Industries is not only “pedal” means of transportation and sports equipment to strengthen leg muscles. In the right hands it is easily converted into a variety of small-scale mechanization, as “modelist-Konstruktor” has repeatedly been told on its pages (№ 11’81, 3’85, 2’87, 7’96). And therefore development, are addressed to cyclists — and fans of night riding with brightly burning (alternator) spotlight, may be useful to other readers.

Industries is not only “pedal” means of transportation and sports equipment to strengthen leg muscles. In the right hands it is easily converted into a variety of small-scale mechanization, as “modelist-Konstruktor” has repeatedly been told on its pages (№ 11’81, 3’85, 2’87, 7’96). And therefore development, are addressed to cyclists — and fans of night riding with brightly burning (alternator) spotlight, may be useful to other readers.

Himself an electrician

THE OUTLET IN THE CARTRIDGE

In order not to keep the additional wiring to connect the auxiliary electrical appliances at work using portable lamps, enough cartridge “carrying” to install a homemade adaptor as shown in the figure. For the manufacture of the adapter is used the lighting cartridge, in which are drilled three holes: one in the bottom under peeled from the glass and glue the cap the blown bulbs and the two side under the plug. Before you glue the base with epoxy resin in the bottom, it is soldered from the inside of a flexible insulated conductor with a length of 45 — 50 mm.

In order not to keep the additional wiring to connect the auxiliary electrical appliances at work using portable lamps, enough cartridge “carrying” to install a homemade adaptor as shown in the figure. For the manufacture of the adapter is used the lighting cartridge, in which are drilled three holes: one in the bottom under peeled from the glass and glue the cap the blown bulbs and the two side under the plug. Before you glue the base with epoxy resin in the bottom, it is soldered from the inside of a flexible insulated conductor with a length of 45 — 50 mm.

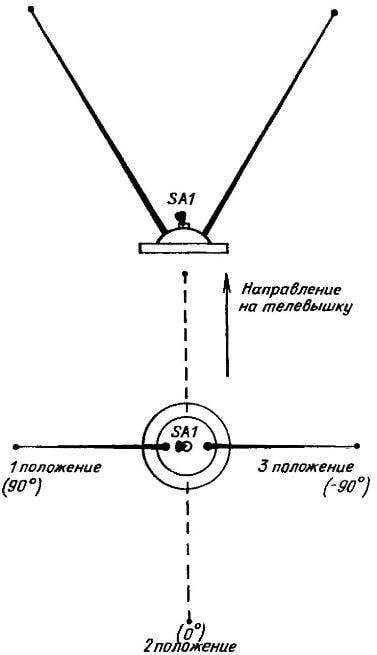

ANTENNA GOOD RECEPTION

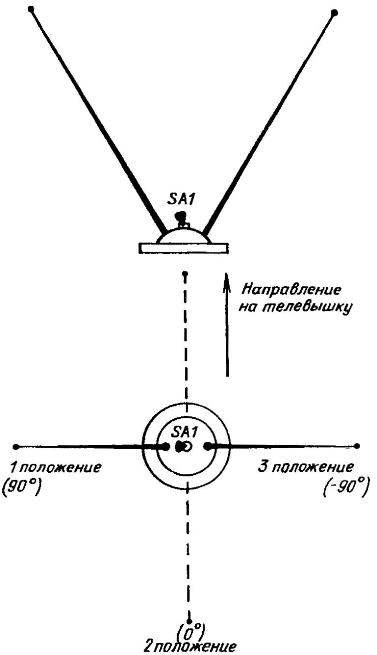

It often happens that the collective TV antenna is not working properly. In our high-rise building, for example, to take a high-quality image with such antenna only one TV channel. At other rescues antiquated room, which involves, unfortunately, a number of disadvantages.

It often happens that the collective TV antenna is not working properly. In our high-rise building, for example, to take a high-quality image with such antenna only one TV channel. At other rescues antiquated room, which involves, unfortunately, a number of disadvantages.

