Cabins cabins are designed in order to provide effective and comfortable work of the personnel on the construction site. These are temporary buildings that together quickly and easily-to understand and serve as guard posts, living quarters, dining room or warehouse. For the manufacture of huts are made of various materials – wood, plastic, metal.

Cabins cabins are designed in order to provide effective and comfortable work of the personnel on the construction site. These are temporary buildings that together quickly and easily-to understand and serve as guard posts, living quarters, dining room or warehouse. For the manufacture of huts are made of various materials – wood, plastic, metal.

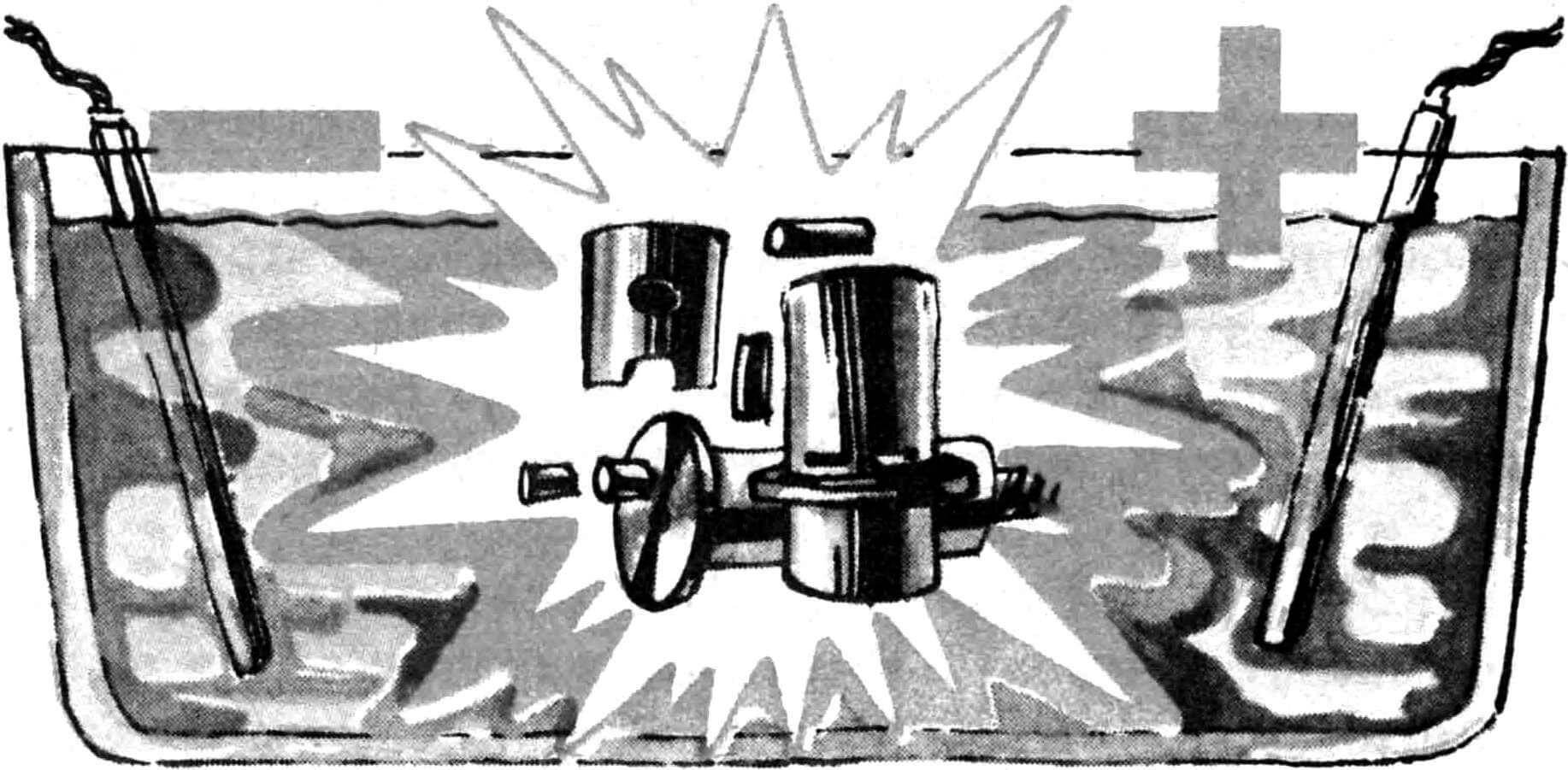

Power Management Center in the Garage

The proposed development has, of course, nothing to do with space. In this case, PMC (Control Center) is a control center for only the power supply of electrical equipment, not for flights into the Universe. Constructively executed as a compact electrical panel, it contains the most essential automatic blocks for a garage. Here are the Read more…

