SMALL SPOOL, BUT PRECIOUS!

SMALL SPOOL, BUT PRECIOUS!

Among multipurpose internal combustion engines, created by our readers, still have not found structures with the spool naturally. Meanwhile, this scheme has proven itself quite well and is often used in power installations of various applications. Under this scheme, for example, in the prewar years in the USSR mass-produced outboard motors LM-7 “Rubinar” and LM-6, which enjoyed great popularity. Known successful attempts of application of the valve timing in the engines of sports motorcycles and model the micro-engines of various applications.

Read more

Vacuum cleaner — large home hard worker: in addition to his primary duties, he can whitewash the ceilings, painting the car, spray the flowers. However, it is possible to “teach” to another profession, and fabricated a simple device by which you can “wash” of various carpets, placing them on the open plain.

Vacuum cleaner — large home hard worker: in addition to his primary duties, he can whitewash the ceilings, painting the car, spray the flowers. However, it is possible to “teach” to another profession, and fabricated a simple device by which you can “wash” of various carpets, placing them on the open plain. Vacuum cleaner — large home hard worker: in addition to his primary duties, he can whitewash the ceilings, painting the car, spray the flowers. However, it is possible to “teach” to another profession, and fabricated a simple device by which you can “wash” of various carpets, placing them on the open plain.

Vacuum cleaner — large home hard worker: in addition to his primary duties, he can whitewash the ceilings, painting the car, spray the flowers. However, it is possible to “teach” to another profession, and fabricated a simple device by which you can “wash” of various carpets, placing them on the open plain.

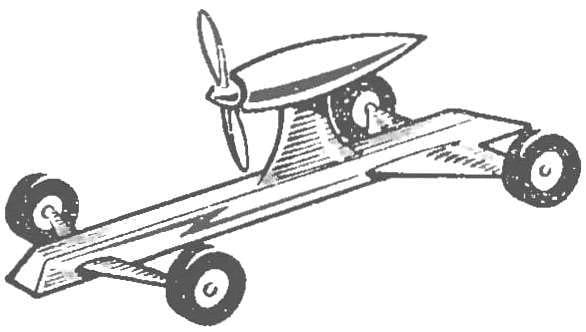

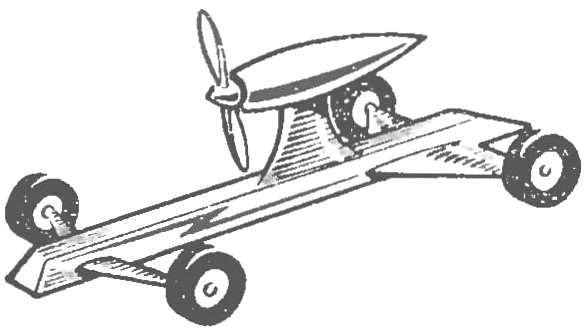

The idea to use as a vehicle motor wheel is tempting. She became interested in members of the laboratory design of compact machines Cute Siberian branch of the USSR ninth-graders Sasha Titarenko and Vitaliy Molchanov. They were attracted by the compact device, no transmission and therefore no loss of mechanical energy in the intermediate links, that is, a higher efficiency motor wheel converting input electrical energy into mechanical energy and the transfer of the latter directly on the propeller — wheel.

The idea to use as a vehicle motor wheel is tempting. She became interested in members of the laboratory design of compact machines Cute Siberian branch of the USSR ninth-graders Sasha Titarenko and Vitaliy Molchanov. They were attracted by the compact device, no transmission and therefore no loss of mechanical energy in the intermediate links, that is, a higher efficiency motor wheel converting input electrical energy into mechanical energy and the transfer of the latter directly on the propeller — wheel.