A SOLDERING IRON WITH A SYRINGE.

Anyone, even a well-equipped modern machine shop to do probably without soldering. And no matter how they fought for the engineering is still in front of us (according to the definition of “Explanatory dictionary of the live great Russian language” V. Dahl) — “iron of different types, in a wooden clasp which is kindled, and, holding it across the metal and tin solder first.”

Anyone, even a well-equipped modern machine shop to do probably without soldering. And no matter how they fought for the engineering is still in front of us (according to the definition of “Explanatory dictionary of the live great Russian language” V. Dahl) — “iron of different types, in a wooden clasp which is kindled, and, holding it across the metal and tin solder first.”

BACKLIGHT HOUSE NUMBERS

Lighting house number and street name in rural areas – is not an empty whim, but a basic necessity. In dark time of day the postman will be able to deliver a telegram, and RAM service come to the rescue. This is especially useful when the backlight lights up automatically at dusk and does not require human intervention. To make such a device might, perhaps, everyone is familiar with the basics of electrical engineering.

Lighting house number and street name in rural areas – is not an empty whim, but a basic necessity. In dark time of day the postman will be able to deliver a telegram, and RAM service come to the rescue. This is especially useful when the backlight lights up automatically at dusk and does not require human intervention. To make such a device might, perhaps, everyone is familiar with the basics of electrical engineering.

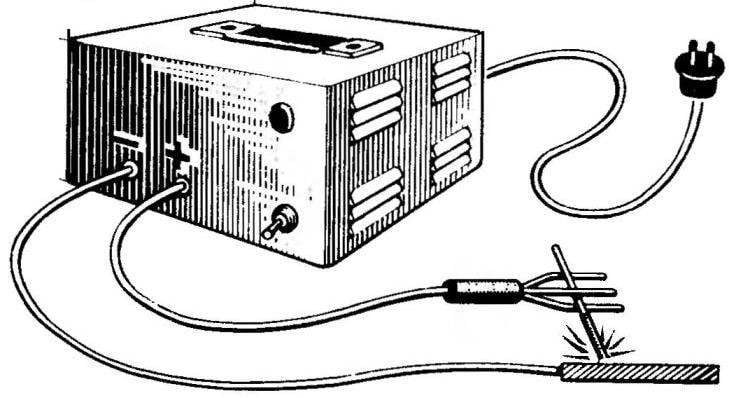

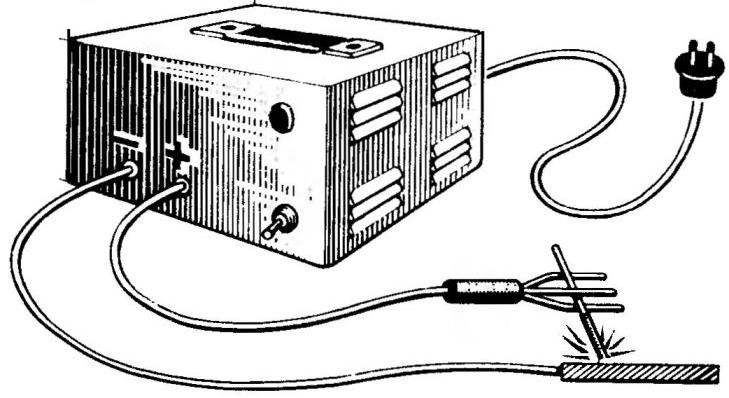

WELD DC

Advantages of welding machines DC before they “perimentally brothers” is well known. It’s mild arc, and the ability to connect thin-walled parts, and less spatter, and the lack of nepreverjenih sites. Even the annoying (and, as it turned out, bad acting people) cod is not. And all because there is no major inherent to the welding apparatus of the alternating current feature — intermittent arcing at the overflow of the sinusoid of the supply voltage through zero (Fig.1).

