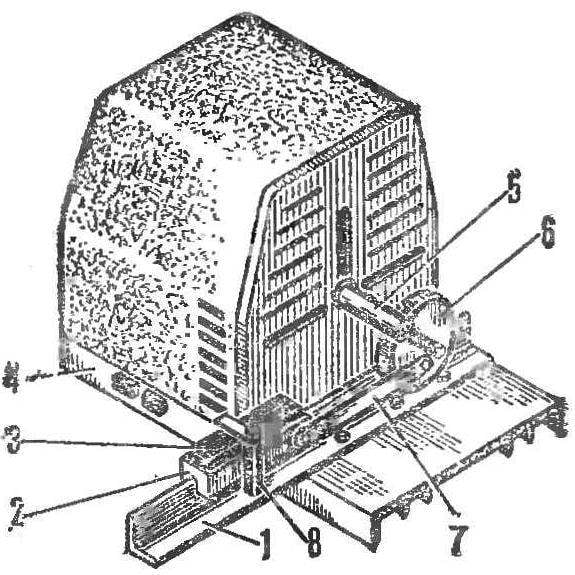

Modern style requires decorating items of furniture, fittings, apartment interior repetitive, intricate configuration of parts; often the enthusiasts to undertake their carved from soft wood, bend metal strips, minted copper. But modern chemistry has given us such great works to such material, like plastic. Enough to make a form — and any item can be repeated any number of times. Simple injection installation, it much easier and expedited the receipt of such “tripe”, designed for syut-2 city of Taganrog.

Modern style requires decorating items of furniture, fittings, apartment interior repetitive, intricate configuration of parts; often the enthusiasts to undertake their carved from soft wood, bend metal strips, minted copper. But modern chemistry has given us such great works to such material, like plastic. Enough to make a form — and any item can be repeated any number of times. Simple injection installation, it much easier and expedited the receipt of such “tripe”, designed for syut-2 city of Taganrog.

Our workshop

MACHINE”ALMAZ”

Diamond glass cutter perfectly cut pane of glass, but the correct use of them is not so easy. Unfortunately, the skills come only when a dozen of the glasses will be irreparably damaged, and the accurate cut out not always. To prevent this from happening, in the process of cutting you want to keep the tool perpendicular to the glass. Pressing force on the tool should be such that diamond left behind when moving a flat, thin, barely visible line. If the force is large, it creates a wide scratch and a touch of glass dust as the glaziers, diamond “barite”. At insufficient same pressing tool scratch does not work at all.

Diamond glass cutter perfectly cut pane of glass, but the correct use of them is not so easy. Unfortunately, the skills come only when a dozen of the glasses will be irreparably damaged, and the accurate cut out not always. To prevent this from happening, in the process of cutting you want to keep the tool perpendicular to the glass. Pressing force on the tool should be such that diamond left behind when moving a flat, thin, barely visible line. If the force is large, it creates a wide scratch and a touch of glass dust as the glaziers, diamond “barite”. At insufficient same pressing tool scratch does not work at all.MARTIN FROM THE FIREPLACE

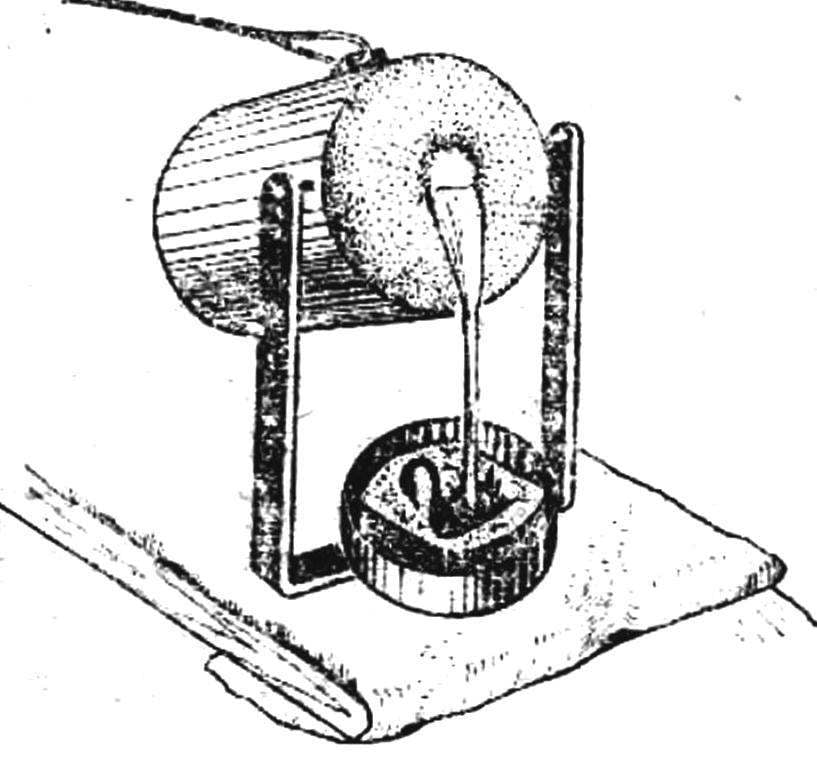

Soldiers, chess pieces, furniture hardware, original buttons, cufflinks, commemorative badges and medals on the occasion of anniversaries of your friends — only a part of the list of products that you can make yourself, casting. This work is quite even those who have not had a similar experience: it is enough to have imagination, to be neat, and of course, to get simple equipment for home foundry.

Soldiers, chess pieces, furniture hardware, original buttons, cufflinks, commemorative badges and medals on the occasion of anniversaries of your friends — only a part of the list of products that you can make yourself, casting. This work is quite even those who have not had a similar experience: it is enough to have imagination, to be neat, and of course, to get simple equipment for home foundry.

