Small-scale mechanization

WINCH: PLOWMAN, KARCZEWSKI AND… MINESWEEPER

Honey extractor

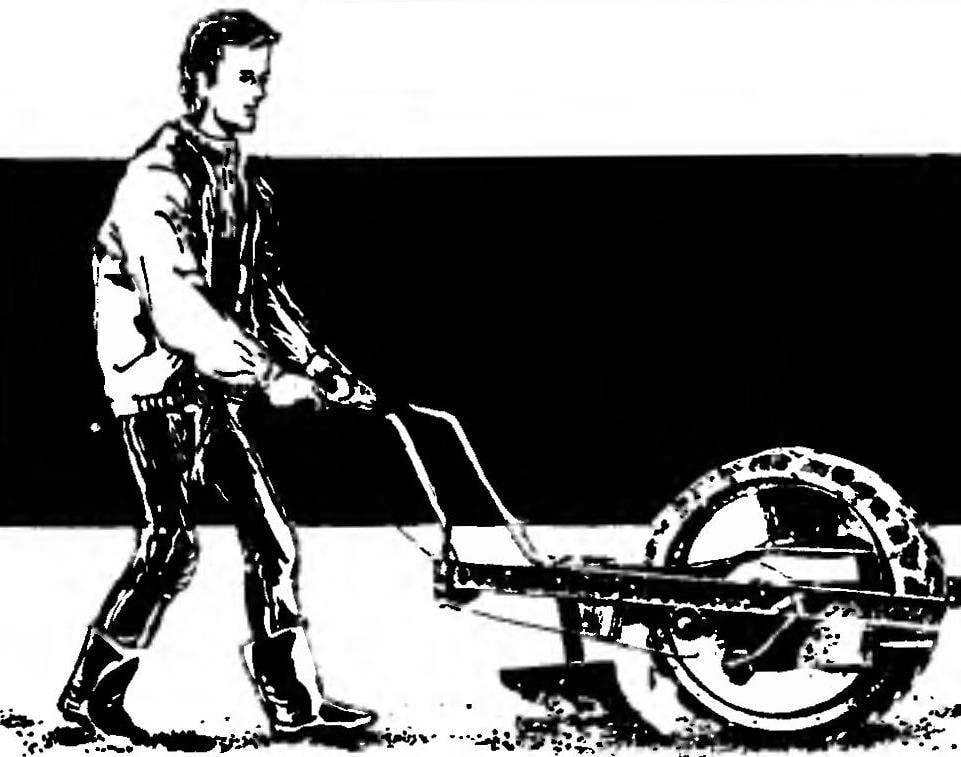

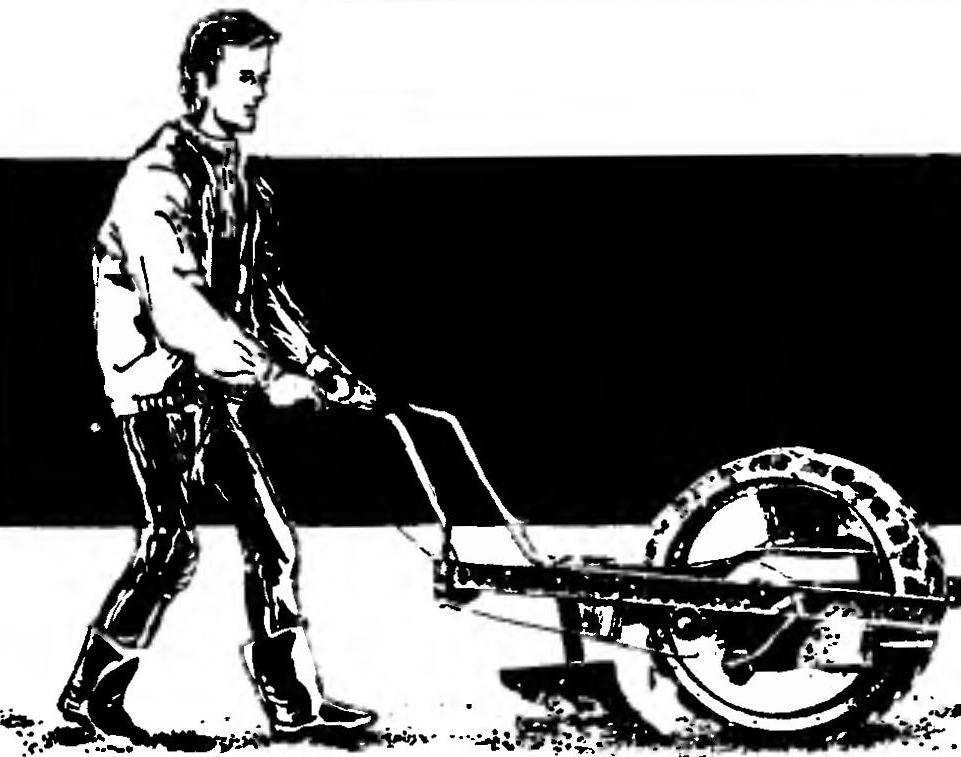

WALK-BEHIND WHEEL

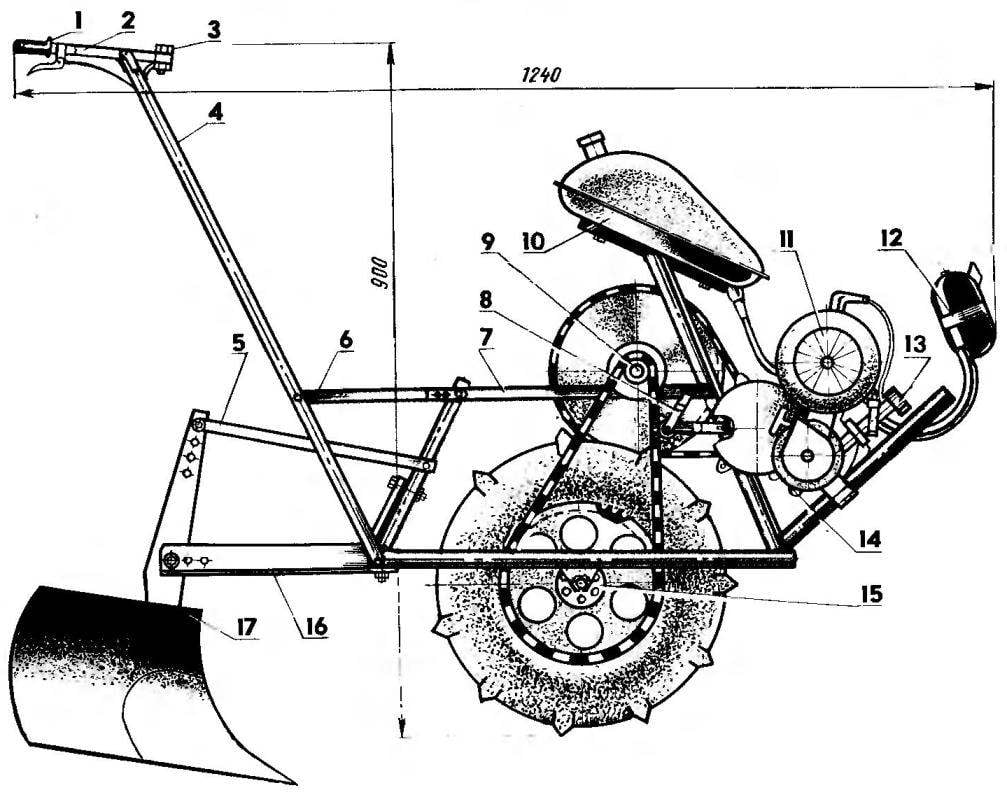

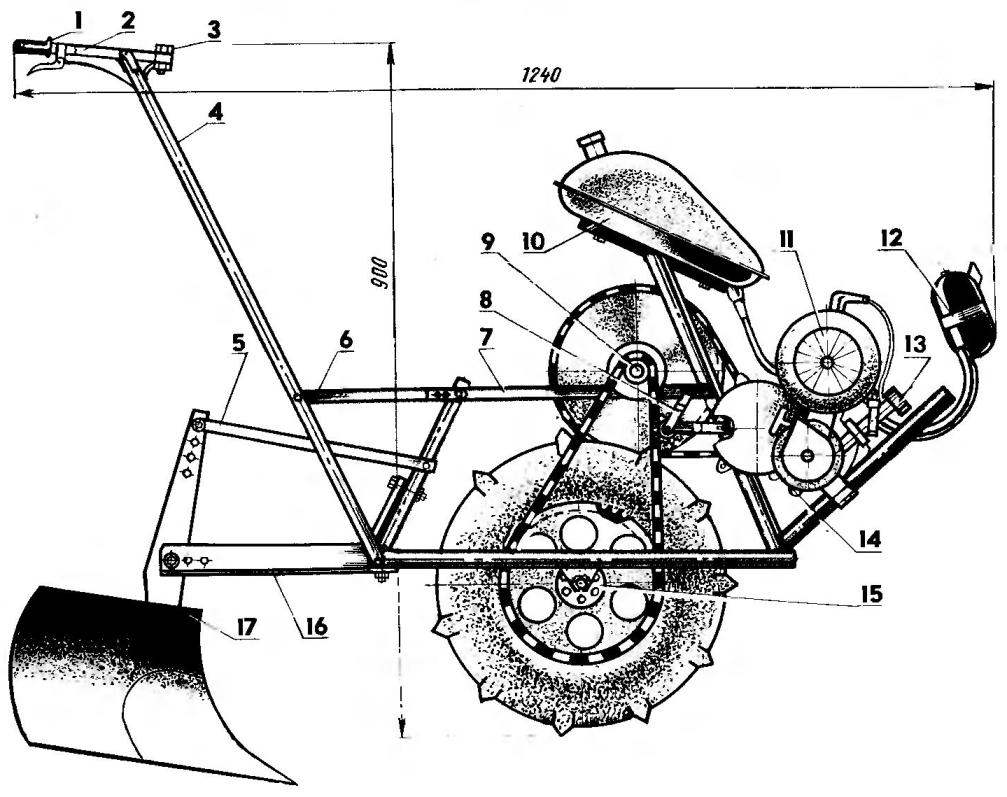

The proposed development is suitable for plowing the infield with a small plow, loosening the soil using the excavation tool. In addition, this cultivator can perform the planting and ridging of potatoes.”The heart of the” mechanical assistant (power plant) the engine of the scooter Elektron with forced air cooling and handles the throttle and clutch (with cables taken from the same scooter). The drive sprocket of the engine is also “a regular”. Gear changes can be left motorolleri, rope. But it is more convenient to bring it directly to the spar tillers. The programs will switch with levers and rods.

The proposed development is suitable for plowing the infield with a small plow, loosening the soil using the excavation tool. In addition, this cultivator can perform the planting and ridging of potatoes.”The heart of the” mechanical assistant (power plant) the engine of the scooter Elektron with forced air cooling and handles the throttle and clutch (with cables taken from the same scooter). The drive sprocket of the engine is also “a regular”. Gear changes can be left motorolleri, rope. But it is more convenient to bring it directly to the spar tillers. The programs will switch with levers and rods.