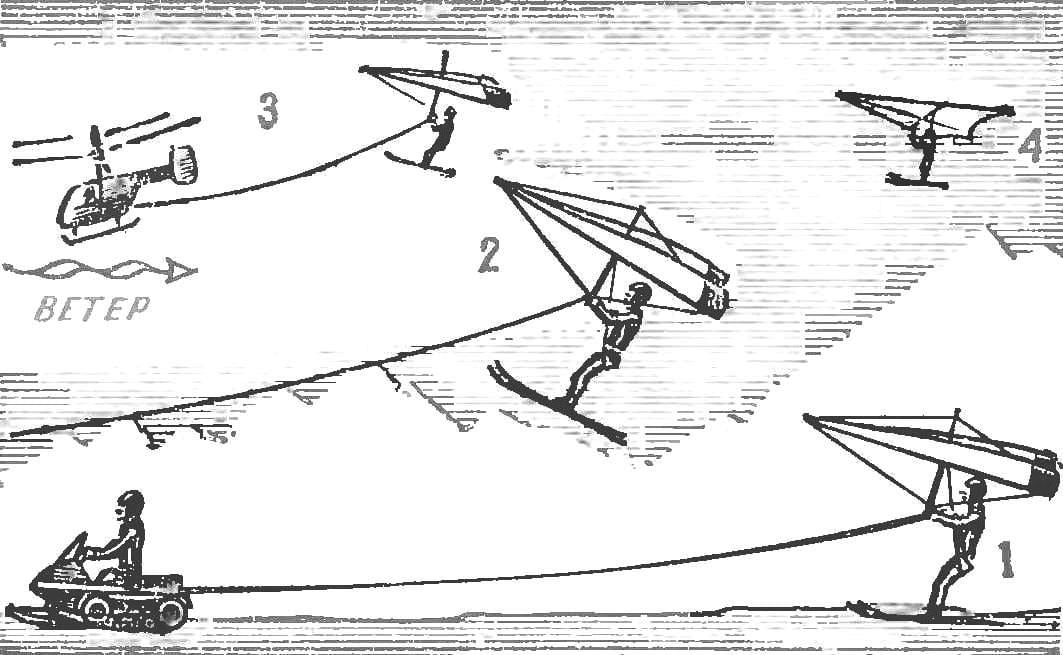

In the third issue of our journal in 1968 published a description of the design of snake-gibralta for water skiers, created by the pioneer of this sport in the USSR — Alexander Casein. Over the years the enthusiasts of technical creativity — IV first skiers — produced a large number of these aircraft. Flying snake-gibralta for the boat or car for many has become a favorite form of recreation. There had also been a successful winter flying in the mountains. Muscovite M. Gokhberg, master of sports of water skiing, winter 1973/74 year was flying on a kite, accelerating on the ski slopes in the area Terskol in the Caucasus.

In the third issue of our journal in 1968 published a description of the design of snake-gibralta for water skiers, created by the pioneer of this sport in the USSR — Alexander Casein. Over the years the enthusiasts of technical creativity — IV first skiers — produced a large number of these aircraft. Flying snake-gibralta for the boat or car for many has become a favorite form of recreation. There had also been a successful winter flying in the mountains. Muscovite M. Gokhberg, master of sports of water skiing, winter 1973/74 year was flying on a kite, accelerating on the ski slopes in the area Terskol in the Caucasus.