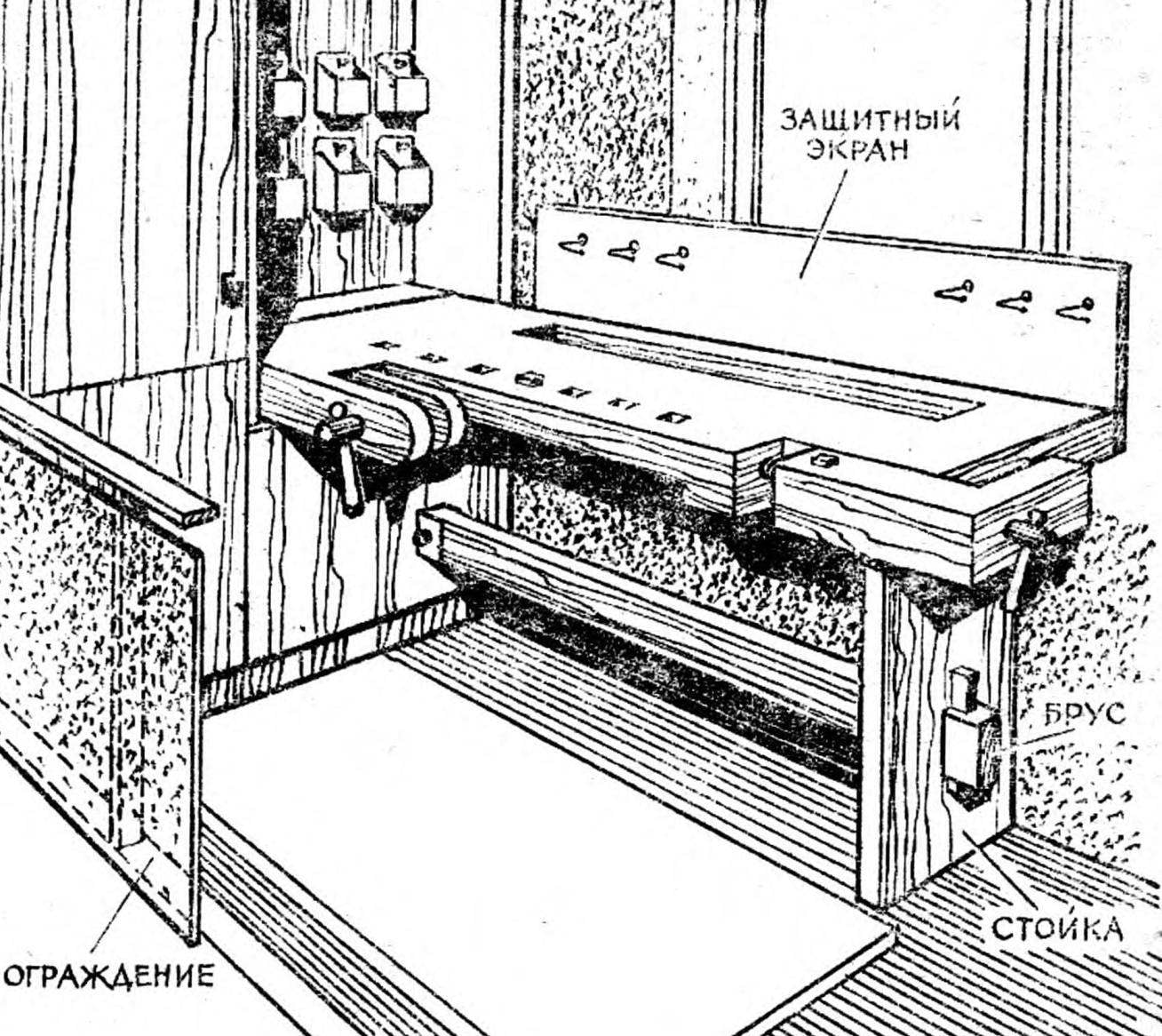

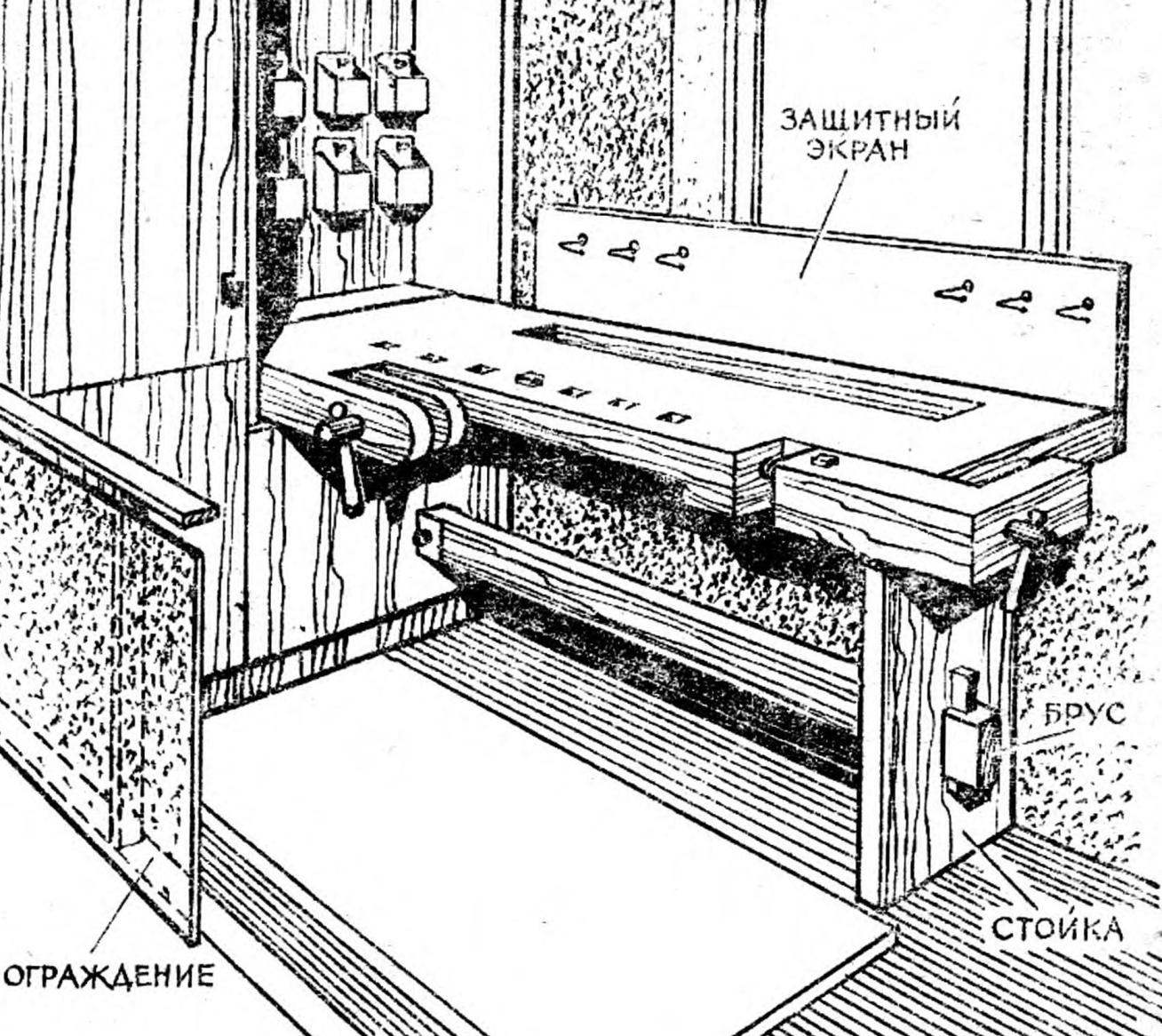

WORKSHOP IN A CITY APARTMENT

Loggia, balcony — a kind of additional area of the apartment. However, it is not particularly large, but how efficiently we use these “extra” square meters? After all, a reasonable approach here is simple to organize the area in the summer (even put up a cot for sleeping), mount the Cabinet to the tool, household items, sports equipment. Finally, to equip a place for carpentry and plumbing work. How to do it?

Loggia, balcony — a kind of additional area of the apartment. However, it is not particularly large, but how efficiently we use these “extra” square meters? After all, a reasonable approach here is simple to organize