Our workshop

PLANE FOR TWO

THE OLD WIZARD GYPSUM

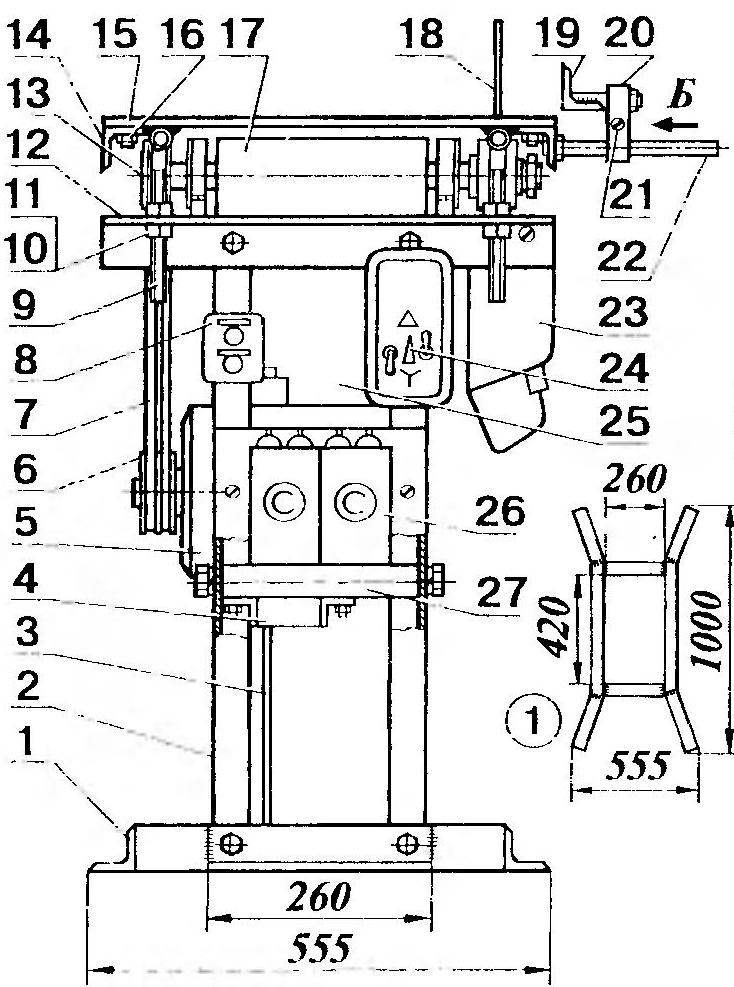

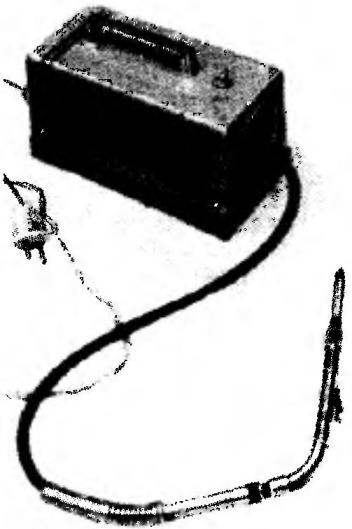

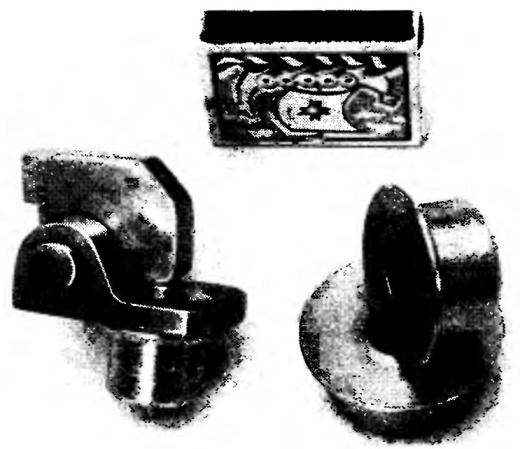

ENGRAVING MACHINE

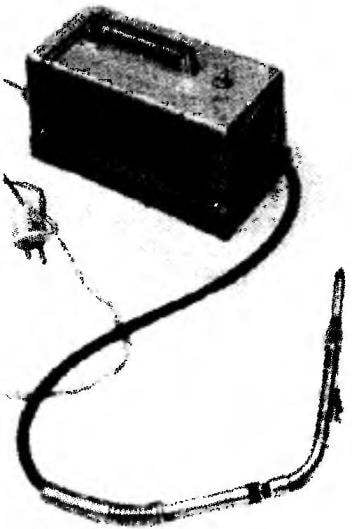

Engraving machine is designed for deep drawing of inscriptions and drawings on metal or plastic. In the machine used flexible shaft with collet BorderStyle from the medical drill. The drive from the electric motor KD-30 UCH power of 60 watts (electric typewriter). The rotation of the motor shaft at a speed of 2700 rpm allows you to do without a reducer.

