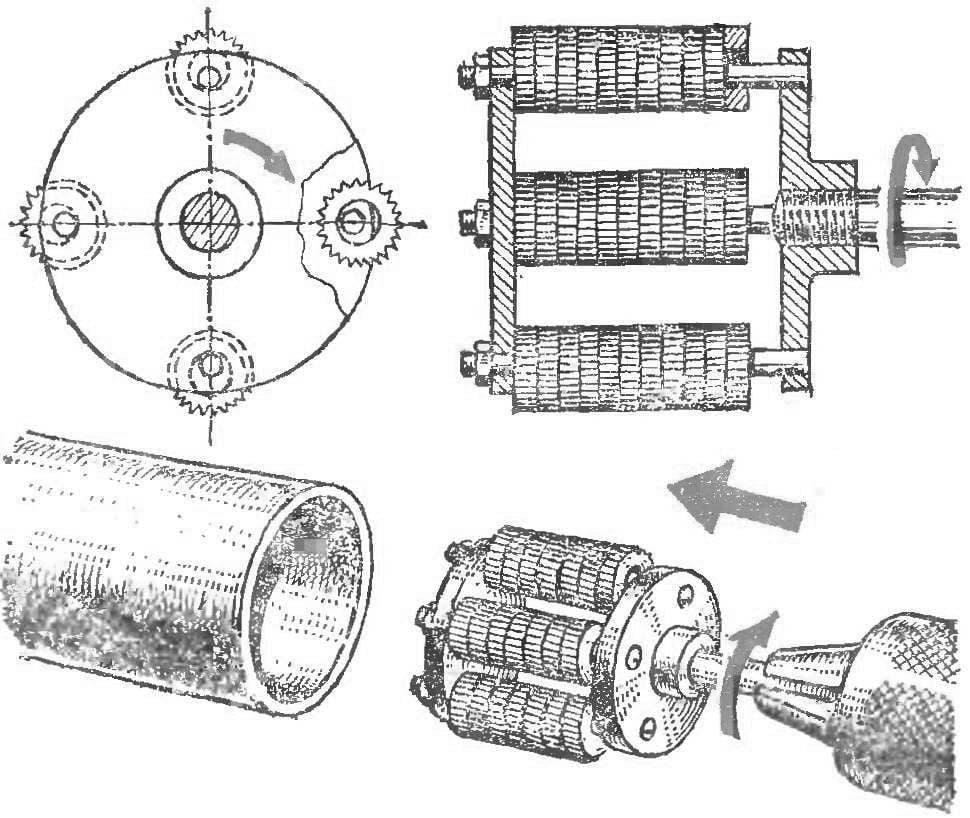

It’s mind typically “ship” device is intended for other, ground targets, Kuibyshev innovator N. Gerasimov developed it to help those who are engaged in the repair of automobile engines.