the area in the summer (even put up a cot for sleeping), mount the Cabinet to the tool, household items, sports equipment. Finally, to equip a place for carpentry and plumbing work. How to do it?THE WINDOW… WITHOUT THE WINDOW

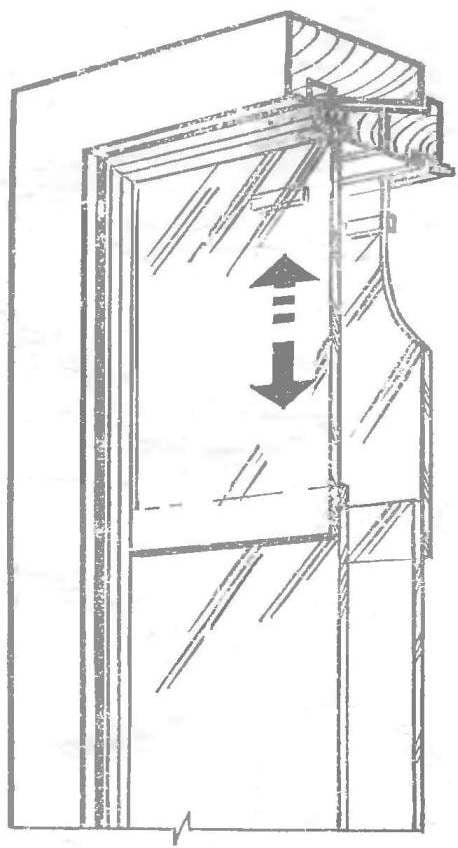

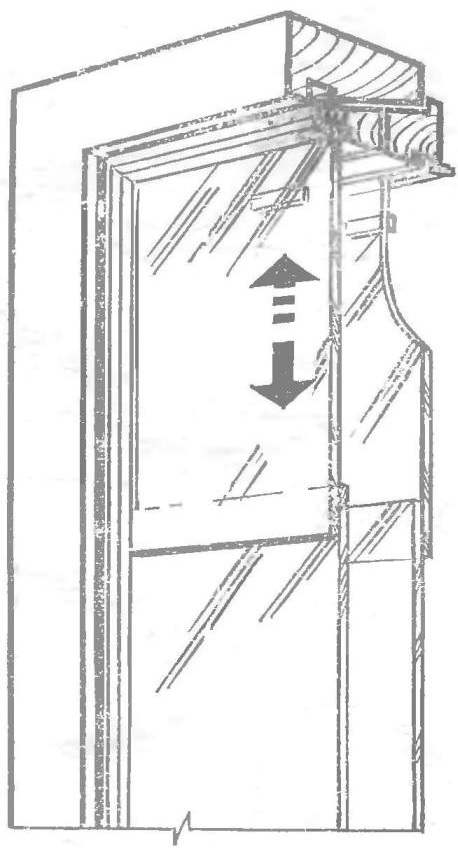

In apartments with paired window units no of vents: the role of narrow casement Windows. This is justified in summer, and then only in good weather; in rain, if he is still with the wind or sideways across the transom is filled with water. In the winter and very uncomfortable: wide open — cold and slightly open in a narrow slit through the frosty wind. That is why often the top of sash major redesigns for ordinary window.