Engraving machine is designed for deep drawing of inscriptions and drawings on metal or plastic. In the machine used flexible shaft with collet BorderStyle from the medical drill. The drive from the electric motor KD-30 UCH power of 60 watts (electric typewriter). The rotation of the motor shaft at a speed of 2700 rpm allows you to do without a reducer.

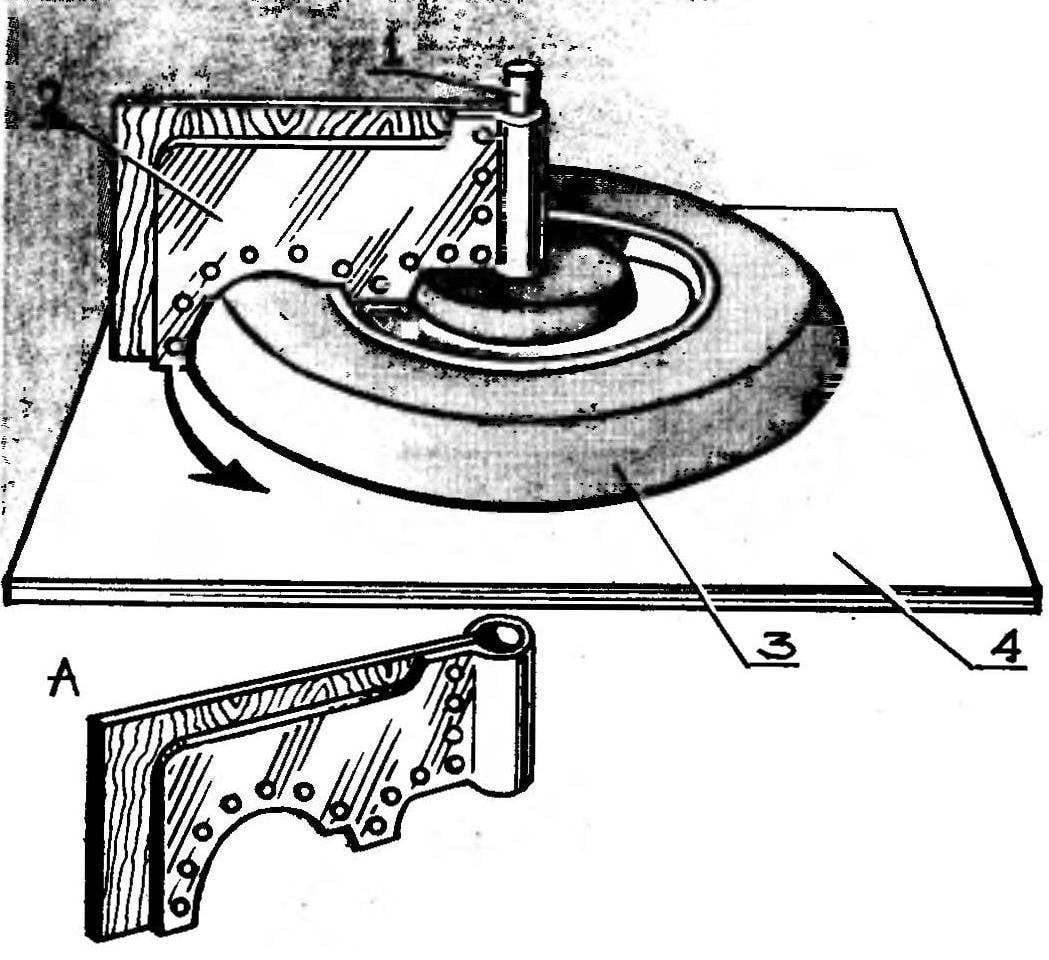

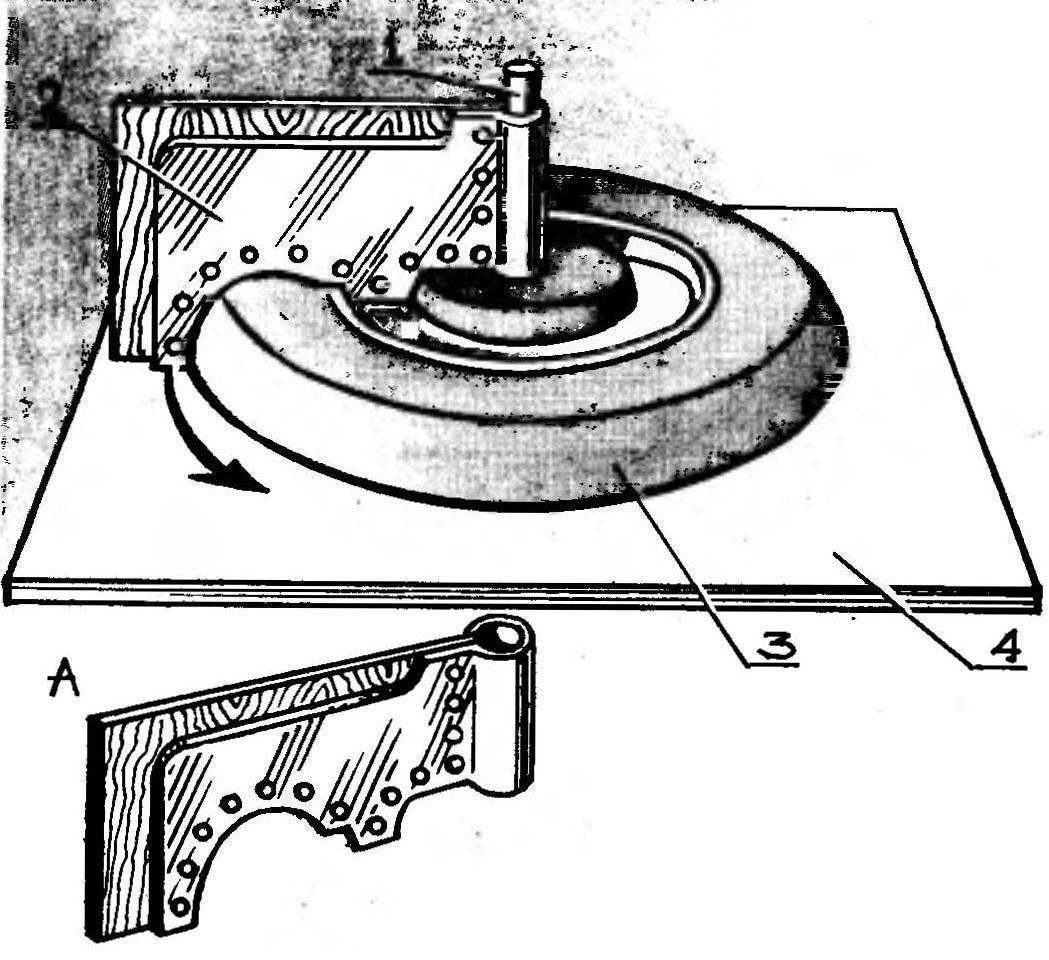

SOLDERING HOOD

When soldering tin-lead solder emits vapours, which are very harmful, especially lead. The smell of rosin is not all pleasant. Some hams even have to leave your favorite passion – grumble’s household. However, there is a way to make exhaust ventilation. For example, I use this for over 20 years. When making use of almost everything is ready. The hoses and the top cover is taken from a vacuum cleaner. The snail and the impeller from the heater of the car “KAMAZ”.

When soldering tin-lead solder emits vapours, which are very harmful, especially lead. The smell of rosin is not all pleasant. Some hams even have to leave your favorite passion – grumble’s household. However, there is a way to make exhaust ventilation. For example, I use this for over 20 years. When making use of almost everything is ready. The hoses and the top cover is taken from a vacuum cleaner. The snail and the impeller from the heater of the car “KAMAZ”.

