With sharp sheet metal and non-metallic materials are regularly confronted each homebrew. The use of manual scissors ineffective (especially for large sheets): for large labor, cut quality is poor.

With sharp sheet metal and non-metallic materials are regularly confronted each homebrew. The use of manual scissors ineffective (especially for large sheets): for large labor, cut quality is poor.

Our workshop

PLANES THE ROTOR

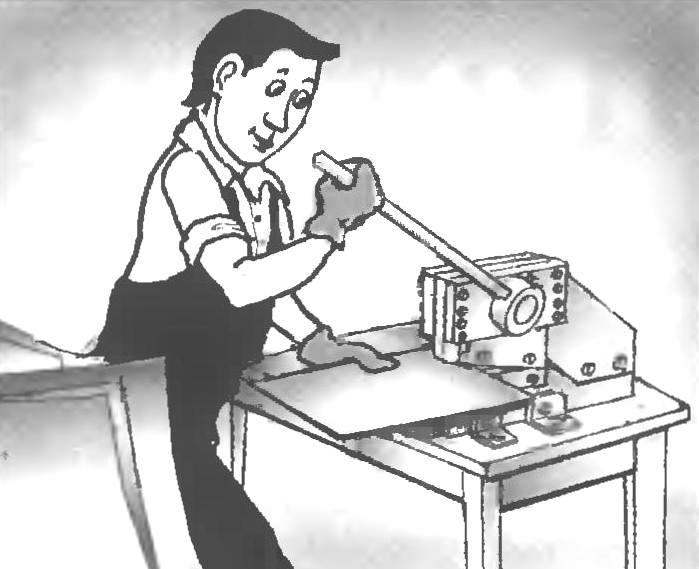

This plane I made, that is, when there’s a rather large amount of work on the harvesting of lumber. During the operation of the tool revealed that he was “tough” even solid wood, and also showed high reliability, comparable with the factory models. Tool performance and quality they planed surfaces, as I expected, was much higher than when processing lumber with hand tools and one.

This plane I made, that is, when there’s a rather large amount of work on the harvesting of lumber. During the operation of the tool revealed that he was “tough” even solid wood, and also showed high reliability, comparable with the factory models. Tool performance and quality they planed surfaces, as I expected, was much higher than when processing lumber with hand tools and one.HAMMER-UNIVERSAL