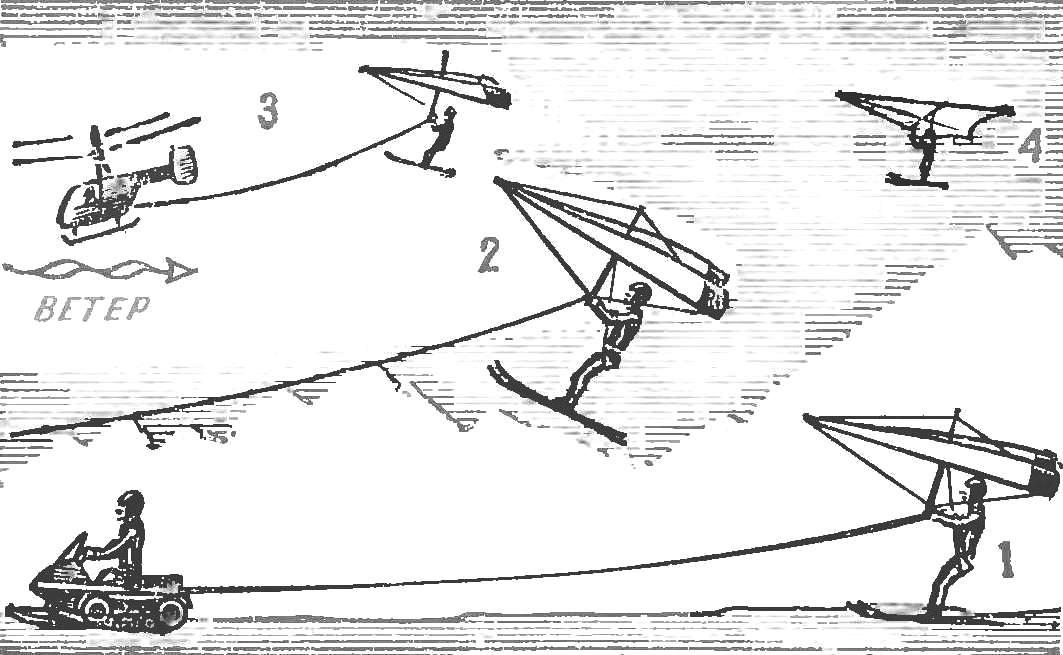

Say, in the Urals during the difficult years of chaos after the civil war an artificer built a car where everything was wooden, even the engine. However, if the wizard so the echo legendary as Leskov’s Levsha, here the use of wood instead of metal in the most important nodes in modern machinery: rolling mills, tractors, cranes, harvesters — not a legend, but a reality of our days.

Say, in the Urals during the difficult years of chaos after the civil war an artificer built a car where everything was wooden, even the engine. However, if the wizard so the echo legendary as Leskov’s Levsha, here the use of wood instead of metal in the most important nodes in modern machinery: rolling mills, tractors, cranes, harvesters — not a legend, but a reality of our days.

The article “Acupuncture for metal”, published in the journal “modelist-Konstruktor” No. 2, 1974, provoked numerous responses, not only individual readers, but also many businesses and organizations. Editorial Board, ENEA USSR and VNIIST continue to receive letters and inquiries on the subject.

The article “Acupuncture for metal”, published in the journal “modelist-Konstruktor” No. 2, 1974, provoked numerous responses, not only individual readers, but also many businesses and organizations. Editorial Board, ENEA USSR and VNIIST continue to receive letters and inquiries on the subject.

SMALL SPOOL, BUT PRECIOUS!

SMALL SPOOL, BUT PRECIOUS!

The car was conceived and executed as a valid simulator for the novice driver — my 15-year-old son Maxim that he could get it driving skills, and also to assemble-disassemble and repair the machine, mastering the technical “ABC”.

The car was conceived and executed as a valid simulator for the novice driver — my 15-year-old son Maxim that he could get it driving skills, and also to assemble-disassemble and repair the machine, mastering the technical “ABC”.

