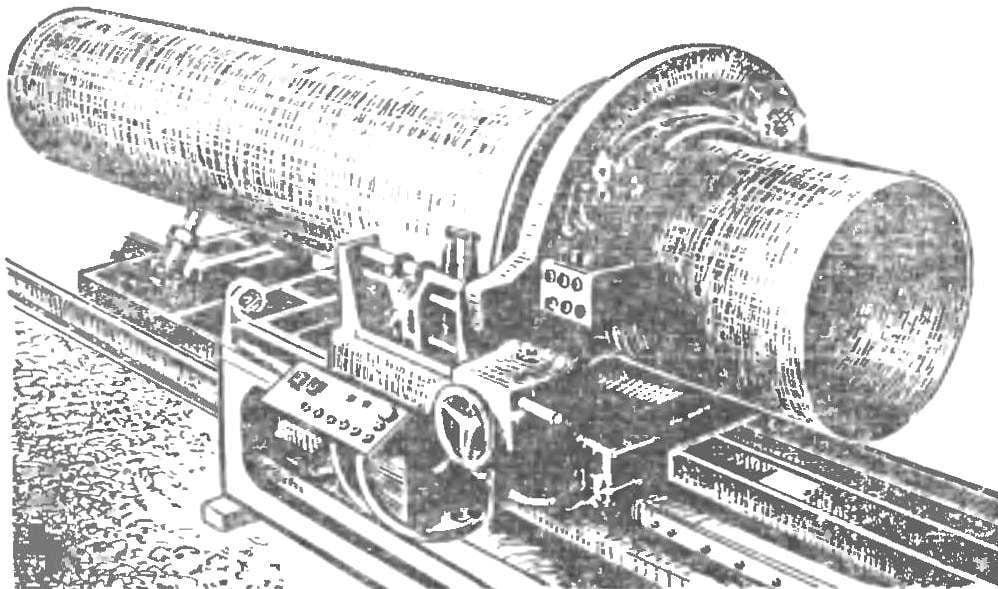

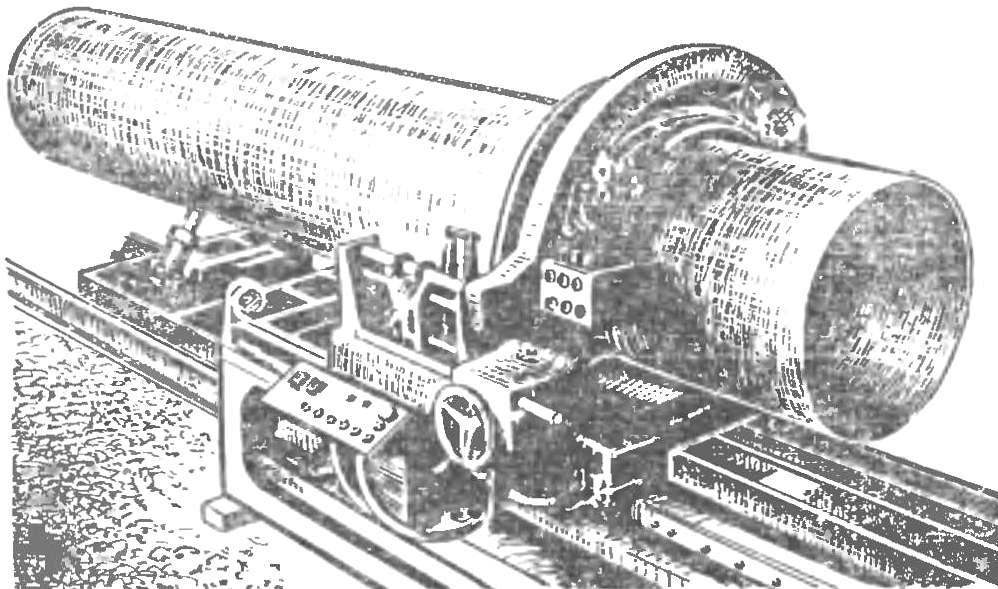

The working head of the machine, snake obviouses his bracket around the pipe, produces a hissing blue tongue of flame. Licking the metal, as if it bites into him and now burns through, slowly slitting thick wall pipe.

The working head of the machine, snake obviouses his bracket around the pipe, produces a hissing blue tongue of flame. Licking the metal, as if it bites into him and now burns through, slowly slitting thick wall pipe.

Our workshop

SCISSORS-HOLE PUNCH

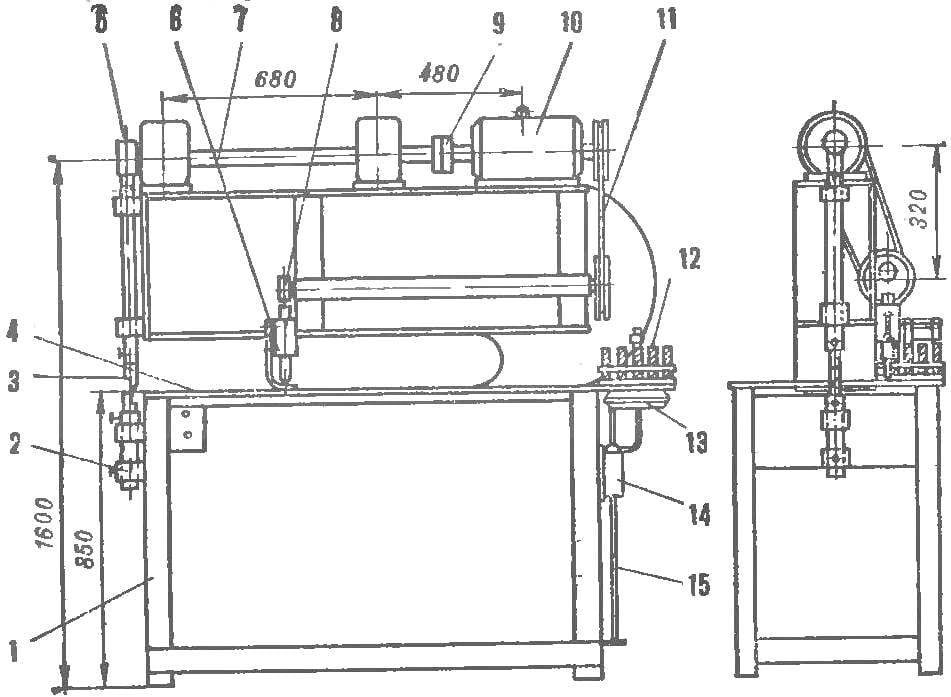

When repairing machinery, especially agricultural, are quite common and at the same time melomakarouna operations cutting of sheet iron, and the manufacture of cardboard strips with holes. Often these works are performed with hand tools that does not provide neither the productivity nor quality.

