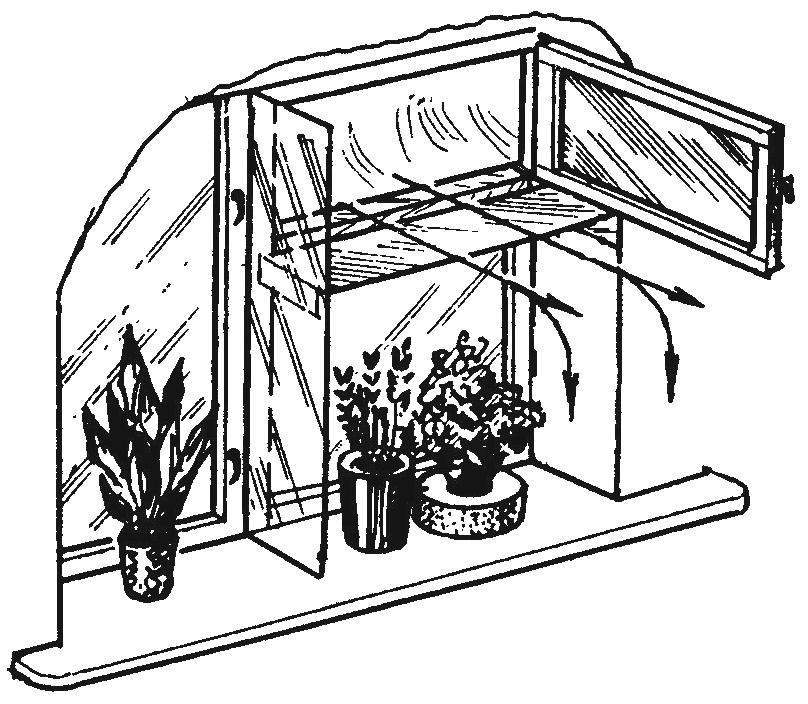

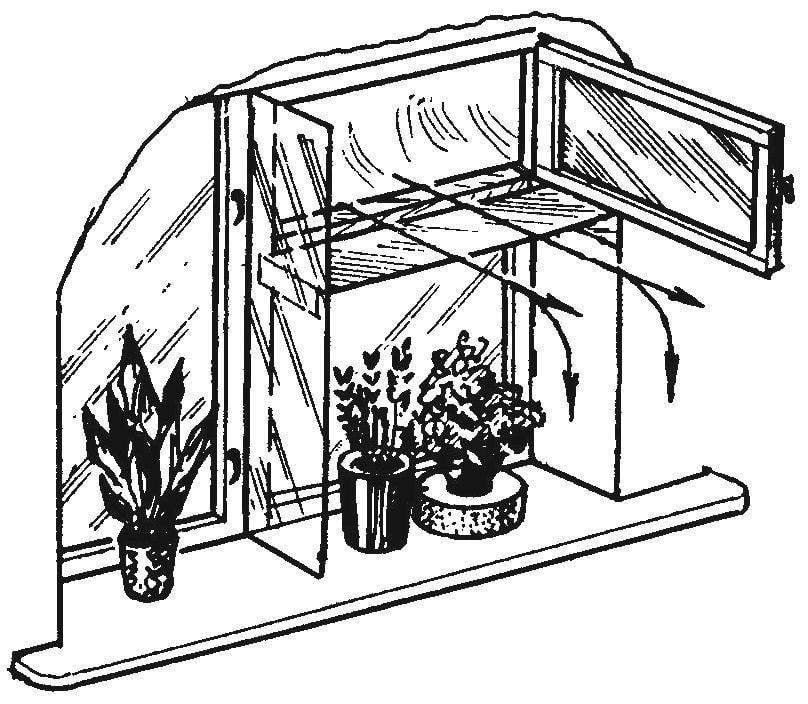

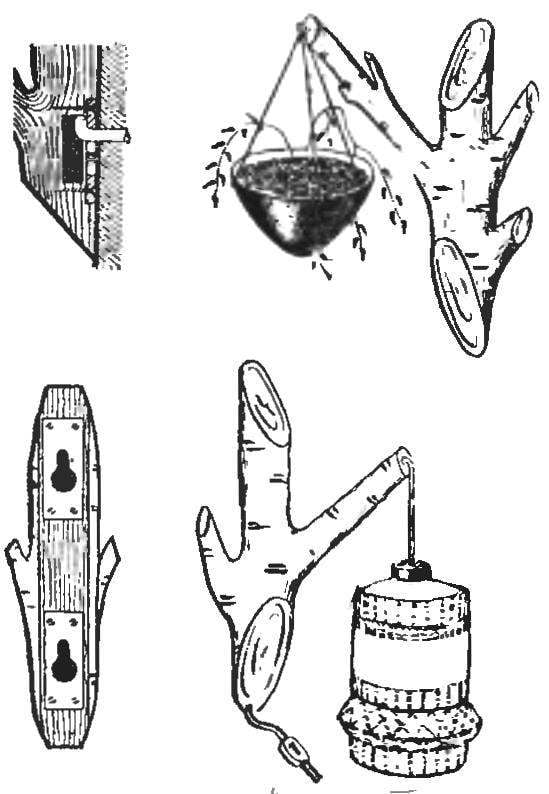

Lovers flowers it is customary to set the pots with ornamental plants directly on the Windows: they are placed on the window sills, so the greens were closer to sources of natural light. However, in the winter when airing the room, the flowers due to cold air can be supercooled. This entails they, like all living organisms, various diseases.

Lovers flowers it is customary to set the pots with ornamental plants directly on the Windows: they are placed on the window sills, so the greens were closer to sources of natural light. However, in the winter when airing the room, the flowers due to cold air can be supercooled. This entails they, like all living organisms, various diseases.PAINTING THE FRAME, WITHOUT STAINING THE GLASS