Advantages of welding machines DC before they “perimentally brothers” is well known. It’s mild arc, and the ability to connect thin-walled parts, and less spatter, and the lack of nepreverjenih sites. Even the annoying (and, as it turned out, bad acting people) cod is not. And all because there is no major inherent to the welding apparatus of the alternating current feature — intermittent arcing at the overflow of the sinusoid of the supply voltage through zero (Fig.1).

THE SOLDERING OF THE RESISTOR

I recommend readers of the magazine is easy to count, easy to manufacture and very reliable electric soldering iron. At my house, for example, these range from “krohotulki” for work with microelectronics to powerful “ax” with which to patch a leaky metal tanks, repairing wells, filters and other large items. Moreover, the heating element of each electrical device is… the appropriate power resistor (type PE or PEV), powered by household outlet voltage is 220 V. the resistance, if they cannot be avoided, reactive, precise, capacitive, allowing to solve very complex electrical problem with the minimum dimensions of the devices.

I recommend readers of the magazine is easy to count, easy to manufacture and very reliable electric soldering iron. At my house, for example, these range from “krohotulki” for work with microelectronics to powerful “ax” with which to patch a leaky metal tanks, repairing wells, filters and other large items. Moreover, the heating element of each electrical device is… the appropriate power resistor (type PE or PEV), powered by household outlet voltage is 220 V. the resistance, if they cannot be avoided, reactive, precise, capacitive, allowing to solve very complex electrical problem with the minimum dimensions of the devices.

THE TUBES BURNED OUT…

Familiar, perhaps, to every household situation: podklyuchayut all household appliances, which is in the apartment, but in the end — tube on the flap burn out from overload. More precisely, due to the excessively increased current in them melt, breaking the electrical circuit, a special low-melting insert and safeguard wiring from the further heating and ignition. Save these simple, in General, the devices and from large troubles in the so-called short circuit due to insulation breakdown, the inclusion of faulty electrical equipment or in the course of work on nabestaanden (particularly dangerous and inappropriate!) sockets, lamp cartridges, etc.

Familiar, perhaps, to every household situation: podklyuchayut all household appliances, which is in the apartment, but in the end — tube on the flap burn out from overload. More precisely, due to the excessively increased current in them melt, breaking the electrical circuit, a special low-melting insert and safeguard wiring from the further heating and ignition. Save these simple, in General, the devices and from large troubles in the so-called short circuit due to insulation breakdown, the inclusion of faulty electrical equipment or in the course of work on nabestaanden (particularly dangerous and inappropriate!) sockets, lamp cartridges, etc.

THE BEST SAUNA HEATER

Outfitting your bathroom under the bath, he decided to make a strong (about 3 — 3.5 kW) and reliable heater. The most appropriate seemed to be elektrokemisk in a tin bucket with asbestos cement terminal block and brass studs, the closed hinged metal housing (Fig. 1). But when I placed this heater in the socket, felt the smell of burning.

Outfitting your bathroom under the bath, he decided to make a strong (about 3 — 3.5 kW) and reliable heater. The most appropriate seemed to be elektrokemisk in a tin bucket with asbestos cement terminal block and brass studs, the closed hinged metal housing (Fig. 1). But when I placed this heater in the socket, felt the smell of burning.

SAMOVAR: AND WOOD, AND A CURRENT

Since the house has antique samovar, a sin not to use them at least on special occasions. You can even with the ignition not to bother, but just ready with boiling water, poured inside. At first, I did not yet matured the decision to equip this relic of a tubular electric heater (Teh), while maintaining almost unchanged the appearance of the samovar and the basis of its unique design.

Since the house has antique samovar, a sin not to use them at least on special occasions. You can even with the ignition not to bother, but just ready with boiling water, poured inside. At first, I did not yet matured the decision to equip this relic of a tubular electric heater (Teh), while maintaining almost unchanged the appearance of the samovar and the basis of its unique design.