When repairing machinery, especially agricultural, are quite common and at the same time melomakarouna operations cutting of sheet iron, and the manufacture of cardboard strips with holes. Often these works are performed with hand tools that does not provide neither the productivity nor quality.NO HANDS, AND SKATING RINKS

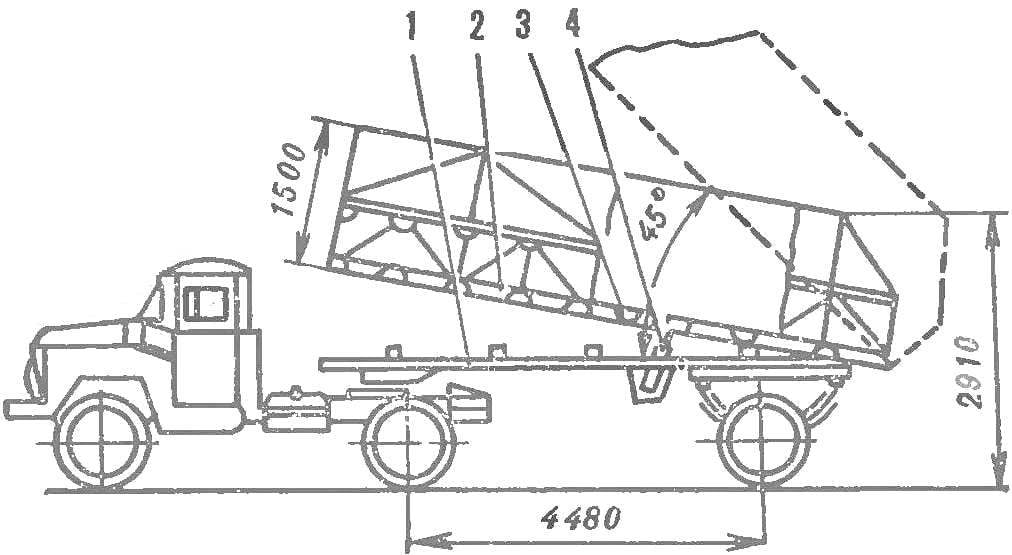

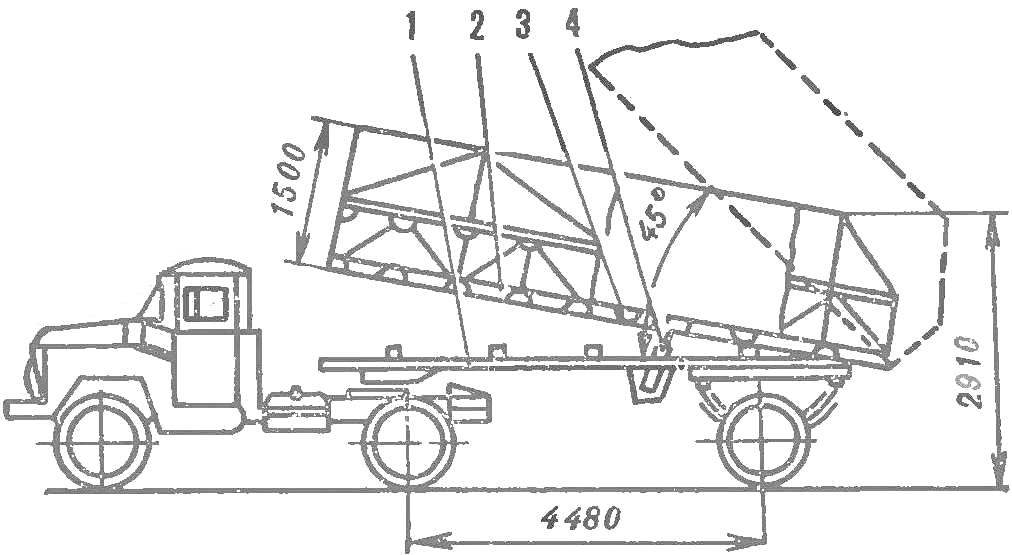

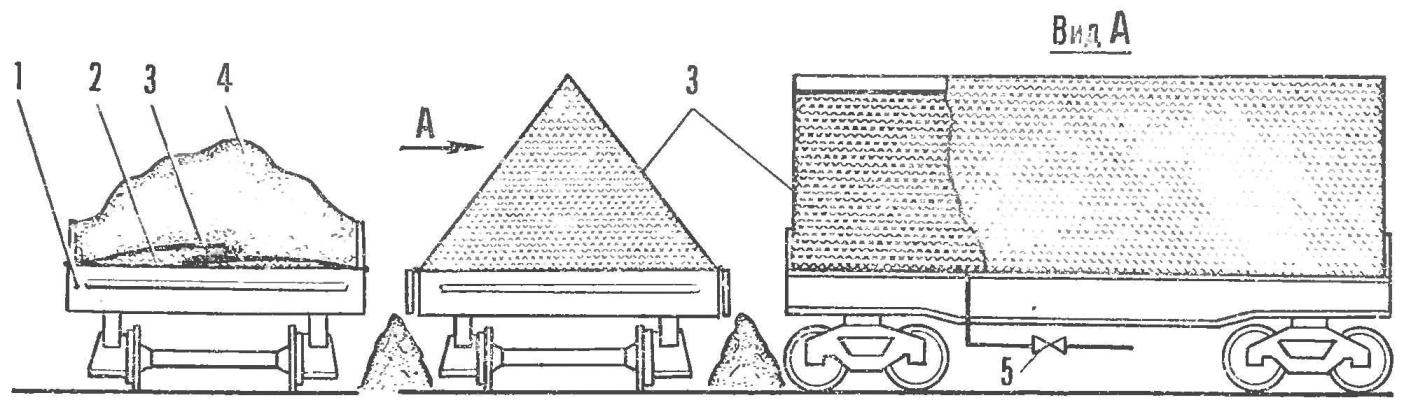

Where will be introduced the trailer (see Fig.), developed plant facilities carpool trust Kuzbasstrans of Glavkuzbasstroy, will not require workers to dump taken on it lumber. A whole load of neat package “move out” on the ground because of the properties of the tipper trailer. This means that won’t affect the quality of the material brought will reduce the downtime of the car for unloading.