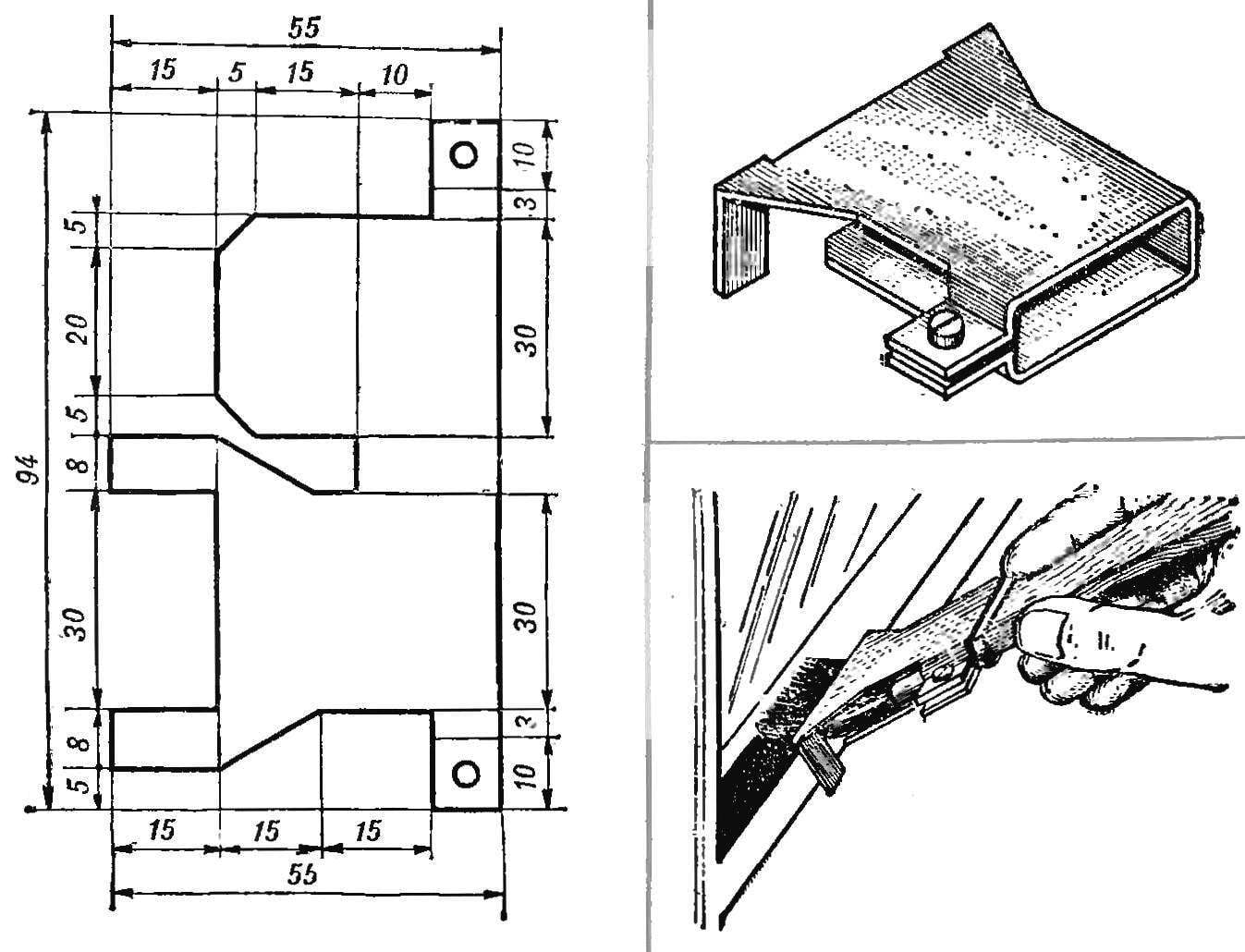

help here’s a basic clamp, cut and bent from aluminium sheet 1.5 mm thick.

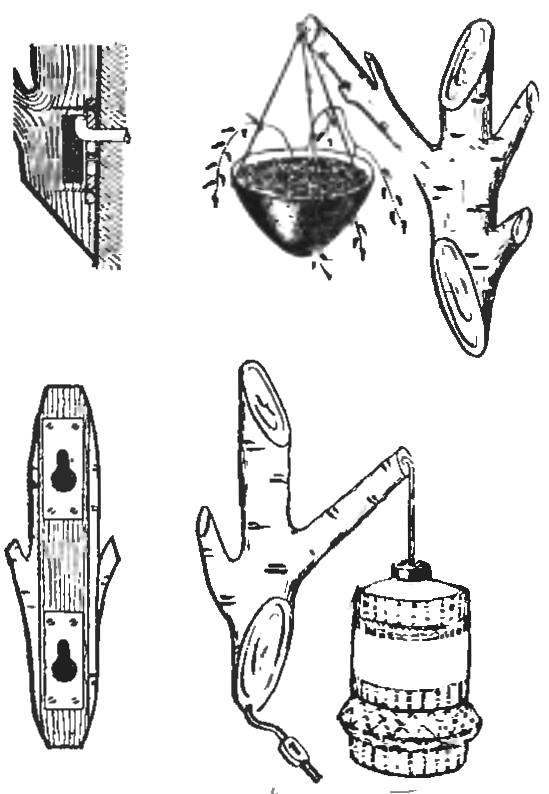

for hanging planters or ceiling can be made of a suitable wood bitch. To strengthen it on the wall, should be treated with a planed one side bitch and screwed to it with screws two metal plates with holes of type “keyhole”. Put this bracket on two crutches or a screw.

for hanging planters or ceiling can be made of a suitable wood bitch. To strengthen it on the wall, should be treated with a planed one side bitch and screwed to it with screws two metal plates with holes of type “keyhole”. Put this bracket on two crutches or a screw.