In apartments with paired window units no of vents: the role of narrow casement Windows. This is justified in summer, and then only in good weather; in rain, if he is still with the wind or sideways across the transom is filled with water. In the winter and very uncomfortable: wide open — cold and slightly open in a narrow slit through the frosty wind. That is why often the top of sash major redesigns for ordinary window.THE PLANE OF THE SKINS

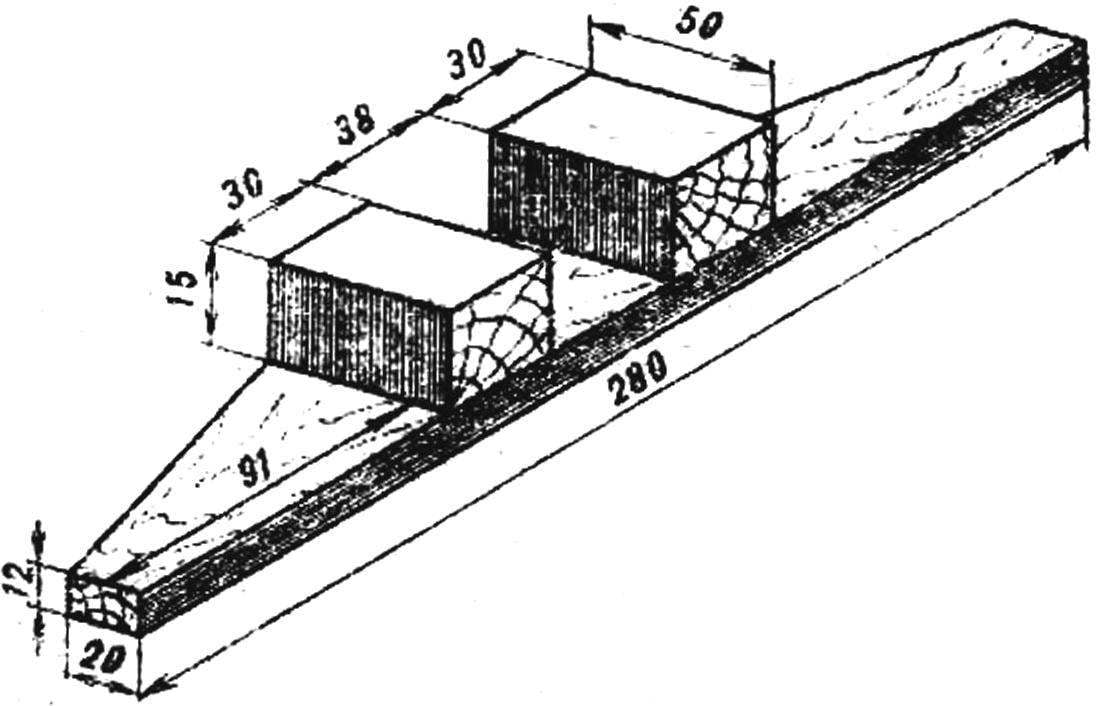

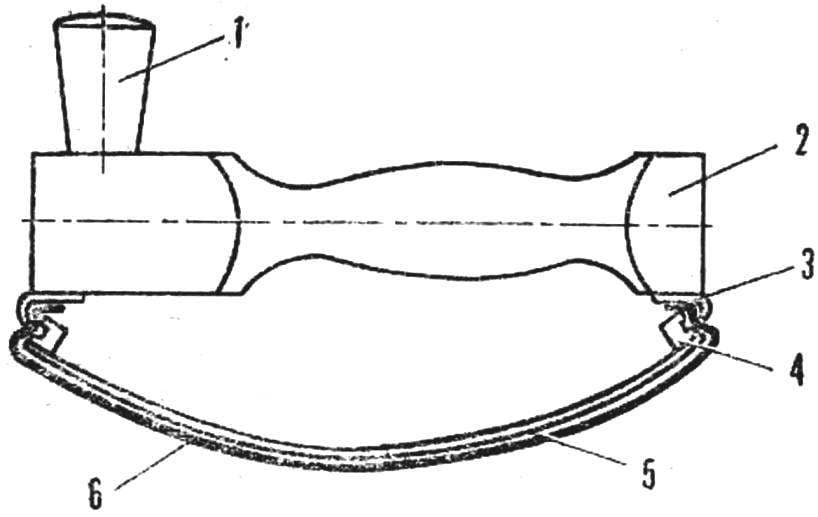

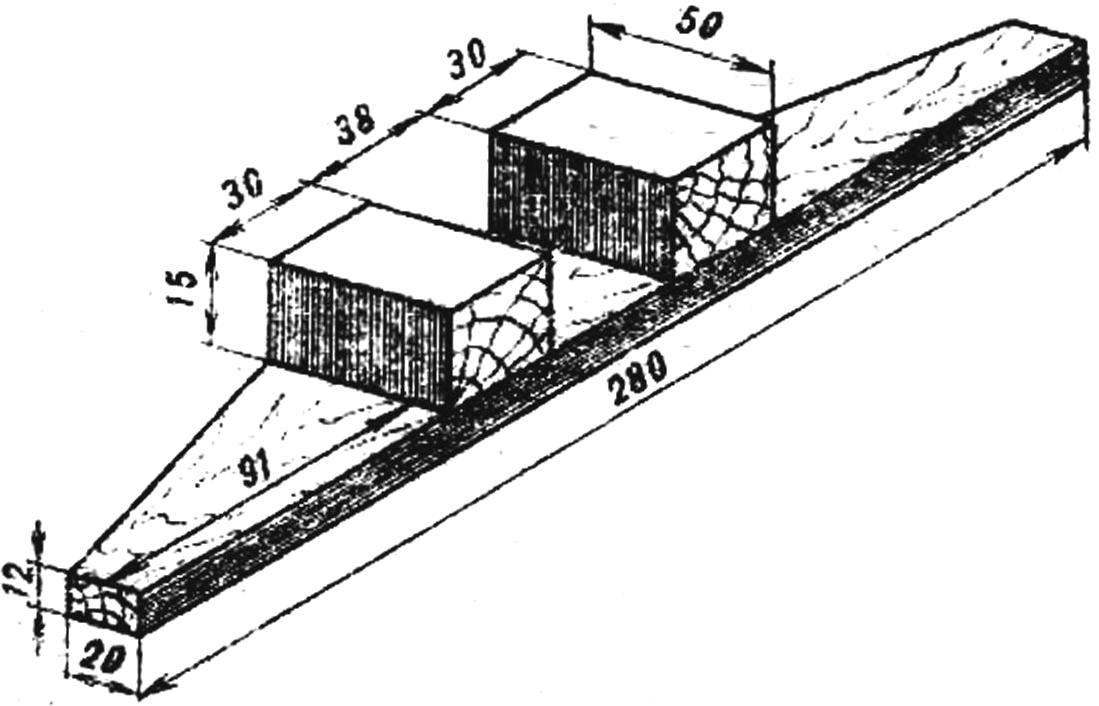

In the processing of metal surfaces and finishing of the joinery is quite often used grinding sandpaper. It is usually navertyvajut on the bar, but they sandpaper wears unevenly, and cleared material remains between it and the surface, preventing their contact. In addition, a significant portion of the abrasive generally remains unused and is discarded.

In the processing of metal surfaces and finishing of the joinery is quite often used grinding sandpaper. It is usually navertyvajut on the bar, but they sandpaper wears unevenly, and cleared material remains between it and the surface, preventing their contact. In addition, a significant portion of the abrasive generally remains unused and is discarded.