Where will be introduced the trailer (see Fig.), developed plant facilities carpool trust Kuzbasstrans of Glavkuzbasstroy, will not require workers to dump taken on it lumber. A whole load of neat package “move out” on the ground because of the properties of the tipper trailer. This means that won’t affect the quality of the material brought will reduce the downtime of the car for unloading.

EXPLOSION-SCISSORS

How soft and manageable fire “snakes” rolled in the hands of the rollers, they are so stubborn and hard to handle in the cold when cutting them on the measuring of the workpiece. Cutting methods — sawing with diamond discs, gas or plasma cutting or not give a smooth, does not require additional processing of the edge of the workpiece, or entail a significant waste of metal.

How soft and manageable fire “snakes” rolled in the hands of the rollers, they are so stubborn and hard to handle in the cold when cutting them on the measuring of the workpiece. Cutting methods — sawing with diamond discs, gas or plasma cutting or not give a smooth, does not require additional processing of the edge of the workpiece, or entail a significant waste of metal.“CLOTHESPIN” FOR METAL

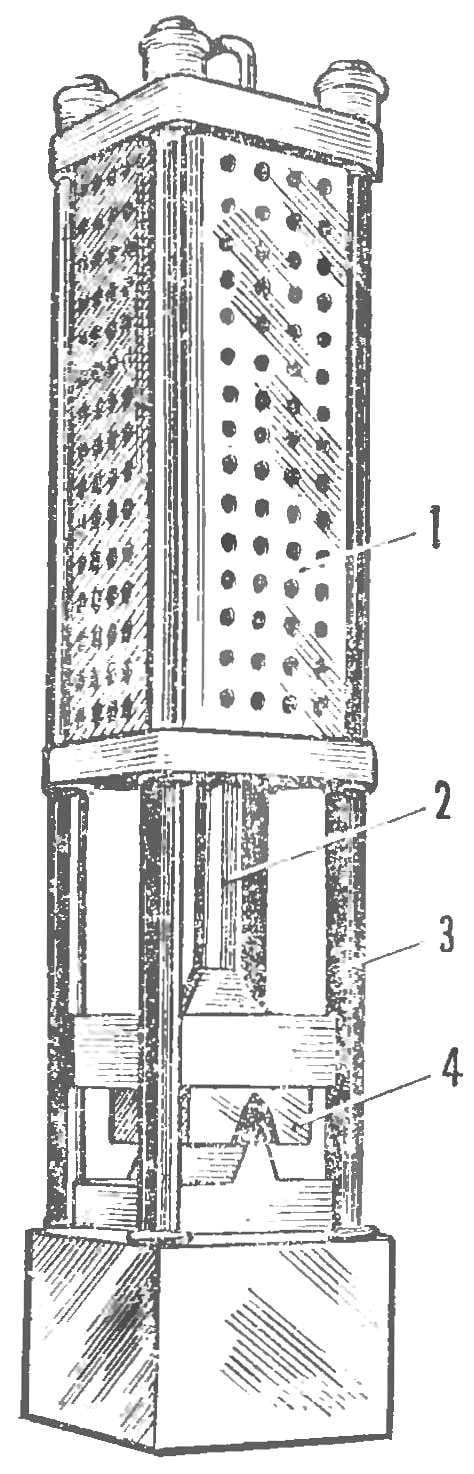

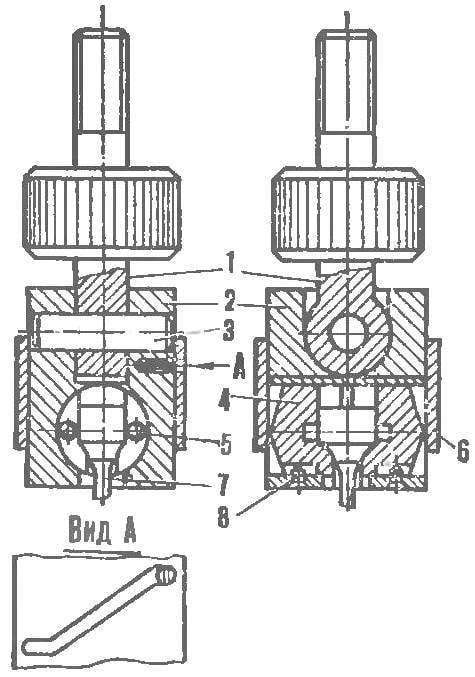

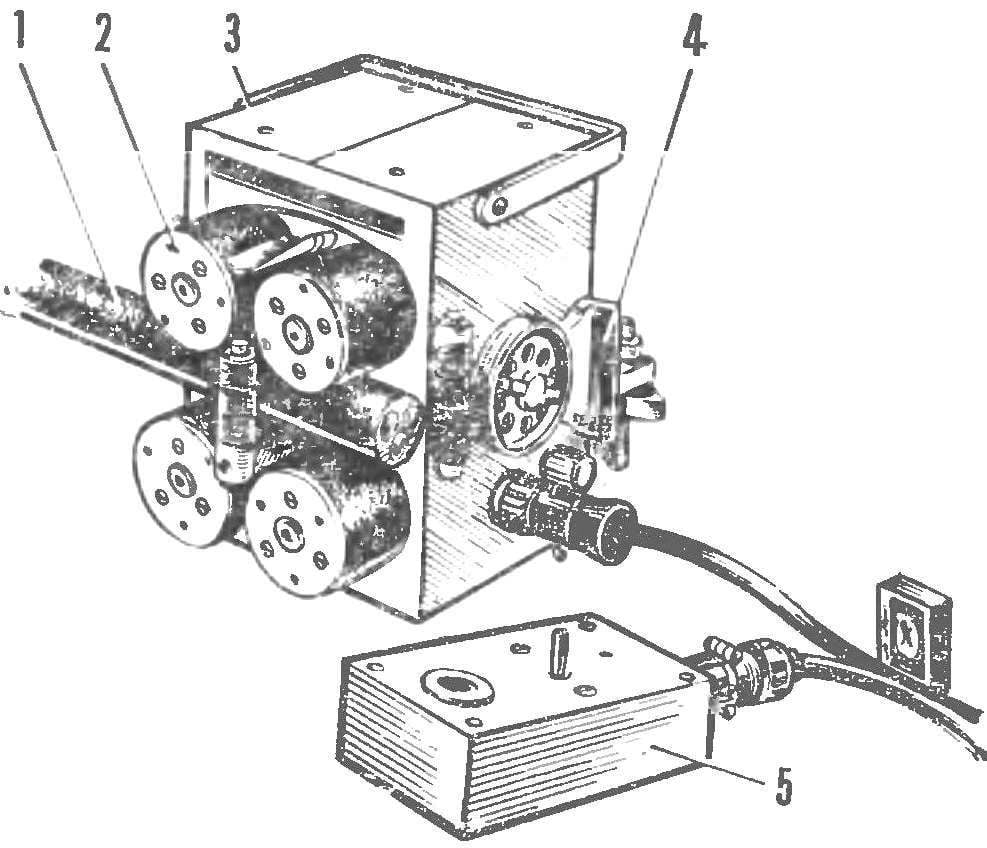

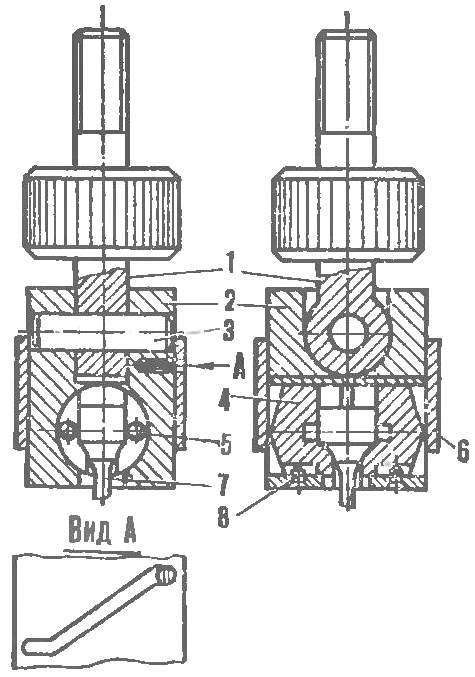

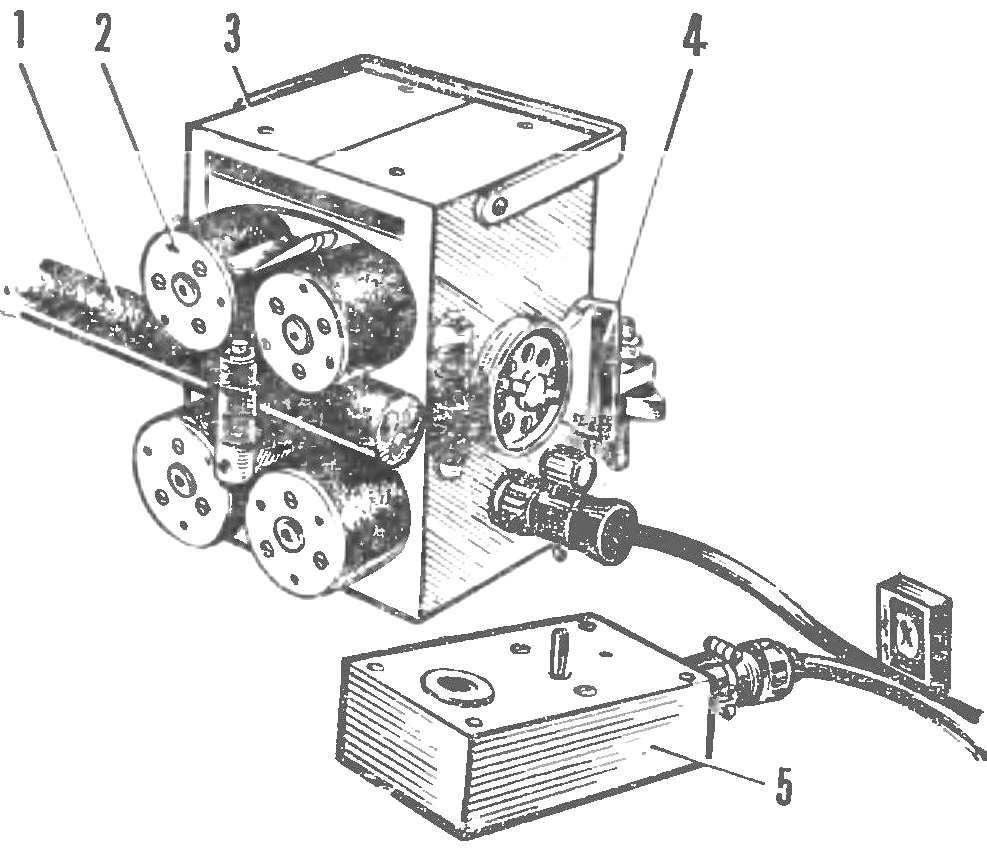

One of the major examination quality, which is a metal or alloy before you can become a responsible part of modern technology, the test of a test sample in tension. However, to determine what load it is able to withstand, you need to mount it in the testing machine. Existing methods or time-consuming, or complex. Innovators V. Kropotin and O. Ermolaev presented at the exhibition of IR-77 is a simple device and yet a very efficient clip (see Fig.), firmly gripping and holding the “pencil” test material.

