It’s safe to say there is not a single sector of the economy of our country, where would be a creative contribution to the implementation of the decisions of the XXV Congress of the party, the tasks of the five-year plan Komsomol members and youth. Tens of thousands of engineering developments of young enthusiasts of technical creativity, innovators and inventors, is introduced in industry, agriculture, construction and transport, contribute to the acceleration of scientific and technological progress, the early implementation of the plan. The best of them were presented at the Central exhibition NTTM-80 in Moscow.

It’s safe to say there is not a single sector of the economy of our country, where would be a creative contribution to the implementation of the decisions of the XXV Congress of the party, the tasks of the five-year plan Komsomol members and youth. Tens of thousands of engineering developments of young enthusiasts of technical creativity, innovators and inventors, is introduced in industry, agriculture, construction and transport, contribute to the acceleration of scientific and technological progress, the early implementation of the plan. The best of them were presented at the Central exhibition NTTM-80 in Moscow.THE WORM GEAR ON A LATHE

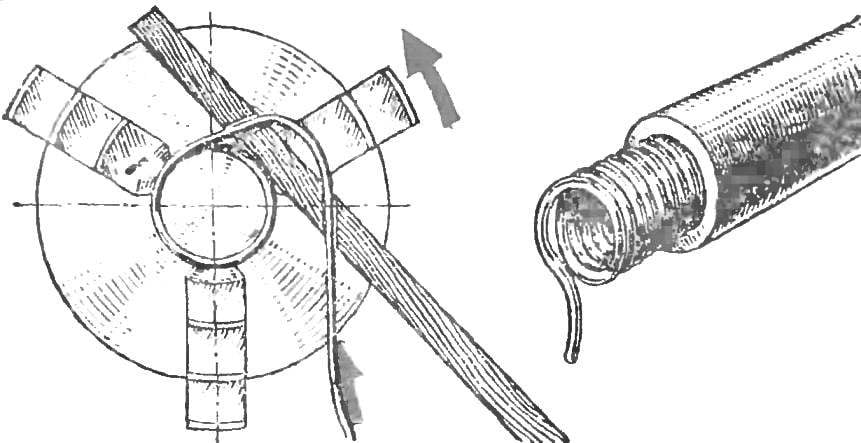

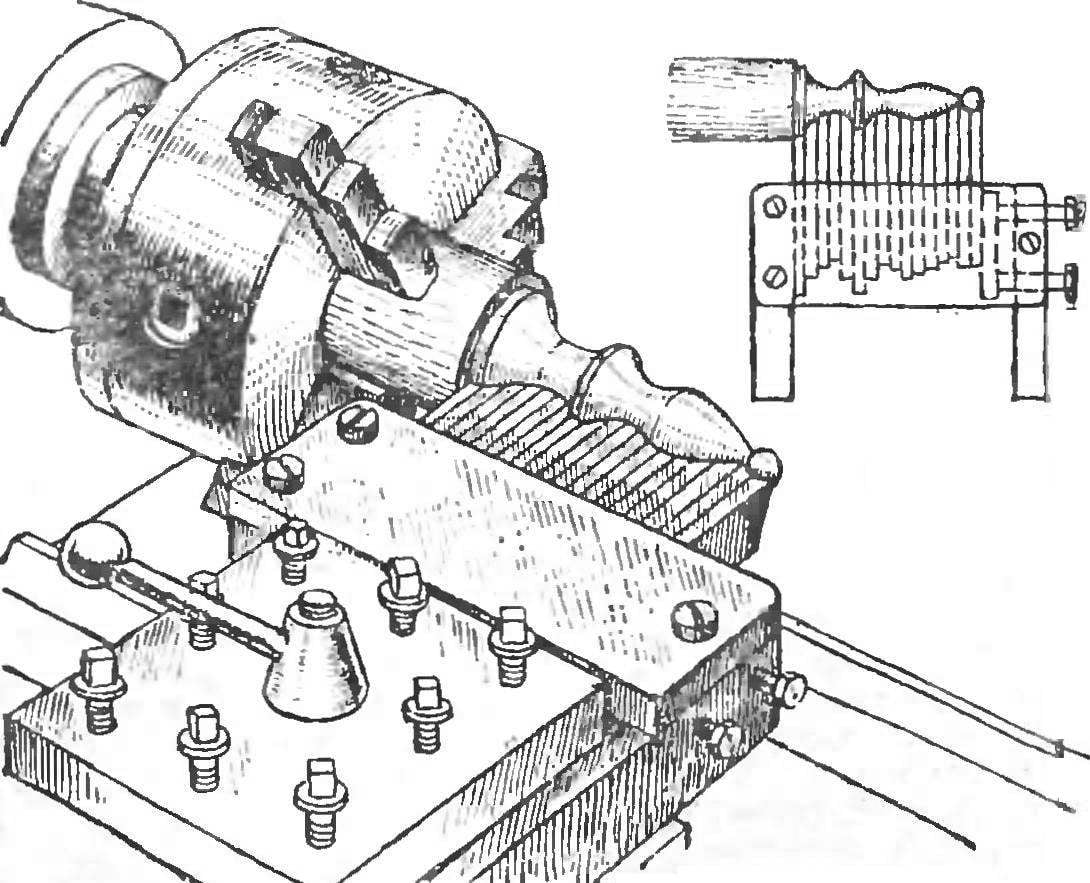

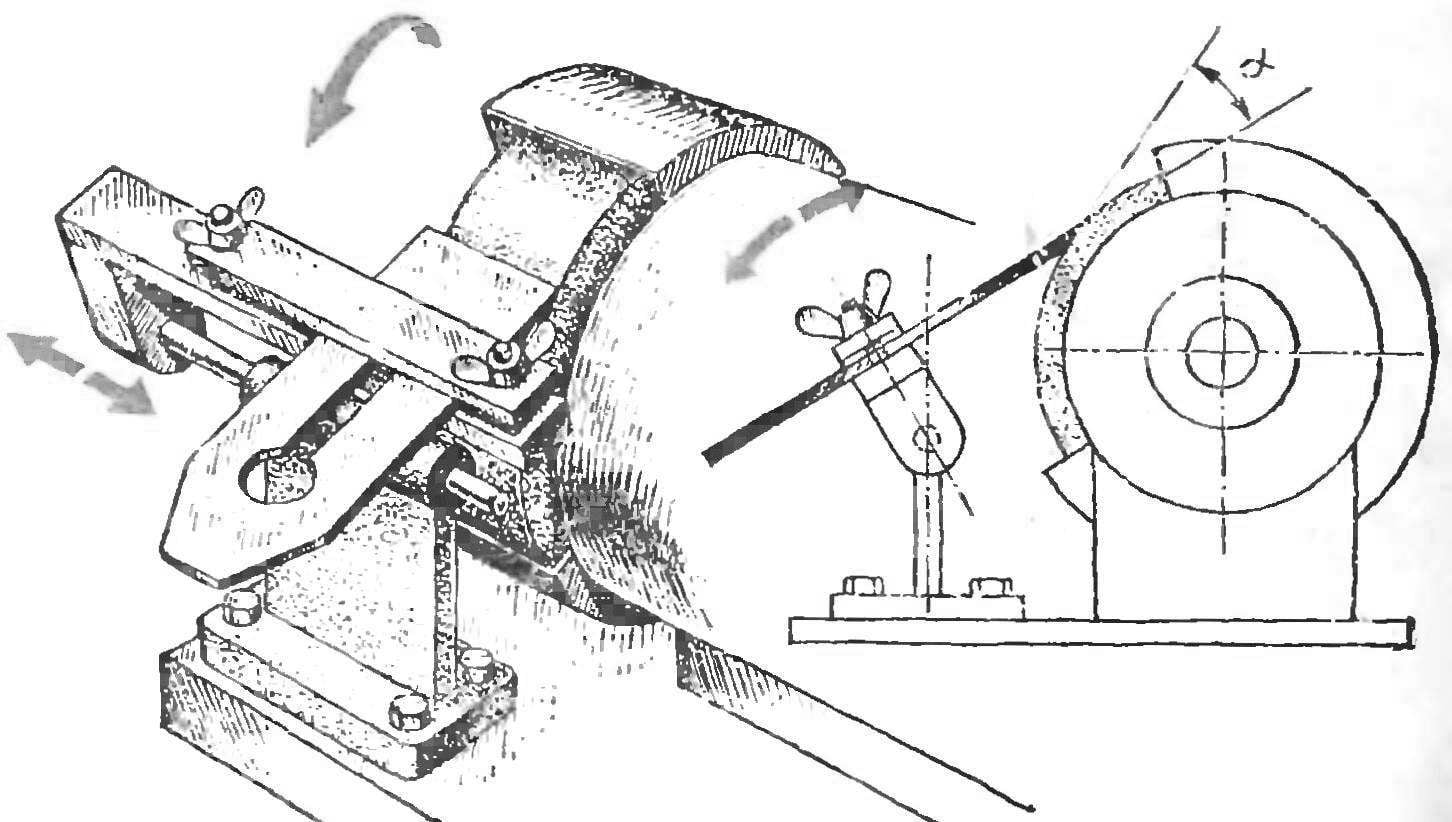

We offer to your attention a simple device with which a lathe can cut the worm wheel with any number of teeth. As the cutting tool used here is the standard tap mounted in the Chuck of the machine and pre-loaded tailstock. The fixture is a mandrel, mounted in the tool holder. Harvesting worm wheel Read more…

