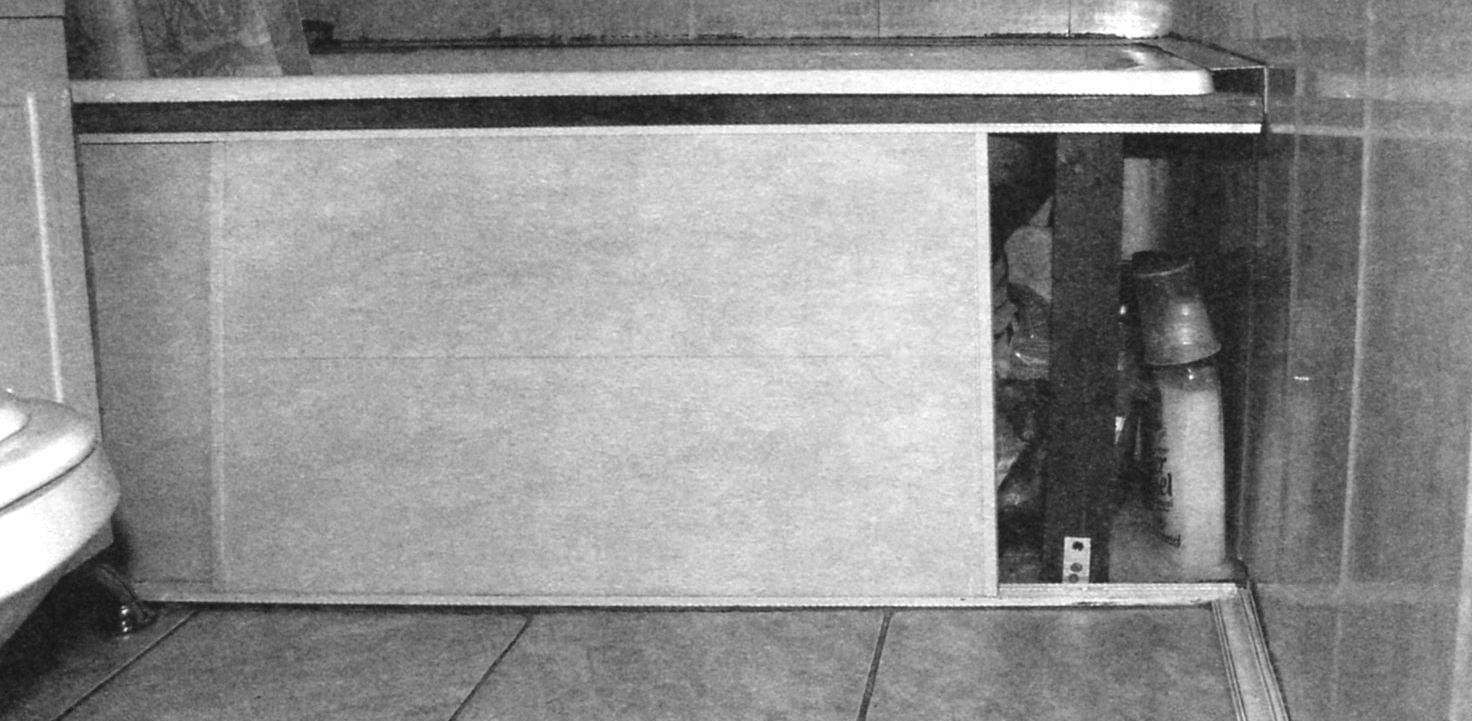

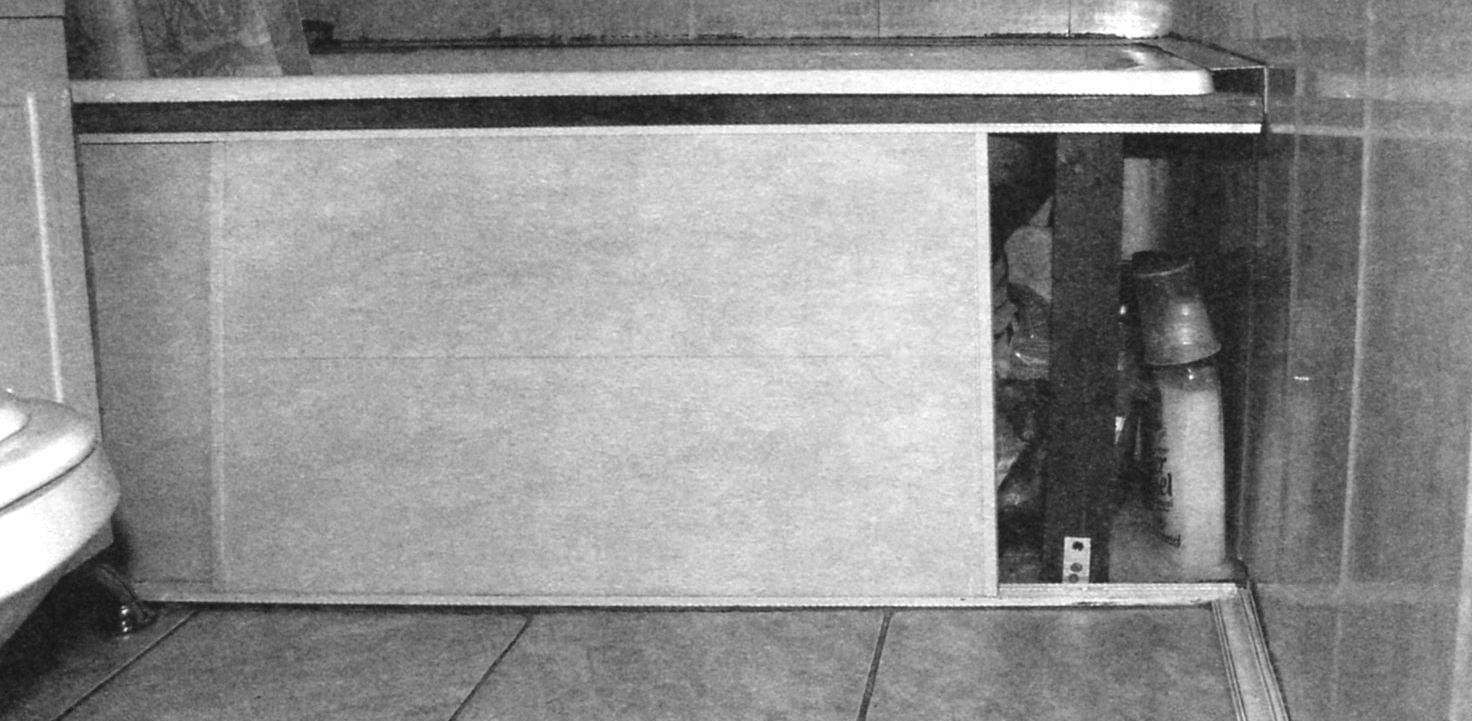

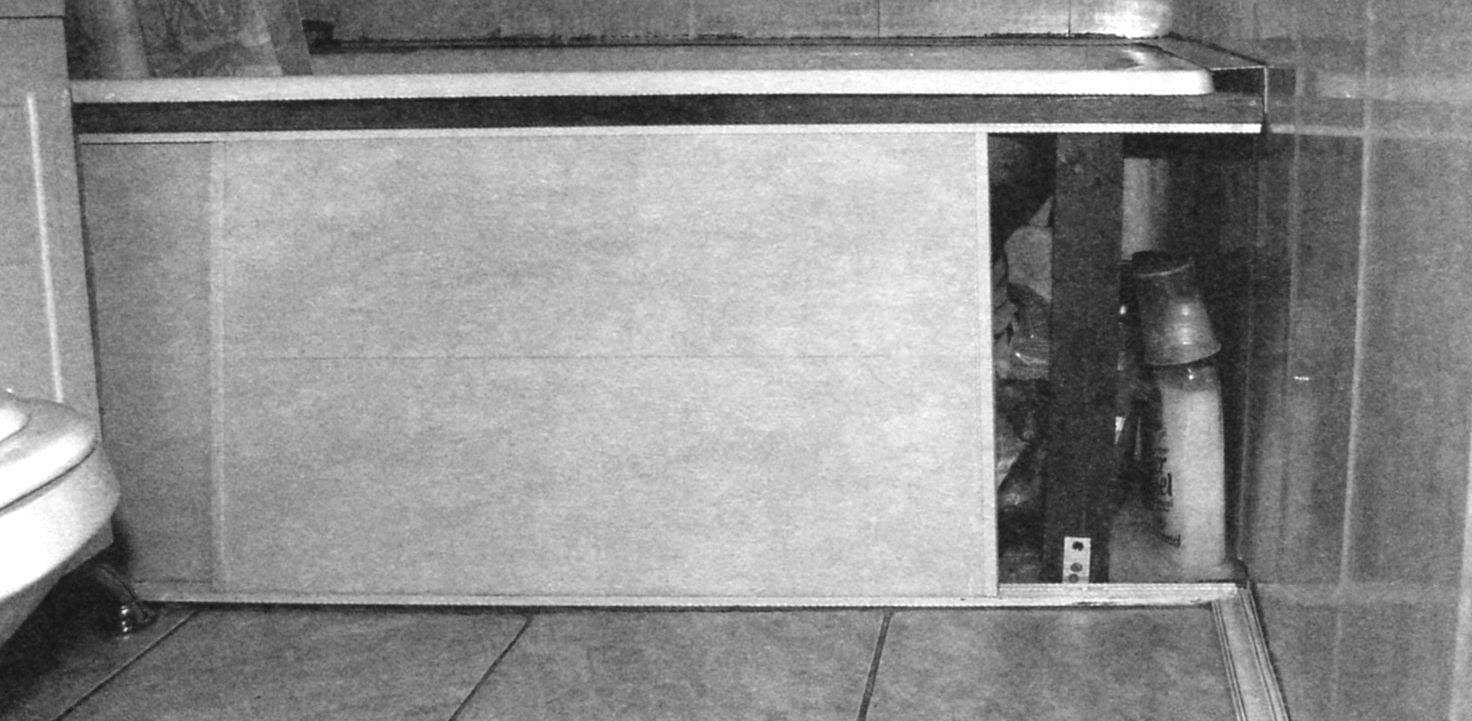

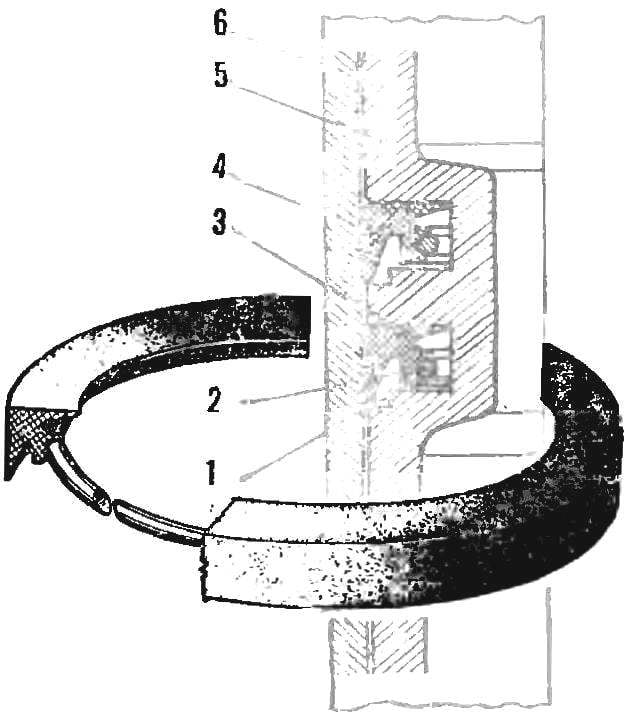

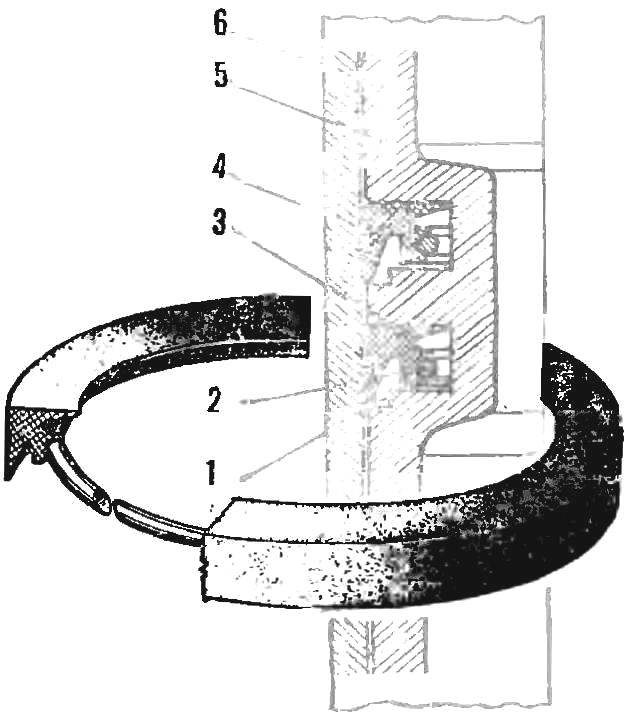

A true master of creativity will suffice even in the bathroom. If your intention is to close the bottom of the bath screen – not in a hurry for him to shop. It’s a simple device if you want you can do it yourself. What matters is that you had minimal DIY skills and the desire to spend a few hours of free time. However, in this case, you do not get to do without going to the store and extra expenses but something can still be saved.

A true master of creativity will suffice even in the bathroom. If your intention is to close the bottom of the bath screen – not in a hurry for him to shop. It’s a simple device