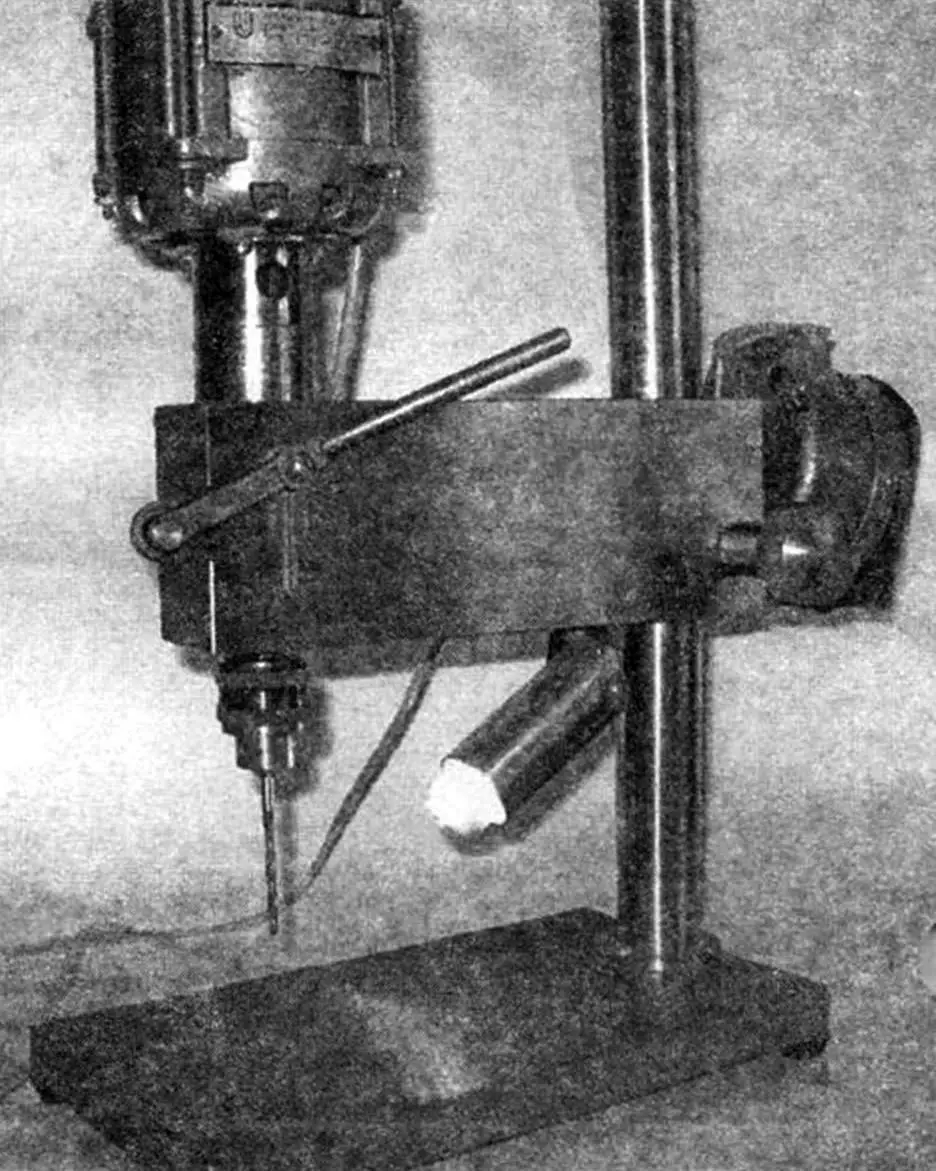

Original and counterfeit: don’t buy a poor quality tool. When you select the tool great a risk to run into an unscrupulous seller, and is reliable and durable products of the famous brand to buy a low-quality forgery, not only is not able to fully perform its function, but also dangerous to life and health of the user. Tampered with not only the tools, but snap to them. in case of failure to repair such a tool is practically impossible: a guarantee that the buyer expects, it does not apply, and damage is usually so severe that it is easier to throw the defective unit.

Original and counterfeit: don’t buy a poor quality tool. When you select the tool great a risk to run into an unscrupulous seller, and is