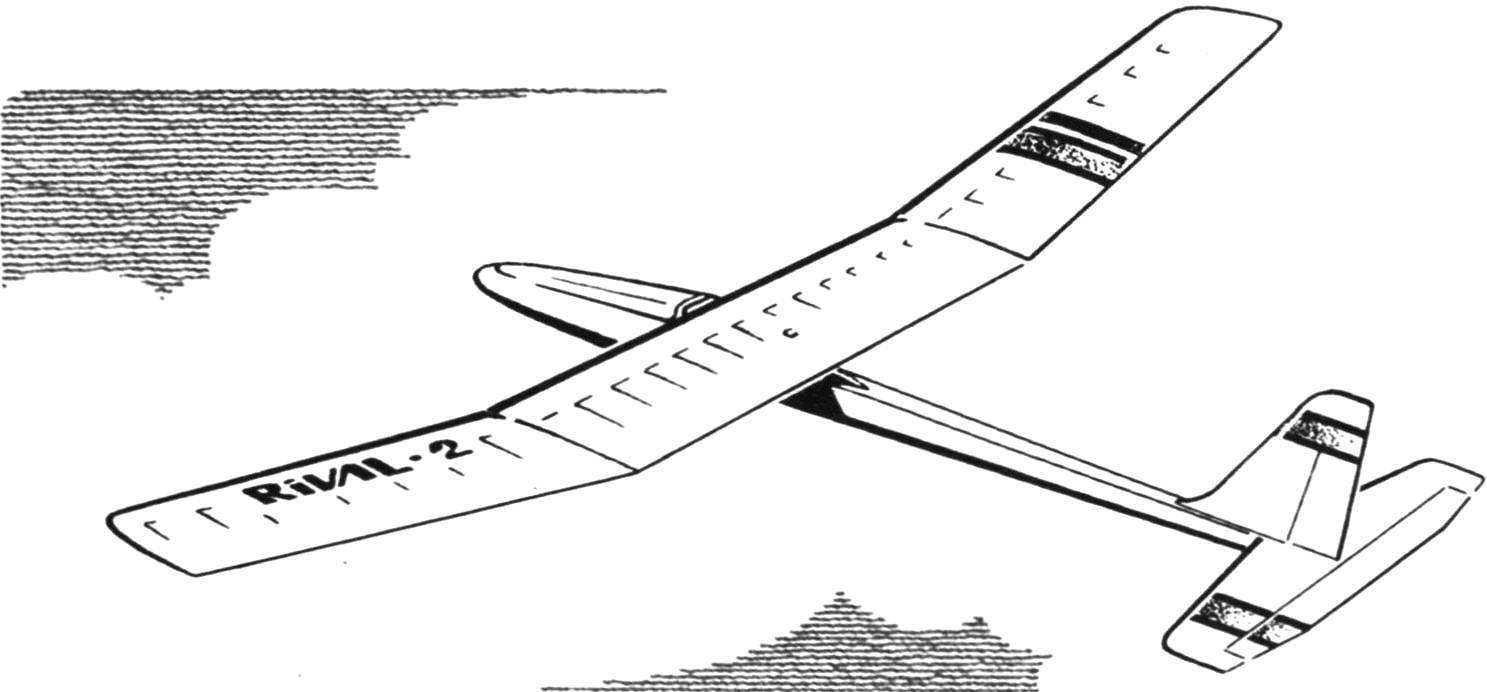

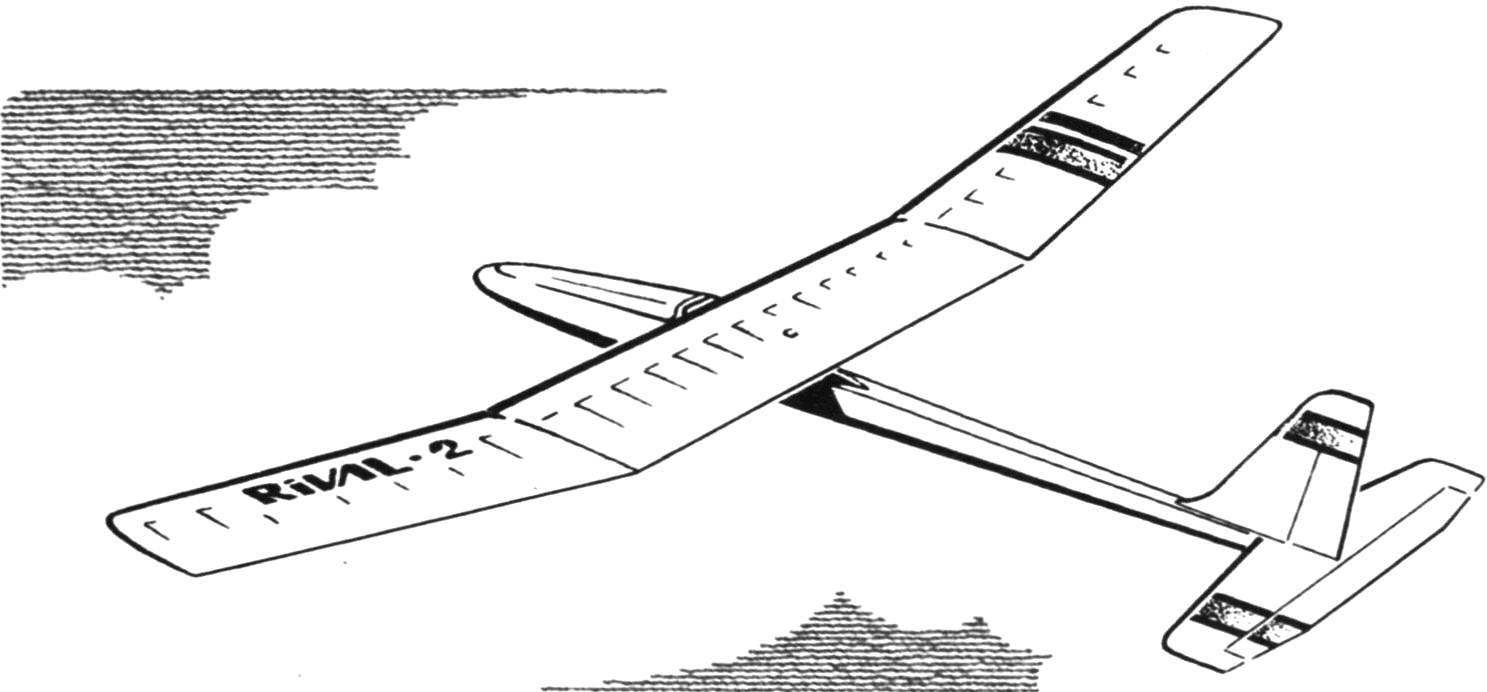

Unfortunately, in Russia, still little known very interesting and popular abroad, the subclass of radio-controlled gliders, the name of which in translation from most foreign languages sound like “throwing the glider”.

Unfortunately, in Russia, still little known very interesting and popular abroad, the subclass of radio-controlled gliders, the name of which in translation from most foreign languages sound like “throwing the glider”.

