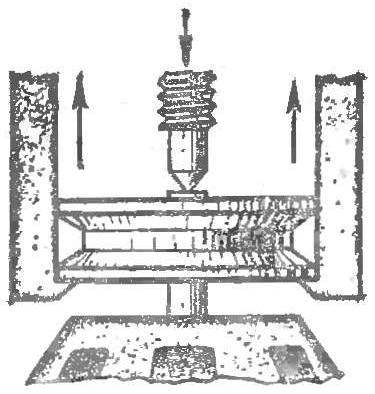

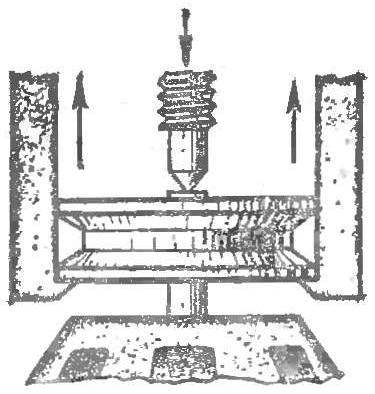

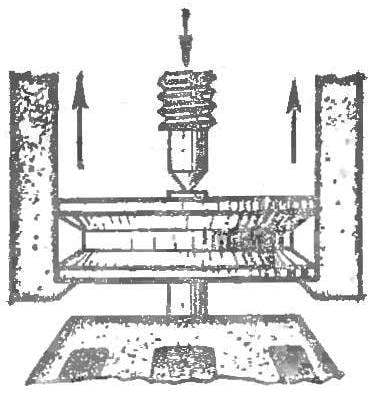

In your journal repeatedly describes the various designs of devices for removing pressed on the shaft bearings, bushings, pulleys. I propose another option — simple in construction and quite versatile. This puller has become my indispensable assistant: allows you to avoid damage to parts during disassembly, making the work easier.

In your journal repeatedly describes the various designs of devices for removing pressed on the shaft bearings, bushings, pulleys. I propose another option — simple in construction and quite versatile. This puller has become my indispensable assistant: allows you to avoid damage to parts during disassembly, making the work easier.PULLER-MINI

In your journal repeatedly describes the various designs of devices for removing pressed on the shaft bearings, bushings, pulleys. I propose another option — simple in construction and quite versatile. This puller has become my indispensable assistant: allows you to avoid damage to parts during disassembly, making the work easier.

In your journal repeatedly describes the various designs of devices for removing pressed on the shaft bearings, bushings, pulleys. I propose another option — simple in construction and quite versatile. This puller has become my indispensable assistant: allows you to avoid damage to parts during disassembly, making the work easier.

