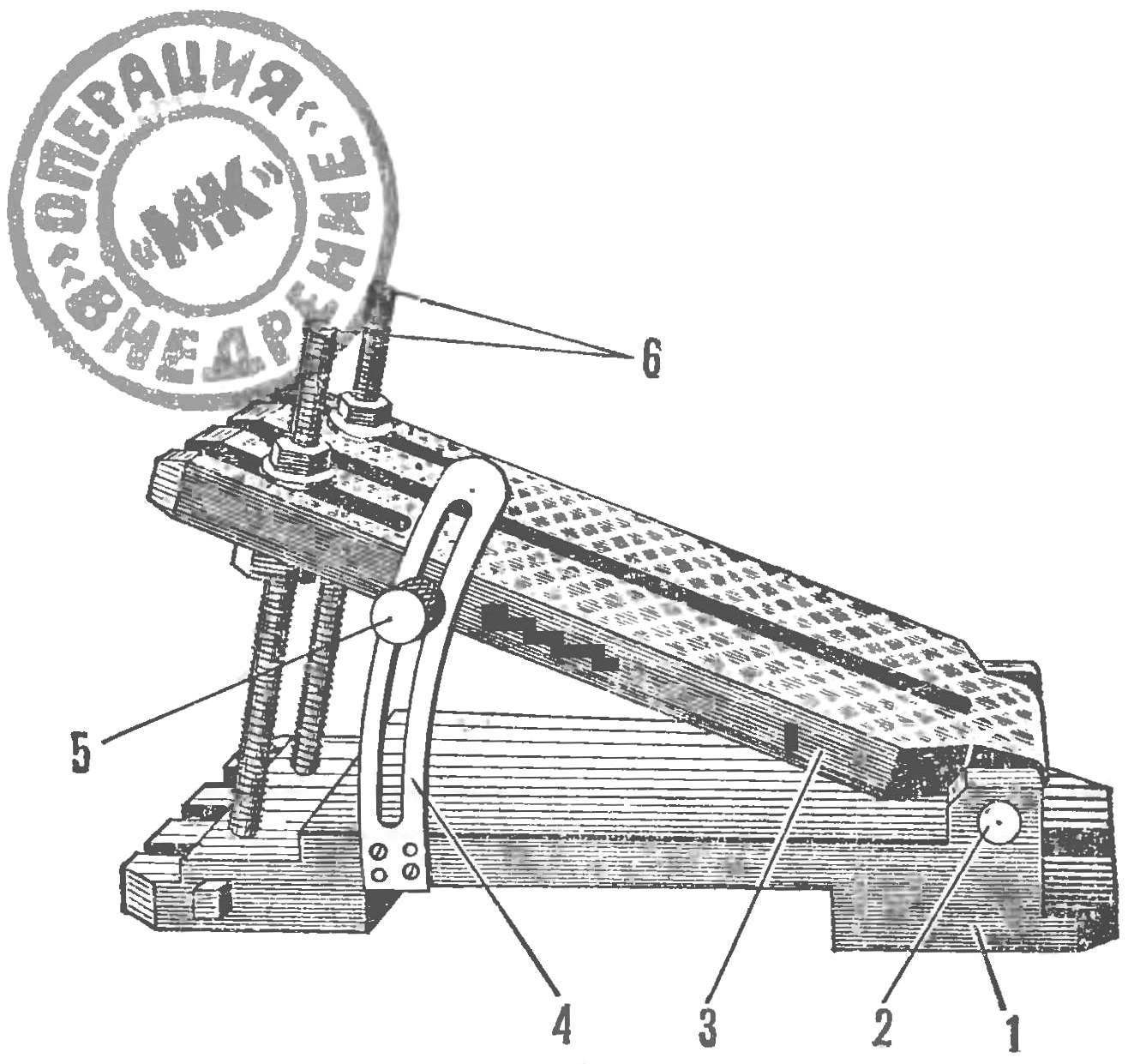

In most cases, the part is placed on the machine perpendicular to the processing tool. A simple device created by Odessa innovator, Tandit, provides a fast and secure workpiece at any angle with an accuracy of 1°.

In most cases, the part is placed on the machine perpendicular to the processing tool. A simple device created by Odessa innovator, Tandit, provides a fast and secure workpiece at any angle with an accuracy of 1°.ANGLE? PLEASE!