THE DEVELOPMENT OF COMMON TECHNICAL REQUIREMENTS

THE DEVELOPMENT OF COMMON TECHNICAL REQUIREMENTS

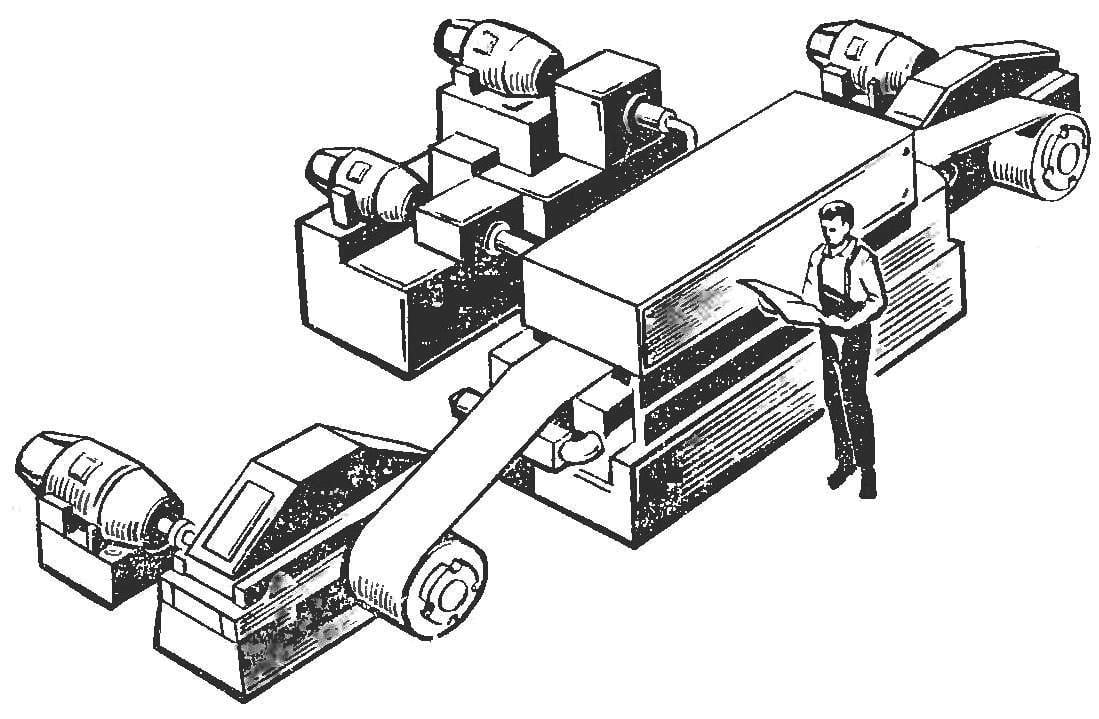

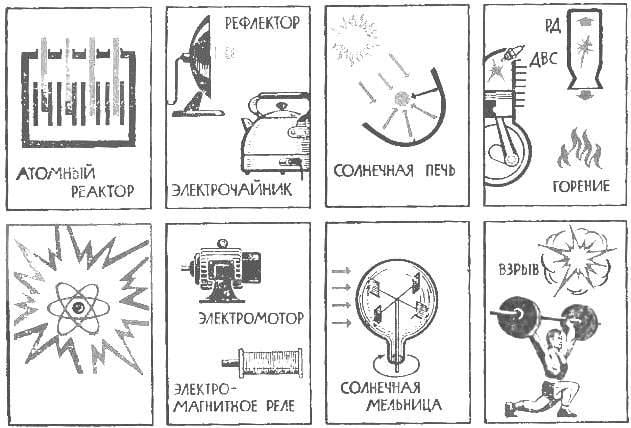

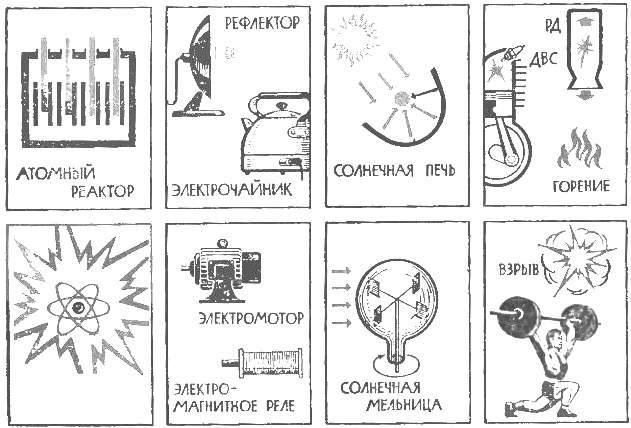

At this stage of the work, outline the design of the actuator, which provides translational movement of the model. Let’s start with the analysis of the already known mechanisms, which are used in a large technique (Fig. 1). Under the terms of our problem, the most acceptable is the idea of using the wheel.

At this stage of the work, outline the design of the actuator, which provides translational movement of the model. Let’s start with the analysis of the already known mechanisms, which are used in a large technique (Fig. 1). Under the terms of our problem, the most acceptable is the idea of using the wheel.