AND IT WILL GO FASTER

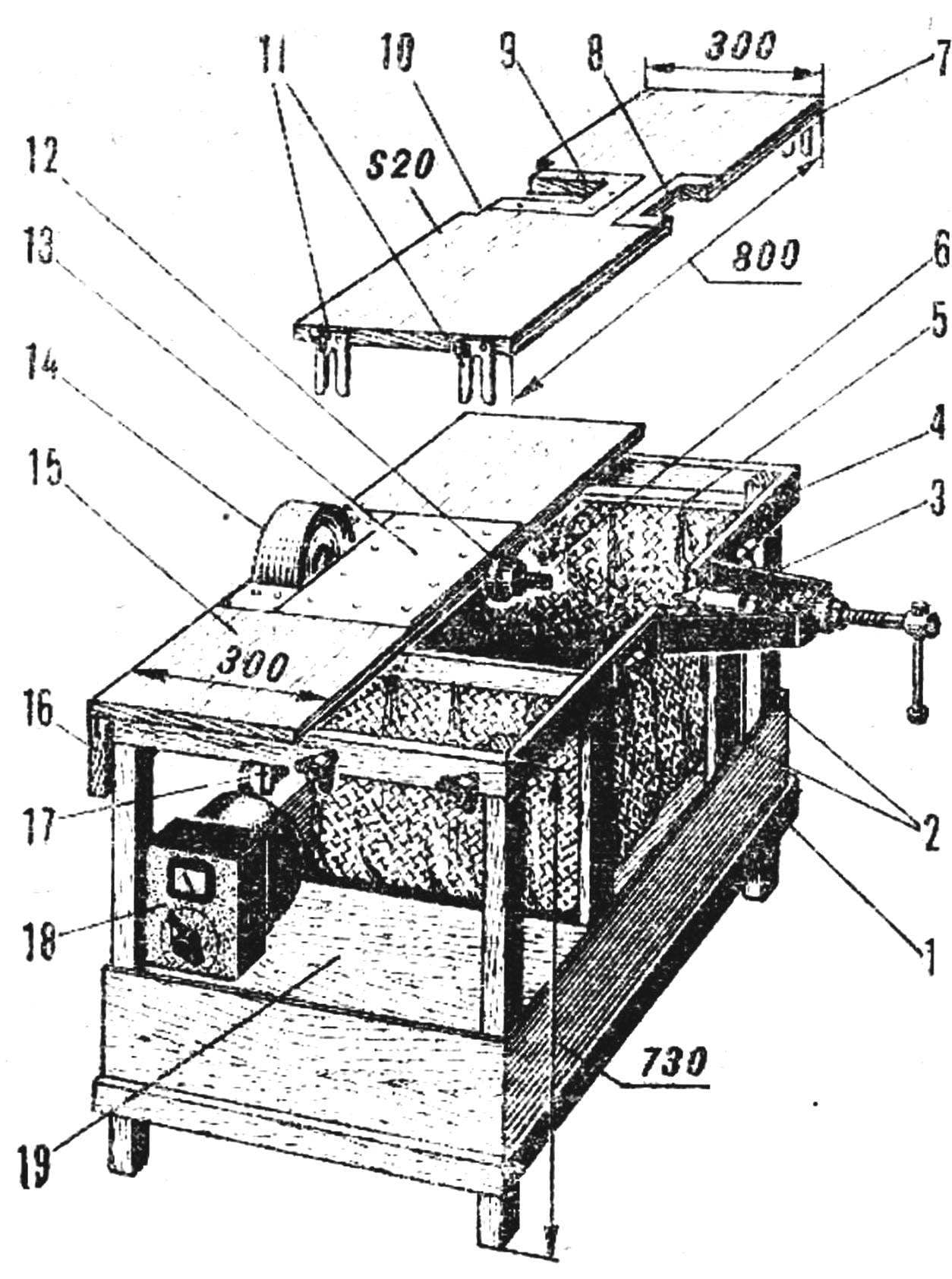

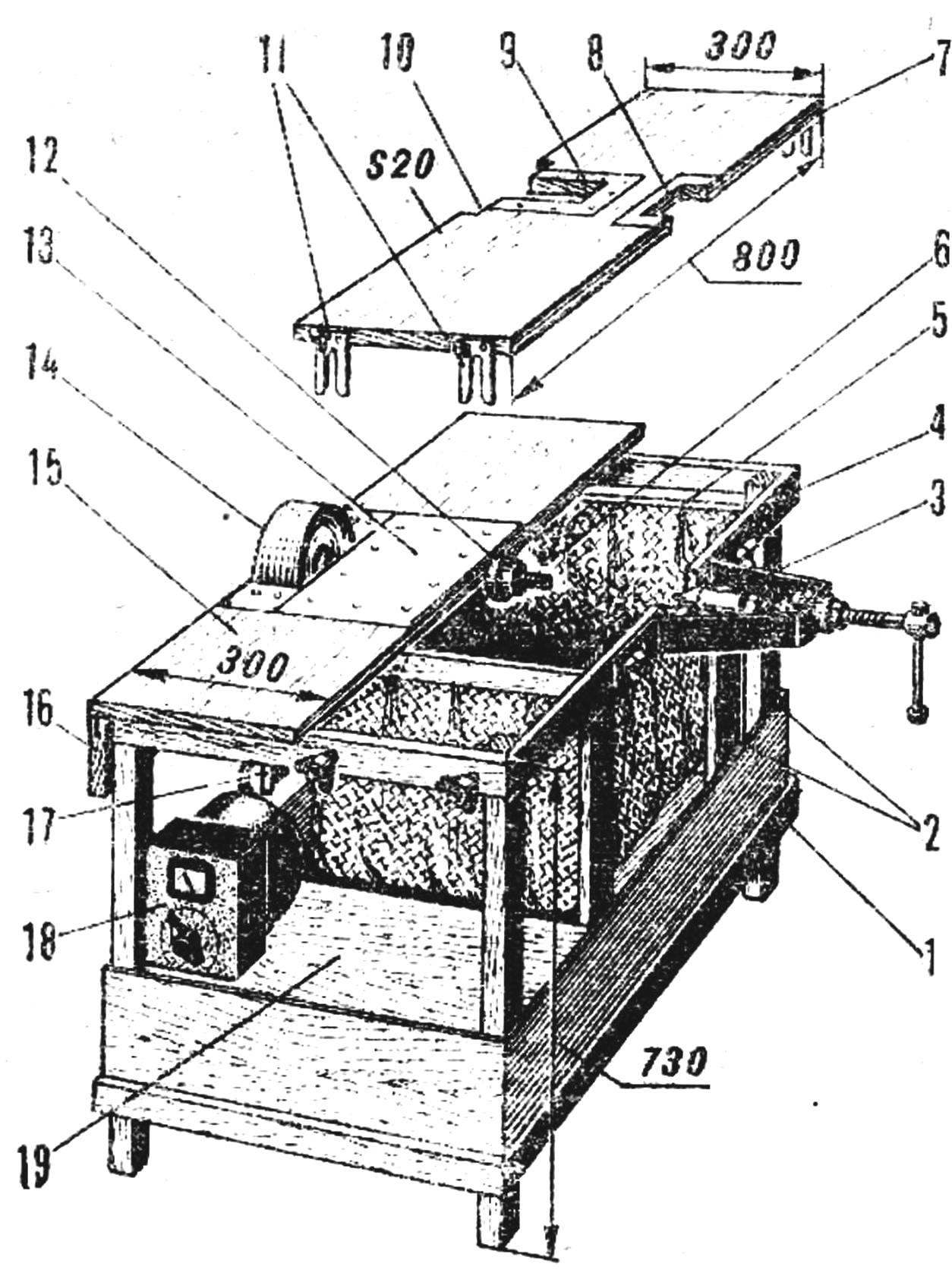

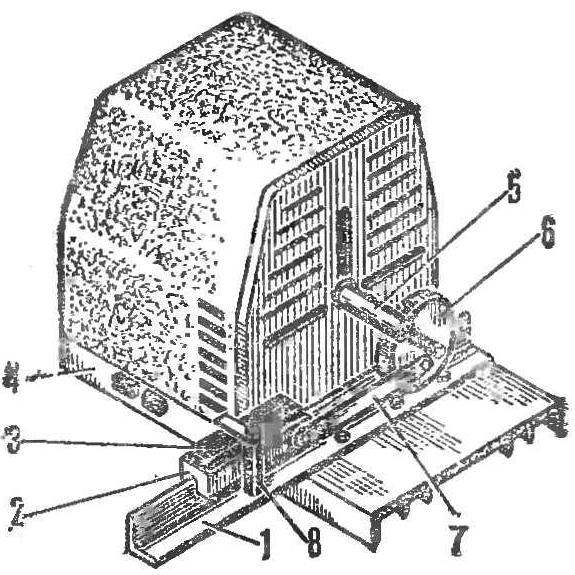

(UNIVERSAL MACHINE). Replacement of manual mechanical tools is of great importance not only in manufacturing, but in the home work of the designer-lover, embodies with wood and metal in their designs. Sometimes even the most simple fixture, primitive stanochki significantly speed up the work, facilitate it and to dramatically improve the quality of the product. That is why in recent years an increasing number of miniature machine tools for processing wood and metal, designed for hobbyists and tinkerers.