In most cases, the part is placed on the machine perpendicular to the processing tool. A simple device created by Odessa innovator, Tandit, provides a fast and secure workpiece at any angle with an accuracy of 1°.

In most cases, the part is placed on the machine perpendicular to the processing tool. A simple device created by Odessa innovator, Tandit, provides a fast and secure workpiece at any angle with an accuracy of 1°.

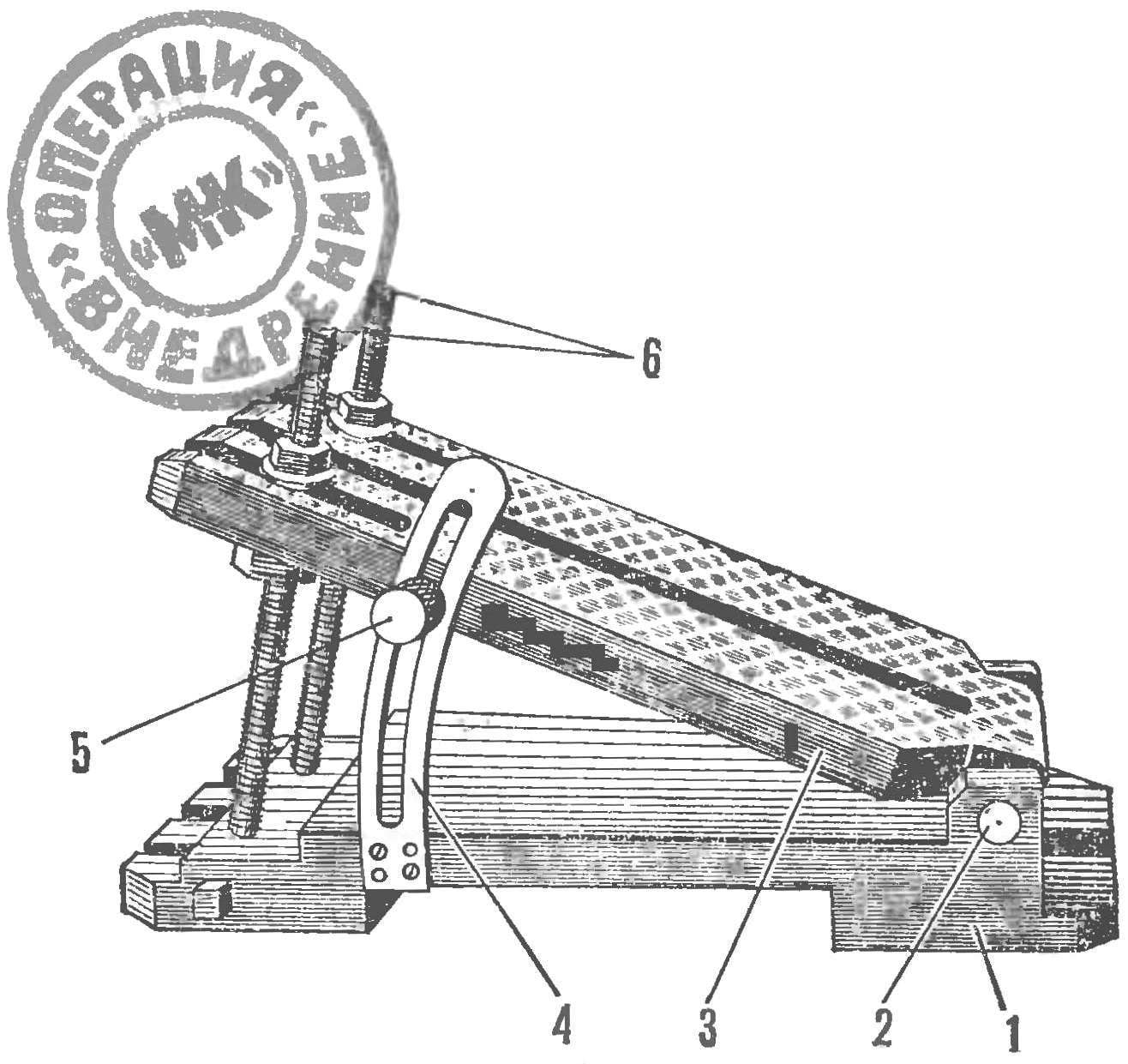

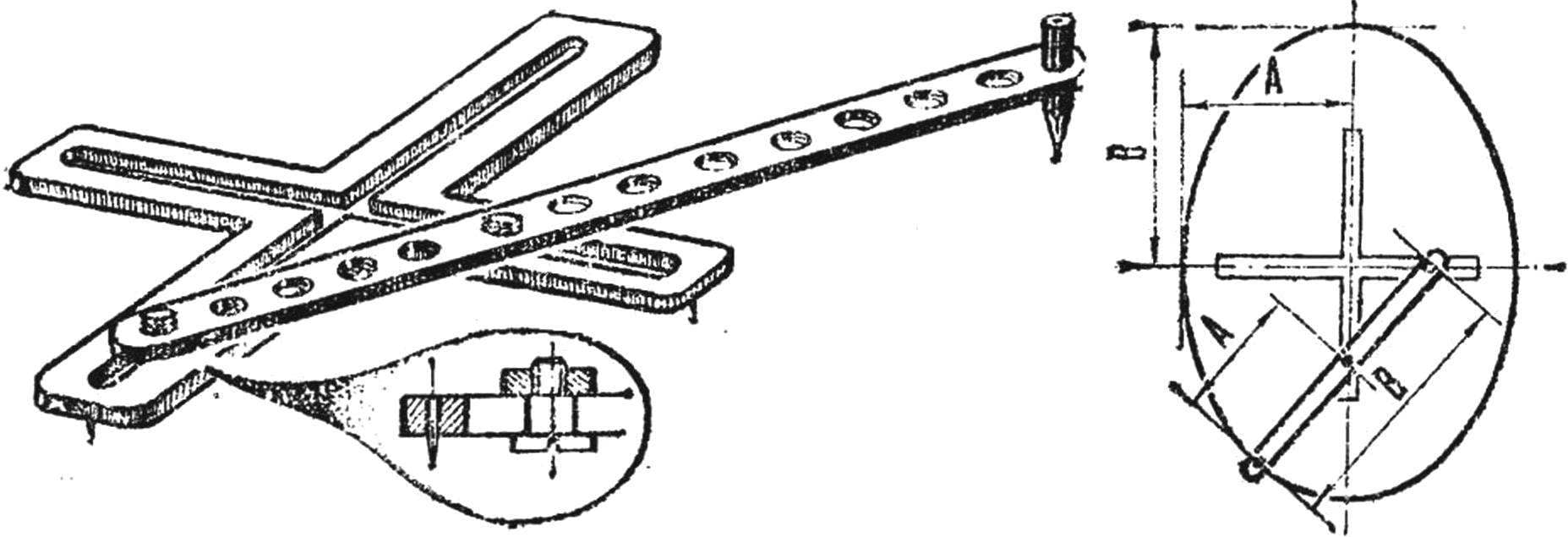

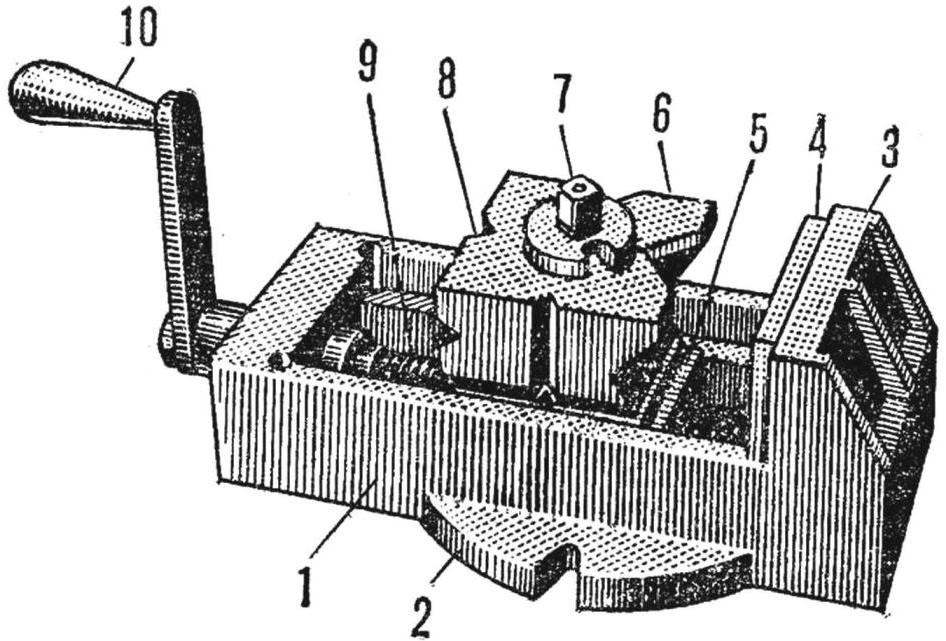

Measure the bore diameter or roller to determine the size of the gap with an accuracy of 0.1 mm it is possible not only with the help of micrometer, Vernier caliper or feeler gauge. Each of the offered here for measuring instruments easy to make at home in just one hour.