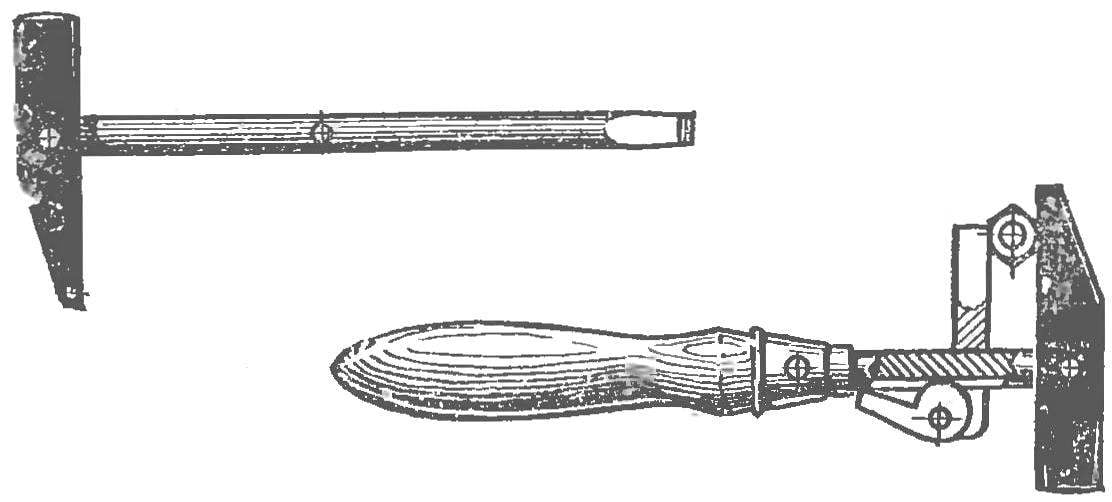

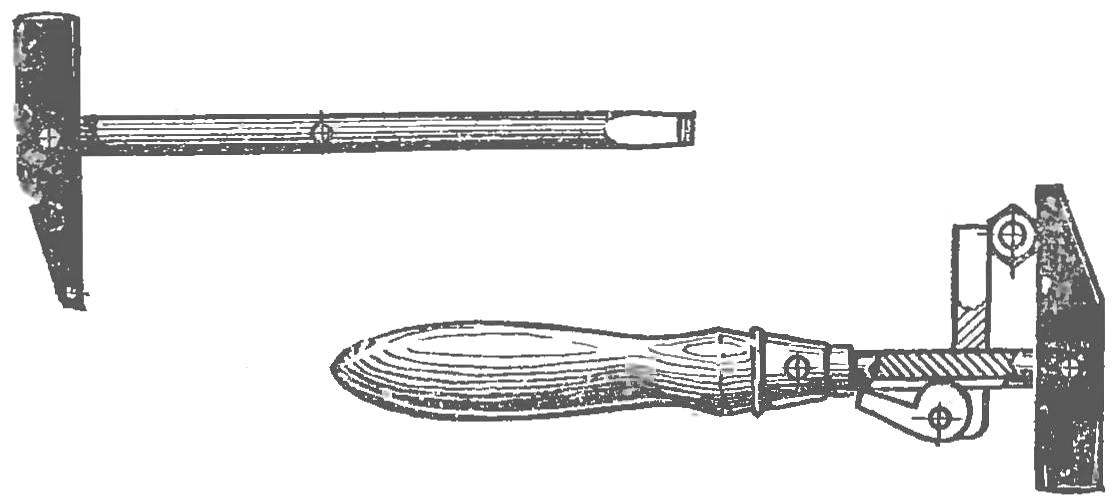

Universal tools do not claim to replace conventional designed to perform one or two operations, but in many cases, the care of equipment, its repair, adjustment is convenient to use them.

Universal tools do not claim to replace conventional designed to perform one or two operations, but in many cases, the care of equipment, its repair, adjustment is convenient to use them.ALL ABOUT SCREWDRIVERS