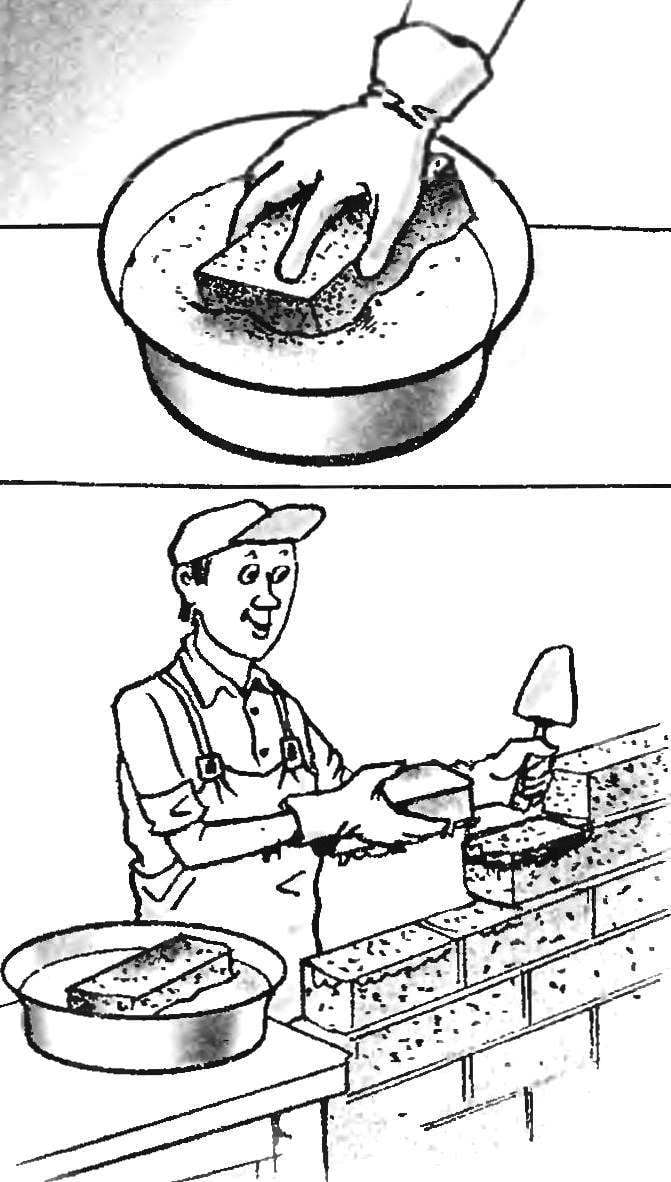

BATH BRICK

When performing masonry for good adhesion of the bricks with a solution good the contact surface of the pre – “primed”—to immerse at least for a few seconds in the previously prepared cement milk. GLUKHOV, Saransk

PAN… WITH BLUE SCREEN

In the design of devices and equipment before the radio often question about their design: sometimes they place boards and panels of their devices in boxes that slides, fishing gear and other containers. Ham D. Plewinski offers as buildings to use more modern products — cases videokasset: they have a low cost; plastic from which they are made, can be easily processed.

In the design of devices and equipment before the radio often question about their design: sometimes they place boards and panels of their devices in boxes that slides, fishing gear and other containers. Ham D. Plewinski offers as buildings to use more modern products — cases videokasset: they have a low cost; plastic from which they are made, can be easily processed.THE MYSTERY OF THE STUBBORN BOLT

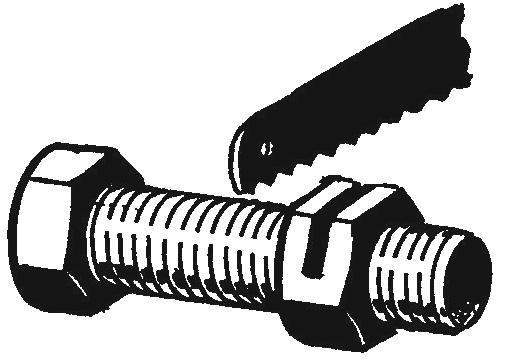

To the two parts worked as a whole — they should be connected to. Where possible, use bonding, soldering or welding, but all these options are permanent fixtures. And here is the bolt to nut connection is universal: he is subject to any material, and if necessary disconnect them tight elements of the design — this fixture is easy to Unscrew. However, such a connection provides the necessary resistance only when the bonded parts are inactive; and in the event of impact, for example, vibration can fail because of such insidious phenomena as samothracian.

To the two parts worked as a whole — they should be connected to. Where possible, use bonding, soldering or welding, but all these options are permanent fixtures. And here is the bolt to nut connection is universal: he is subject to any material, and if necessary disconnect them tight elements of the design — this fixture is easy to Unscrew. However, such a connection provides the necessary resistance only when the bonded parts are inactive; and in the event of impact, for example, vibration can fail because of such insidious phenomena as samothracian.