Measure the bore diameter or roller to determine the size of the gap with an accuracy of 0.1 mm it is possible not only with the help of micrometer, Vernier caliper or feeler gauge. Each of the offered here for measuring instruments easy to make at home in just one hour.

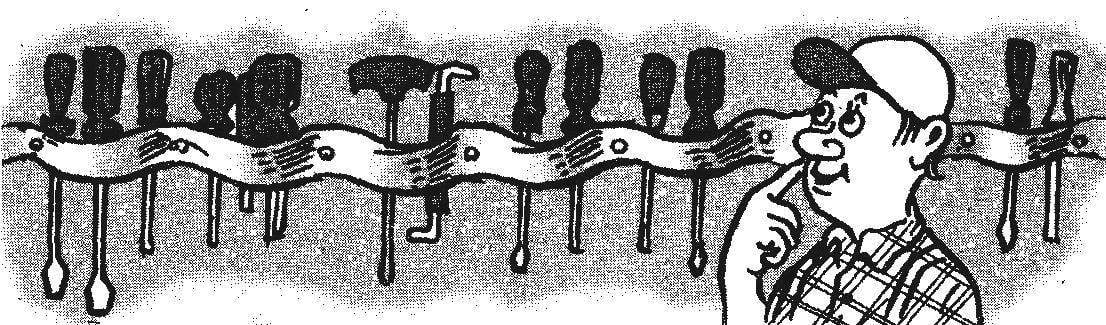

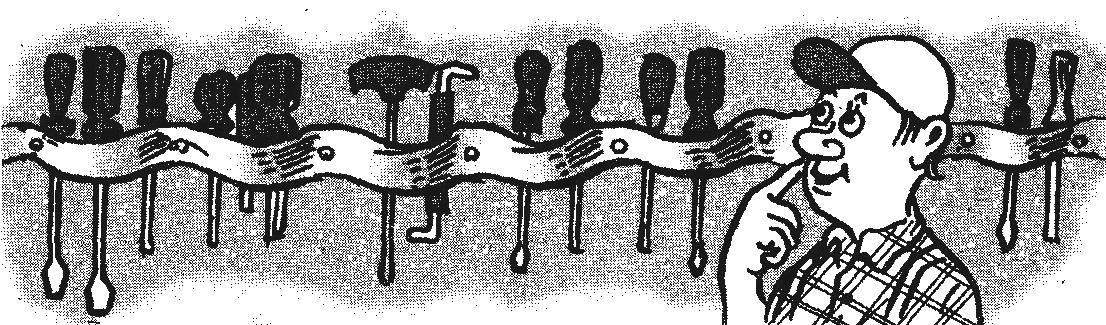

No one is surprised that for drilling different holes require different tools. The bit set can not do, does not matter. The trouble is that the tool change takes a lot of precious minutes. How to avoid this! In various companies are innovators in different ways solve this problem. There was, for example, drill bits with a stepped diameter, one such tool allows you to drill small and large holes. And where this range should be really very great work on the turret with permanently fixed at their range of drills.

No one is surprised that for drilling different holes require different tools. The bit set can not do, does not matter. The trouble is that the tool change takes a lot of precious minutes. How to avoid this! In various companies are innovators in different ways solve this problem. There was, for example, drill bits with a stepped diameter, one such tool allows you to drill small and large holes. And where this range should be really very great work on the turret with permanently fixed at their range of drills.