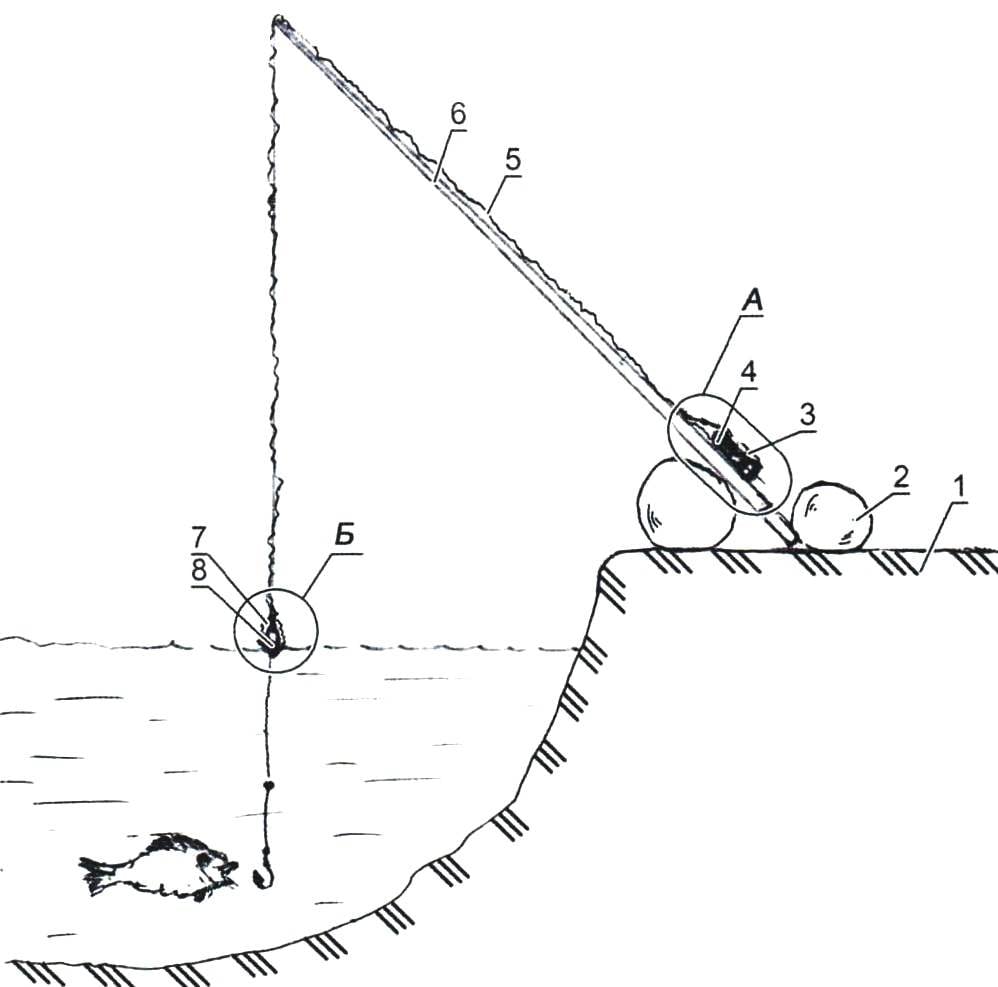

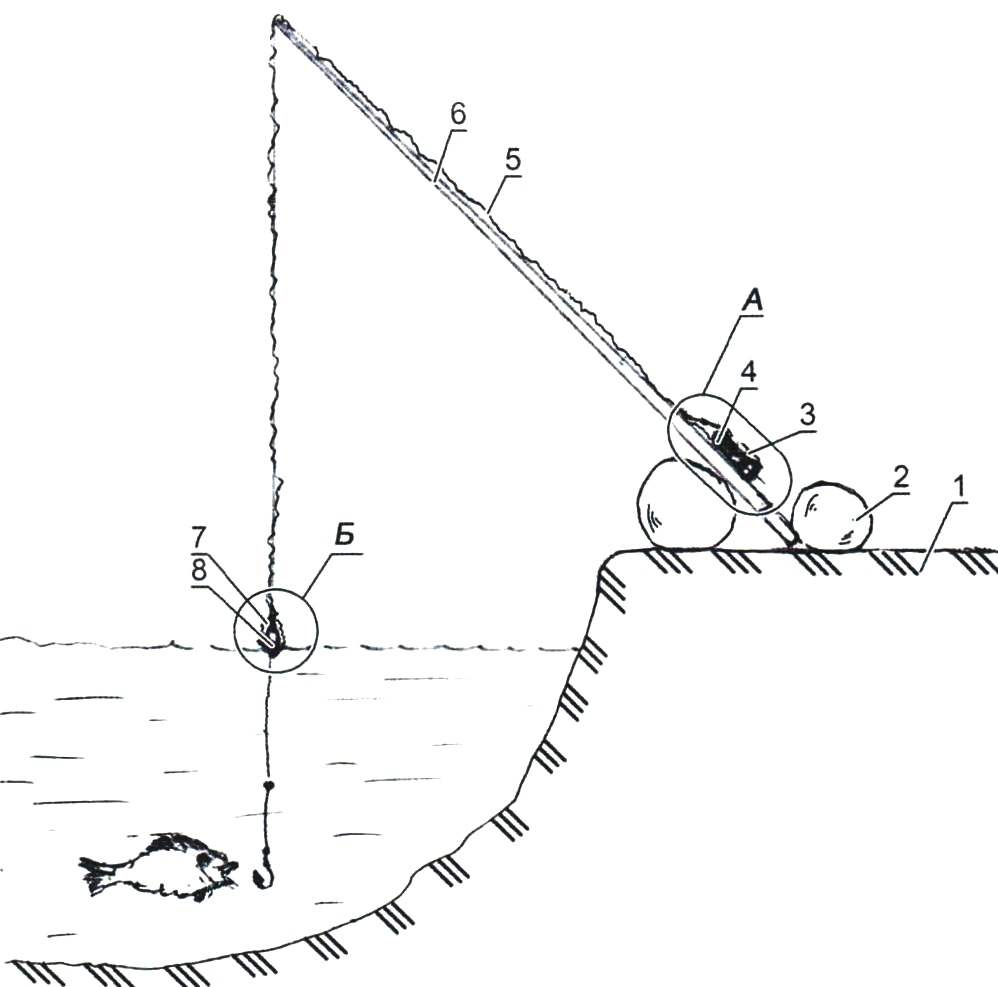

FROM FLASHLIGHT INTO A FLOAT

Many are addicted to fishing for them this activity is a fascinating vacation. The very same UDA, rod, adise is one of the oldest fishing gear; by definition of V. I. dal’s dictionary, it is “spun horsehair forests, with one (or more) hook, which is sometimes linked to special powada; hook is attached above the sinker, above, depending on the depth, the float, the upper end attached to the rod, the shaky stick”. However, progress is inexorable. To replace the forest horsehair came nylon fishing line, floats of nylon and become electrified. Improving manual fishing gears and devoted this article.

Many are addicted to fishing for them this activity is a fascinating vacation. The very same UDA, rod, adise is one of the oldest fishing gear; by definition of V. I. dal’s dictionary, it is “spun horsehair forests, with one (or more) hook, which is sometimes linked to special powada; hook is attached above the sinker, above, depending on the depth, the float, the upper end attached to the rod, the shaky stick”. However, progress is inexorable. To replace the forest horsehair came nylon fishing line, floats of nylon and become electrified. Improving manual fishing gears and devoted this article.