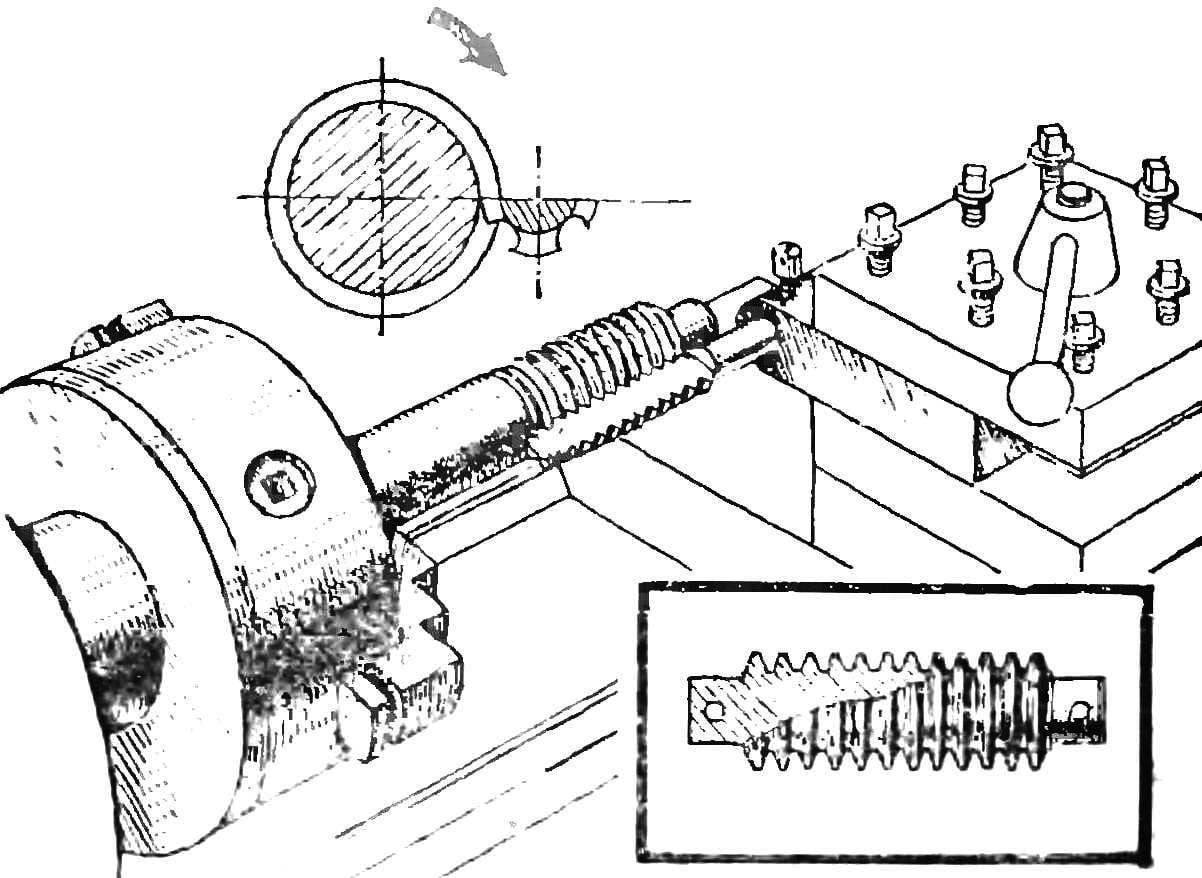

It’s mind typically “ship” device is intended for other, ground targets, Kuibyshev innovator N. Gerasimov developed it to help those who are engaged in the repair of automobile engines.GEAR RACK ON THE LATHE