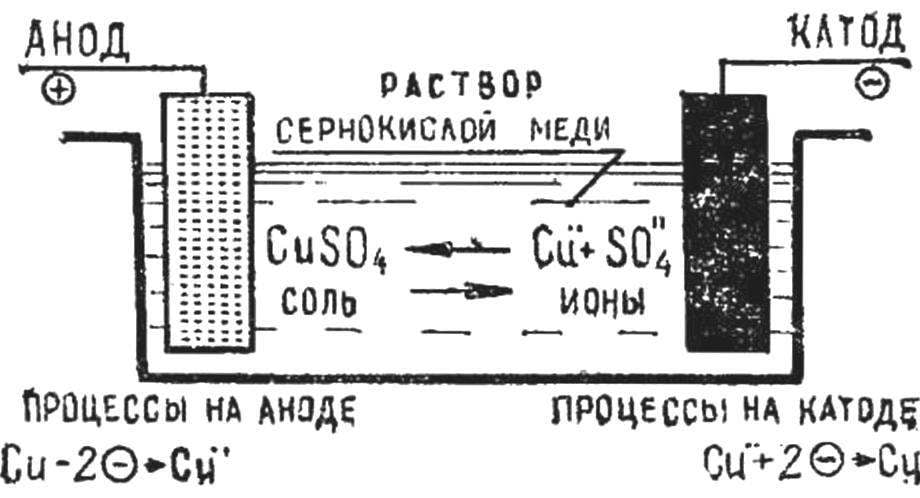

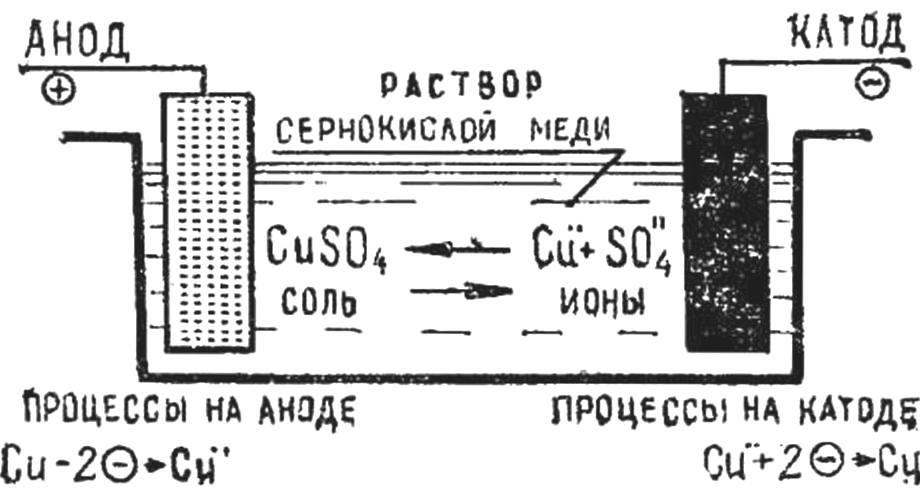

The electroforming technique of electrolytic deposition of metals on the surface of various objects (matrices) with the aim of obtaining accurate metal copies were first developed and applied in practice in 1838 by the Russian scientist, academician B. S. Jacobi. With his direct participation had made many great works of art, statues and bas-reliefs for St. Isaac’s Cathedral, Hermitage Museum, Winter Palace, Peter and Paul Cathedral, including the famous Quadriga to front of the Bolshoi theater in Moscow.

The electroforming technique of electrolytic deposition of metals on the surface of various objects (matrices) with the aim of obtaining accurate metal copies were first developed and applied in practice in 1838 by the Russian scientist, academician B. S. Jacobi. With his direct participation had made many great works of art, statues and bas-reliefs for St. Isaac’s Cathedral, Hermitage Museum, Winter Palace, Peter and Paul Cathedral, including the famous Quadriga to front of the Bolshoi theater in Moscow.