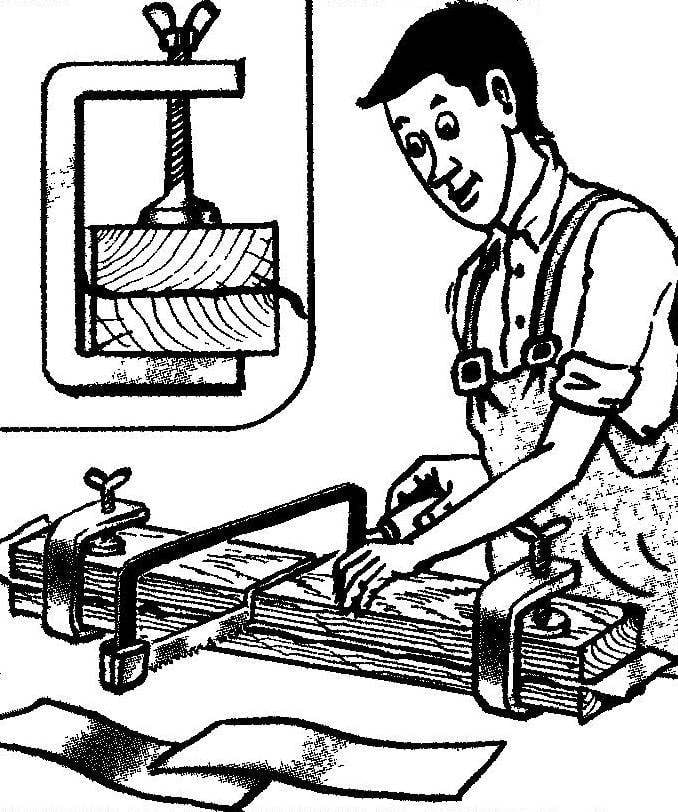

“SANDWICH” FOR THE SAW

If you want to cut thin metal band, and needed the scissors at hand — rescue a hacksaw. However, to use it, not scoreif fragile metal, it is necessary to resort to the simple device. Stripe is embedded between two wooden bars and clamped two clamps. Now you can safely cut a “sandwich” — section Read more…

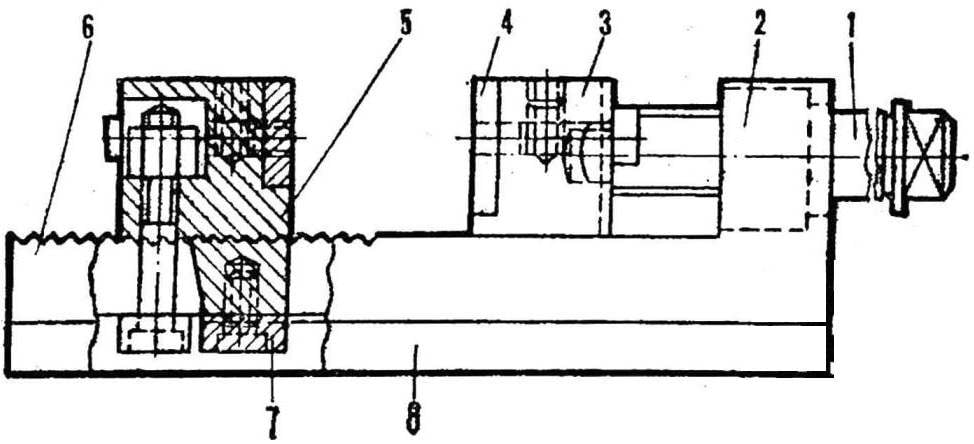

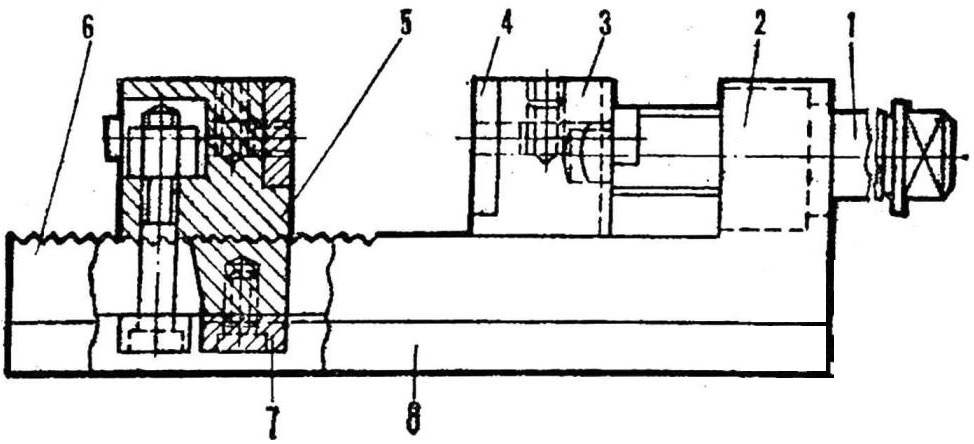

THE VISE ON THE MACHINE

It would seem that this device has already acquired a classical form; in any case, each representation there is a tool with movable and stationary jaws, and a screw feed. However, innovators are creating new kinds: specific and universal. That’s the job of the innovator K. Malkova (Leningrad plant conveying systems named after S. M. Kirov). His grip is possible, first, to simultaneously process multiple parts. Secondly, they are easy to attach versatile-modular fixtures. Finally, the vise can be used for installation on the drilling machine to facilitate the clamping of large parts.