SPIKES? NO PROBLEM

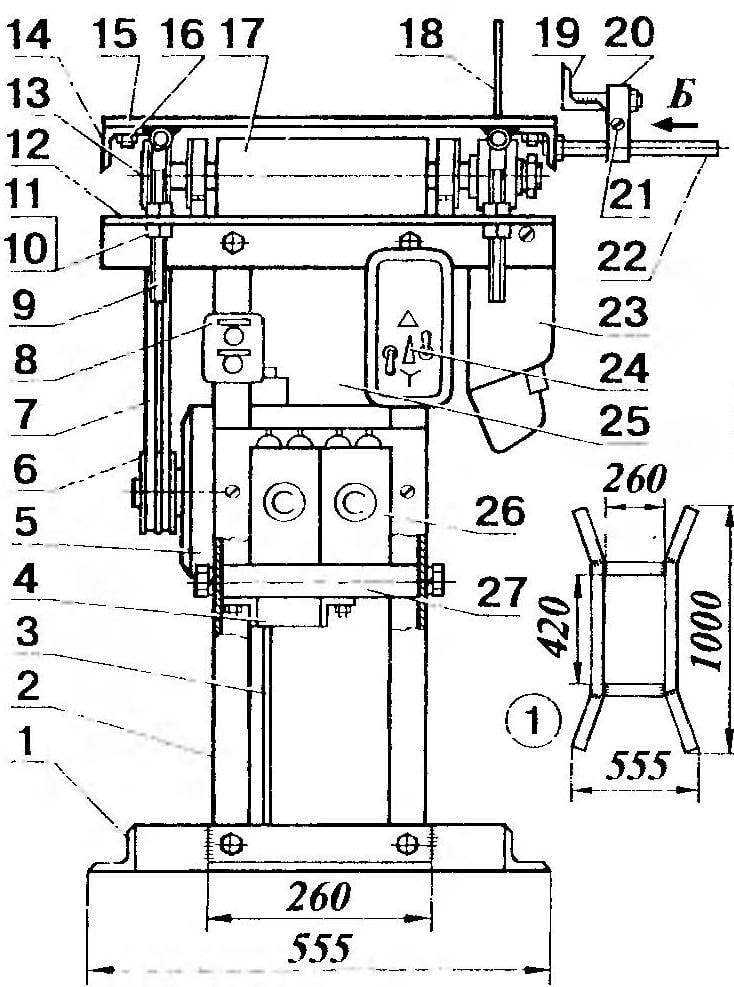

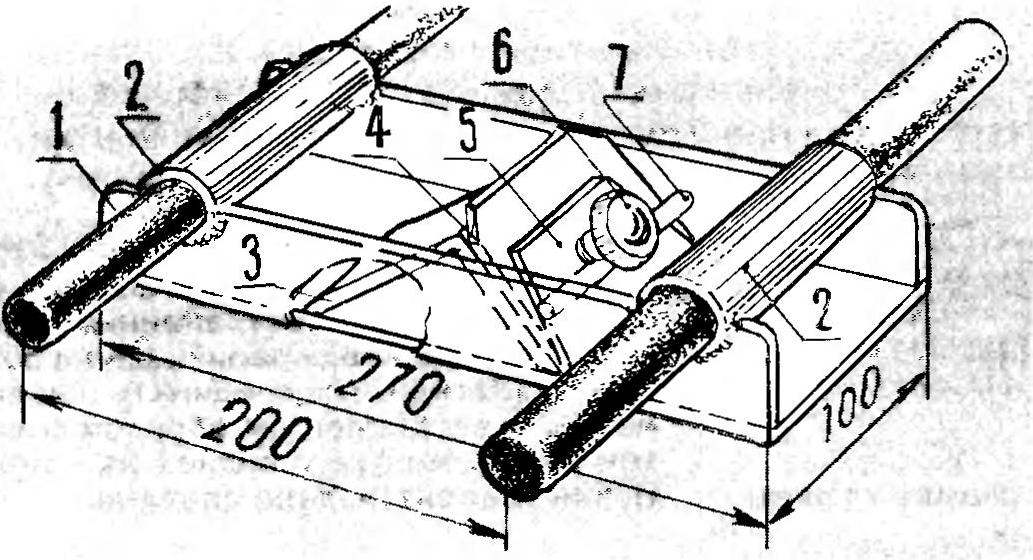

Most comfortable furniture, “serious” joinery collect connecting parts on the thorns. Technical requirements for the quality of such nodes is usually very high. Run them by milling or using special equipment. Existing designs handmade kiparisov, regardless of their complexity, there are drawbacks, and one of them — a large thick spikes with little their length and the insufficient depth of the eyes, the inconvenience of zapilivanie, and hence risk of injury.

Most comfortable furniture, “serious” joinery collect connecting parts on the thorns. Technical requirements for the quality of such nodes is usually very high. Run them by milling or using special equipment. Existing designs handmade kiparisov, regardless of their complexity, there are drawbacks, and one of them — a large thick spikes with little their length and the insufficient depth of the eyes, the inconvenience of zapilivanie, and hence risk of injury.