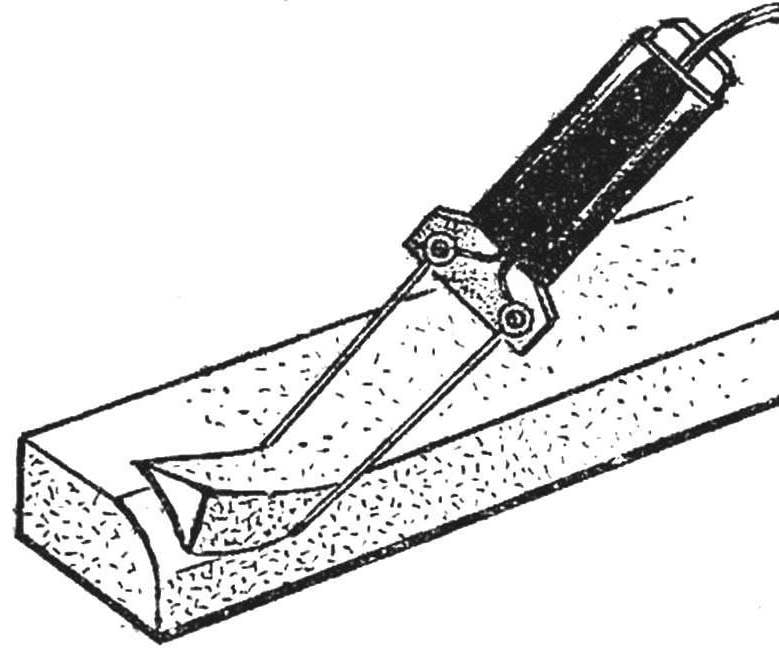

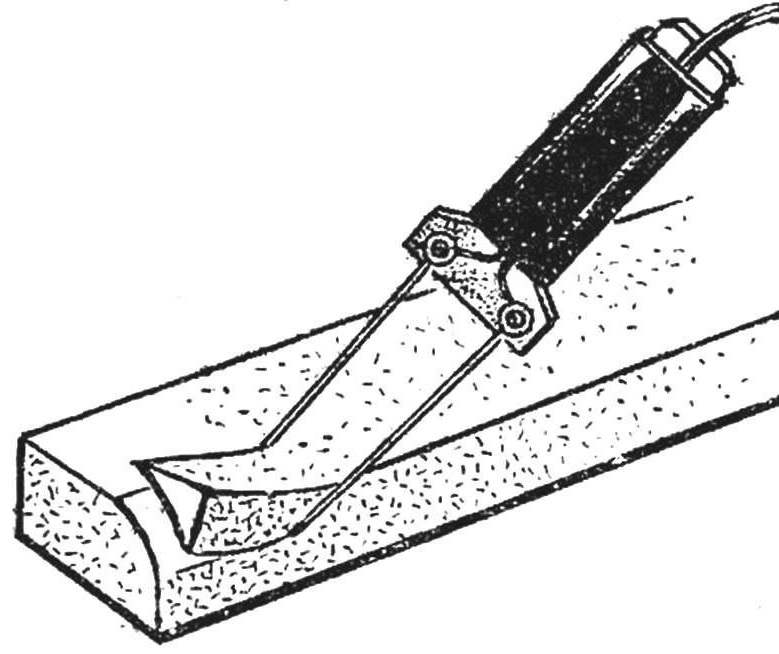

If you have a rectifier for charging automobile batteries, a step-down transformer or Latr you will be able to make thermoresin cutting foam. The cutting

If you have a rectifier for charging automobile batteries, a step-down transformer or Latr you will be able to make thermoresin cutting foam. The cutting

Until recently, this metal and Assembly tool for screwing-unscrewing small fasteners and understand that special needs were not. Every Amateur designer or a mechanic, vehicle enthusiast, having in the Arsenal of his Studio a couple of sets of screwdrivers (under “slot” and by “cross”), they completely and treated. Head of cogs, bolts, screws in various household tools, appliances and even cars of domestic production, too, had, respectively, either slotted or Phillips working the nest.

Until recently, this metal and Assembly tool for screwing-unscrewing small fasteners and understand that special needs were not. Every Amateur designer or a mechanic, vehicle enthusiast, having in the Arsenal of his Studio a couple of sets of screwdrivers (under “slot” and by “cross”), they completely and treated. Head of cogs, bolts, screws in various household tools, appliances and even cars of domestic production, too, had, respectively, either slotted or Phillips working the nest.

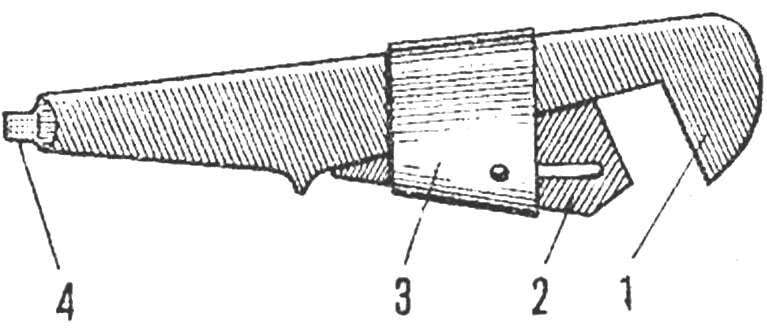

No, of course not with fire, as fire with fire as the saying goes, and… turn away. Because the wedge as the main element included in the design of the unusual wrench proposed Nikolaev innovators. The originality of the tool lies in the fact that in contrast to the known devices there are no grooves, rods, worms, axles. The key is extremely simple, reliable, very easy to use.