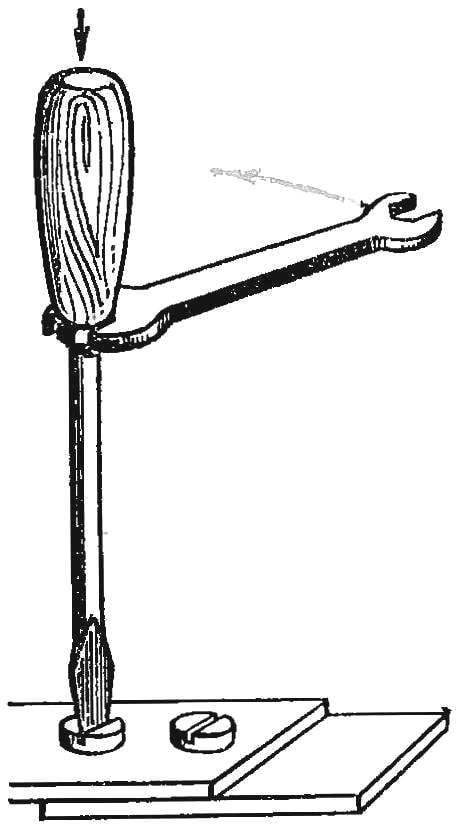

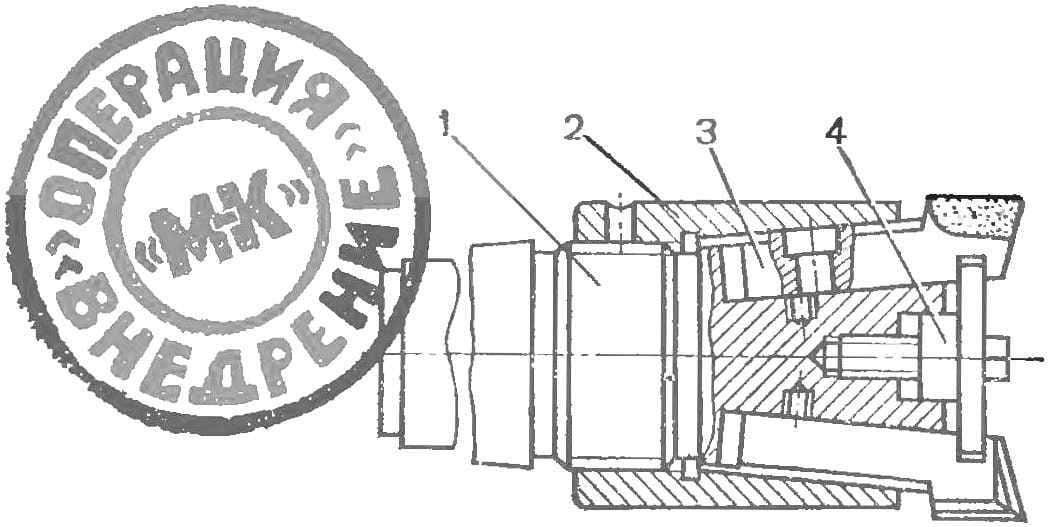

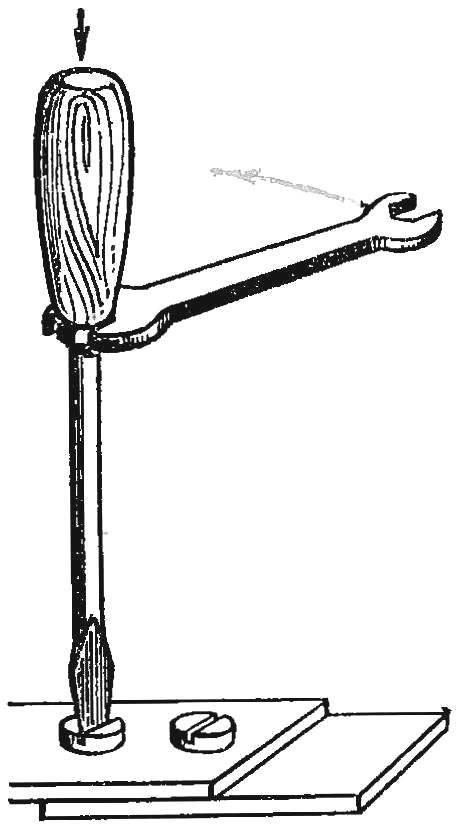

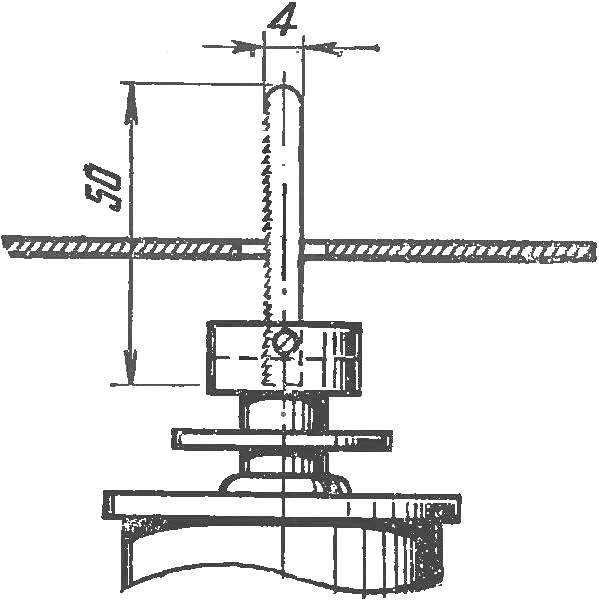

Screwdriver is a tool, which, perhaps, to the greatest extent characterizes the “homebrew”. Any self-respecting “handy” invent to themselves “personal” screwdriver, unlike any previously seen.

Screwdriver is a tool, which, perhaps, to the greatest extent characterizes the “homebrew”. Any self-respecting “handy” invent to themselves “personal” screwdriver, unlike any previously seen.“FIGURE” SAW