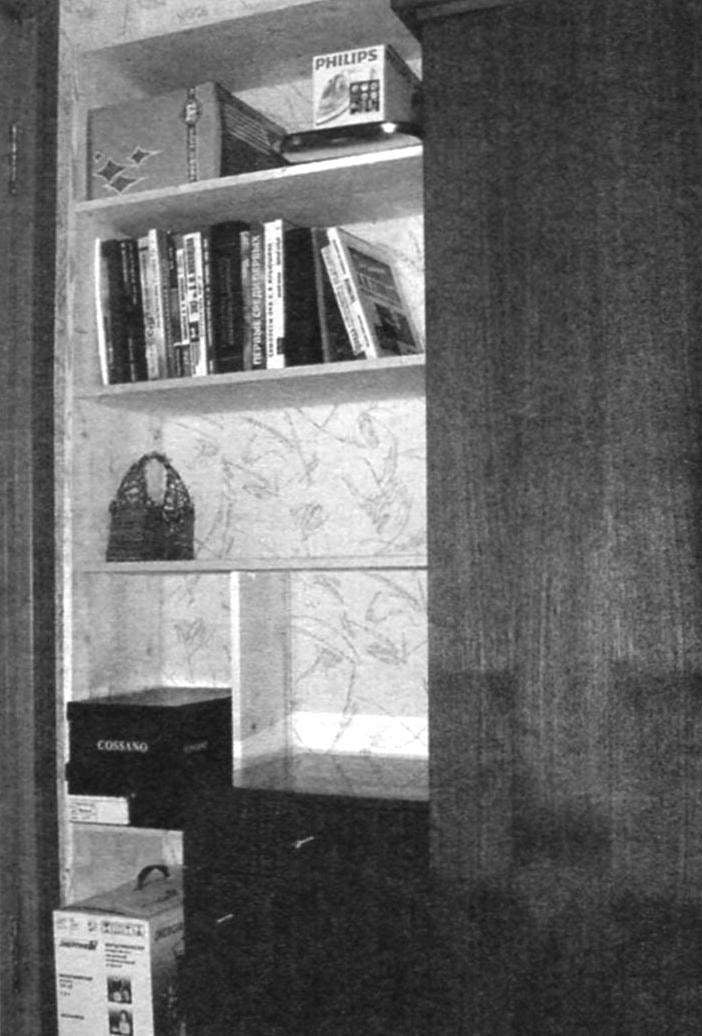

In many apartments you can find small “secret” and rarely used by tenants. These include, in particular, include space for doors. At the same time, they can be used for storage of various “trifles” and even books. In my humble study also found a similar area, where well placed shelving. His sketch was hand quickly. Then came the trip to the store for buying furniture boards (planed boards) of “forest”: the three – dimensions 18x300x2000 mm, one mm and one 18x200x2000-18x200x1000 mm and three dozen screws self-tapping screws and two “corners” for mounting the rack to the wall.

In many apartments you can find small “secret” and rarely used by tenants. These include, in particular, include space for doors. At the same time, they can be used for storage of various “trifles” and even books. In my humble study also found a similar area, where well placed shelving. His sketch was hand quickly. Then came the trip to the store for buying furniture boards (planed boards) of “forest”: the three – dimensions 18x300x2000 mm, one mm and one 18x200x2000-18x200x1000 mm and three dozen screws self-tapping screws and two “corners” for mounting the rack to the wall.

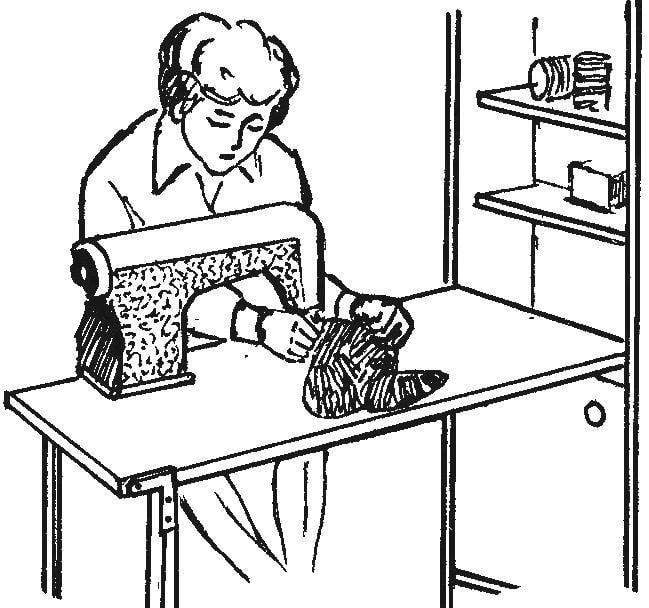

For a good housewife sewing machine still for home craftsman — drill with the tool: things are absolutely necessary. But in that and in other case to work and still want to carve out at least a small area. How to equip for employment of sewing — tells the Hungarian magazine”, Earmaster”.

For a good housewife sewing machine still for home craftsman — drill with the tool: things are absolutely necessary. But in that and in other case to work and still want to carve out at least a small area. How to equip for employment of sewing — tells the Hungarian magazine”, Earmaster”.