One of the major examination quality, which is a metal or alloy before you can become a responsible part of modern technology, the test of a test sample in tension. However, to determine what load it is able to withstand, you need to mount it in the testing machine. Existing methods or time-consuming, or complex. Innovators V. Kropotin and O. Ermolaev presented at the exhibition of IR-77 is a simple device and yet a very efficient clip (see Fig.), firmly gripping and holding the “pencil” test material.“SPEED” BOLT

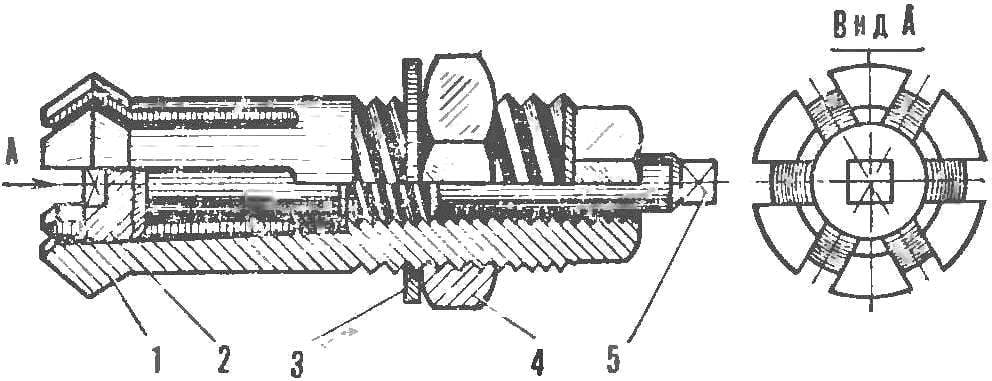

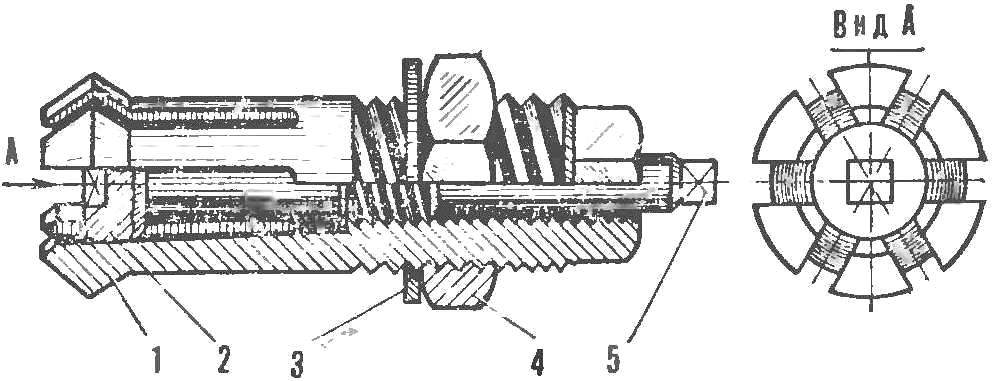

Not only fitter or installer, but any technician knows to connect the two parts with the bolt, insert it through the hole, then throw the washer and finally screw and tighten the nut. As you can see, thus there is a double work: there is not only the Assembly of parts but also the Assembly of the bolt.

Not only fitter or installer, but any technician knows to connect the two parts with the bolt, insert it through the hole, then throw the washer and finally screw and tighten the nut. As you can see, thus there is a double work: there is not only the Assembly of parts but also the Assembly of the bolt.UNLOADS THE AIR…