reliable and durable products of the famous brand to buy a low-quality forgery, not only is not able to fully perform its function, but also dangerous to life and health of the user. Tampered with not only the tools, but snap to them. in case of failure to repair such a tool is practically impossible: a guarantee that the buyer expects, it does not apply, and damage is usually so severe that it is easier to throw the defective unit.

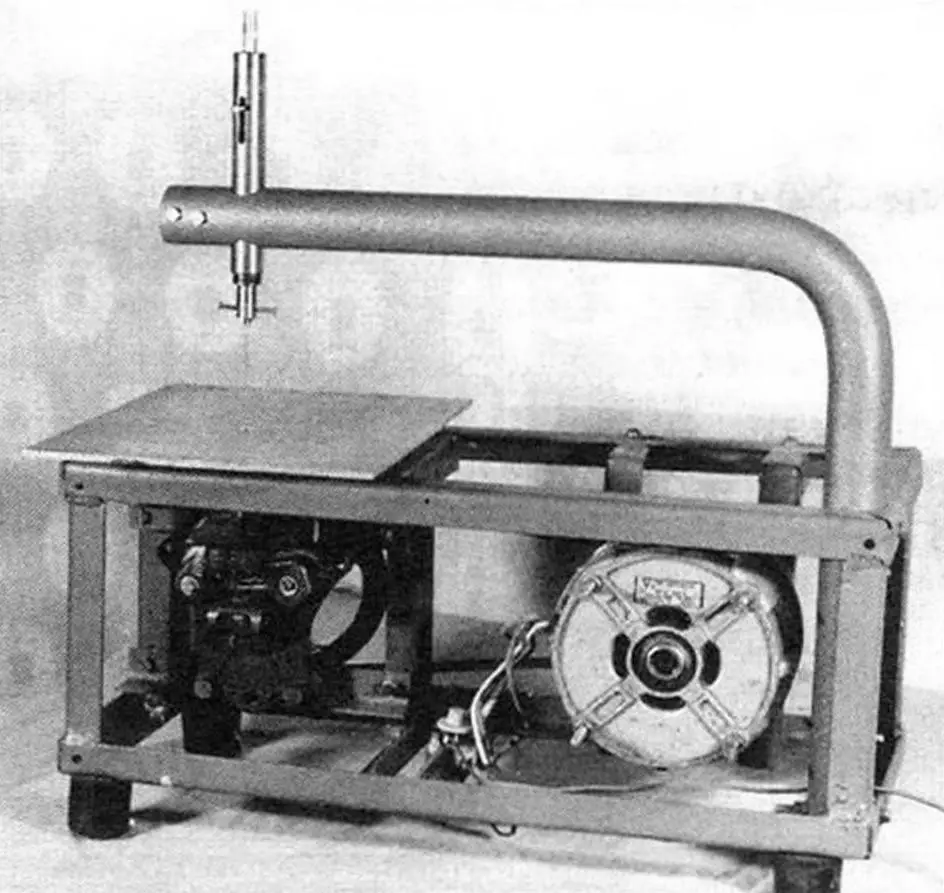

In the Soviet Union it issued certificate number 365089. Obtained patents in Italy, Sweden and France. License was purchased by the famous firms in the United States, and Japan; they are interested in many companies in Germany, Belgium, England and other foreign countries.