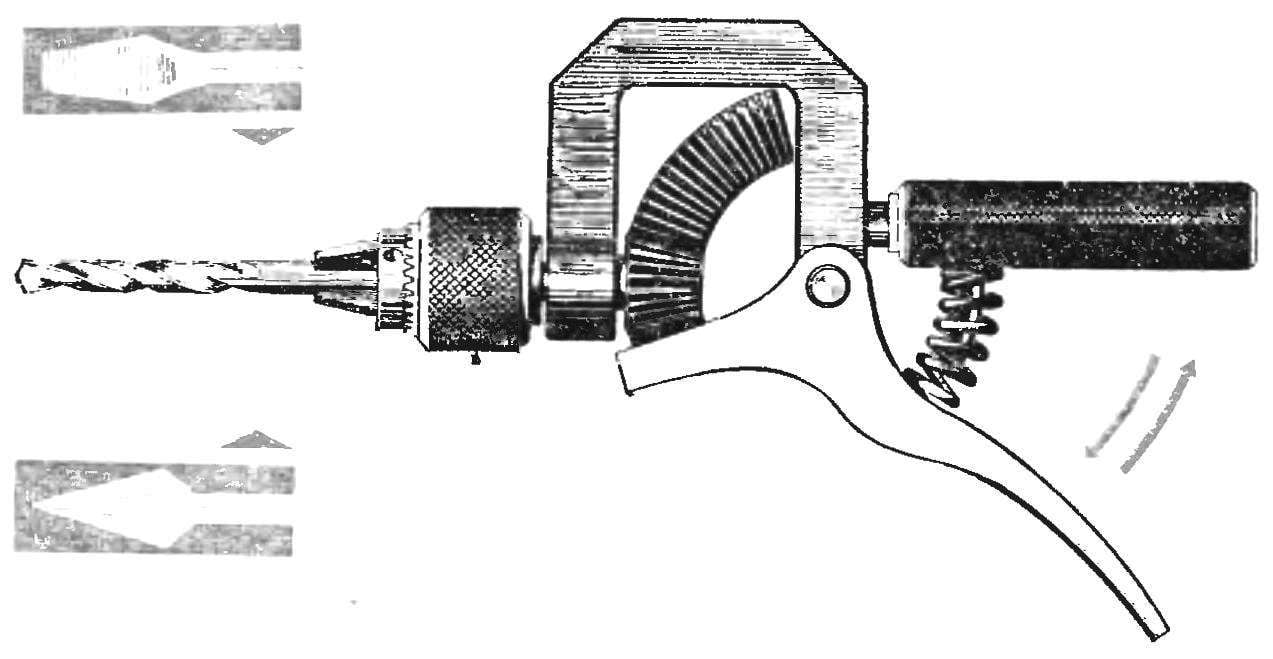

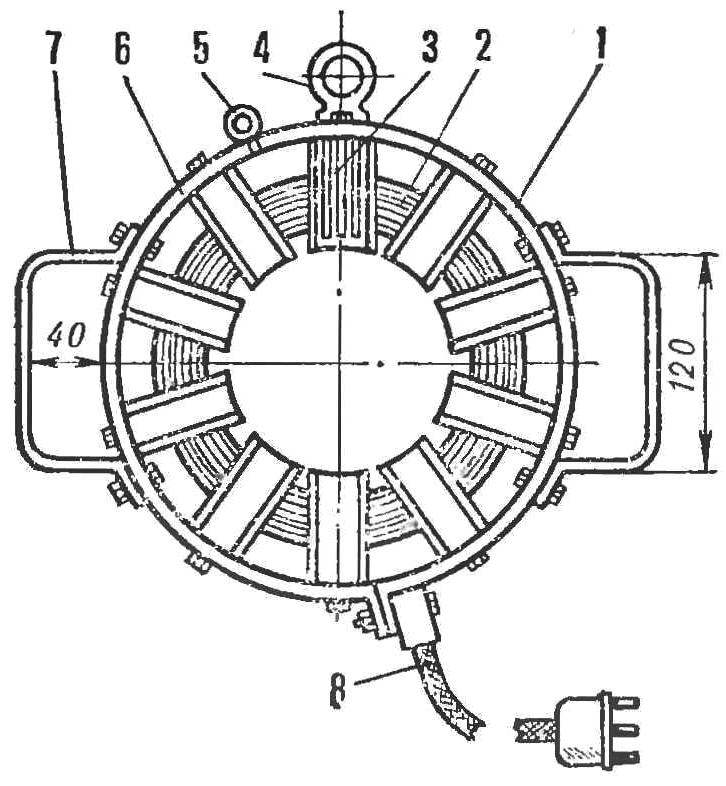

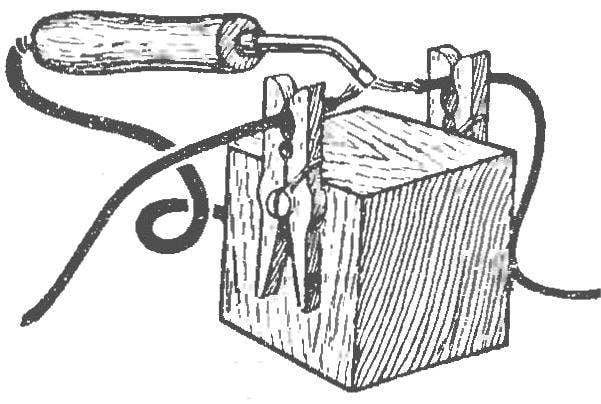

Sometimes it is difficult to remove on finger tight ring, but much harder — pressed on the shaft bushing or bearing, Not accidentally creating a variety of devices. One of such devices is presented at the NTTM-78 innovator Vladimir Gusev. His puller is very simple and is intended for locksmith’s and repair work — for example, the removal of the bearings from the shaft of the motors. Crank handle with screw case, with the teeth pull the chain and the gripper bar are all a device this portable remover. For adjustment of grippers for various diameter bearings or dismantling of the cross member bushings are supplied with screws.

Sometimes it is difficult to remove on finger tight ring, but much harder — pressed on the shaft bushing or bearing, Not accidentally creating a variety of devices. One of such devices is presented at the NTTM-78 innovator Vladimir Gusev. His puller is very simple and is intended for locksmith’s and repair work — for example, the removal of the bearings from the shaft of the motors. Crank handle with screw case, with the teeth pull the chain and the gripper bar are all a device this portable remover. For adjustment of grippers for various diameter bearings or dismantling of the cross member bushings are supplied with screws.

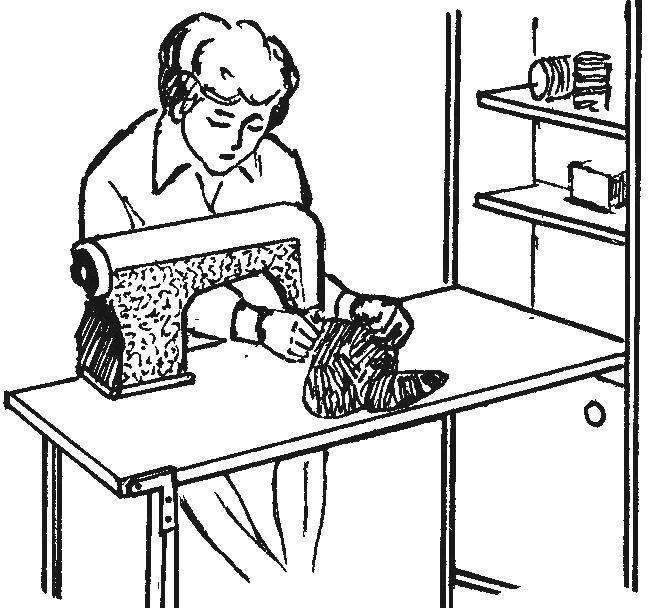

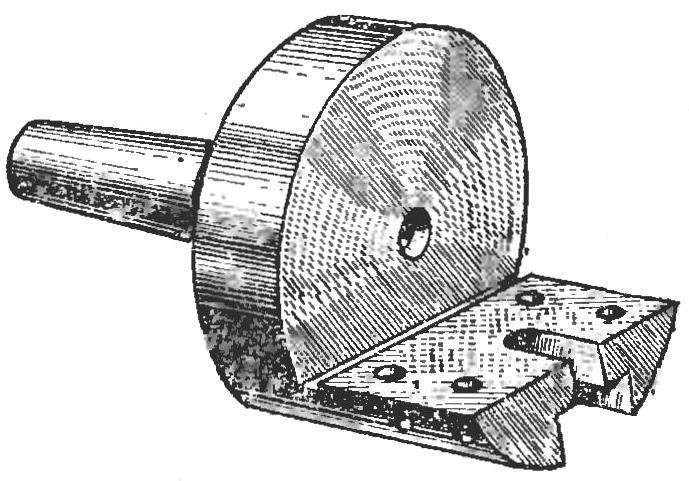

During fabrication of the models all of us often have to process with high precision perpendicular and aligned the holes for the bearings and bushings in housings, crankcases, engines and other complex pieces. For this run, using the device proposed by the Leningrad automodellista master of sports of international class N. Trinium.

During fabrication of the models all of us often have to process with high precision perpendicular and aligned the holes for the bearings and bushings in housings, crankcases, engines and other complex pieces. For this run, using the device proposed by the Leningrad automodellista master of sports of international class N. Trinium.