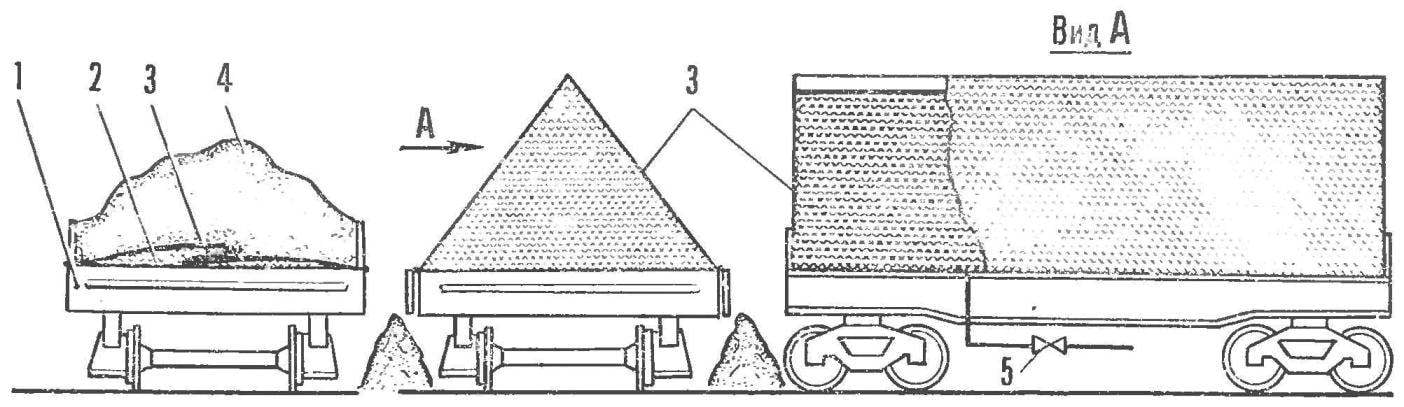

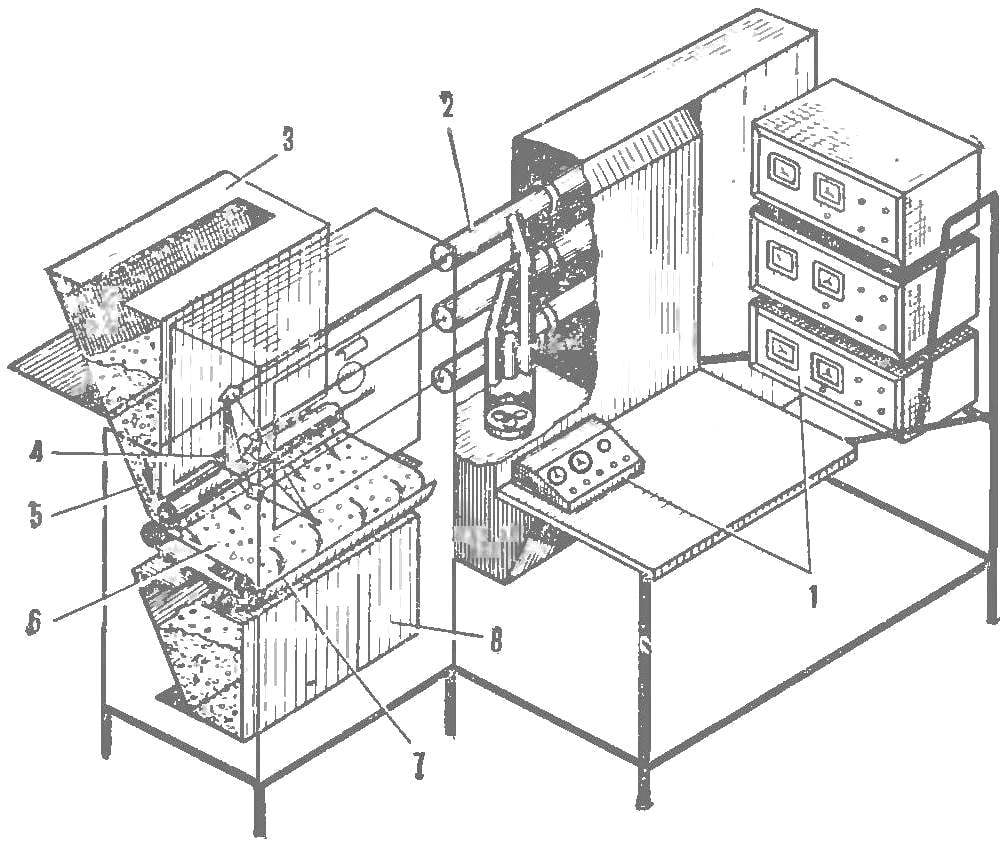

A considerable amount of manual labor required unloading bulk materials from open railway platforms. They increase especially in the off-season, when the materials can regedit. This leads to complex and costly discharge, and often to excess downtime rolling stock.

A considerable amount of manual labor required unloading bulk materials from open railway platforms. They increase especially in the off-season, when the materials can regedit. This leads to complex and costly discharge, and often to excess downtime rolling stock.USEFUL VIBRATION

