applies primarily to the production of their own designs) can be used multiple ways of fastening plates, cylinders or tubes In the pictures are some of the options appropriate devices.

Billet parts designed for machining, not be displaced, to rotate, to vibrate or deform under the action of the cutter. In the process of manual handling (this applies primarily to the production of their own designs) can be used multiple ways of fastening plates, cylinders or tubes In the pictures are some of the options appropriate devices.

Science fiction writers and scientists still scratching their heads on all sorts of devices and methods to overcome gravity — gravity. And in many industries, young innovators, participants NTTM, meanwhile, create a fixture, albeit more modest, to make “weightless” various mechanized tools, in particular, the heavy — electric.

Science fiction writers and scientists still scratching their heads on all sorts of devices and methods to overcome gravity — gravity. And in many industries, young innovators, participants NTTM, meanwhile, create a fixture, albeit more modest, to make “weightless” various mechanized tools, in particular, the heavy — electric.

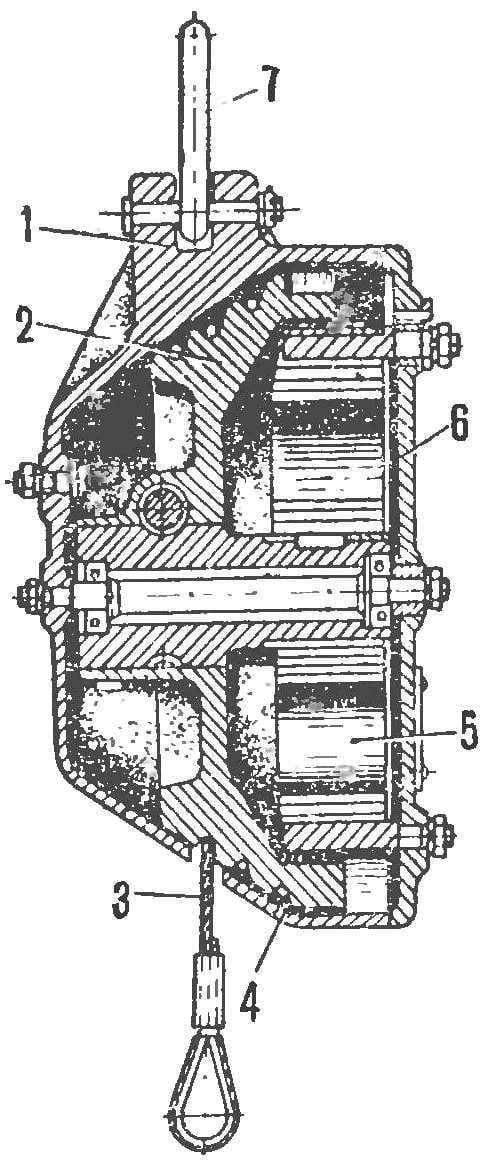

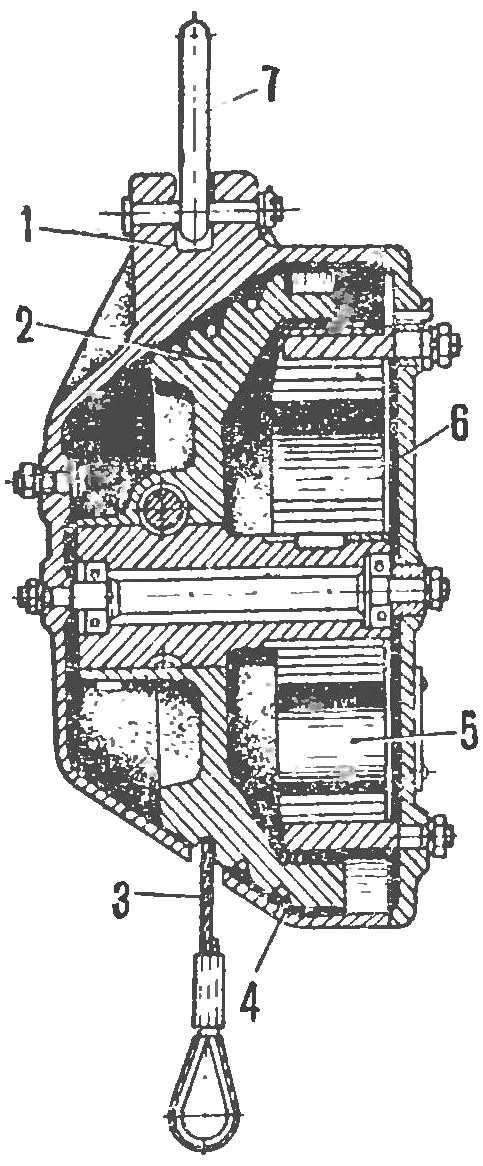

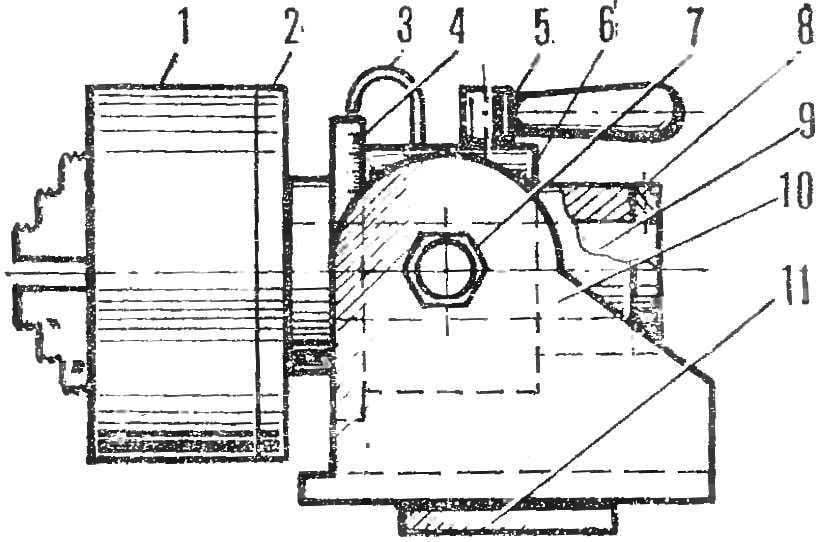

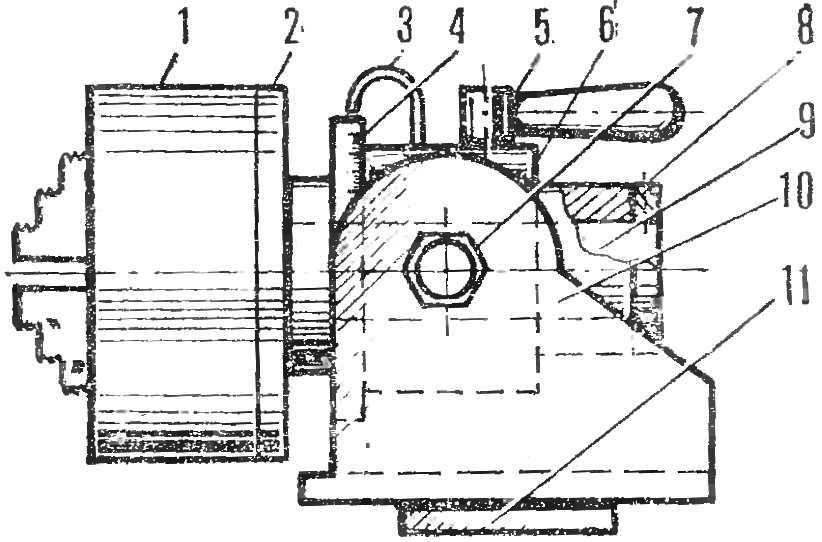

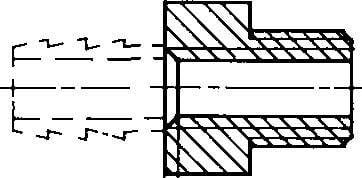

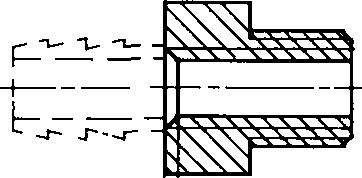

This head is easy to do if your workshop has a lathe and welding machine, Setting it to any milling machine that can handle the head bolts penetrate the splines and spline grooves, cut into the gear teeth and to perform other operations. All items shown in the picture. A few clarifications. The base of the head is made from two steel angled sections with a flange width of 120 mm, welded among themselves. to between cheeks kept the size of 70 mm.