if you want you can do it yourself. What matters is that you had minimal DIY skills and the desire to spend a few hours of free time. However, in this case, you do not get to do without going to the store and extra expenses but something can still be saved.SCREEN FOR BATH

A true master of creativity will suffice even in the bathroom. If your intention is to close the bottom of the bath screen – not in a hurry for him to shop. It’s a simple device if you want you can do it yourself. What matters is that you had minimal DIY skills and the desire to spend a few hours of free time. However, in this case, you do not get to do without going to the store and extra expenses but something can still be saved.

A true master of creativity will suffice even in the bathroom. If your intention is to close the bottom of the bath screen – not in a hurry for him to shop. It’s a simple device if you want you can do it yourself. What matters is that you had minimal DIY skills and the desire to spend a few hours of free time. However, in this case, you do not get to do without going to the store and extra expenses but something can still be saved.

How to make the electrolyte alkaline batteries? What are components, what should be the charging current, how long to charge? Electrolyte — aqueous solution of potassium hydroxide with a density of 1,19 — 1,21 g/cm3 with the addition of 20±1 g/l of lithium hydroxide monohydrate (Li0Н.H20). (This corresponds to GOST 9285-59. At -20±1°C or -40±1°C batteries should work for an aqueous solution of potassium hydroxide with a density of 1.26 — 1.28 g/cm3 without addition of lithium hydroxide.)