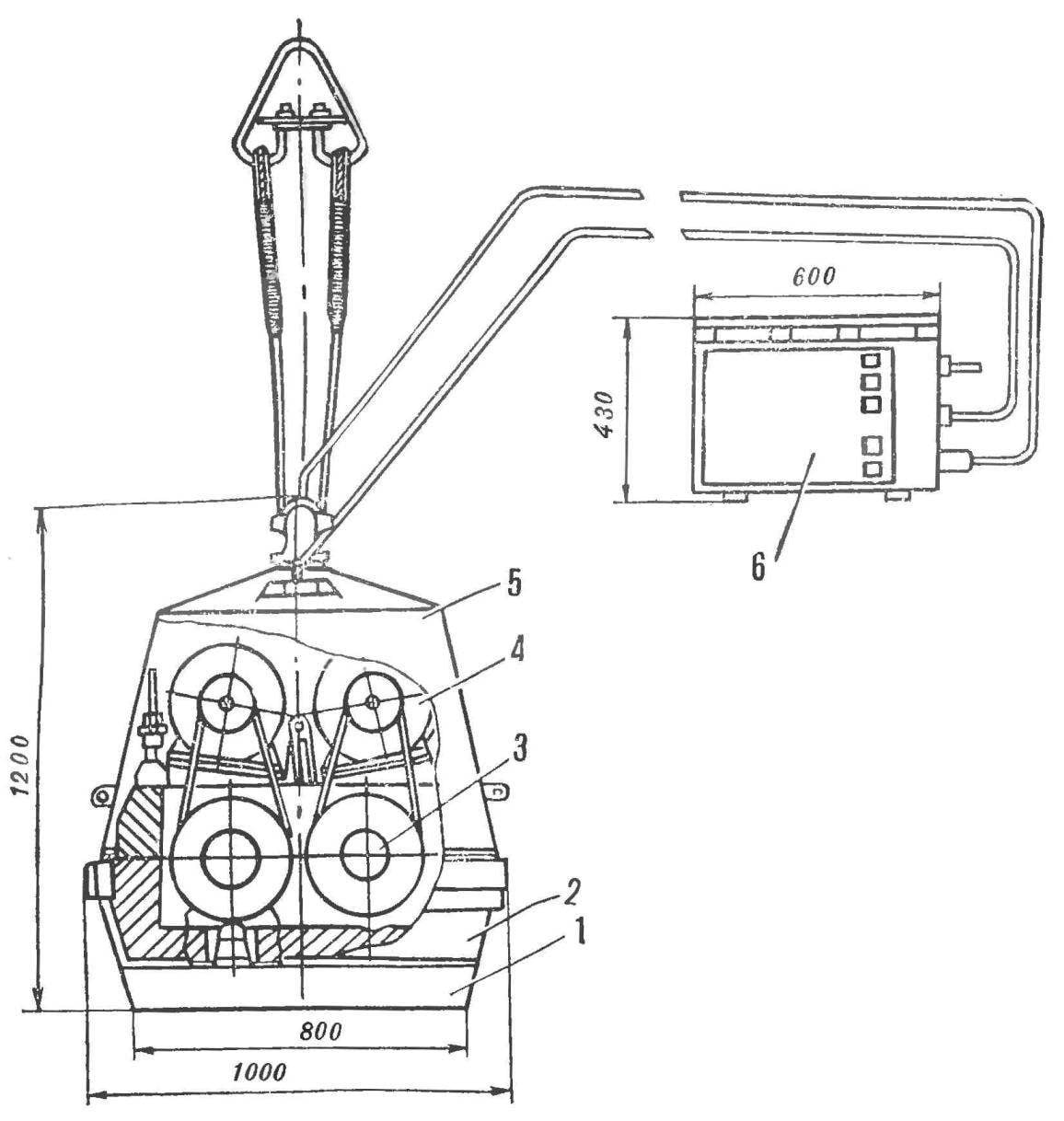

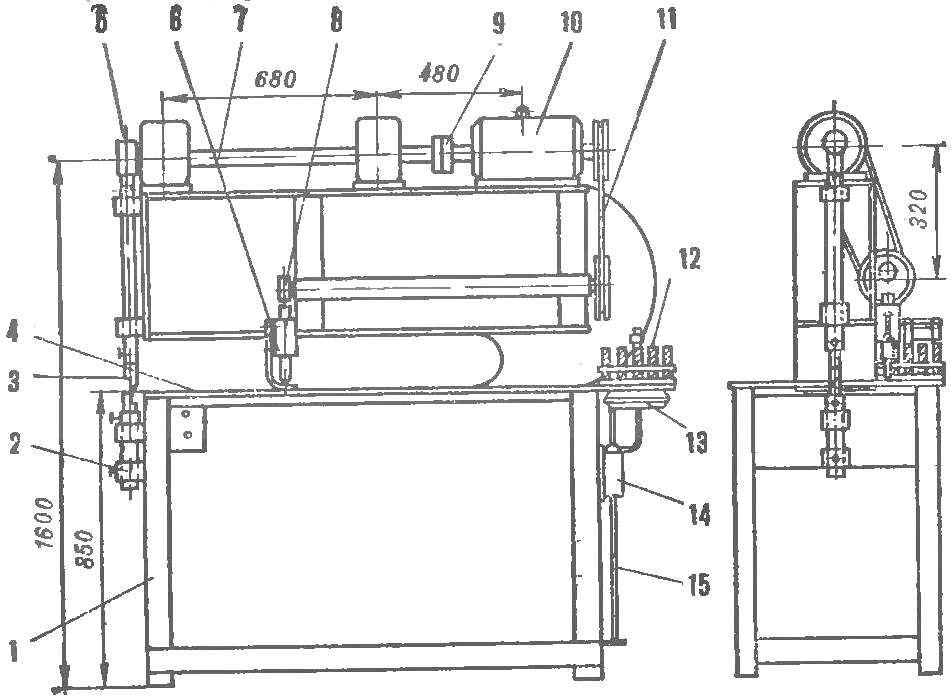

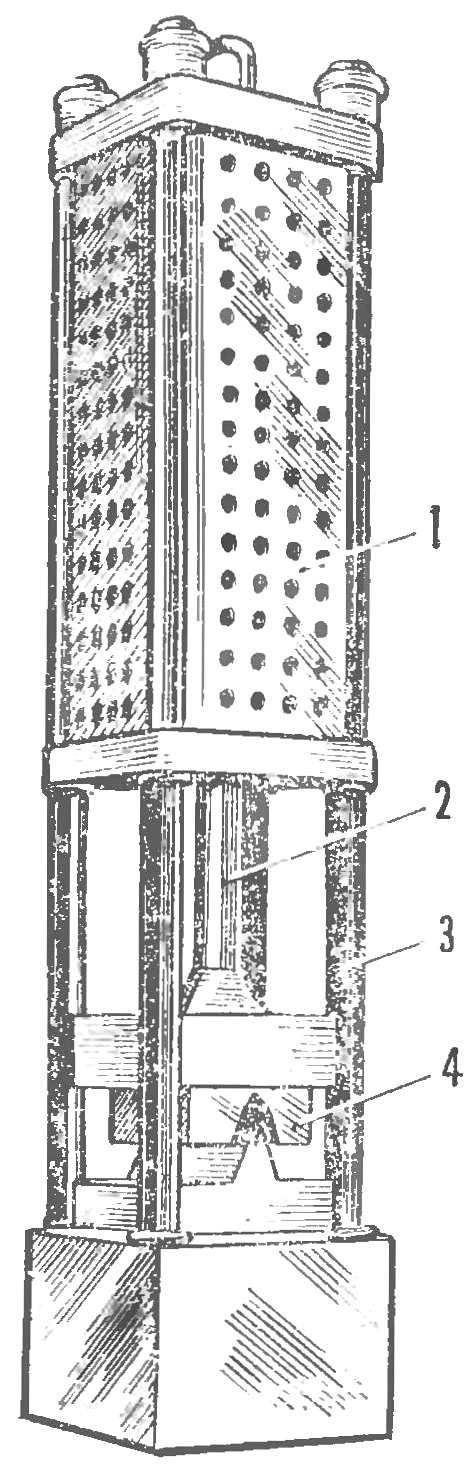

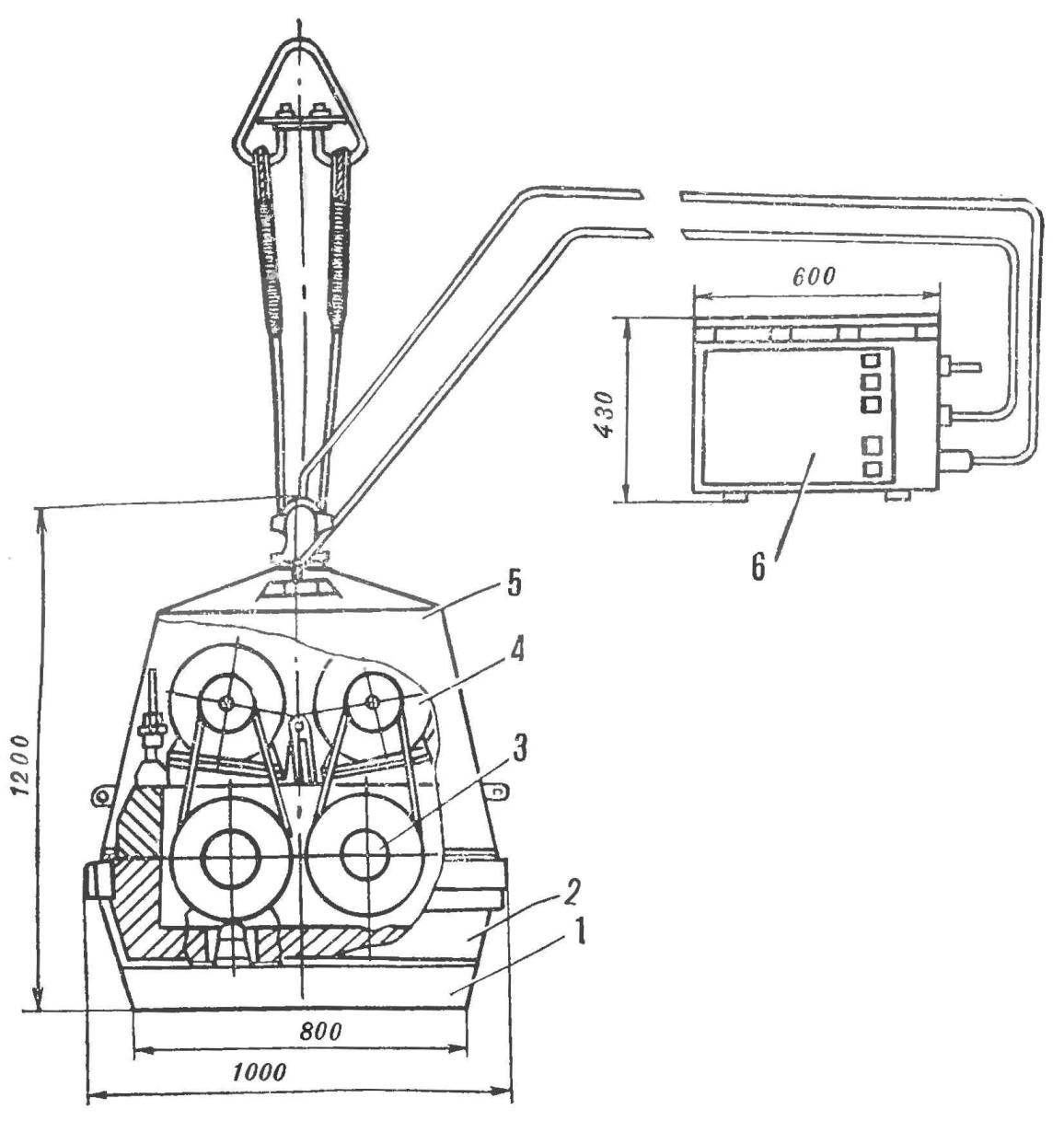

There is a whole range of different mechanisms for various kinds of sealing and tamping in construction from rollers to vibrotables. The device, created at the Central scientific-research and design-experimental Institute of organization, mechanization and technical assistance construction, will be indispensable where you want a layered soil compaction when backfilling the dug-up trenches, especially if the work is performed in cramped conditions in close proximity to foundations, pipelines, sewers.

There is a whole range of different mechanisms for various kinds of sealing and tamping in construction from rollers to vibrotables. The device, created at the Central scientific-research and design-experimental Institute of organization, mechanization and technical assistance construction, will be indispensable where you want a layered soil compaction when backfilling the dug-up trenches, especially if the work is performed in cramped conditions in close proximity to foundations, pipelines, sewers.