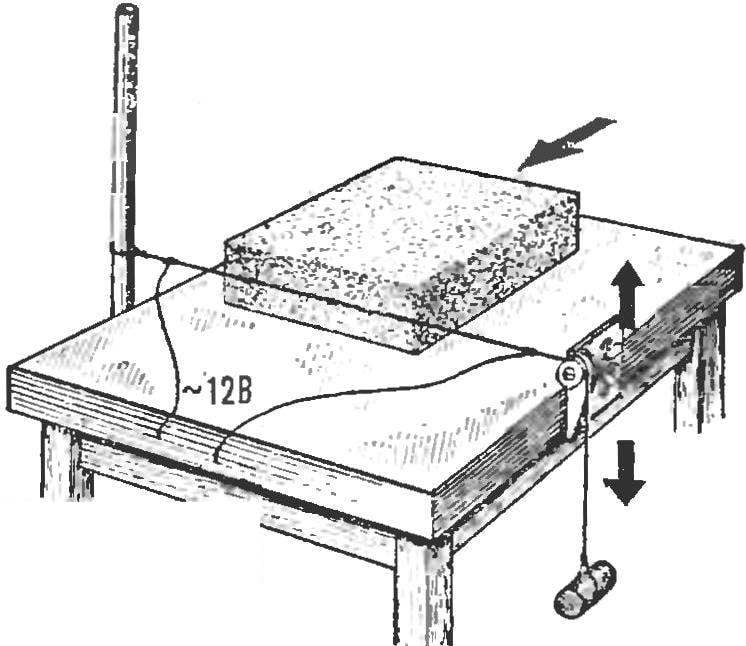

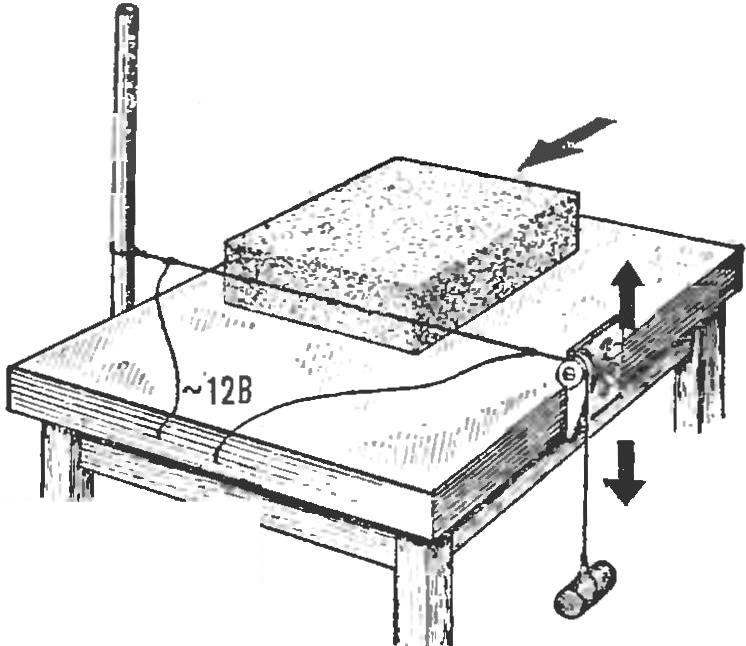

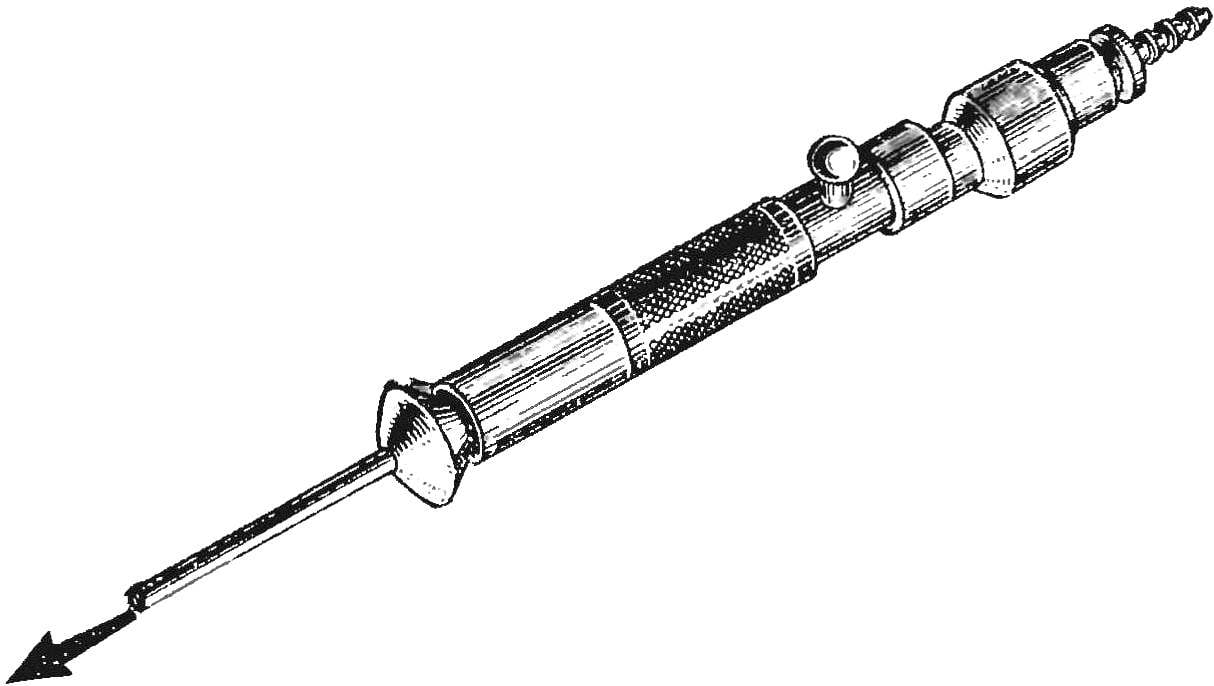

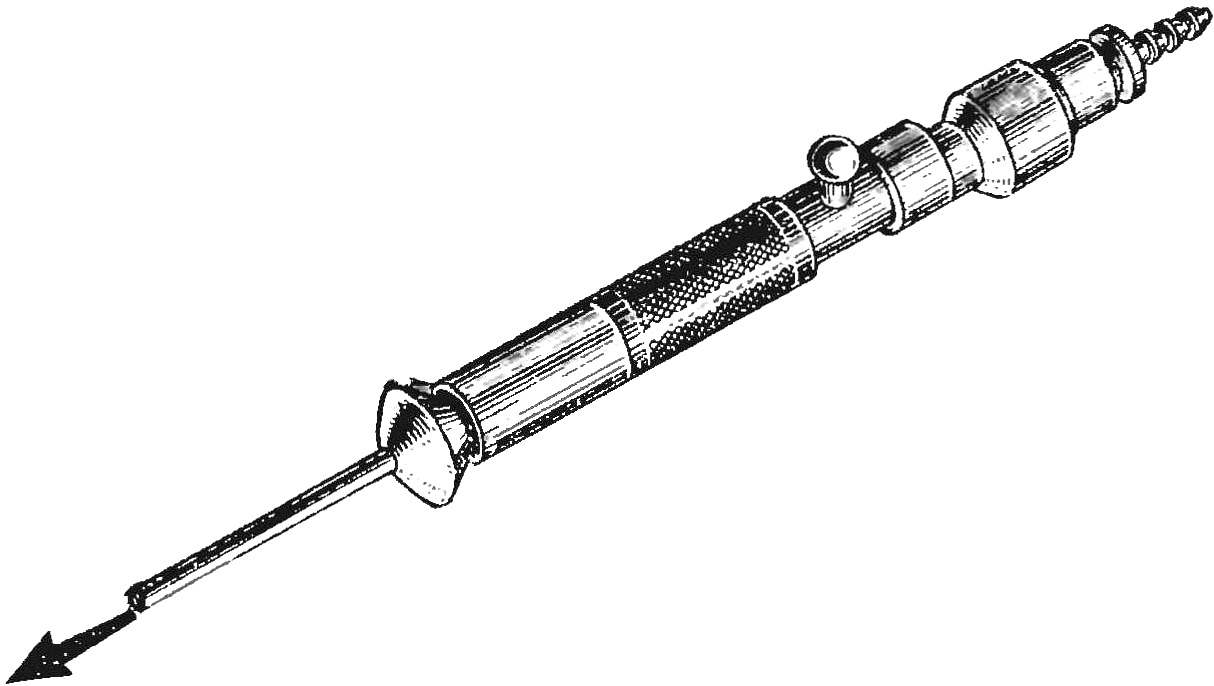

Offer two method of cutting large sheets of foam. Nichrome filament is suspended vertically (Fig. 1) or stretched horizontally to the table surface (Fig. 2). Adjusting in the first case, the distance from the filament to a movable guide area and the second the height and angle of the thread relative to the surface of the table, it is possible to obtain blanks of all shapes and sizes. The expansion of the filament during heating is selected with the cargo.

Offer two method of cutting large sheets of foam. Nichrome filament is suspended vertically (Fig. 1) or stretched horizontally to the table surface (Fig. 2). Adjusting in the