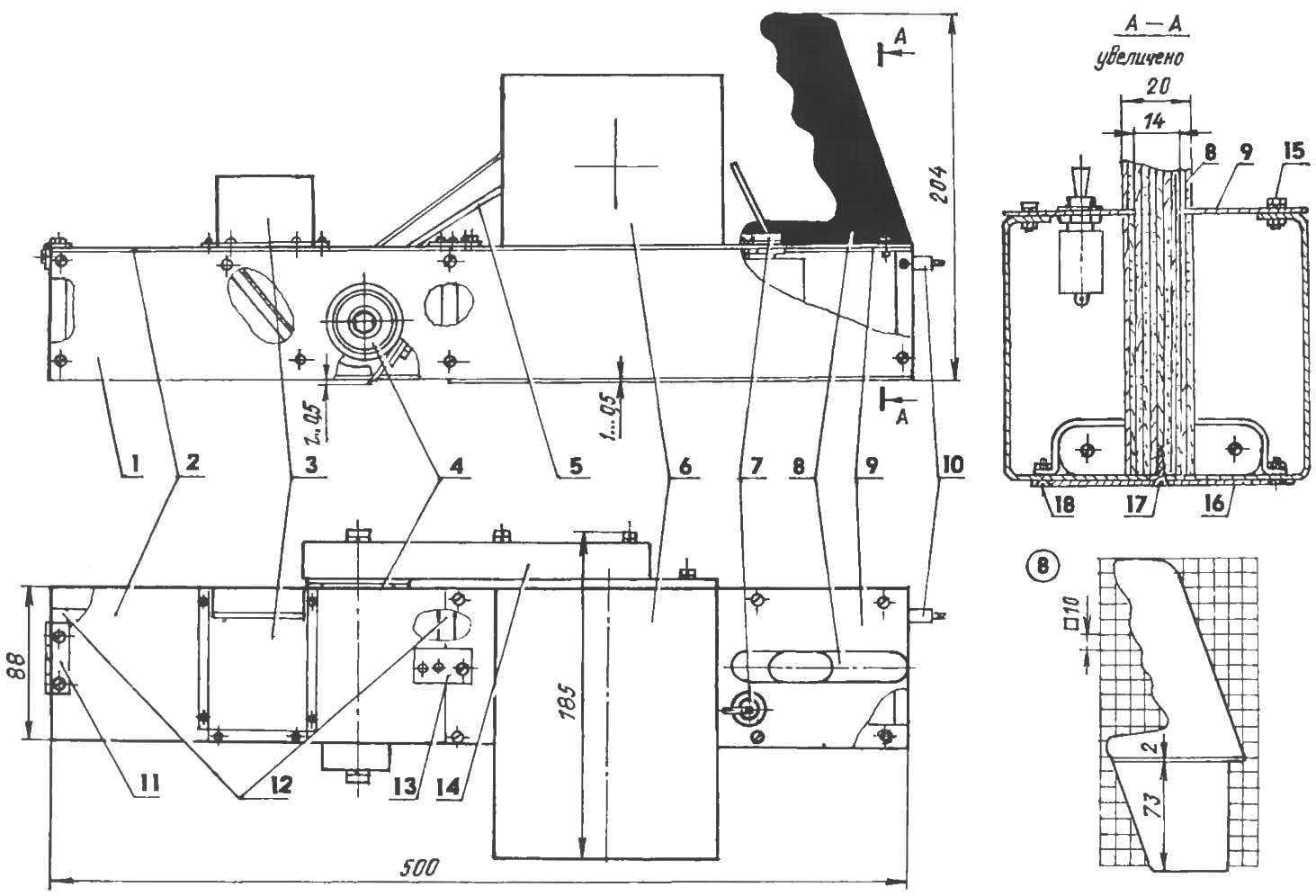

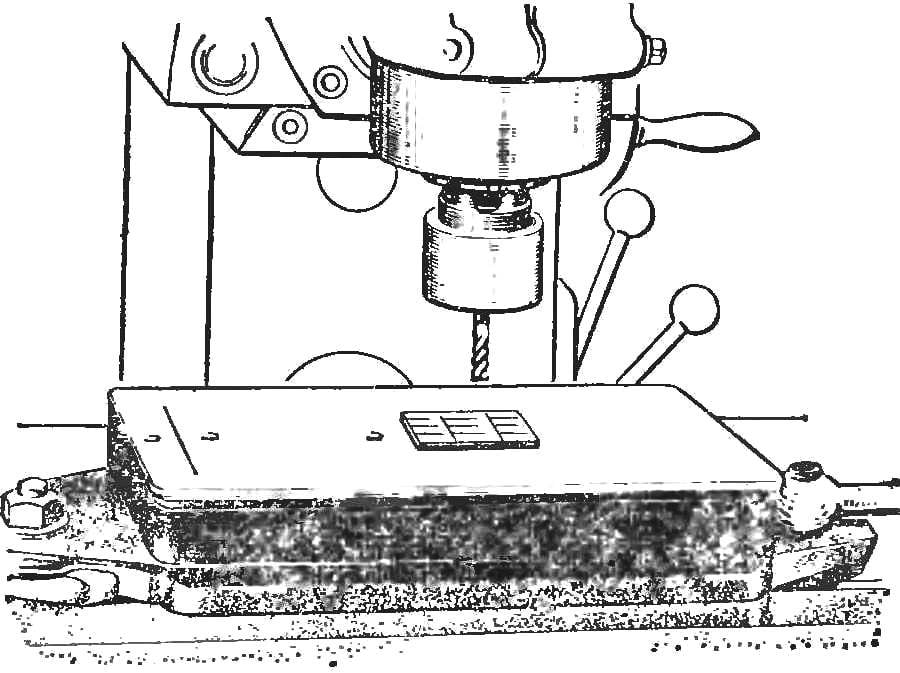

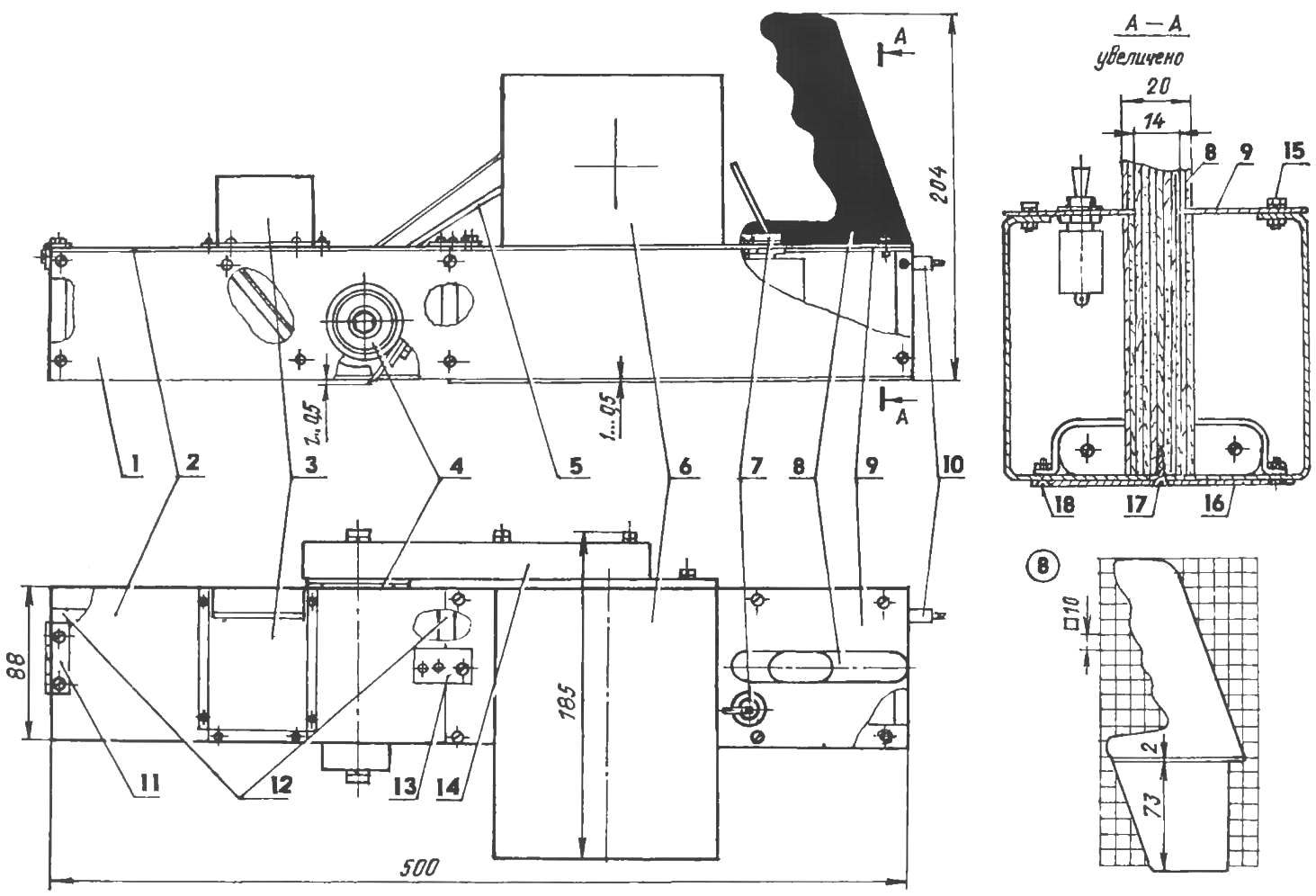

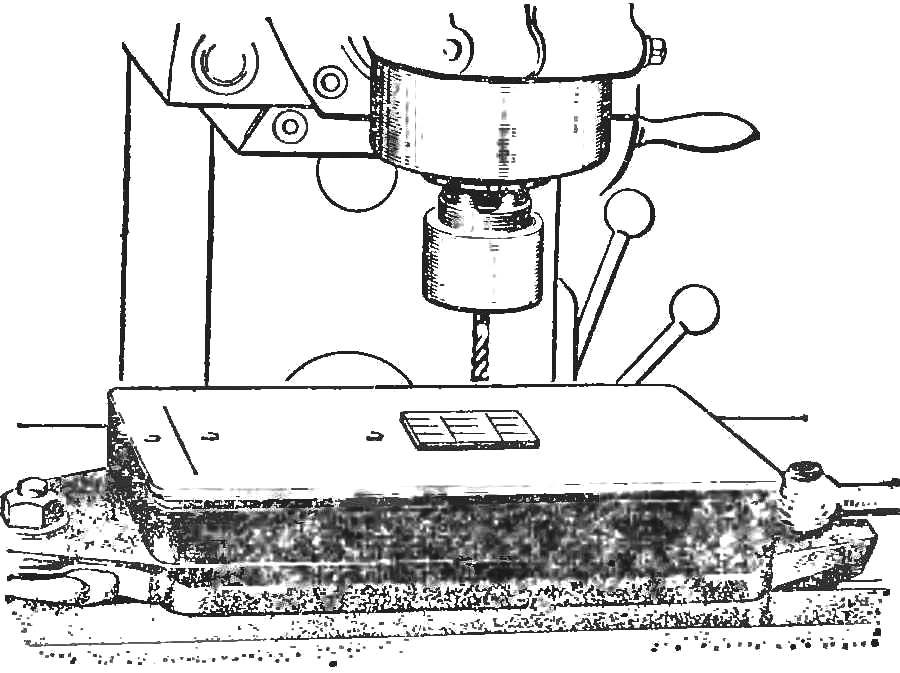

Electric jigsaws are of type AL-1, AL-2, produced by Cheboksary electric plant, the range of work performed is very limited. For example, due to the design features of the jig saw it is impossible to work with a wide sheet of plywood or plastic. And cutting tool quickly fails: the files are often broken or torn.