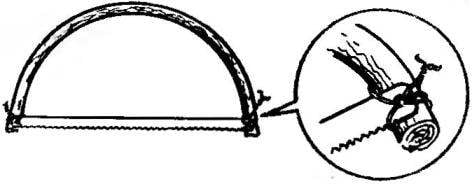

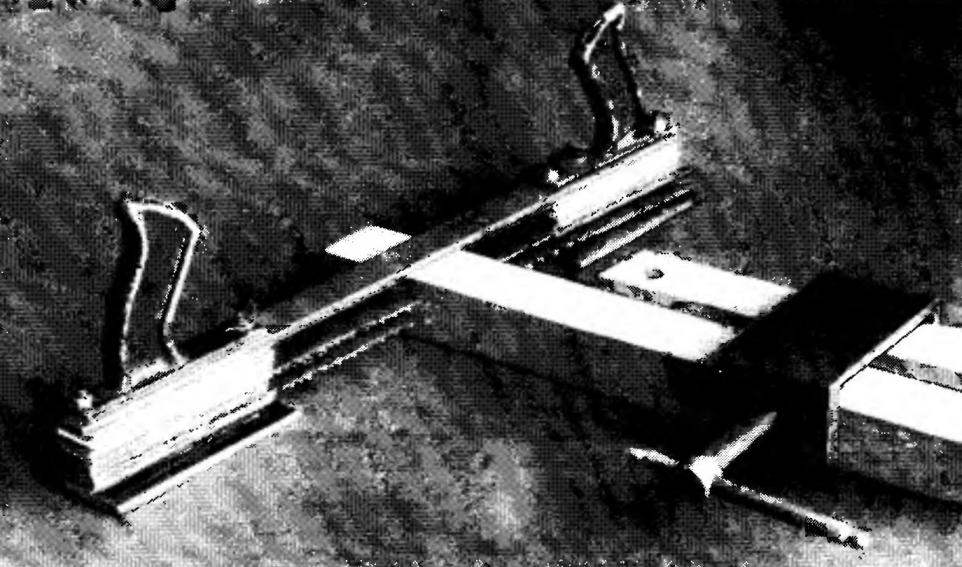

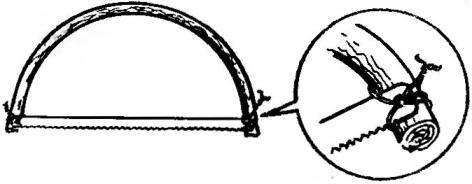

HACKSAW FROM SCRAP MATERIALS

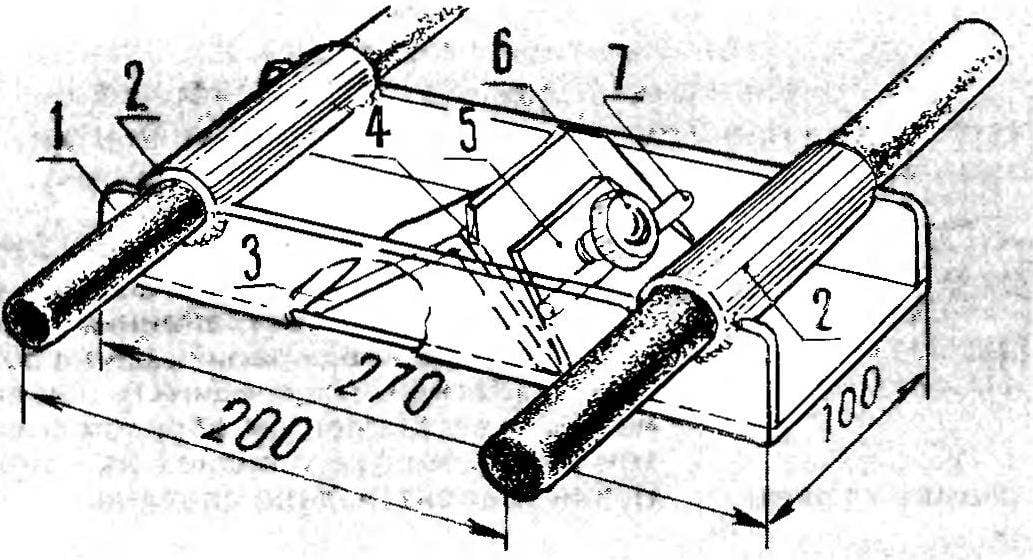

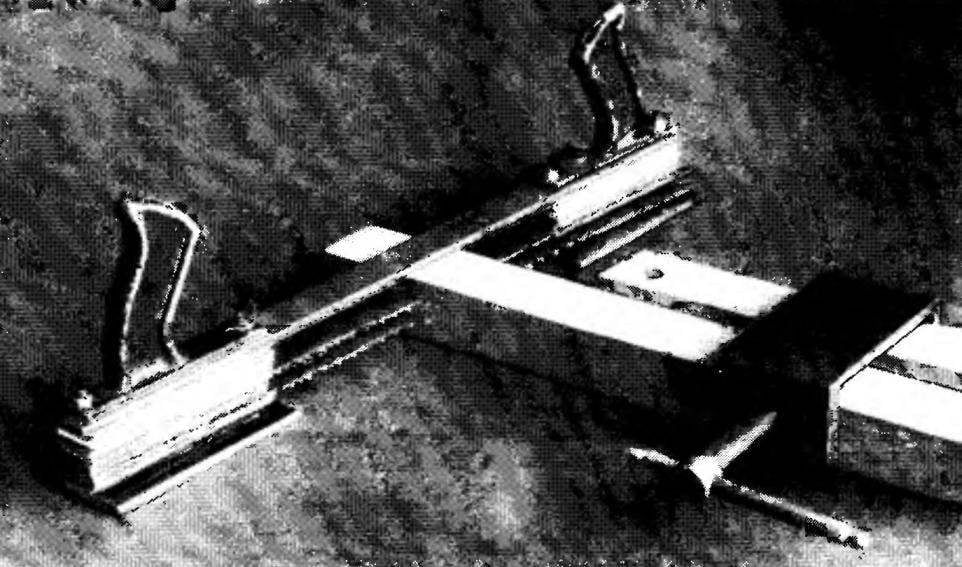

As an Amateur I sometimes need a tool that is rarely or on sale, or is not satisfied by construction, (and today — and for the price). So we have to invent and produce itself, looking for possible easy solutions. I would like to share with readers his versions of such popular devices as the machine (frame) for sawing metal.

As an Amateur I sometimes need a tool that is rarely or on sale, or is not satisfied by construction, (and today — and for the price). So we have to invent and produce itself, looking for possible easy solutions. I would like to share with readers his versions of such popular devices as the machine (frame) for sawing metal.

FOR ALL OCCASIONS — VAMA

The old masters of carpentry there is a very handy versatile tool, which is to remind home to craftsmen working with wood. The device is called Vama. It is an indispensable tool when you need to glue the frame to make a panel of boards, assemble with glue so-called furniture of boards.

The old masters of carpentry there is a very handy versatile tool, which is to remind home to craftsmen working with wood. The device is called Vama. It is an indispensable tool when you need to glue the frame to make a panel of boards, assemble with glue so-called furniture of boards.

THE LAYOUT WITHOUT A TEMPLATE