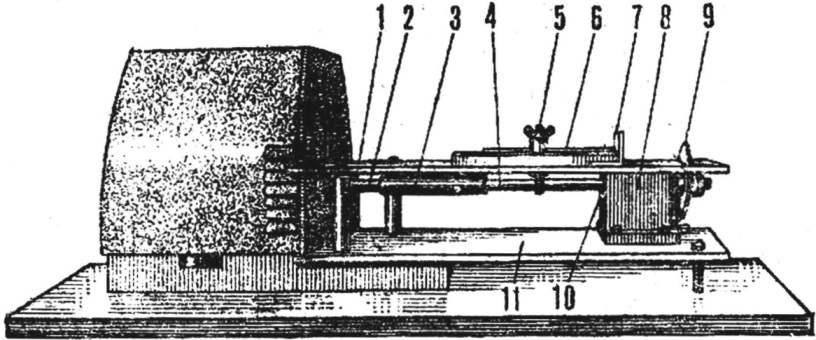

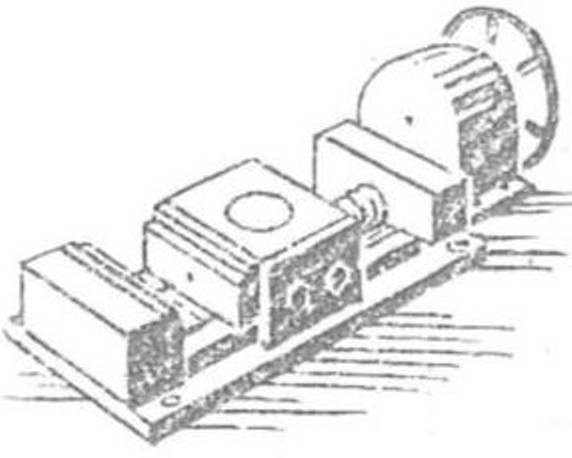

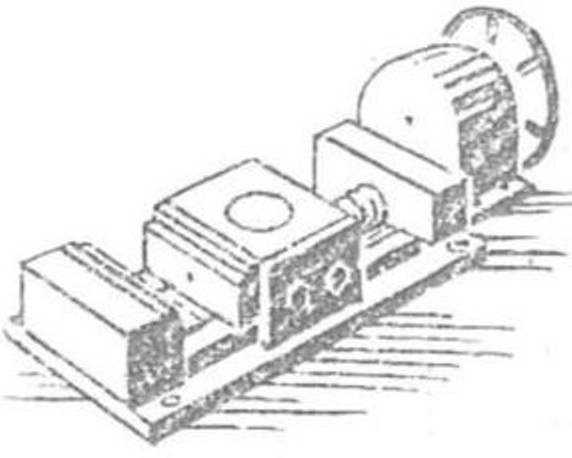

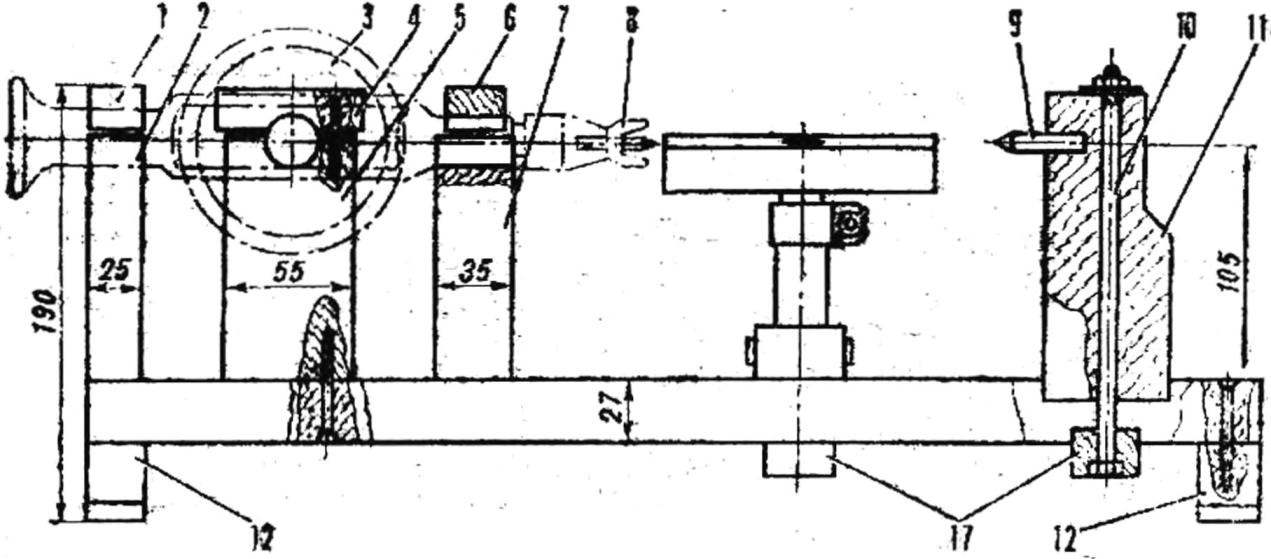

Machine UK-4 is still popular among hobbyists and tinkerers. Over the years of its release, home craftsmen invented many devices to improve its performance and broadening the range of operations. Many of these upgrades were reported in the “M-K”. However, nothing was said about using his motor at full capacity. But it is quite enough to handle larger workpieces than the number specified in the passport of the machine. And the need for such a feature: in this we have repeatedly seen at work in our model aircraft club. Here and was made a fixture that allowed to increase the depth of milling parts using standard cutters b to 17 mm with their width up to 260 mm instead of 60.

Machine UK-4 is still popular among hobbyists and tinkerers. Over the years of its release, home craftsmen invented many devices to improve its performance and broadening the range of operations. Many of these upgrades were reported in the “M-K”. However, nothing was said about using his motor at full capacity. But it is quite enough to handle larger workpieces than the number specified in the passport of the machine. And the need for such a feature: in this we have repeatedly seen at work in our model aircraft club. Here and was made a fixture that allowed to increase the depth of milling parts using standard cutters b to 17 mm with their width up to 260 mm instead of 60.