In the Soviet Union it issued certificate number 365089. Obtained patents in Italy, Sweden and France. License was purchased by the famous firms in the United States, and Japan; they are interested in many companies in Germany, Belgium, England and other foreign countries.

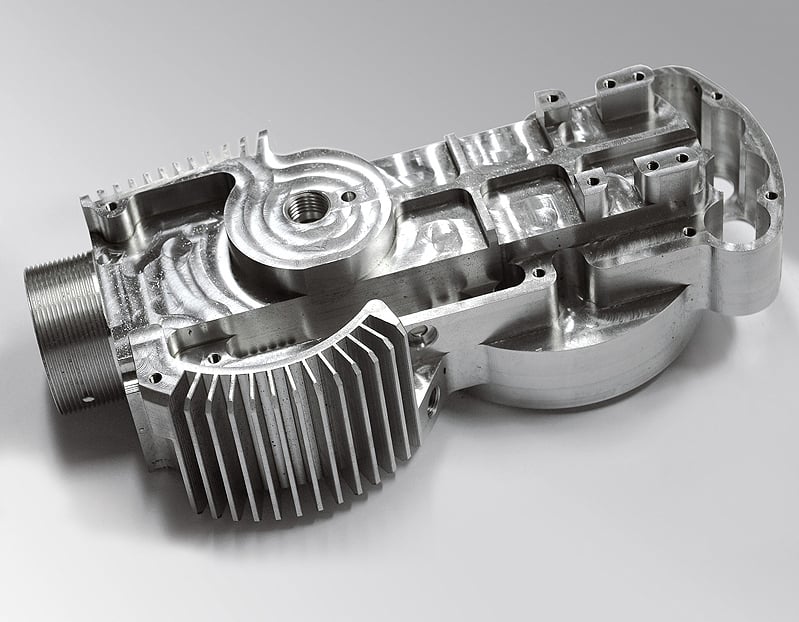

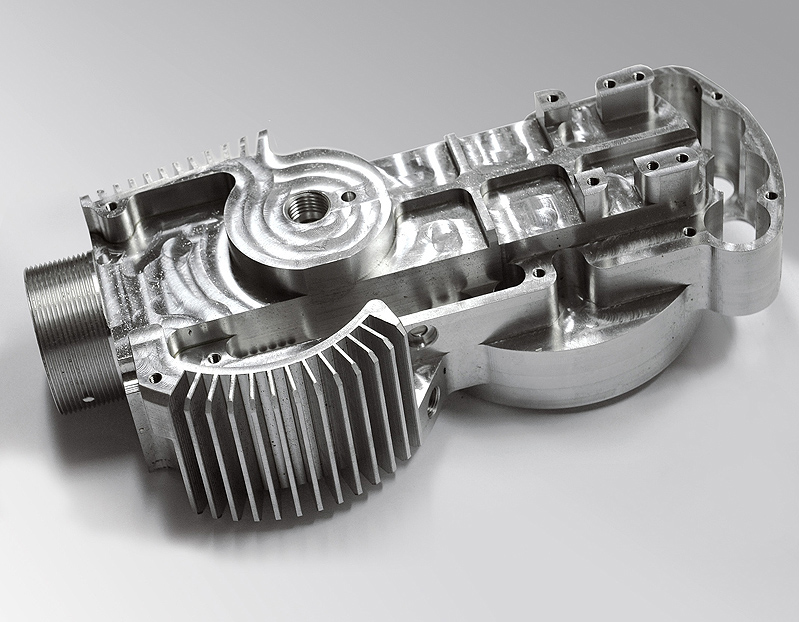

To date, the most popular are metal fabrication services custom service companies, whose activity is directly connected with the processing of metals.

To date, the most popular are metal fabrication services custom service companies, whose activity is directly connected with the processing of metals.