It would seem that this device has already acquired a classical form; in any case, each representation there is a tool with movable and stationary jaws, and a screw feed. However, innovators are creating new kinds: specific and universal. That’s the job of the innovator K. Malkova (Leningrad plant conveying systems named after S. M. Kirov). His grip is possible, first, to simultaneously process multiple parts. Secondly, they are easy to attach versatile-modular fixtures. Finally, the vise can be used for installation on the drilling machine to facilitate the clamping of large parts.BAG GARDENER

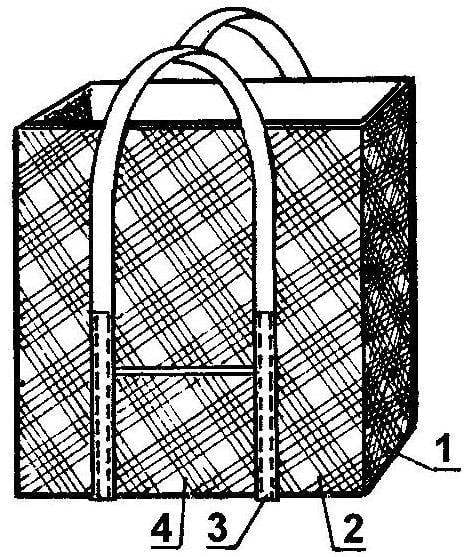

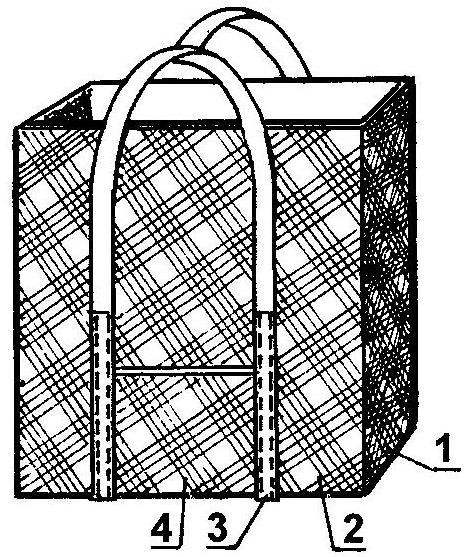

If you still have segments of a durable fabric, you can sew a voluminous shopping bag—for example, work in the garden. Two identical rectangle of fabric on three sides are connected by one long, narrow flap—rectangular shapes. Get the product, having the form of a box without a lid.

If you still have segments of a durable fabric, you can sew a voluminous shopping bag—for example, work in the garden. Two identical rectangle of fabric on three sides are connected by one long, narrow flap—rectangular shapes. Get the product, having the form of a box without a lid.