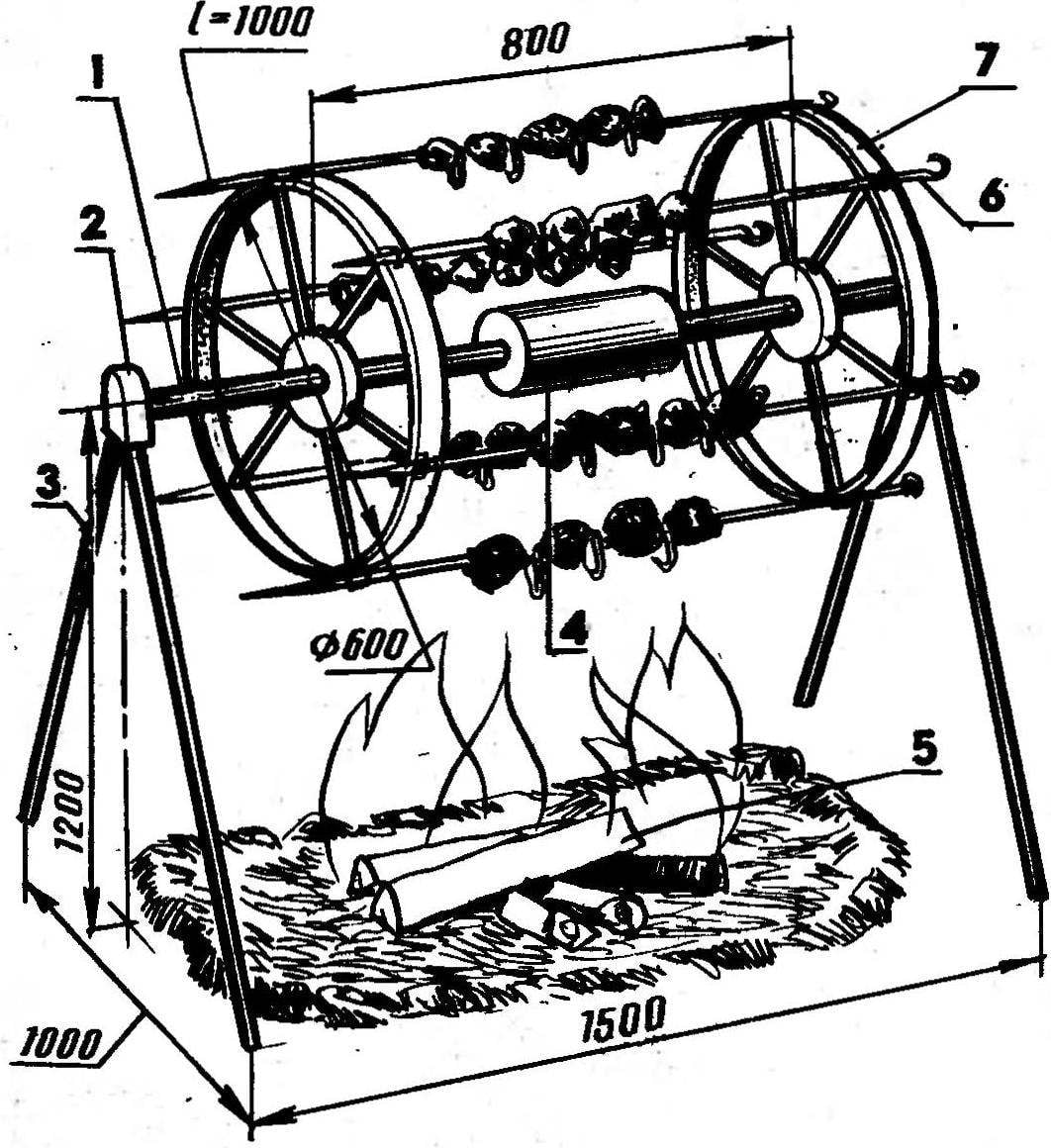

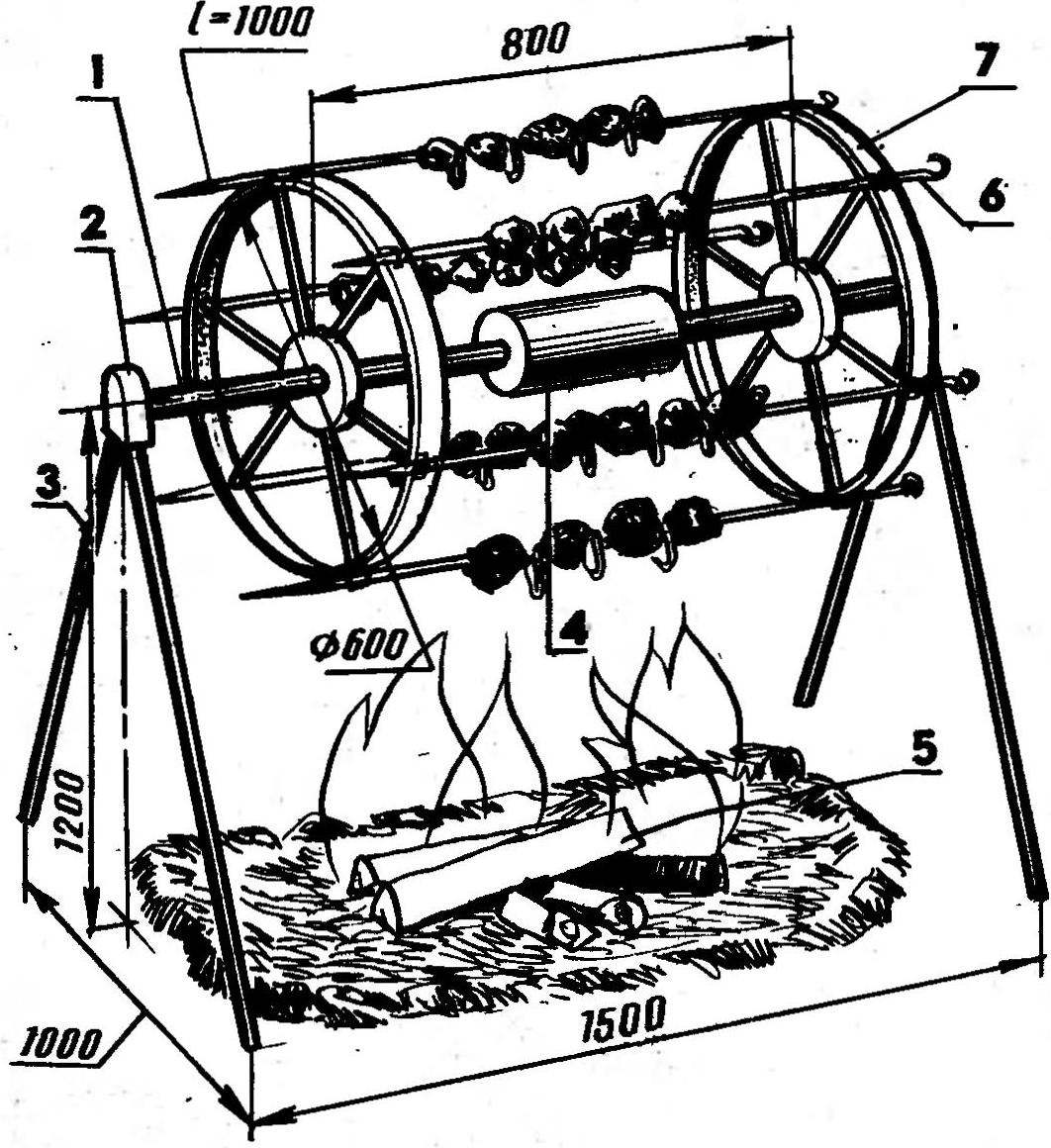

WHEEL SKEWER…

EASY TO WASH, AND SORT

HARNESSED THE WINCH..

Winch, in combination with a plow, not news. Especially for owners of small plots of land on which these pretty simple and reliable konstruktsii a great way has already established itself. Unlike the mini-tractor winch not compacts the soil. And not stalled, as the tillers. But almost all traction motor power goes into useful work — plowing the earth towed plow. The winch is held securely in place by anchor legs which, with a kind of bayonet shovels, lengo deepened into the ground. Plowing are together, making a furrow for furrow. With a partner, the duties of which include the return of the plow n the beginning of the furrow may be 10-year-old child. High kachestvo spalni is guaranteed even at extremely inconvenient uchastkah (slopes with a profile like a “washboard”) and heavy soils.

Winch, in combination with a plow, not news. Especially for owners of small plots of land on which these pretty simple and reliable konstruktsii a great way has already established itself. Unlike the mini-tractor winch not compacts the soil. And not stalled, as the tillers. But almost all traction motor power goes into useful work — plowing the earth towed plow. The winch is held securely in place by anchor legs which, with a kind of bayonet shovels, lengo deepened into the ground. Plowing are together, making a furrow for furrow. With a partner, the duties of which include the return of the plow n the beginning of the furrow may be 10-year-old child. High kachestvo spalni is guaranteed even at extremely inconvenient uchastkah (slopes with a profile like a “washboard”) and heavy soils.

ARSENAL GARDEN

FOLDABLE MOTO – CULTIVATOR

When creating mechanical prepolitical, tillers and other small tools, the tinkerers are facing a number of problems: from the study of kinematics (reliability, compactness, and originality of technical solutions), acquisition for the planned machines of the nodes of parts (cheap motor, for example) and ending with the Assembly and debugging of the whole structure. How to overcome the most common difficulties and become the owner of a quite workable tiller, is published below material.

When creating mechanical prepolitical, tillers and other small tools, the tinkerers are facing a number of problems: from the study of kinematics (reliability, compactness, and originality of technical solutions), acquisition for the planned machines of the nodes of parts (cheap motor, for example) and ending with the Assembly and debugging of the whole structure. How to overcome the most common difficulties and become the owner of a quite workable tiller, is published below material.