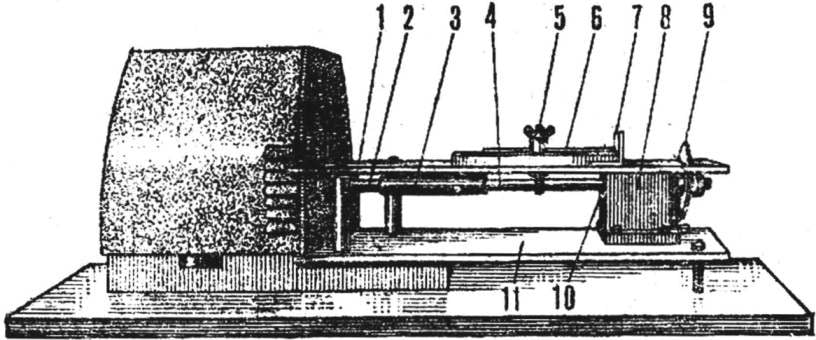

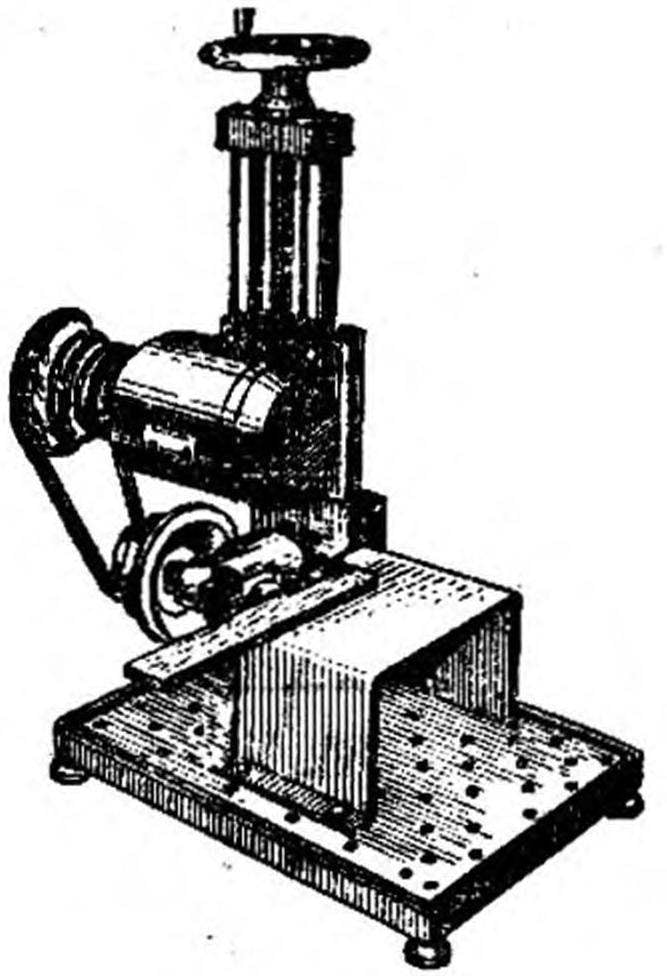

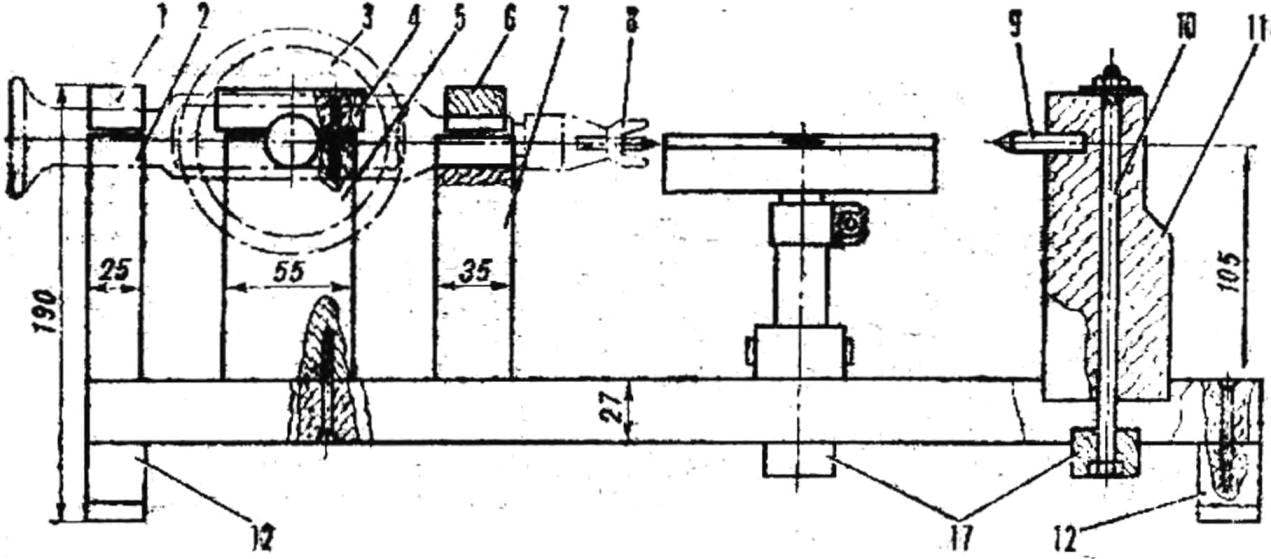

In one of the shows can viewers was submitted to design a universal machine, designed by the engraver of the suburban town of Troitsk Y. M. Orlov. Not only a discussion of a design program participants, but also by the numerous letters received by the author, editions, TV and the magazine “M-K” showed how great the interest was this table versatile machine capable of performing a number of operations for machining a variety of materials. To meet numerous requests, the editors asked the author designs to tell more about it.

In one of the shows can viewers was submitted to design a universal machine, designed by the engraver of the suburban town of Troitsk Y. M. Orlov. Not only a discussion of a design program participants, but also by the numerous letters received by the author, editions, TV and the magazine “M-K” showed how great the interest was this table versatile machine capable of performing a number of operations for machining a variety of materials. To meet numerous requests, the editors asked the author designs to tell more about it.