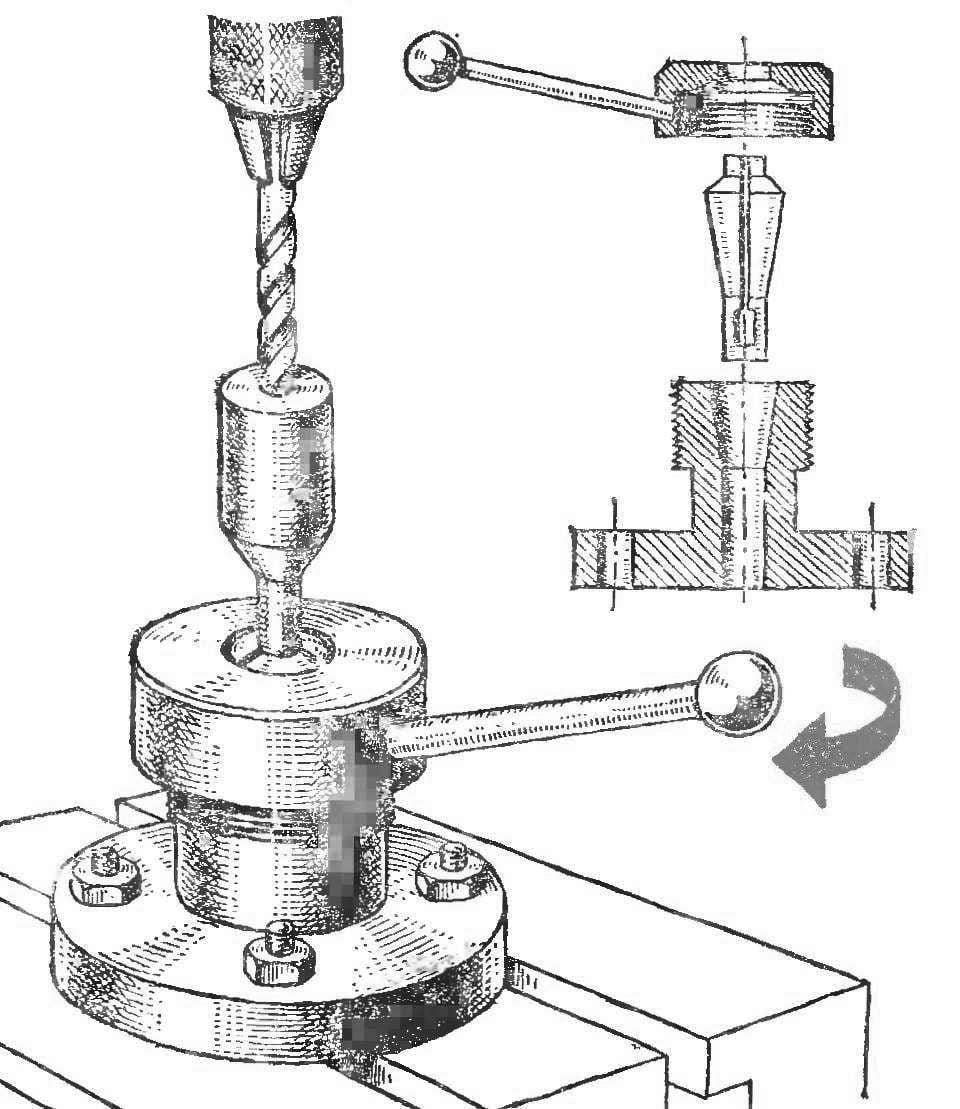

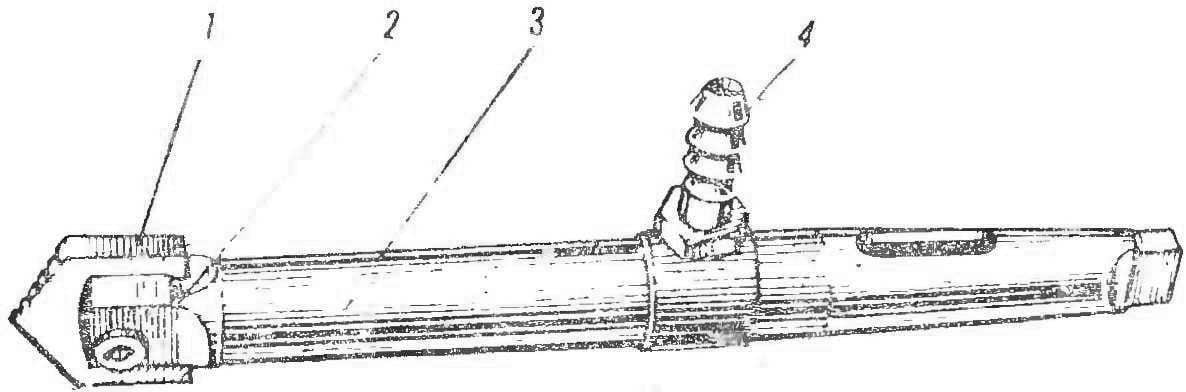

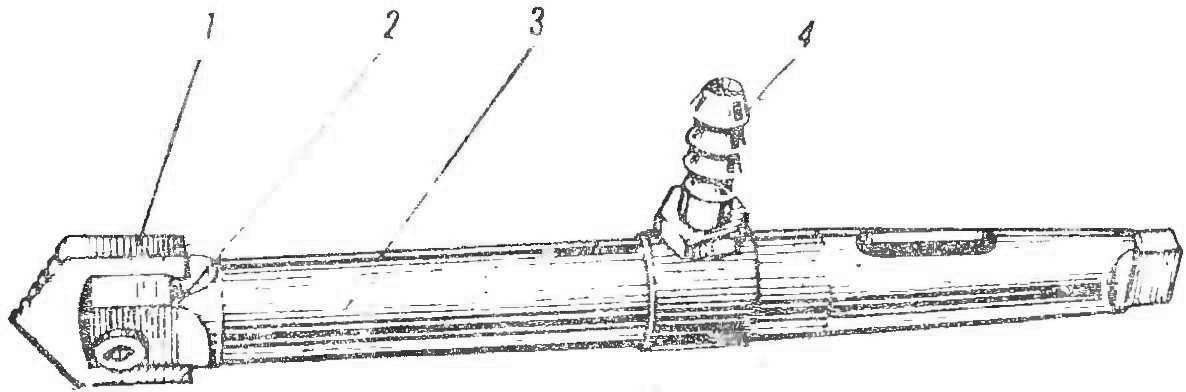

We offer you a simplified method of manufacturing a cylindrical gear rack. It can be done with a conventional tap, picking up the thread profile in accordance with your existing gear. Before working make a simple mandrel is a steel bar with a hole, which is inserted into the tap. The tap should be to Read more…

Offer homebrew. engaged in the manufacture or have manufactured furniture with doors mounted on piano hinges to replace them on domestic furniture, because the presence of piano hinges, even on well made furniture clearly indicates its self-made origin is unsightly.