How to make the electrolyte alkaline batteries? What are components, what should be the charging current, how long to charge? Electrolyte — aqueous solution of potassium hydroxide with a density of 1,19 — 1,21 g/cm3 with the addition of 20±1 g/l of lithium hydroxide monohydrate (Li0Н.H20). (This corresponds to GOST 9285-59. At -20±1°C or -40±1°C batteries should work for an aqueous solution of potassium hydroxide with a density of 1.26 — 1.28 g/cm3 without addition of lithium hydroxide.)

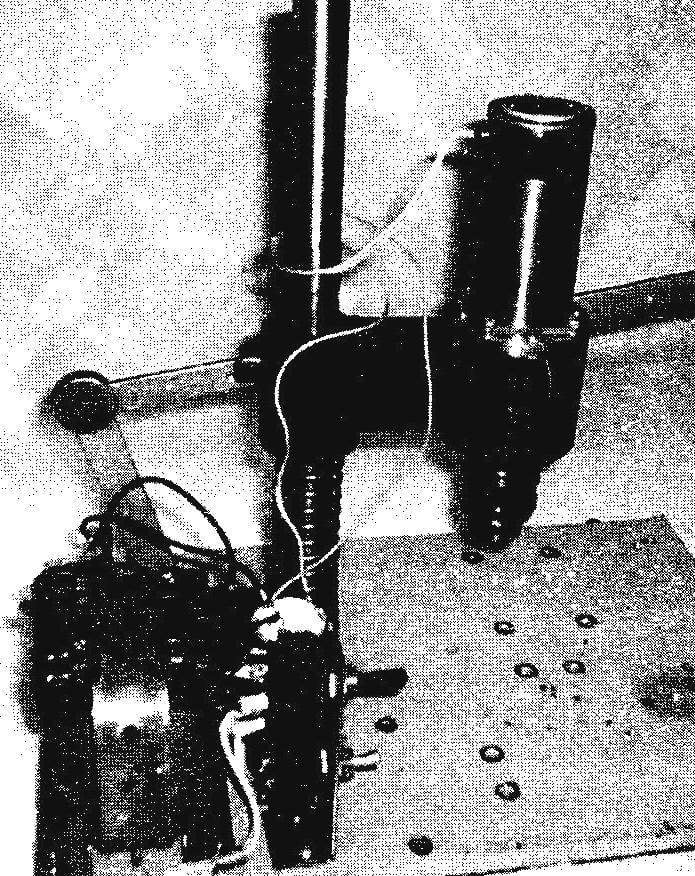

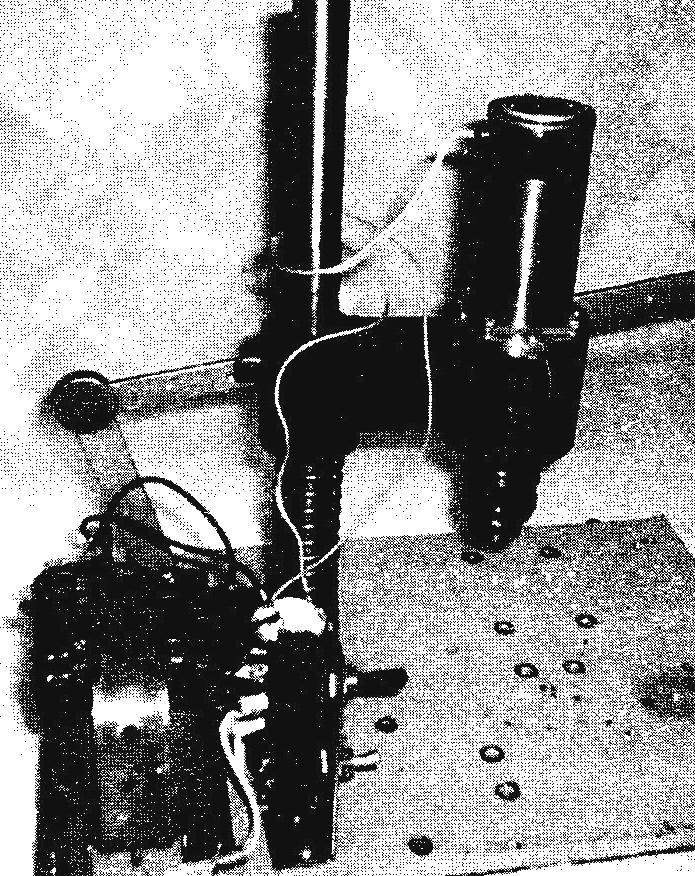

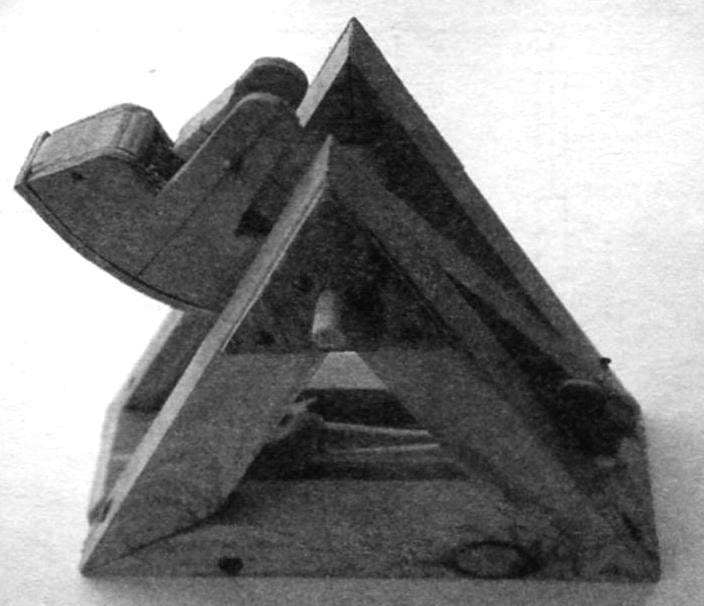

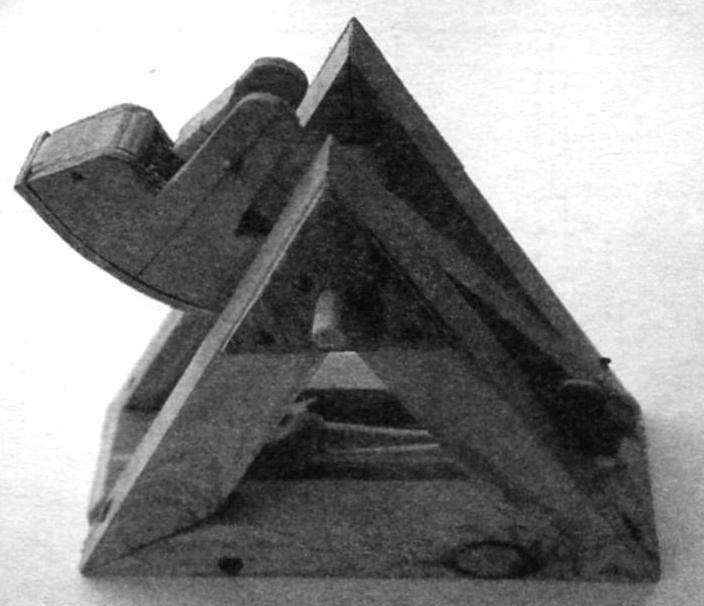

When faced with the need to drill numerous fine holes in printed circuit boards for electronic devices, it was found that a power drill in this case is not such a good assistant she is loud, and the power of it excessive. Then decided to make a small tabletop drill press is more suitable for such work. The present machine has a small size, low power consumption and, importantly, virtually silent — you can work even when all the household slept. And drilling the holes with diameter from 1 to 6 mm permissible even in aluminum workpieces.

When faced with the need to drill numerous fine holes in printed circuit boards for electronic devices, it was found that a power drill in this case is not such a good assistant she is loud, and the power of it excessive. Then decided to make a small tabletop drill press is more suitable for such work. The present machine has a small size, low power consumption and, importantly, virtually silent — you can work even when all the household slept. And drilling the holes with diameter from 1 to 6 mm permissible even in aluminum workpieces.

Many of us have been fascinated by the exploits of Ivanhoe, Lancelot, read about the struggle and death of evpatii Kolovrat, admired the stories of John. P. P. Tolkien. These interests were awakened the interest in the distant past, gathered like-minded people and dreamers in the clubs history and reconstruction.

Many of us have been fascinated by the exploits of Ivanhoe, Lancelot, read about the struggle and death of evpatii Kolovrat, admired the stories of John. P. P. Tolkien. These interests were awakened the interest in the distant past, gathered like-minded people and dreamers in the clubs history and reconstruction.