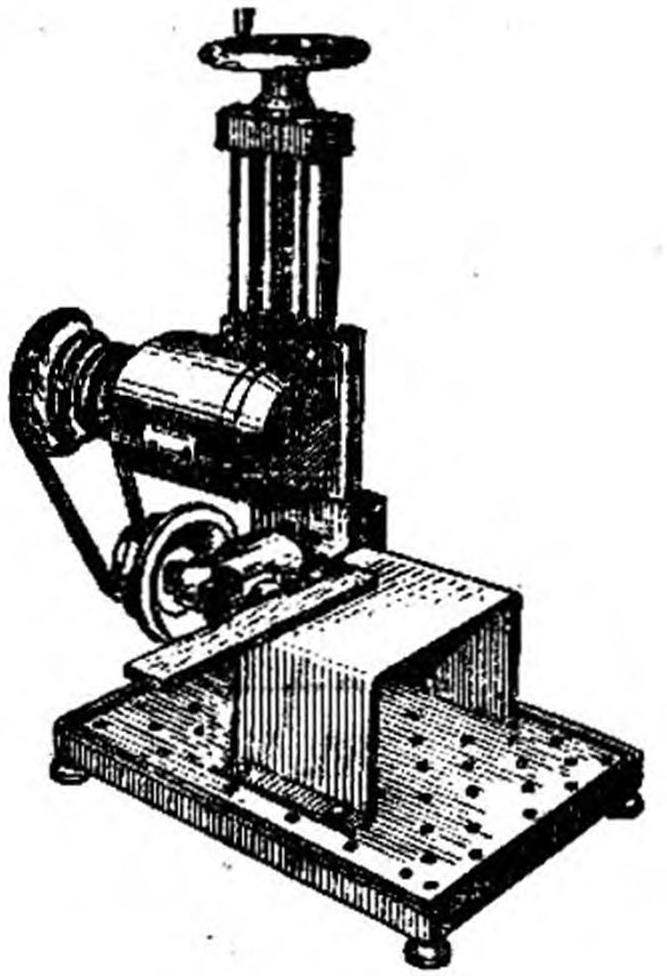

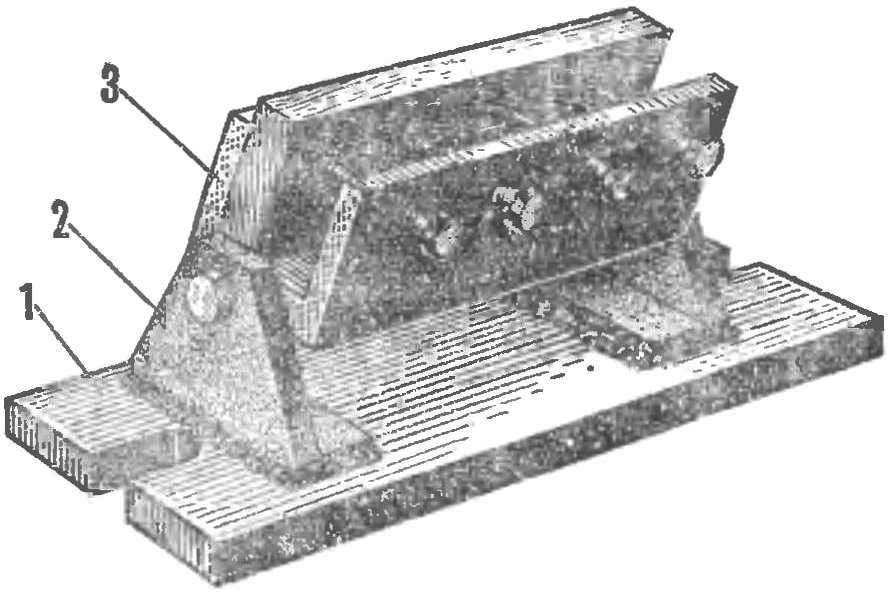

Designed for parts that are in processing it is necessary to fix in an inclined position. Clip design is simple: to steel base welded corners-brackets; on a coaxial screw-clamps rotated box, which can be installed in a wide range of angles.

Designed for parts that are in processing it is necessary to fix in an inclined position. Clip design is simple: to steel base welded corners-brackets; on a coaxial screw-clamps rotated box, which can be installed in a wide range of angles.

This device will serve you well — will facilitate the drilling of holes: in the grip gear grip force and a half times more than usual, which increases the reliability of fastening, and turn the handwheel Udinese than a normal pen. Changing pads (each of them attached to the jaws by two screws M8), it is possible to clamp items of different configuration Maksimalna thickness up to 80 mm. the design of the grip to the gearbox all the parts are quite simple, made of steel of common grades.

This device will serve you well — will facilitate the drilling of holes: in the grip gear grip force and a half times more than usual, which increases the reliability of fastening, and turn the handwheel Udinese than a normal pen. Changing pads (each of them attached to the jaws by two screws M8), it is possible to clamp items of different configuration Maksimalna thickness up to 80 mm. the design of the grip to the gearbox all the parts are quite simple, made of steel of common grades.

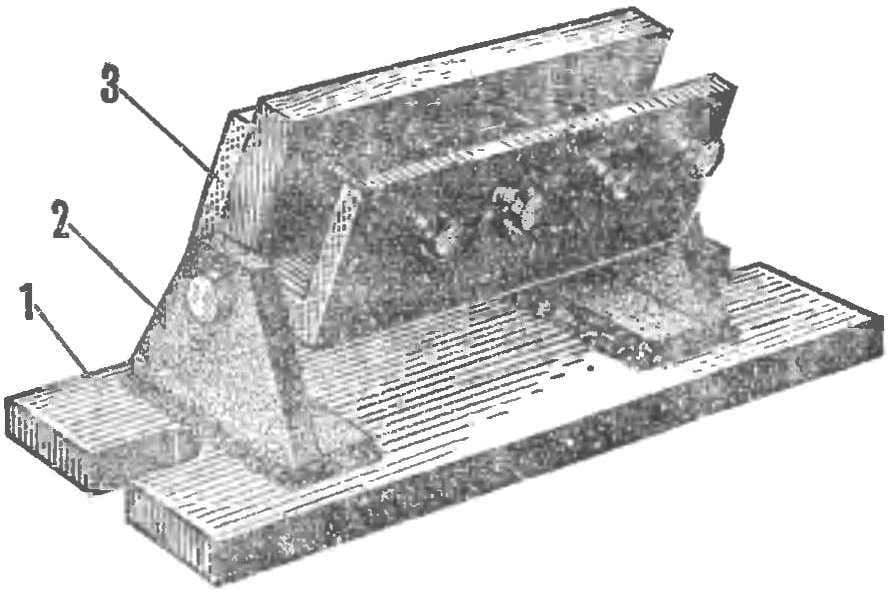

Winds on the cutter scented shavings. And from small billets emerge the contours of a rolling pin, tolkushkoy, arm day hand tools… there are all sorts of useful things you can do with a lathe. But to make it the simplest version, for example on the basis of the drills, but anyone can do it DIY, as almost all parts of the machine available and easily processed material: pine or birch sticks.

Winds on the cutter scented shavings. And from small billets emerge the contours of a rolling pin, tolkushkoy, arm day hand tools… there are all sorts of useful things you can do with a lathe. But to make it the simplest version, for example on the basis of the drills, but anyone can do it DIY, as almost all parts of the machine available and easily processed material: pine or birch sticks.