first case, the distance from the filament to a movable guide area and the second the height and angle of the thread relative to the surface of the table, it is possible to obtain blanks of all shapes and sizes. The expansion of the filament during heating is selected with the cargo.

Cut the ribbon at the ceremonial opening of the Central exhibition NTTM-80 at ENEA USSR — a kind of finish of the third, final stage of all-Union review of scientific and technical creativity of youth, which was dedicated to the 110th anniversary of Lenin’s birth. In the halls of 20 thousand exhibits in the country — 20 million boys and girls, young innovators, making a creative contribution to the acceleration of scientific and technical progress. During the four years of the tenth five year plan participants NTTM various sectors of the economy developed more than 4 million rationalization proposals, inventions, giving a saving of over RUB 5 billion.

Cut the ribbon at the ceremonial opening of the Central exhibition NTTM-80 at ENEA USSR — a kind of finish of the third, final stage of all-Union review of scientific and technical creativity of youth, which was dedicated to the 110th anniversary of Lenin’s birth. In the halls of 20 thousand exhibits in the country — 20 million boys and girls, young innovators, making a creative contribution to the acceleration of scientific and technical progress. During the four years of the tenth five year plan participants NTTM various sectors of the economy developed more than 4 million rationalization proposals, inventions, giving a saving of over RUB 5 billion.