Electric jigsaws are of type AL-1, AL-2, produced by Cheboksary electric plant, the range of work performed is very limited. For example, due to the design features of the jig saw it is impossible to work with a wide sheet of plywood or plastic. And cutting tool quickly fails: the files are often broken or torn.ARSENAL QUALITY

CHAINMAIL FOR THE METAL. Like invisible arrows, affects the corrosion of metal surfaces operating in hostile or wet environments. Rust stains, caked wounds cover almost the entire surface of the structure, reducing its strength, significantly reducing the service life. Widely used for corrosion control coatings are not always effective, especially in high temperatures.

CHAINMAIL FOR THE METAL. Like invisible arrows, affects the corrosion of metal surfaces operating in hostile or wet environments. Rust stains, caked wounds cover almost the entire surface of the structure, reducing its strength, significantly reducing the service life. Widely used for corrosion control coatings are not always effective, especially in high temperatures.GRINDING IN THE “BATH”

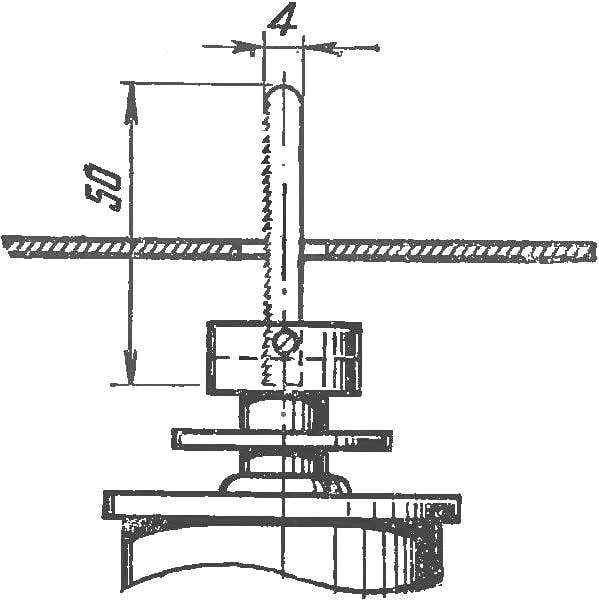

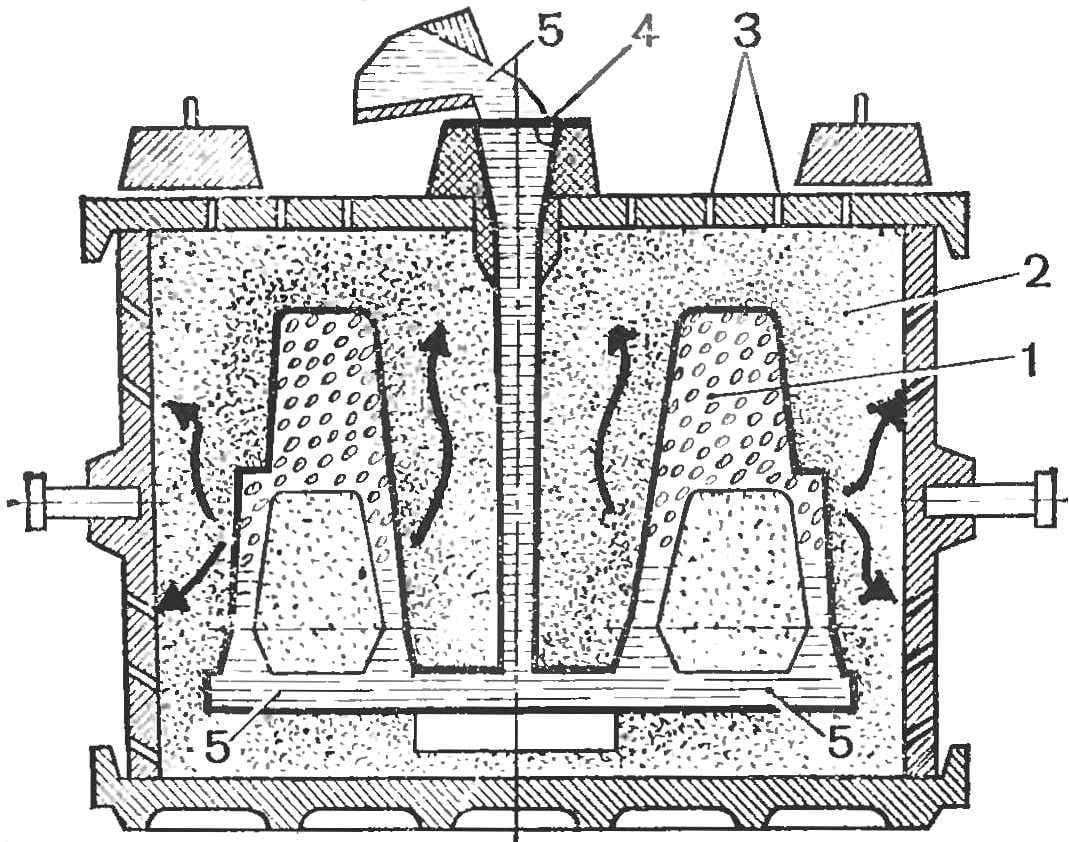

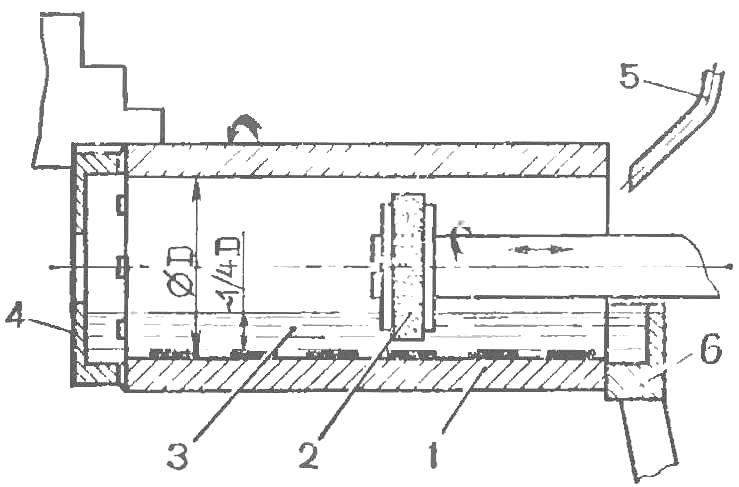

An ingenious solution processing grinding wheel internal surface of tubes or hollow parts offered innovators N. Epifanov, A. Chuprikov, Y. Shabalin.

An ingenious solution processing grinding wheel internal surface of tubes or hollow parts offered innovators N. Epifanov, A. Chuprikov, Y. Shabalin.ETERNAL MILL

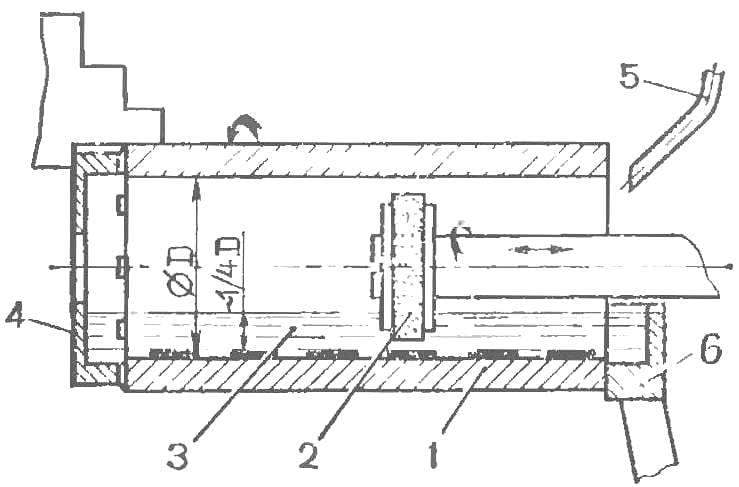

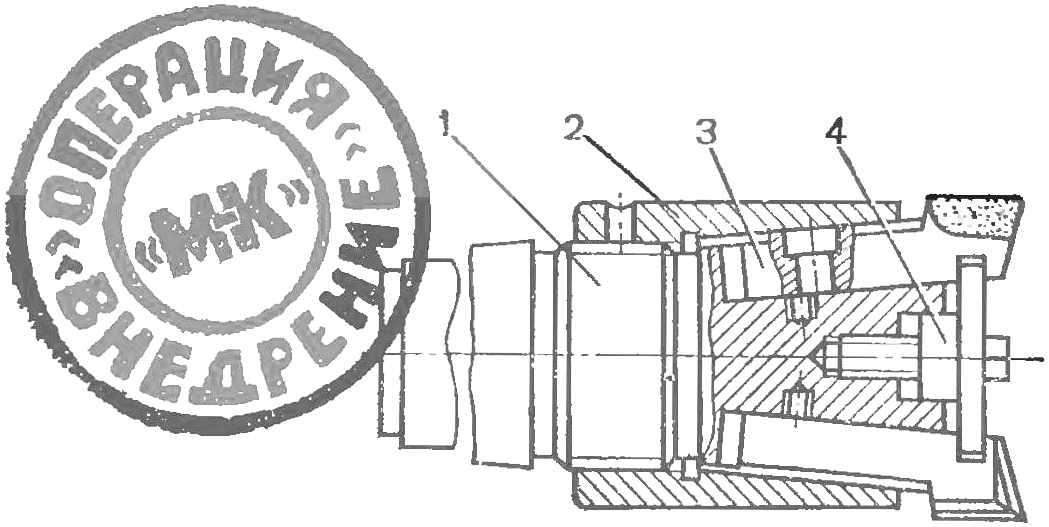

Yes, how would it work, no matter how perithecial — it does not decrease! To maintain a times a predetermined diameter with high accuracy allows her to design feature.