Product handling abrasive tool (grinding) in most cases is finishing and finishing operation, ensuring high-purity and surface quality. Use it for rough work — cleaning workpieces from scale, removal of scallops on castings, smoothing welded joints, and for sharpening all kinds of cutting tools.

Product handling abrasive tool (grinding) in most cases is finishing and finishing operation, ensuring high-purity and surface quality. Use it for rough work — cleaning workpieces from scale, removal of scallops on castings, smoothing welded joints, and for sharpening all kinds of cutting tools.

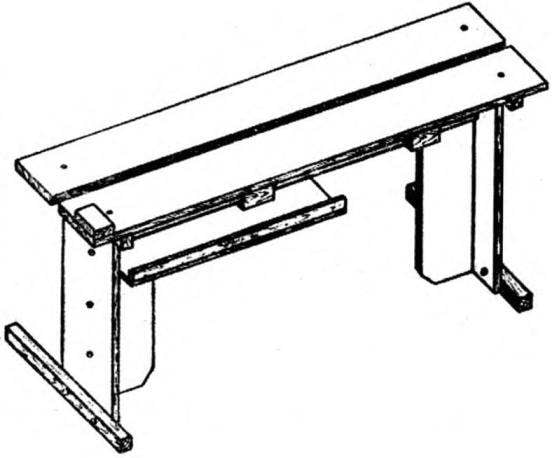

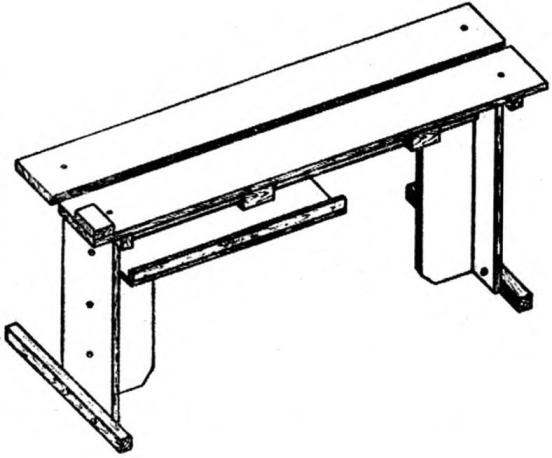

What should be the bench? Of course, durable and easy to use! However, many, in addition to this, note the compactness and the possibility of quick disassembly, as not all fans polotical have at their disposal a workshop or utility room; urban residents often have to settle for a balcony or loggia. I hope that my design collapsible workbench will appeal not only easy to use and storage, but also ease of manufacture.

What should be the bench? Of course, durable and easy to use! However, many, in addition to this, note the compactness and the possibility of quick disassembly, as not all fans polotical have at their disposal a workshop or utility room; urban residents often have to settle for a balcony or loggia. I hope that my design collapsible workbench will appeal not only easy to use and storage, but also ease of manufacture.