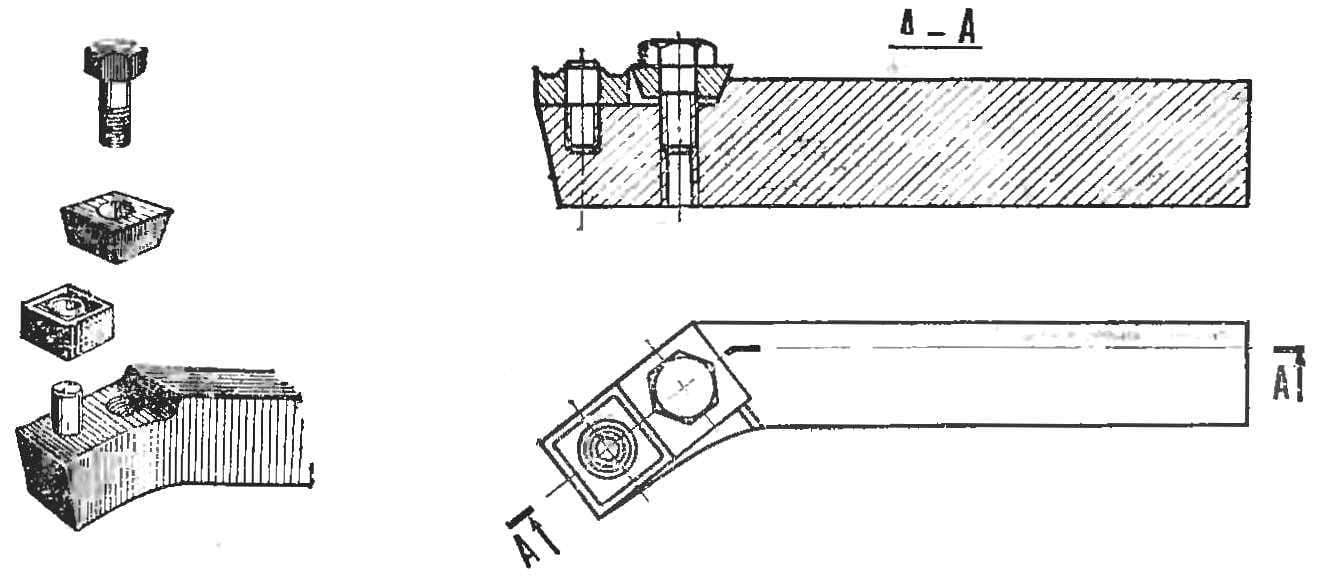

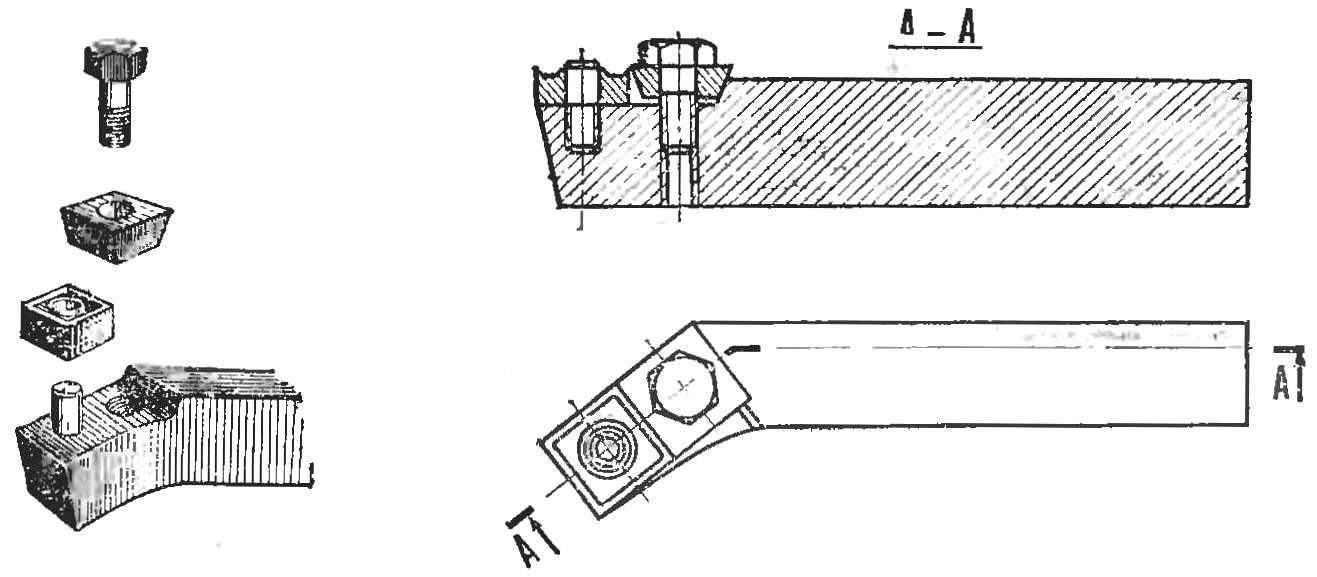

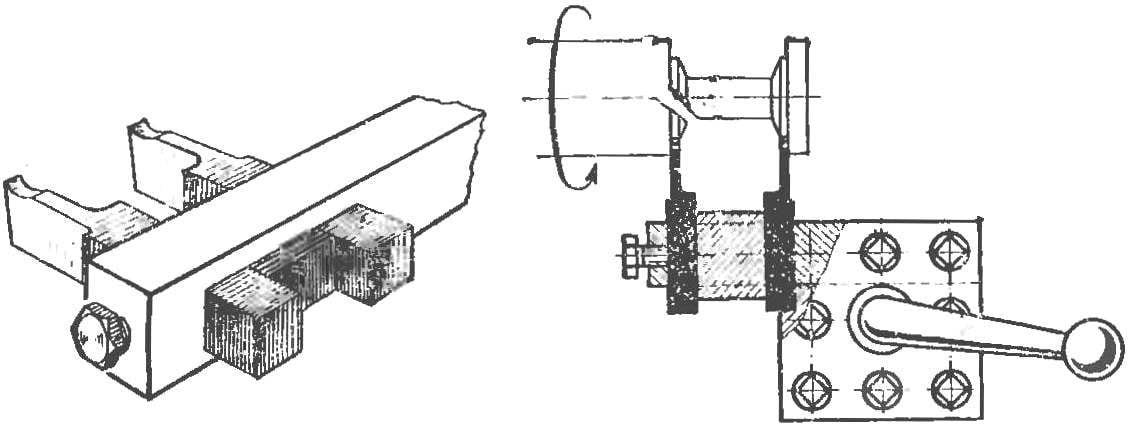

Rationalization proposal Lyubertsy student of secondary school № 42 of Yuri Furmanov. How to ensure all novice turners cutters? Almost every school workshop this problem exists. The HSS tools quickly become dull and break in inexperienced hands boys, standard tool holders with brazed them on the plates from hard alloys are not suitable for school machines high. The same applies to the most affordable cutters with exchangeable sintered plate (durable, able to withstand the most critical conditions).

Rationalization proposal Lyubertsy student of secondary school № 42 of Yuri Furmanov. How to ensure all novice turners cutters? Almost every school workshop this problem exists. The HSS tools quickly become dull and break in inexperienced hands boys, standard tool holders with brazed them on the plates from hard alloys are not suitable for school machines high. The same applies to the most affordable cutters with exchangeable sintered plate (durable, able to withstand the most critical conditions).