Usually machines, mechanisms and assemblies during installation is fixed to the mounting surface or Foundation of several bolts. The centers of the bolt holes, usually marked with templates, taken from the base mounted units. Work sin a long, time-consuming, requiring the involvement of specialists of high qualification. However, to avoid markup errors that reduce the reliability of fastening is not always possible.

Usually machines, mechanisms and assemblies during installation is fixed to the mounting surface or Foundation of several bolts. The centers of the bolt holes, usually marked with templates, taken from the base mounted units. Work sin a long, time-consuming, requiring the involvement of specialists of high qualification. However, to avoid markup errors that reduce the reliability of fastening is not always possible.

CREATIVE CORNER

I was always surprised how passionate people are literally “cuts out” even in their small apartments place under house workshop while compactly arranging the equipments and tools efficiently using the available space. His creative area in the acquired country house I arranged in the wall between the Windows. Initially hoped to use it as temporary. Therefore, as the basis for it were made simple homemade rack, assembled mainly from only one planed boards with a thickness of 10 mm and a width of 120 mm.

I was always surprised how passionate people are literally “cuts out” even in their small apartments place under house workshop while compactly arranging the equipments and tools efficiently using the available space. His creative area in the acquired country house I arranged in the wall between the Windows. Initially hoped to use it as temporary. Therefore, as the basis for it were made simple homemade rack, assembled mainly from only one planed boards with a thickness of 10 mm and a width of 120 mm.