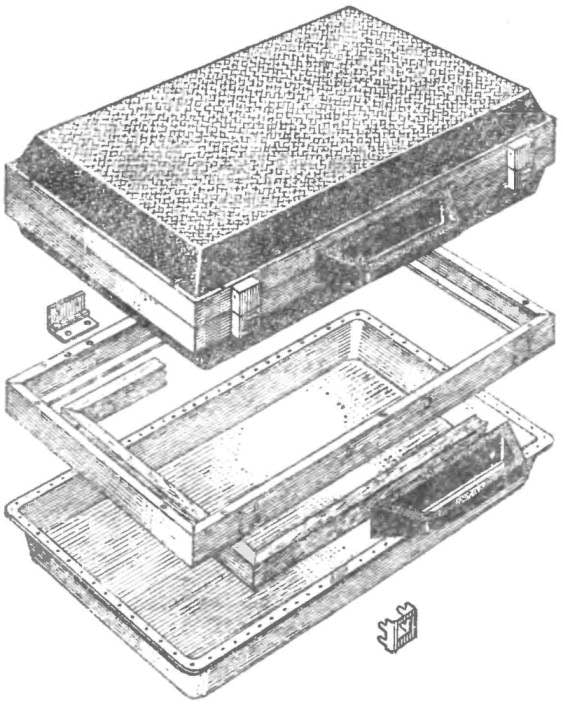

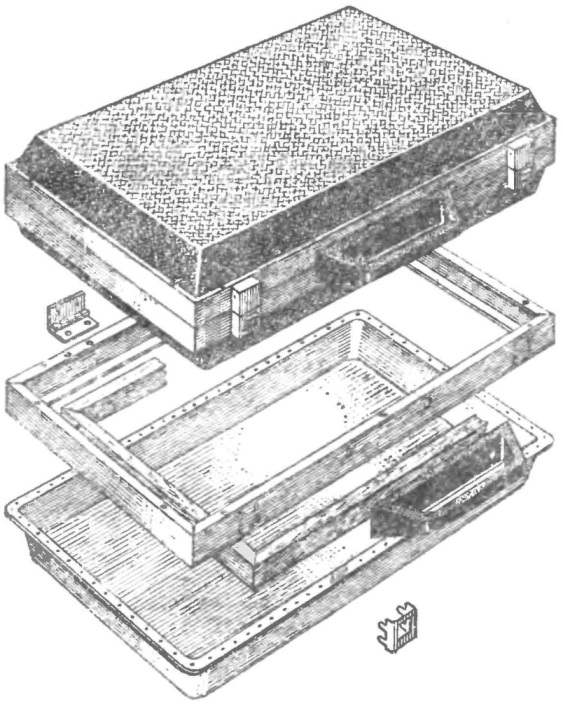

Here is not a typo: not a cupcake, namely the case — hard chemodanchik-“the diplomat”. Many prefer the soft portfolio: more fashionable, and the safety of the papers, drawings and books in this hard case is guaranteed. But what then of the spiritual?

Here is not a typo: not a cupcake, namely the case — hard chemodanchik-“the diplomat”. Many prefer the soft portfolio: more fashionable, and the safety of the papers, drawings and books in this hard case is guaranteed. But what then of the spiritual?