Yes, how would it work, no matter how perithecial — it does not decrease! To maintain a times a predetermined diameter with high accuracy allows her to design feature.EXPRESS BURNING

Very often for finishing wood products use burning. Even if this operation is performed by a special device — cautery, it is very time consuming, especially when applied to a variety of complex patterns. I want to offer successfully tried mechanized method of burning intricate patterns and various applications. It is much more productive than the traditional method and besides, it was pretty spectacular.

Very often for finishing wood products use burning. Even if this operation is performed by a special device — cautery, it is very time consuming, especially when applied to a variety of complex patterns. I want to offer successfully tried mechanized method of burning intricate patterns and various applications. It is much more productive than the traditional method and besides, it was pretty spectacular.FOAM-CASTER

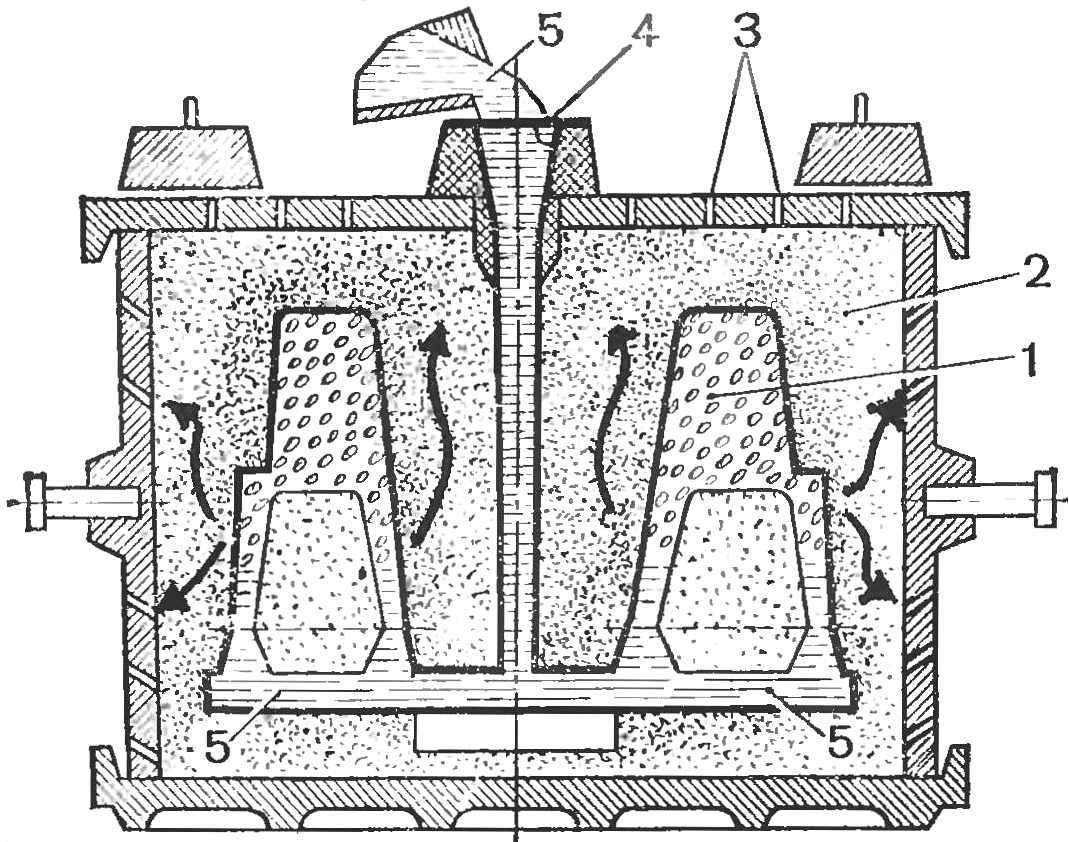

Not only the shipbuilders there is a need for one-time, single steel casting of certain parts. In these cases, existing technology has to pre-make a wooden model to receive the outdoor imprint in the mold and core boxes for the formation of internal cavities of the casting. The complexity of manufacturing of model kits three to five times higher than the complexity of manufacturing of the castings.

Not only the shipbuilders there is a need for one-time, single steel casting of certain parts. In these cases, existing technology has to pre-make a wooden model to receive the outdoor imprint in the mold and core boxes for the formation of internal cavities of the casting. The complexity of manufacturing of model kits three to five times higher than the complexity of manufacturing of the castings.