(UNIVERSAL MACHINE). Replacement of manual mechanical tools is of great importance not only in manufacturing, but in the home work of the designer-lover, embodies with wood and metal in their designs. Sometimes even the most simple fixture, primitive stanochki significantly speed up the work, facilitate it and to dramatically improve the quality of the product. That is why in recent years an increasing number of miniature machine tools for processing wood and metal, designed for hobbyists and tinkerers.

LEVER HANDLED

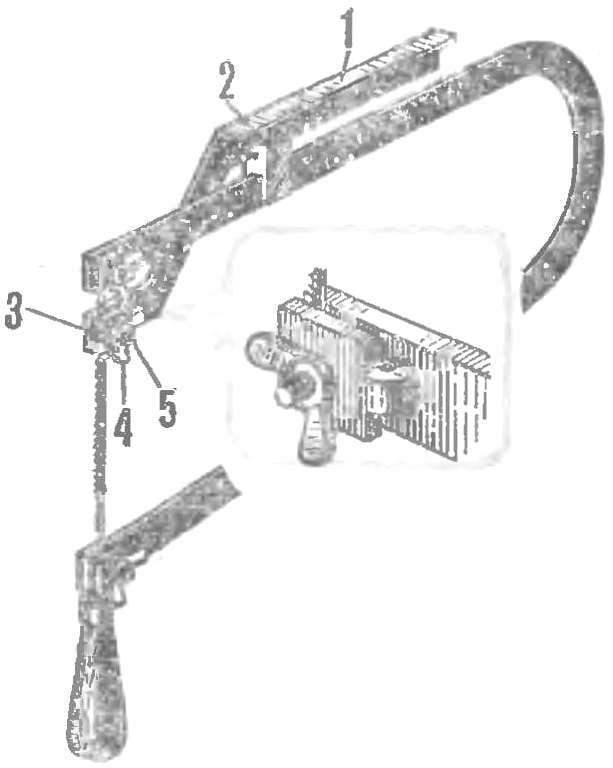

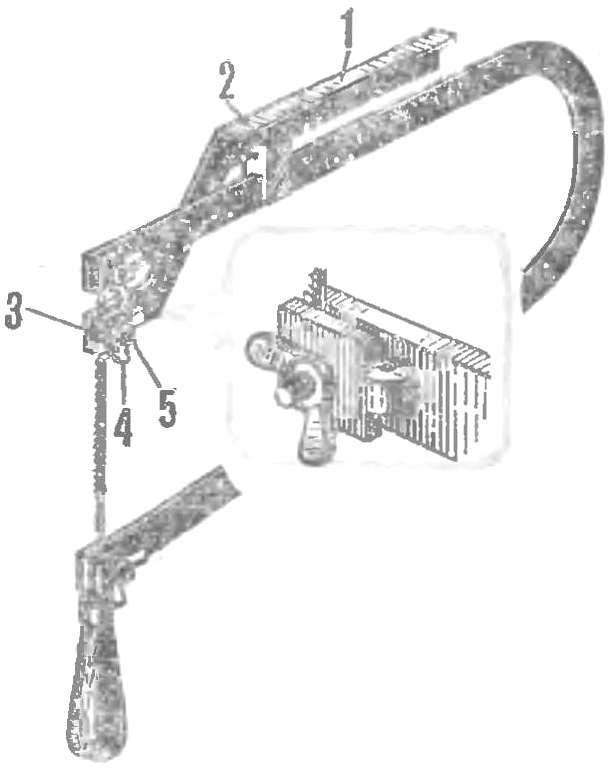

One who is engaged in sawing wood, is constantly faced with difficulties and inconveniences that arise when a seemingly simple process — the clip blade in the jigsaw. Assistance here will have a fixture, the basis of which are the lever, bearing and clamp. All items are made from metal strips with a thickness of 2 mm.

One who is engaged in sawing wood, is constantly faced with difficulties and inconveniences that arise when a seemingly simple process — the clip blade in the jigsaw. Assistance here will have a fixture, the basis of which are the lever, bearing and clamp. All items are made from metal strips with a thickness of 2 mm.LARGE DIAMETER? DO