This head is easy to do if your workshop has a lathe and welding machine, Setting it to any milling machine that can handle the head bolts penetrate the splines and spline grooves, cut into the gear teeth and to perform other operations. All items shown in the picture. A few clarifications. The base of the head is made from two steel angled sections with a flange width of 120 mm, welded among themselves. to between cheeks kept the size of 70 mm.

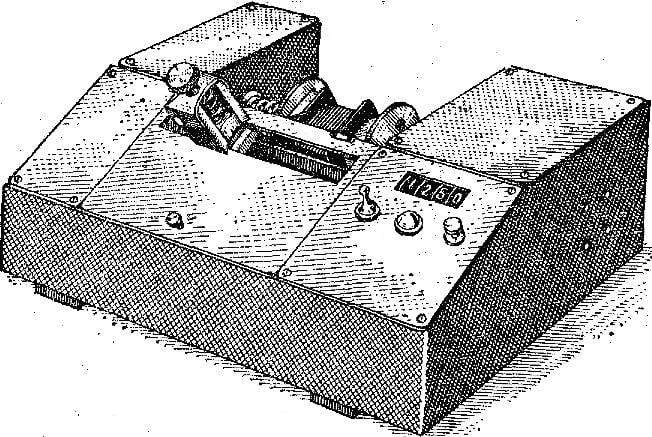

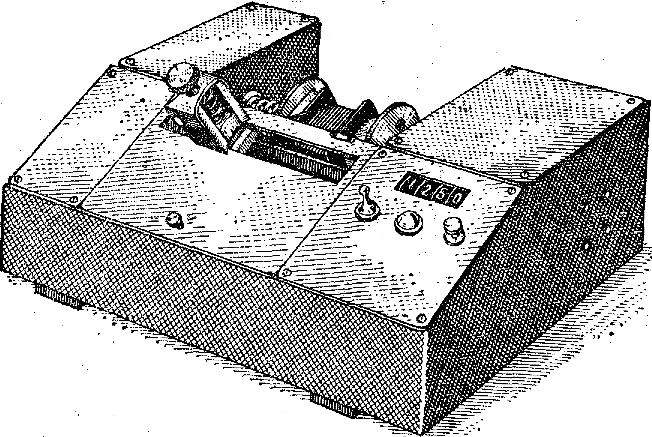

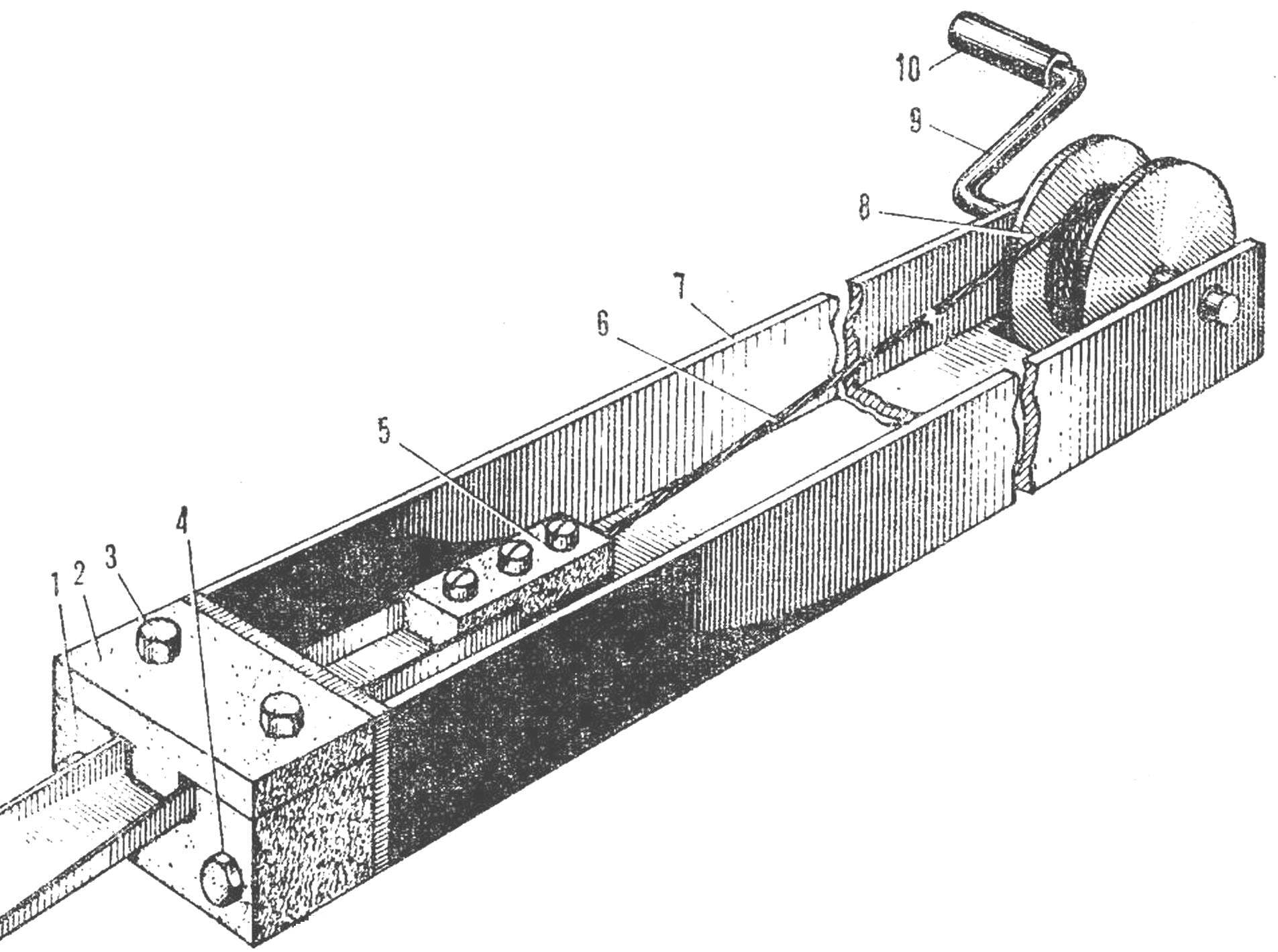

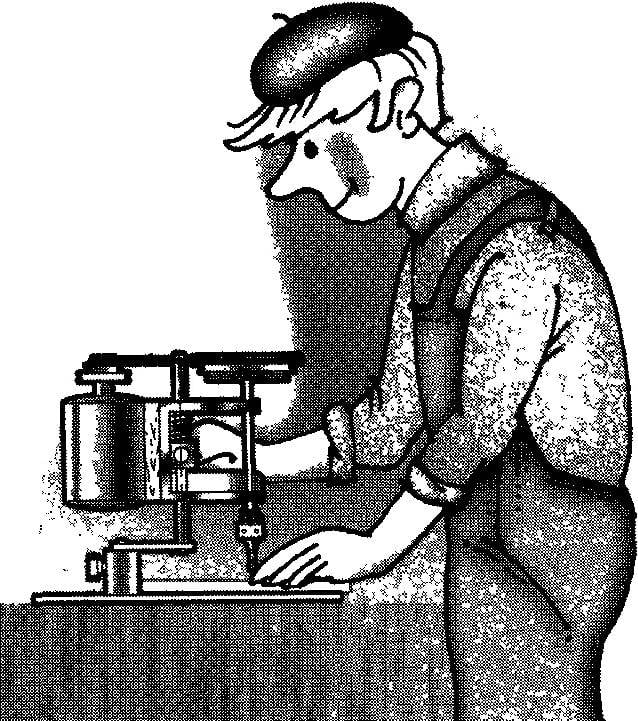

Once his hands were wound transformer coils, he knows how difficult, unproductive and laborious this work. It is necessary not only to carefully, turn to turn, put the wire on the frame, but do it with the necessary — is the same for all coil — tension and not make a mistake when counting turns.