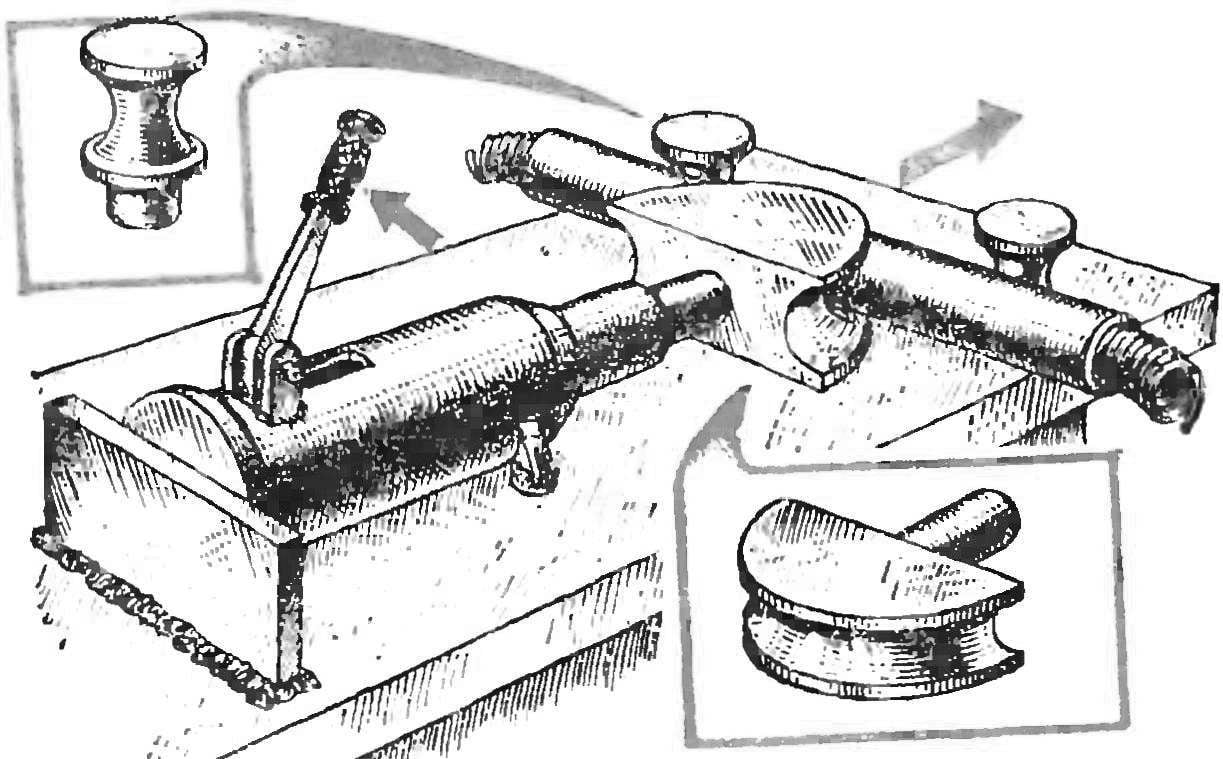

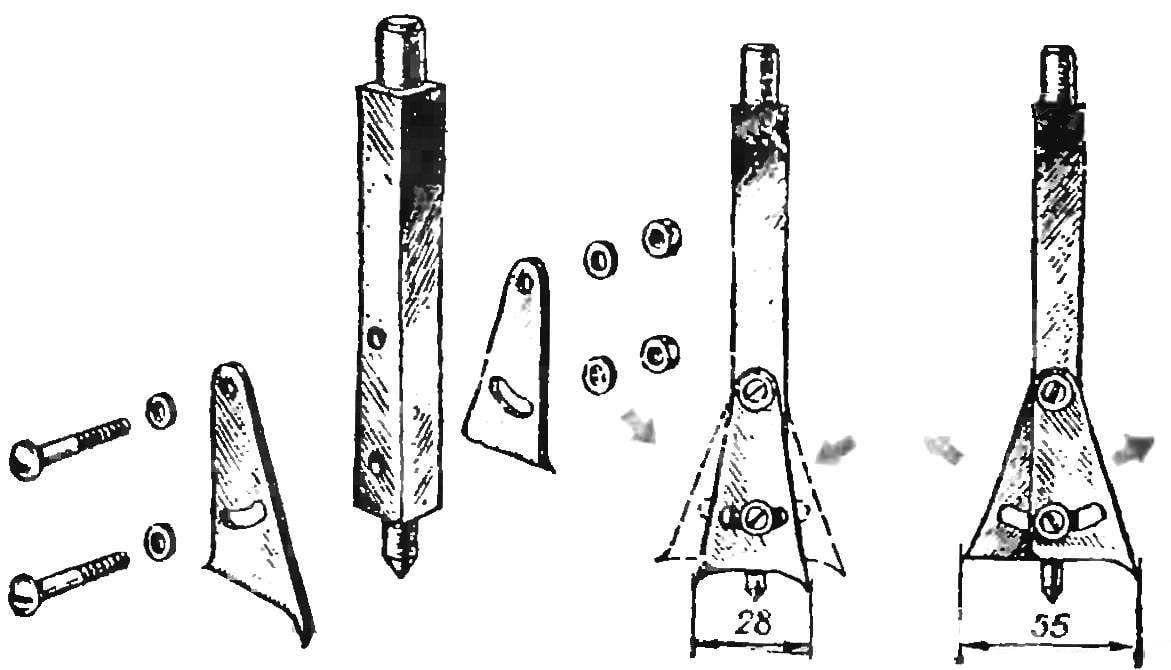

When the device watering system for garden plot or in the garden many problems arise when it is necessary to bend a metal tube. Meanwhile. not that hard to assemble a simple machine (see picture) for flexible aluminium, copper and thinwalled steel tubes with an outer diameter of 20 mm.

When the device watering system for garden plot or in the garden many problems arise when it is necessary to bend a metal tube. Meanwhile. not that hard to assemble a simple machine (see picture) for flexible aluminium, copper and thinwalled steel tubes with an outer diameter of 20 mm.