No, of course not with fire, as fire with fire as the saying goes, and… turn away. Because the wedge as the main element included in the design of the unusual wrench proposed Nikolaev innovators. The originality of the tool lies in the fact that in contrast to the known devices there are no grooves, rods, worms, axles. The key is extremely simple, reliable, very easy to use.

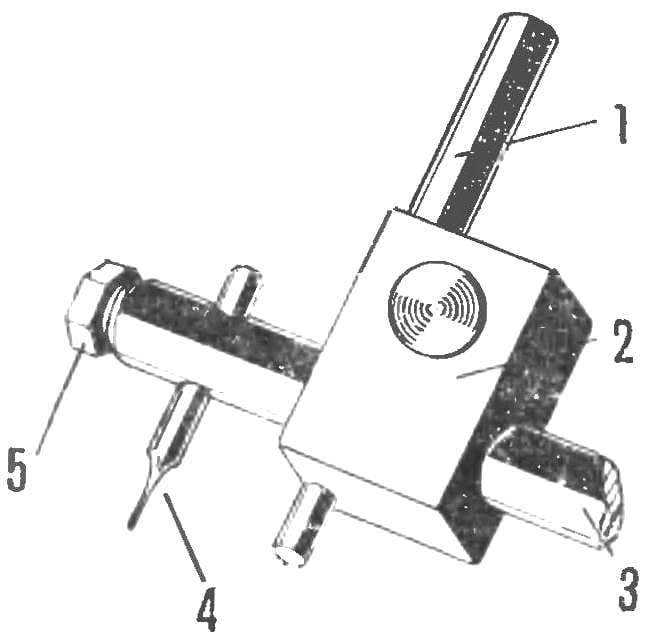

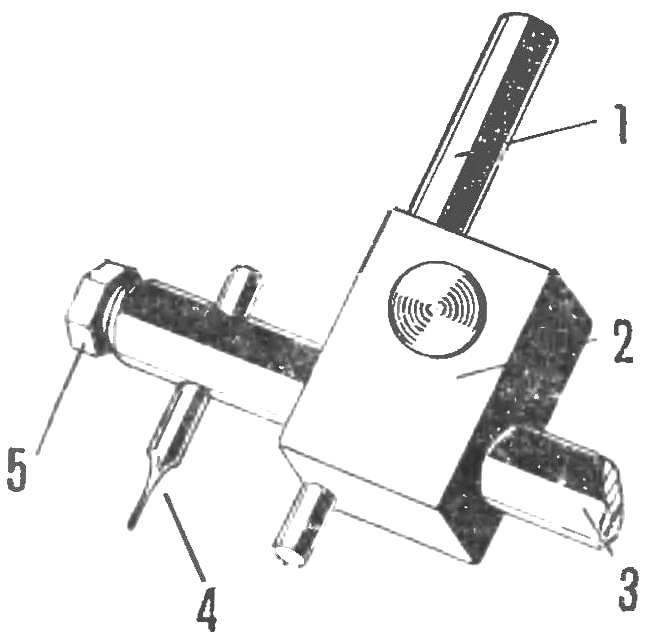

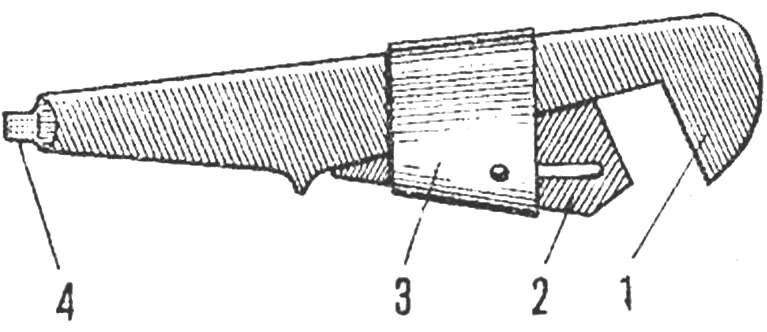

They look close to the “classic” scheme: have a body and a fixed jaw, a screw that moves the movable jaw, lugs for attaching to the workplace. But for all its similarity to conventional new grip thanks to the clever solution of their design has acquired much greater opportunities, become universal. The main feature of the original clamping device, developed by Turner M. Babichev, Vitebsk machine-tool plant named after Comintern is movable sponge: it is made in the form of rotary drum. In other details the innovator has made the changes.