Once his hands were wound transformer coils, he knows how difficult, unproductive and laborious this work. It is necessary not only to carefully, turn to turn, put the wire on the frame, but do it with the necessary — is the same for all coil — tension and not make a mistake when counting turns.

For bending metal rods and pipes there are many ways and devices. Most often this operation is performed on the bending. But not everyone (even of the workman person) he has. The easiest method is when one end of the workpiece is securely fixed in a suitable place (e.g. in a vise), and holding the other bend If bend the end of the short, he put on a corresponding segment of the pipe, using it as a grip and lever. But this method does not provide either the quality or the accuracy of the bend radius.

For bending metal rods and pipes there are many ways and devices. Most often this operation is performed on the bending. But not everyone (even of the workman person) he has. The easiest method is when one end of the workpiece is securely fixed in a suitable place (e.g. in a vise), and holding the other bend If bend the end of the short, he put on a corresponding segment of the pipe, using it as a grip and lever. But this method does not provide either the quality or the accuracy of the bend radius.

Dear editors! Send a description of simple tools that may be needed in the manufacture of furniture Think it will appeal to many I have it used successfully for years.

Dear editors! Send a description of simple tools that may be needed in the manufacture of furniture Think it will appeal to many I have it used successfully for years.

Pump chamber of a Bicycle wheel, for example after repair or tire, the operation is quite tedious because of the low performance of the supplied pump. Besides, there are pumps, hose attach at the end — then the job is also heavy. Because the pump has to keep on weight, creating pressure with one hand and the other opposing him, that is producing double the work.

Pump chamber of a Bicycle wheel, for example after repair or tire, the operation is quite tedious because of the low performance of the supplied pump. Besides, there are pumps, hose attach at the end — then the job is also heavy. Because the pump has to keep on weight, creating pressure with one hand and the other opposing him, that is producing double the work.

You never tried to bend metal sections “area” or “channel”? If you had, then you probably know how hard it is, especially if the profile is lengthy. Simple drawing mill, made by me, allows you to run a variety of shaped metal profiles with a thickness up to one millimeter in almost any length. In the case are plastic and metals 3 steel grades and the stainless steel, aluminum alloys and brass.

You never tried to bend metal sections “area” or “channel”? If you had, then you probably know how hard it is, especially if the profile is lengthy. Simple drawing mill, made by me, allows you to run a variety of shaped metal profiles with a thickness up to one millimeter in almost any length. In the case are plastic and metals 3 steel grades and the stainless steel, aluminum alloys and brass.

In the manufacture of printed circuit boards have to drill a lot of holes. This is best done on a drill press. But many radio Amateurs it is? But it is not so difficult to do.

In the manufacture of printed circuit boards have to drill a lot of holes. This is best done on a drill press. But many radio Amateurs it is? But it is not so difficult to do.

In the manufacture of personal watercraft, hidrocaribe and other small-tonnage vessels to protect the surface from moisture and make the case the mechanical strength is widely used fiberglass. However, faced with the complexity of the processing surfaces having a large area (an average of about 8 m2). In this rational use of mechanized tools (electric drill, grinding machine, type “Electra” etc.).

In the manufacture of personal watercraft, hidrocaribe and other small-tonnage vessels to protect the surface from moisture and make the case the mechanical strength is widely used fiberglass. However, faced with the complexity of the processing surfaces having a large area (an average of about 8 m2). In this rational use of mechanized tools (electric drill, grinding machine, type “Electra” etc.).