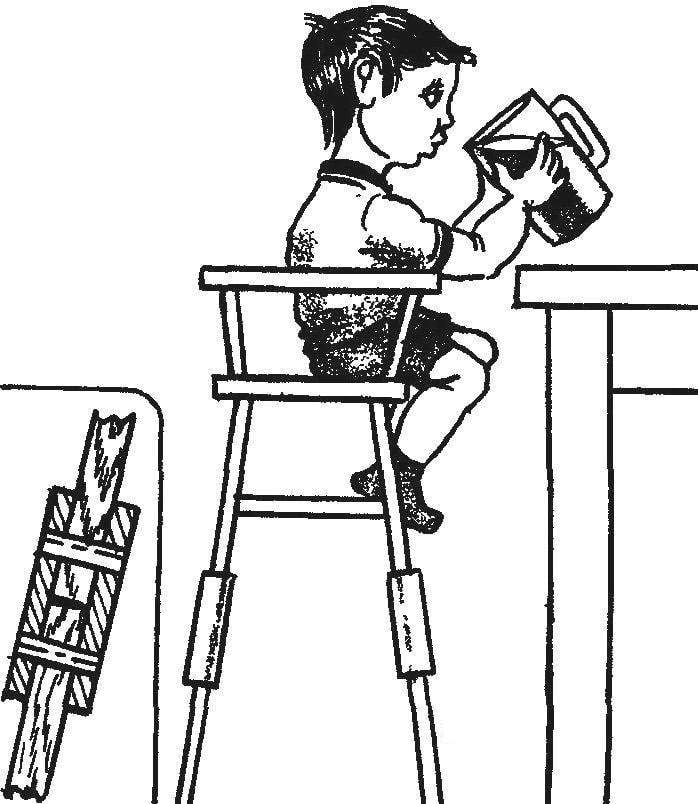

A BABY SEAT

Child loves to sit with the adults at one table. Make it personal “chair”, it’s easy. Take a chair and extends his legs with wooden rods and metal sleeves from scraps of pipe of suitable diameter. This chair will last baby a long time: as it grows the insert can be shortened accordingly.