They look close to the “classic” scheme: have a body and a fixed jaw, a screw that moves the movable jaw, lugs for attaching to the workplace. But for all its similarity to conventional new grip thanks to the clever solution of their design has acquired much greater opportunities, become universal. The main feature of the original clamping device, developed by Turner M. Babichev, Vitebsk machine-tool plant named after Comintern is movable sponge: it is made in the form of rotary drum. In other details the innovator has made the changes.

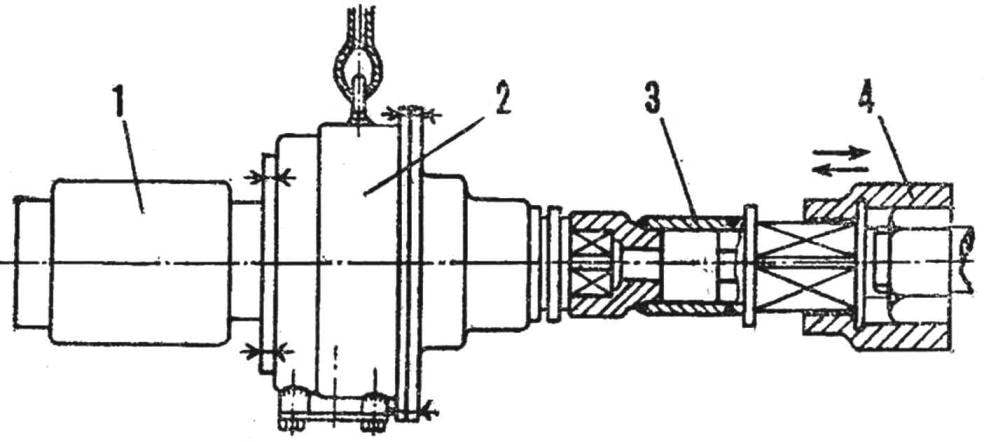

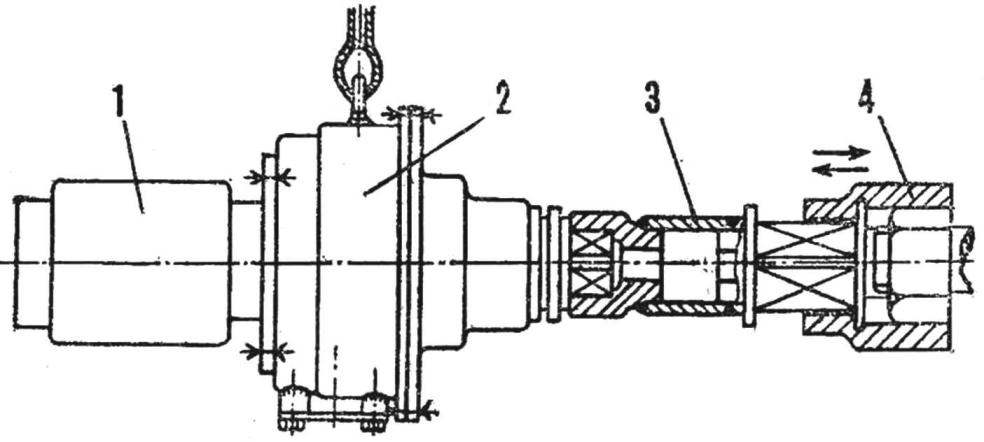

For modern engineering and many other sectors of the economy it’s not uncommon for such large structures, in which the Assembly or disassembly of powerful bolting already exempt from the ordinary hand tools or power one working. That’s why the innovators of Novo-Gorkovsky oil refinery created a powerful Electromechanical wrench. It is a two-stage planetary gear associated with seriesname DC motor with a power of 0.9—1.0 kW. The torque transmitted to them at the nut is 825 KGM.

For modern engineering and many other sectors of the economy it’s not uncommon for such large structures, in which the Assembly or disassembly of powerful bolting already exempt from the ordinary hand tools or power one working. That’s why the innovators of Novo-Gorkovsky oil refinery created a powerful Electromechanical wrench. It is a two-stage planetary gear associated with seriesname DC motor with a power of 0.9—1.0 kW. The torque transmitted to them at the nut is 825 KGM.