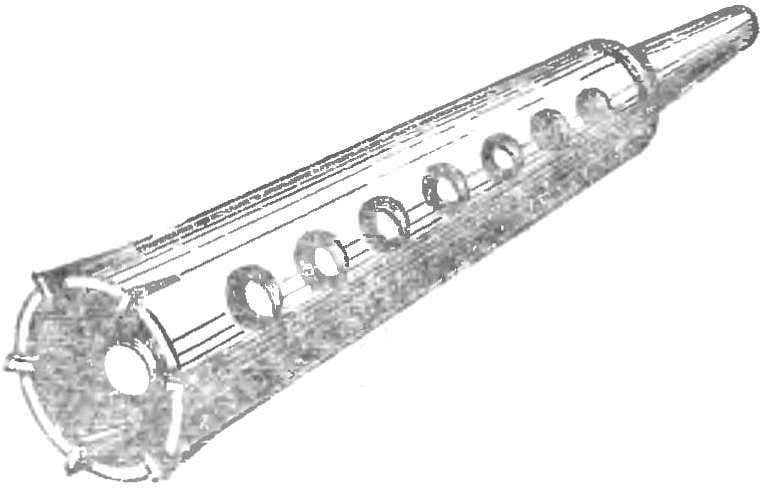

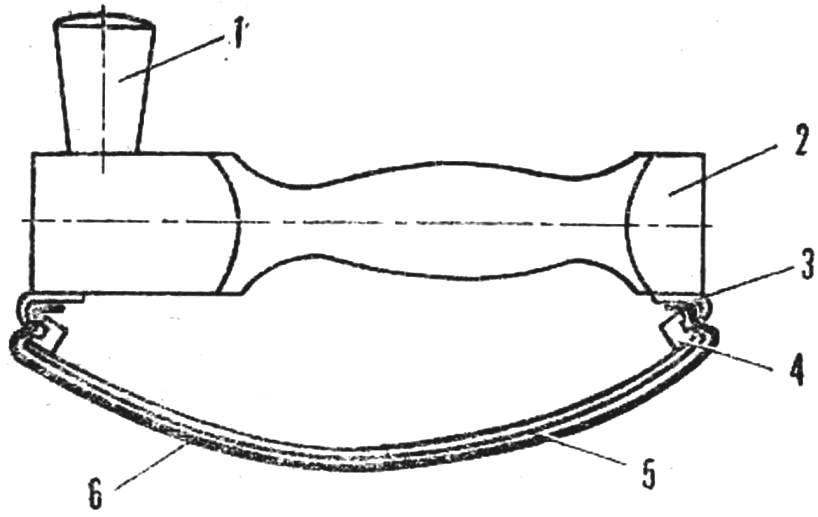

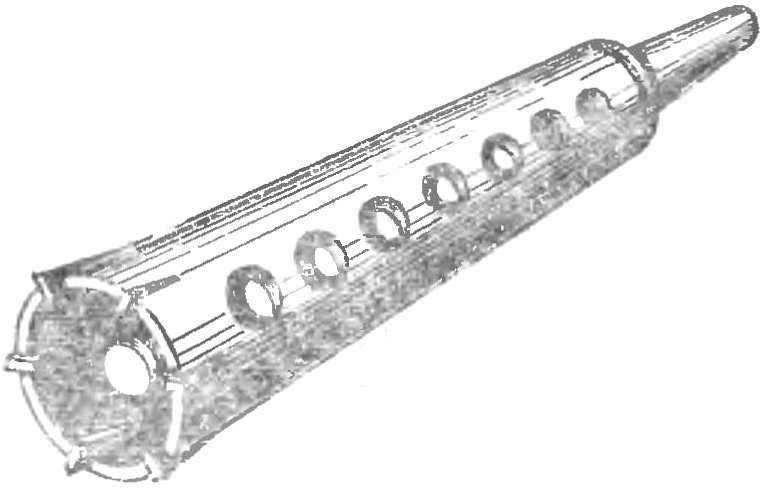

In the practice of the house master, there are cases when you need to drill a large diameter hole, and nothing. In this case, will help improvised hollow drill bit, suitable for non-ferrous metals, plastics, wood. It leaves a cylindrical disc, which can also be used, and quite a bit of shavings.

In the practice of the house master, there are cases when you need to drill a large diameter hole, and nothing. In this case, will help improvised hollow drill bit, suitable for non-ferrous metals, plastics, wood. It leaves a cylindrical disc, which can also be used, and quite a bit of shavings.RULED BY “SHUTTLE”

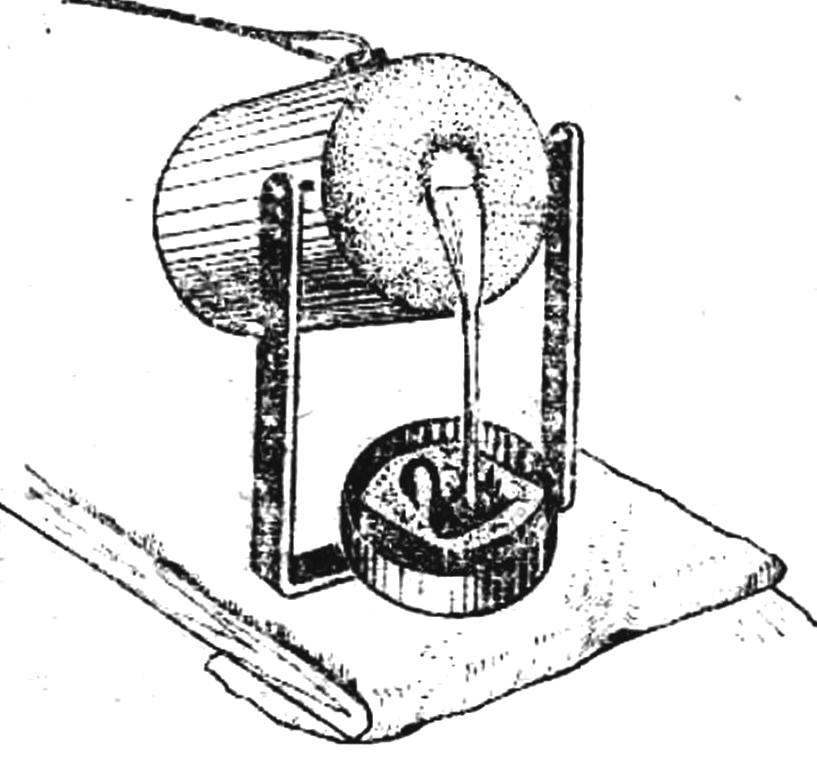

DPJ-quality processing of wood of iron planers, chisels and other tools necessary not only to sharpen, but to rule. This is achieved by lapping on the touchstone — the operation usually done manually and require usually more qualified skills than sharpening on elektrotochilo.

DPJ-quality processing of wood of iron planers, chisels and other tools necessary not only to sharpen, but to rule. This is achieved by lapping on the touchstone — the operation usually done manually and require usually more qualified skills than sharpening on elektrotochilo.