LITTLE POWERHOUSE

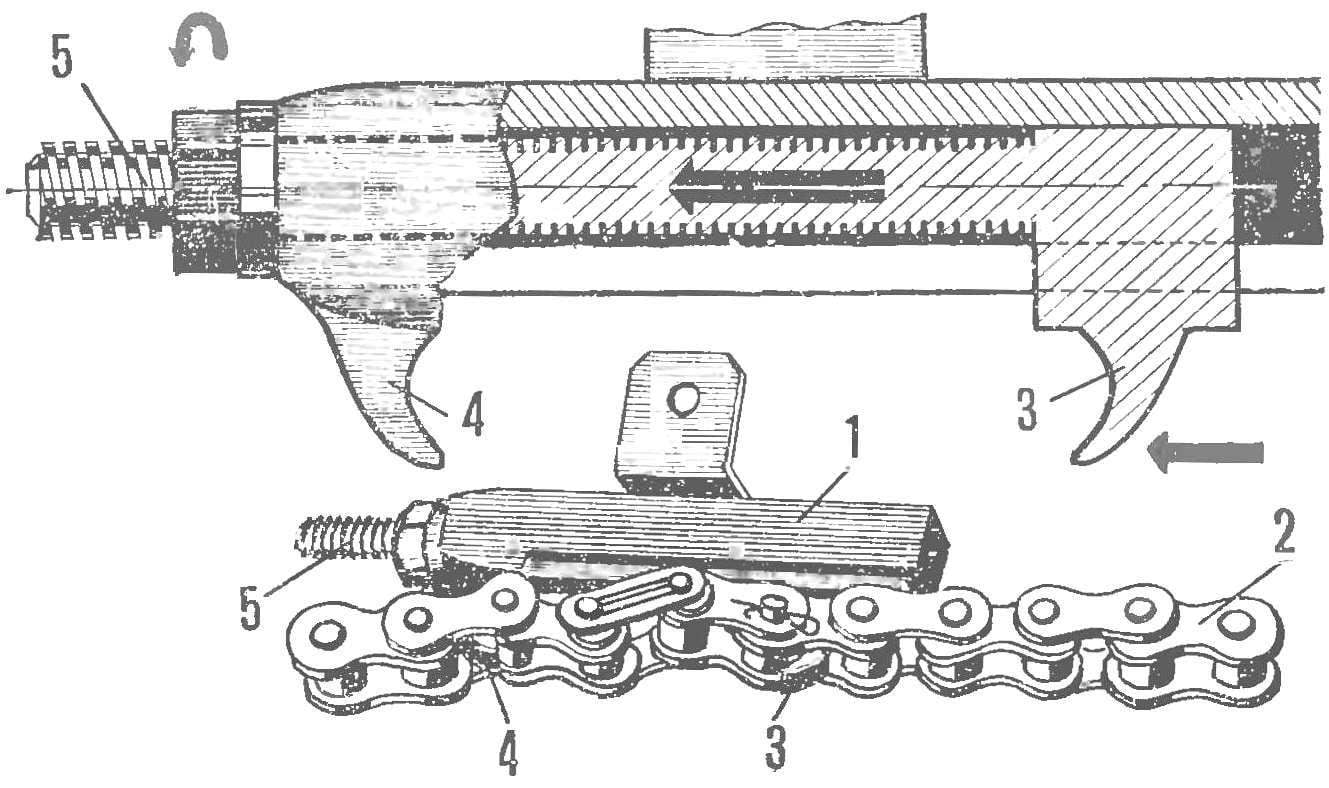

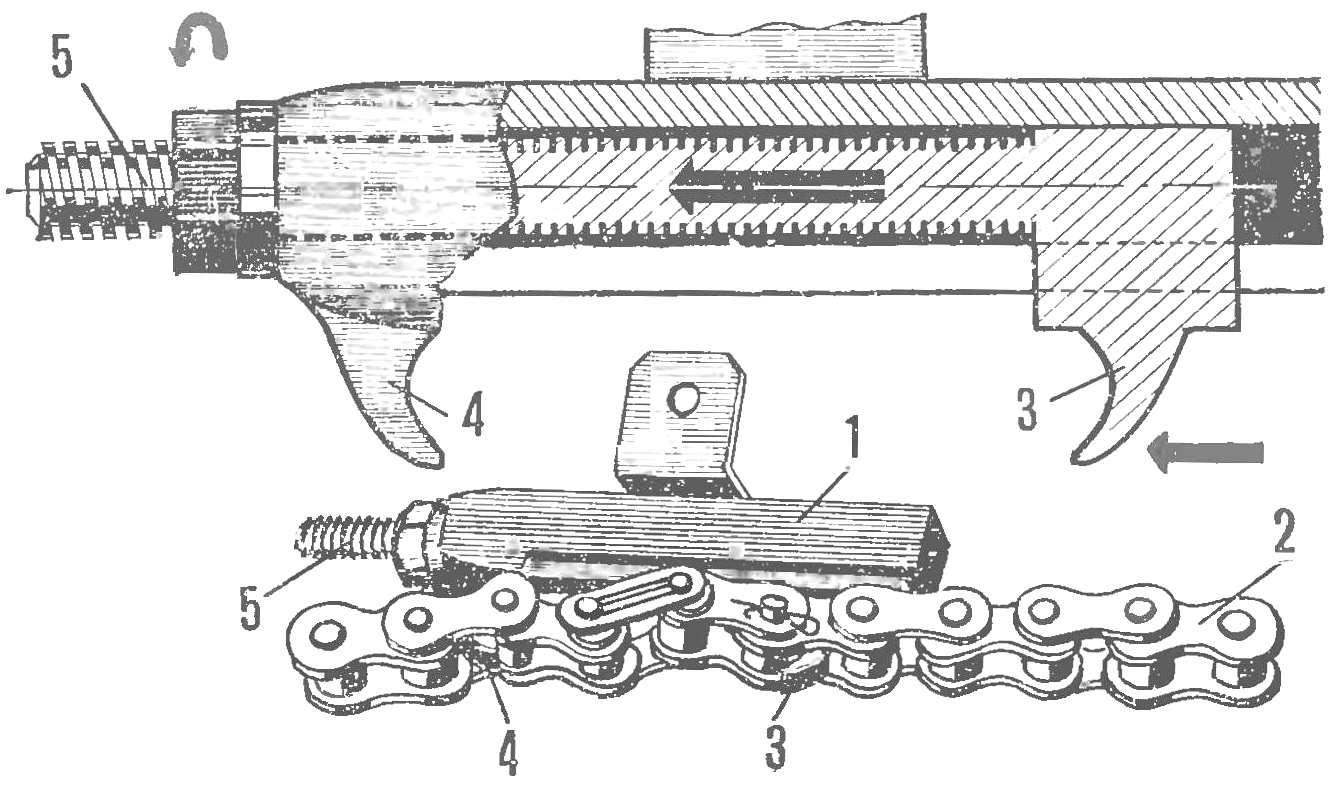

A variety of roller chain, like a Bicycle or a motorcycle, are used on many machines, including most agricultural units. With their Assembly during the repair of machines of great assistance can provide a simple tool offered by pioneer A. Yurchenko (see figure).

A variety of roller chain, like a Bicycle or a motorcycle, are used on many machines, including most agricultural units. With their Assembly during the repair of machines of great assistance can provide a simple tool offered by pioneer A. Yurchenko (see figure).

STEP… IN THE CLOSET

1. In order to achieve maximum capacity of the height of the majority of cases—a Lee, book or kitchen—use as a rule, taller than a man. To get something lying at the top, you have to resort to using ladders or to substitute other AIDS type of stool that is not always safe.

1. In order to achieve maximum capacity of the height of the majority of cases—a Lee, book or kitchen—use as a rule, taller than a man. To get something lying at the top, you have to resort to using ladders or to substitute other AIDS type of stool that is not always safe.