The compressor is one of the machines, which are frequently encountered in various production areas. Among the vulnerable sites that require durability and long remained a piston ring. It wear led to the deterioration of integrity, performance and efficiency of the unit.

The compressor is one of the machines, which are frequently encountered in various production areas. Among the vulnerable sites that require durability and long remained a piston ring. It wear led to the deterioration of integrity, performance and efficiency of the unit.

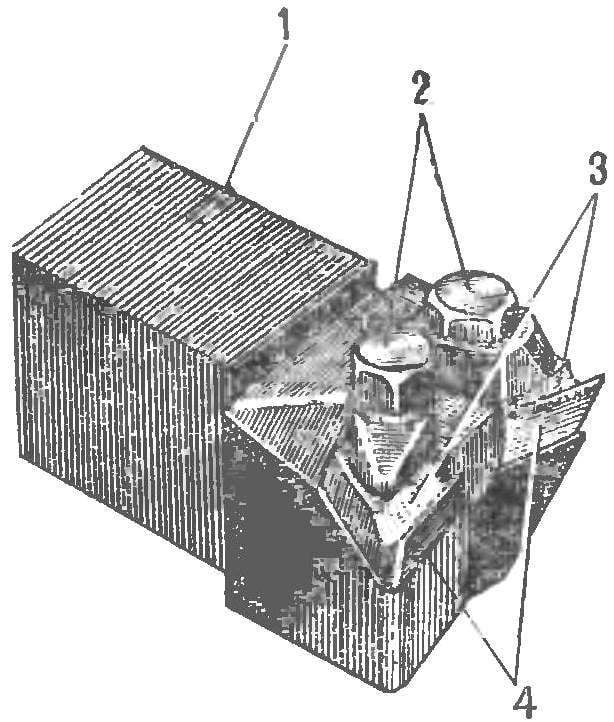

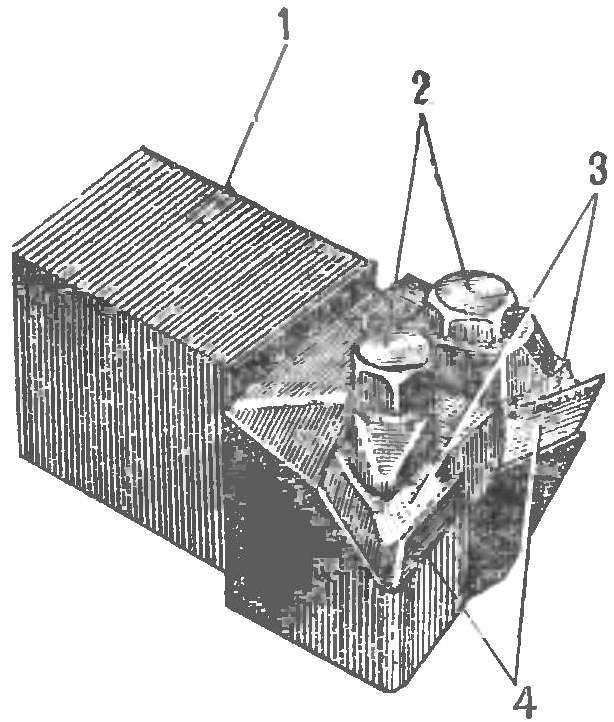

Remember PushPull fabulous animal which could jump not only forward but also backward, because instead of a tail he had a second head? About it can not help reminiscent of the original bilateral cutter, manufactured by the innovators of the Gorky machine-tool production Association. Tool on a conventional tool holder has two cutting inserts mounted on carbide lining and is mounted to the top clamps. Under the clamps located struzhkolomy.