TRIPLE LASER

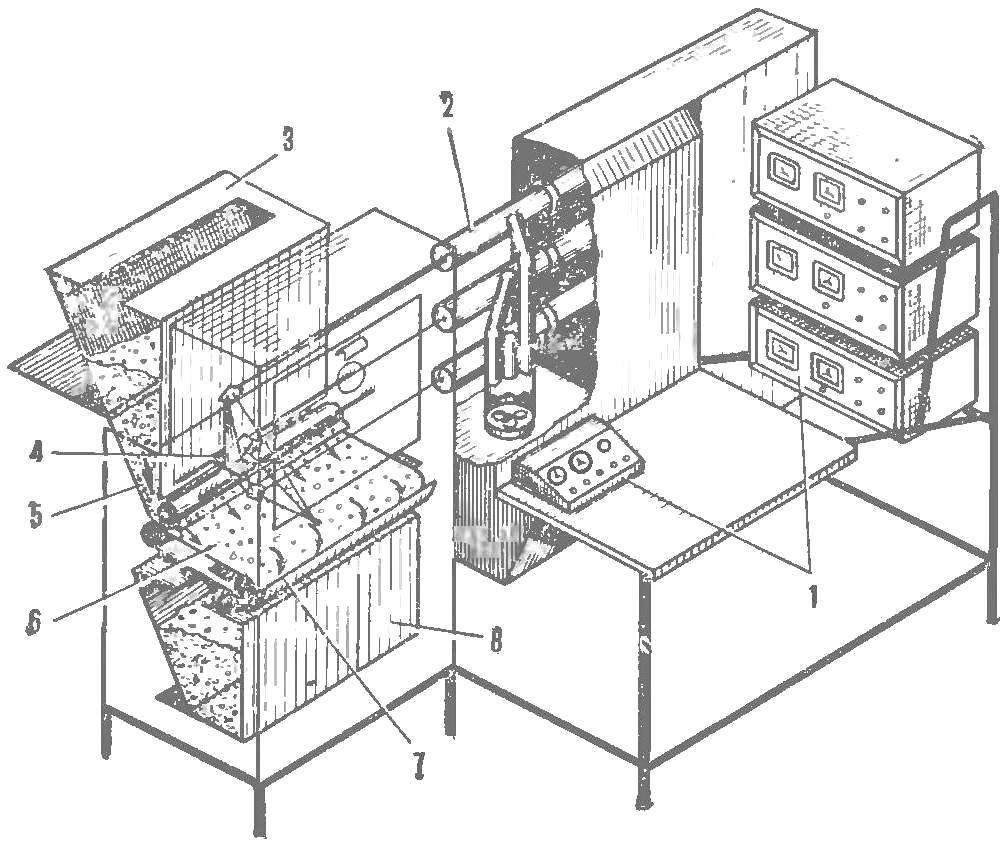

Recent studies have shown that laser beams act on the seeds of agricultural plants as an active stimulant, arousing in them the reserve force, increasing productivity, zastausia from disease.

Recent studies have shown that laser beams act on the seeds of agricultural plants as an active stimulant, arousing in them the reserve force, increasing productivity, zastausia from disease. “ELECTROMURES”

The name given to the original device, designed to replace manual labor when laying trunk cables with a diameter up to 60 mm. With their heavy lashes, as if boatmen twine could handle, holding at the same time, only a few people. Hard work and assumes “Electrobolt”.

The name given to the original device, designed to replace manual labor when laying trunk cables with a diameter up to 60 mm. With their heavy lashes, as if boatmen twine could handle, holding at the same time, only a few people. Hard work and assumes “Electrobolt”.