Offer homebrew. engaged in the manufacture or have manufactured furniture with doors mounted on piano hinges to replace them on domestic furniture, because the presence of piano hinges, even on well made furniture clearly indicates its self-made origin is unsightly.

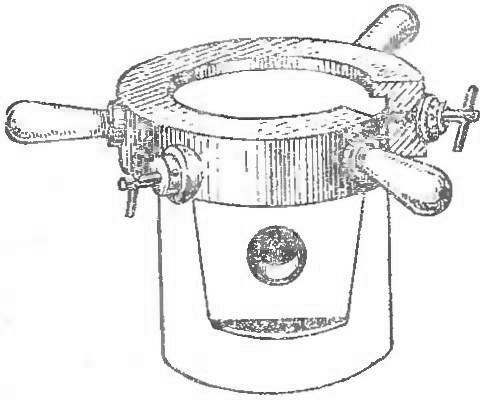

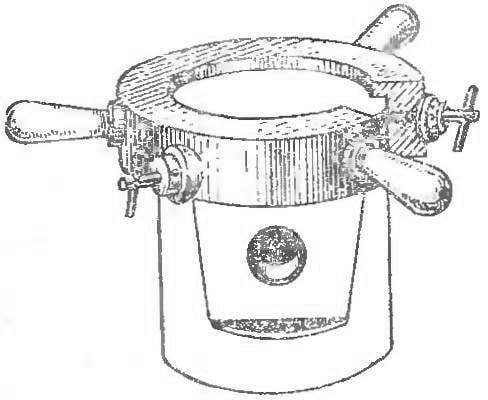

Building solutions, lubricating oils, protective fluids, paint, varnishes for coating of many modern “self-leveling” materials require special spray tips.

Building solutions, lubricating oils, protective fluids, paint, varnishes for coating of many modern “self-leveling” materials require special spray tips.