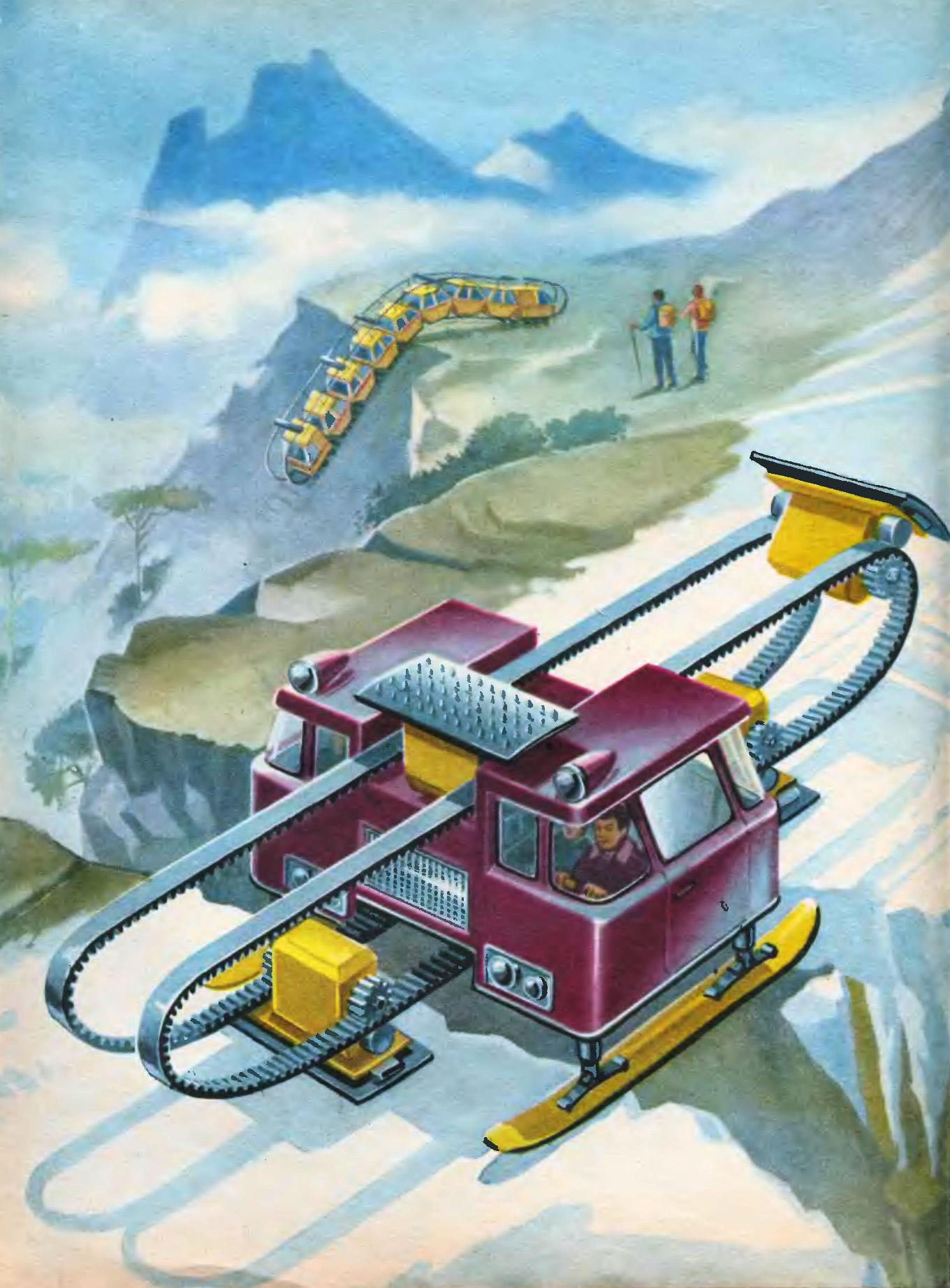

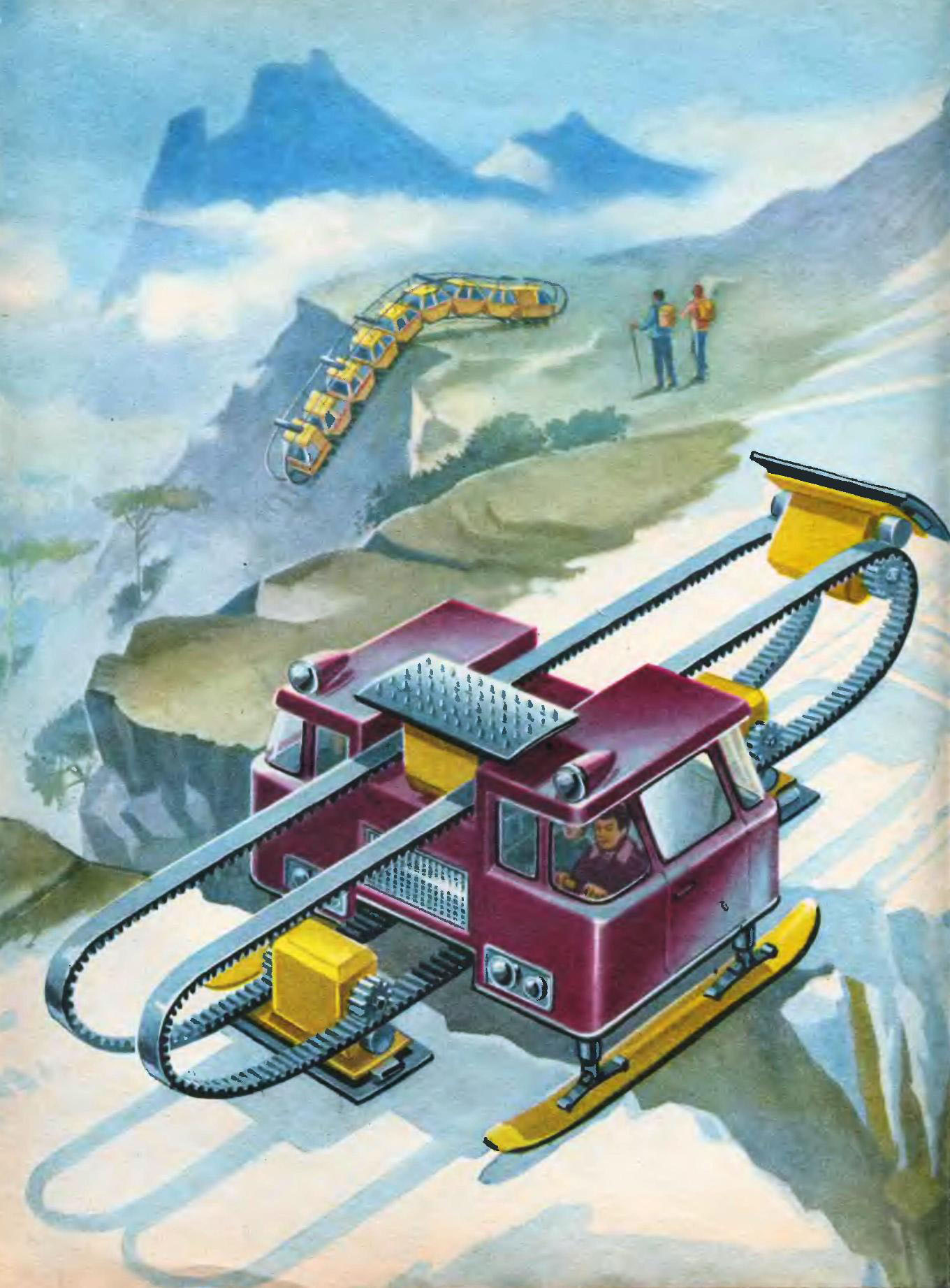

Every time lugging bulky geophysical equipment on mountain glaciers, I wanted a jeep. Finally it was received. And here we tracked the car-amphibians against snow-capped mountains… revved the motor and the machine, lost in the snow at the cabin, moved slowly. Ahead was the forehead of the glacier. Pretty flat for Hiking standards: degree fifteen. But the driver knew that the snow he did not take, and took the car sideways. In the middle of the forehead jumped out the caterpillar.

Every time lugging bulky geophysical equipment on mountain glaciers, I wanted a jeep. Finally it was received. And here we tracked the car-amphibians against snow-capped mountains… revved the motor and the machine, lost in the snow at the cabin, moved slowly. Ahead was the forehead of the glacier. Pretty flat for Hiking standards: degree fifteen. But the driver knew that the snow he did not take, and took the car sideways. In the middle of the forehead jumped out the caterpillar.