Remember PushPull fabulous animal which could jump not only forward but also backward, because instead of a tail he had a second head? About it can not help reminiscent of the original bilateral cutter, manufactured by the innovators of the Gorky machine-tool production Association. Tool on a conventional tool holder has two cutting inserts mounted on carbide lining and is mounted to the top clamps. Under the clamps located struzhkolomy.

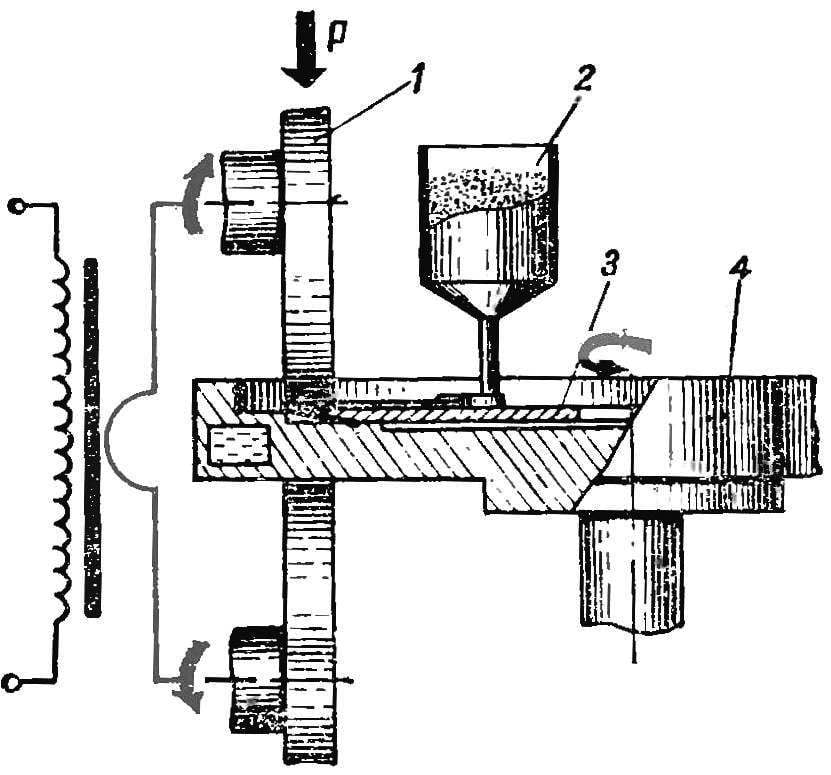

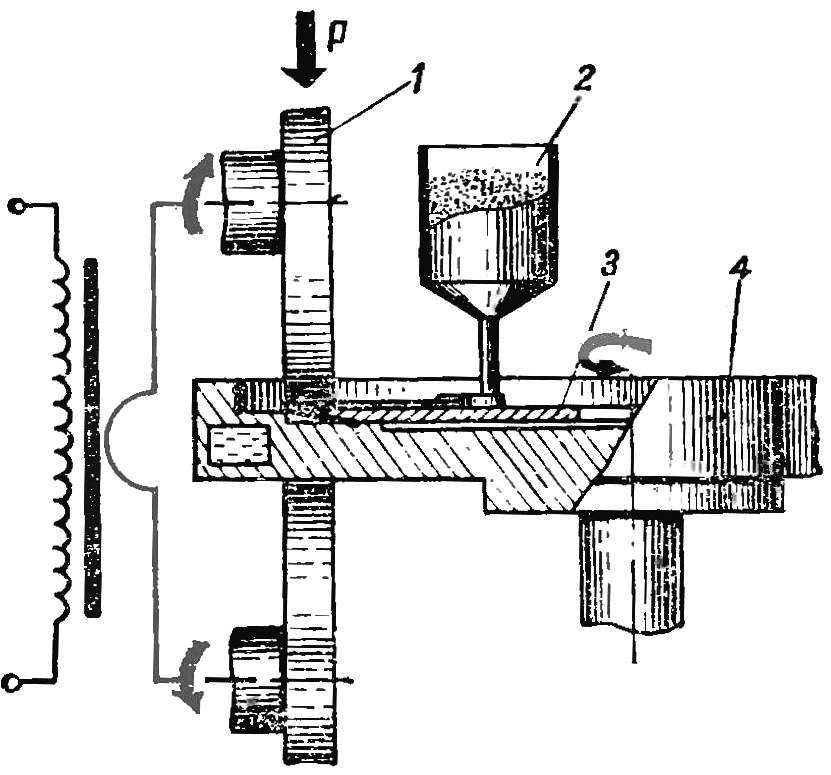

From circular knives, no matter where they worked in agricultural units, in the fields or in industrial plants, — wear out really fast sharp working edge. Therefore, innovators tend to find the most effective method of restoring the load of the tool.

From circular knives, no matter where they worked in agricultural units, in the fields or in industrial plants, — wear out really fast sharp working edge. Therefore, innovators tend to find the most effective method of restoring the load of the tool.