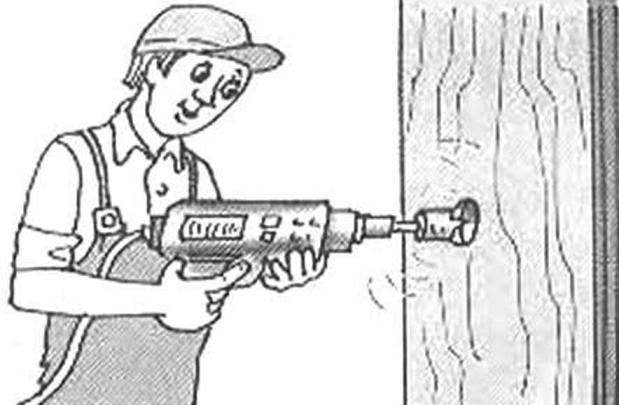

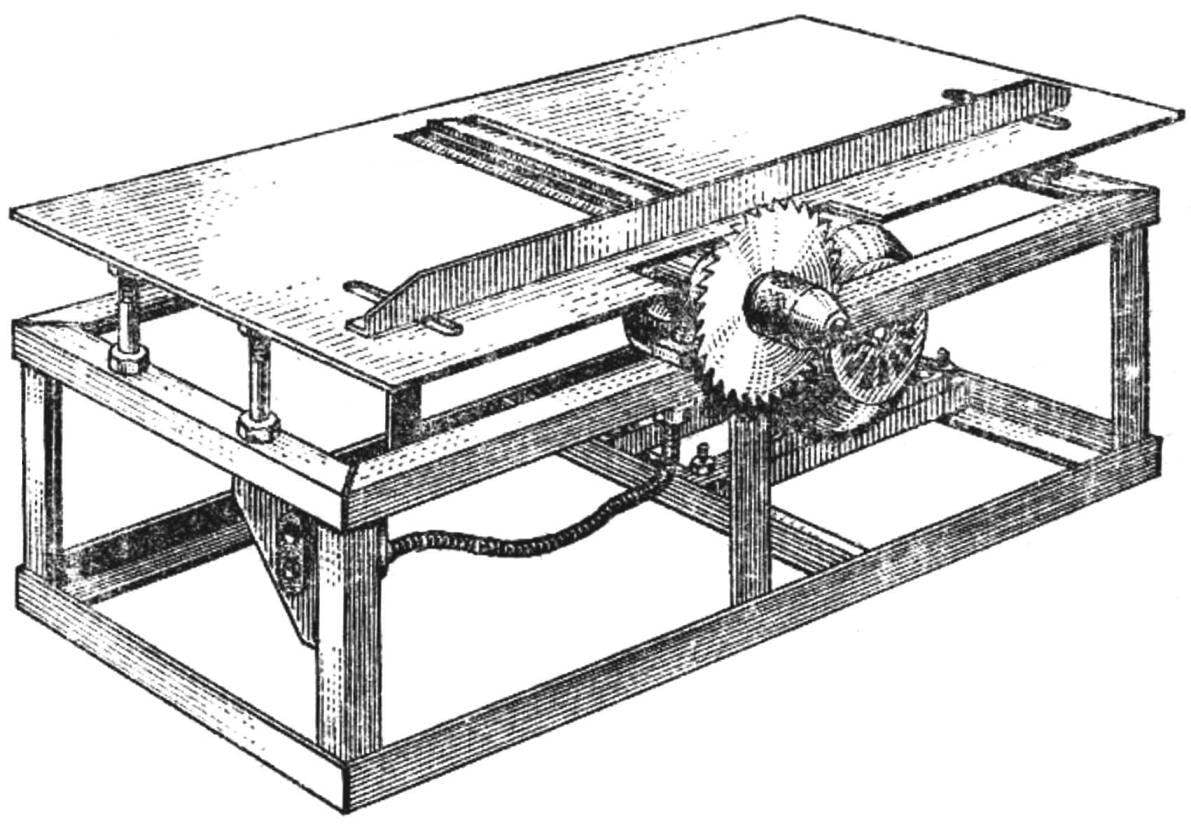

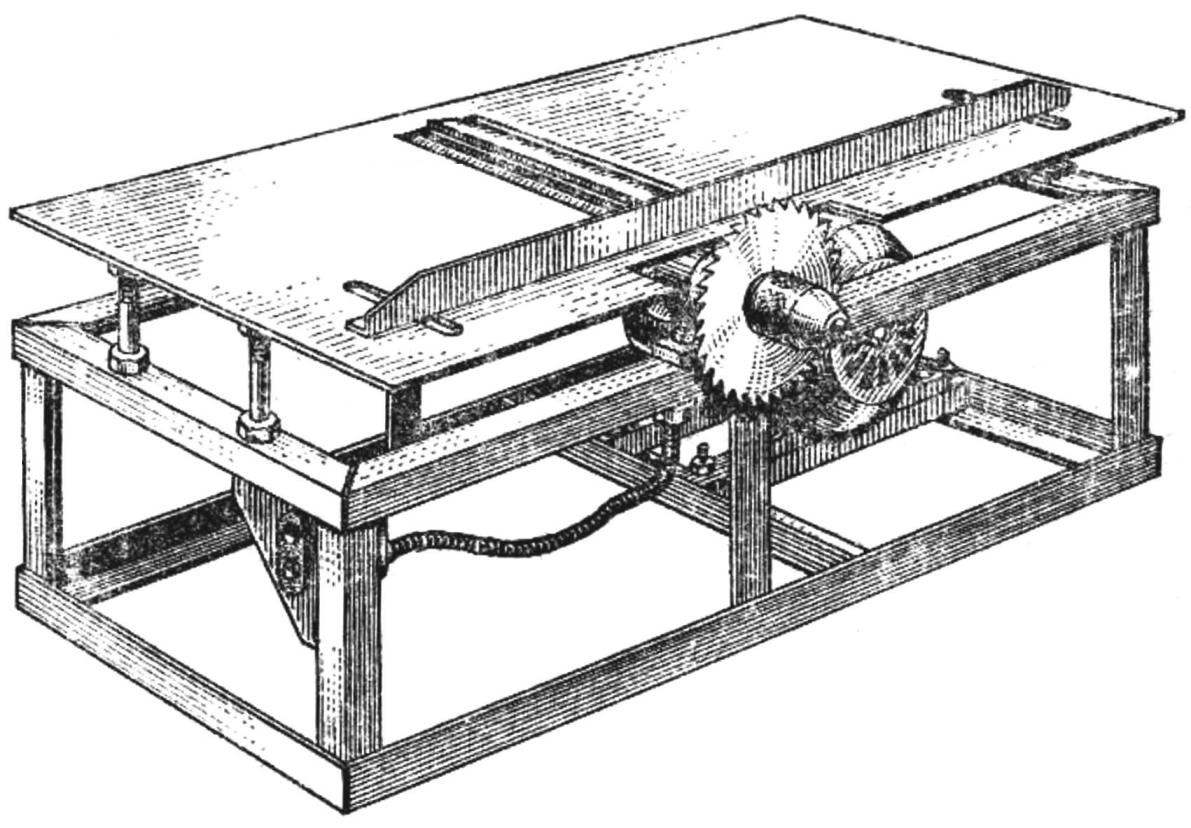

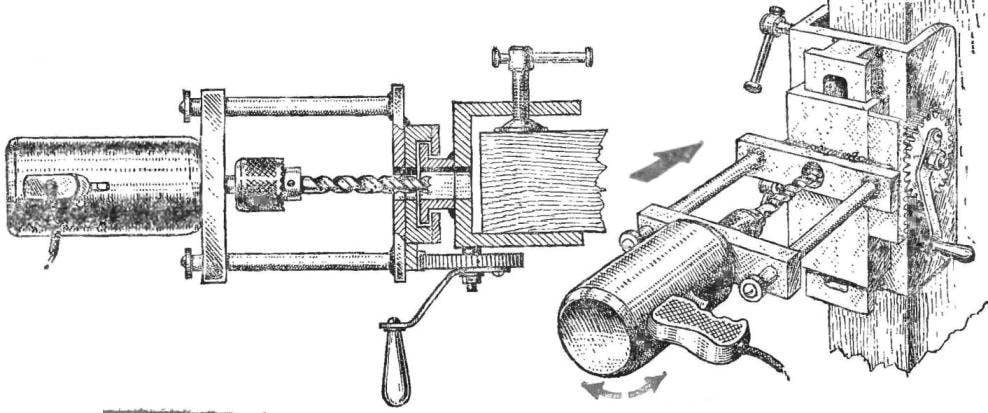

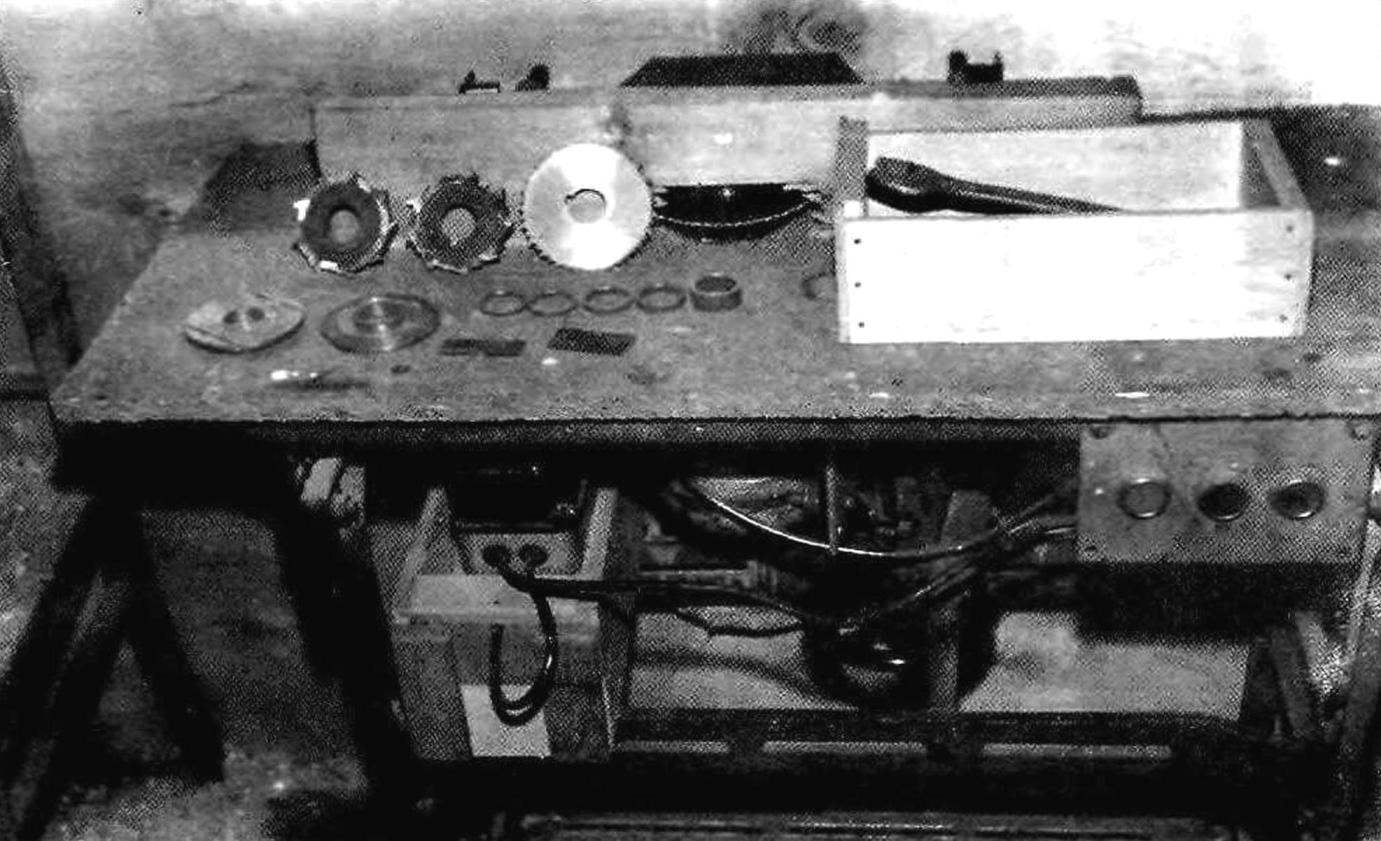

The machine is attractive for its versatility. It must be equipped with protective devices. Over the slot in the table it is necessary to install a height-adjustable pressure roller. Then Board when planing stops to jump and escape from the hands of: the quality will be better and fingers — safer. Of course, we cannot forget about the protective fence of the saw blade. And again. Because jaw Chuck is not moved, feeding parts for drilling, obviously, have to manually. To mechanize this process is also useful.

The machine is attractive for its versatility. It must be equipped with protective devices. Over the slot in the table it is necessary to install a height-adjustable pressure roller. Then Board when planing stops to jump and escape from the hands of: the quality will be better and fingers — safer. Of course, we