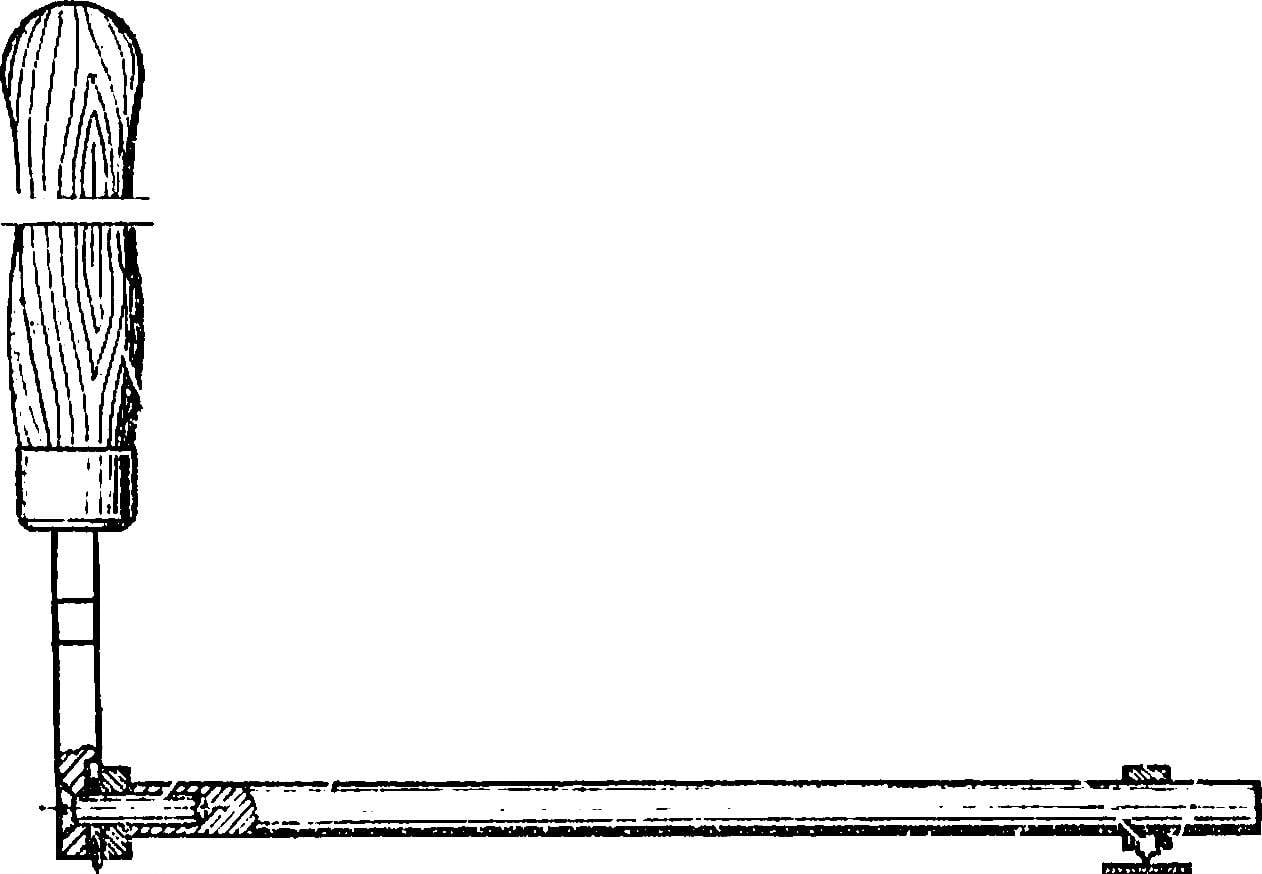

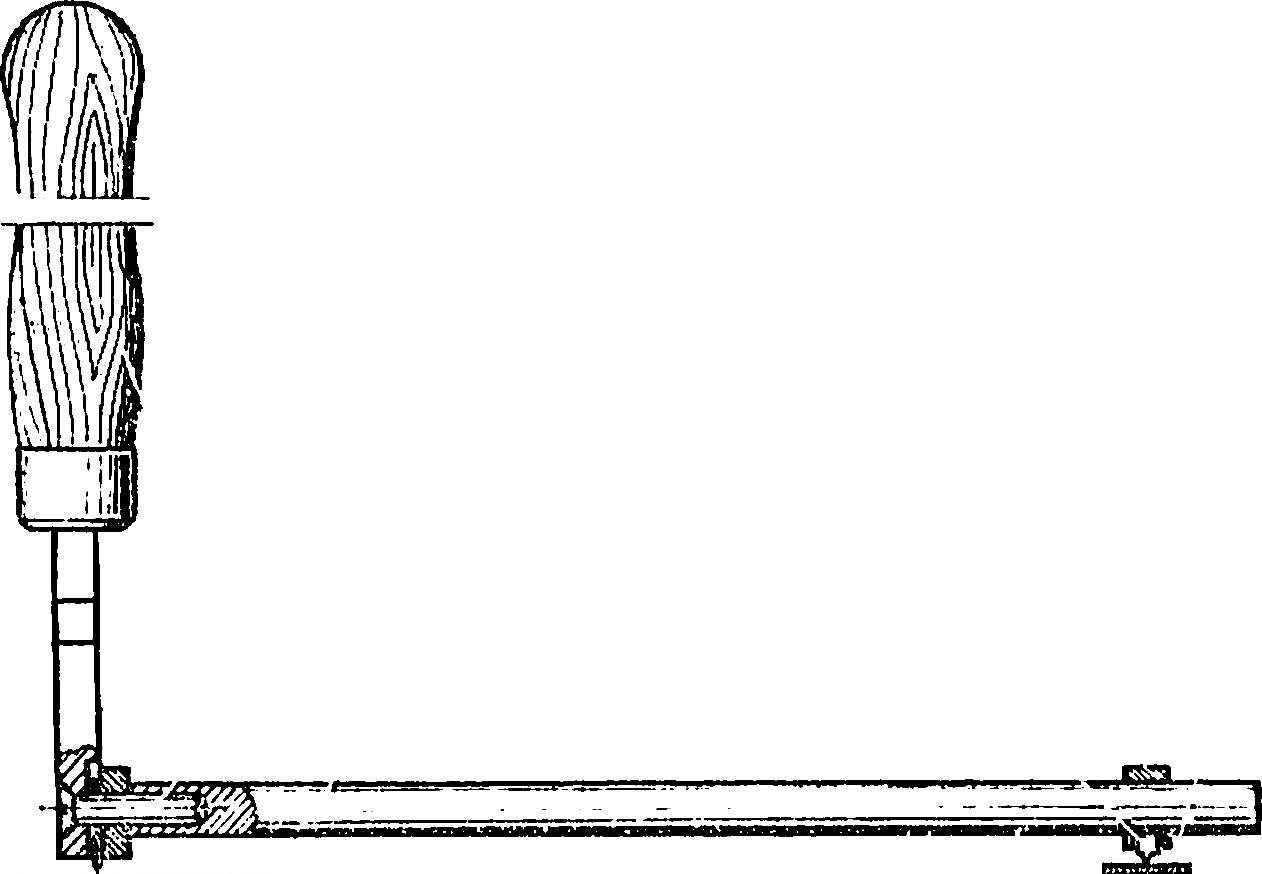

To cut a round hole of large diameter, to make a glass disk or a ring will help this simple tool.

To cut a round hole of large diameter, to make a glass disk or a ring will help this simple tool.