cannot forget about the protective fence of the saw blade. And again. Because jaw Chuck is not moved, feeding parts for drilling, obviously, have to manually. To mechanize this process is also useful.

Modern engineering makes high demands on the materials, and they, in turn, to the machining tools. Not by chance all the exhibitions NTTM necessarily demonstrates the new development of young innovators dedicated to solving these problems taking into account the specifics and requirements of each specific production, and often cross-sectoral in nature.

Modern engineering makes high demands on the materials, and they, in turn, to the machining tools. Not by chance all the exhibitions NTTM necessarily demonstrates the new development of young innovators dedicated to solving these problems taking into account the specifics and requirements of each specific production, and often cross-sectoral in nature.

I’m a subscriber “Modeller-designer” already since 1972. Much of that time has changed, but the content of the magazine, I (and not only me) are quite satisfied. Let increased its subscription price (which is of course not pleased, but not scared — I understand the difficulties of the editors), I’ll write a journal, yet it will exist. Not going to list those topics in it that interest me the most is all that can be done in a home workshop, ranging from simple stools to, for example, motoriety. I also do many things with their hands (friends call me by this “local Kulibin”).

I’m a subscriber “Modeller-designer” already since 1972. Much of that time has changed, but the content of the magazine, I (and not only me) are quite satisfied. Let increased its subscription price (which is of course not pleased, but not scared — I understand the difficulties of the editors), I’ll write a journal, yet it will exist. Not going to list those topics in it that interest me the most is all that can be done in a home workshop, ranging from simple stools to, for example, motoriety. I also do many things with their hands (friends call me by this “local Kulibin”).